Scroll cable detecting robot

A robot and cable technology, applied in the field of robots, can solve problems such as impracticability, low work efficiency, and danger, and achieve the effects of reducing friction, reliable operation, and stable climbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention is described in detail:

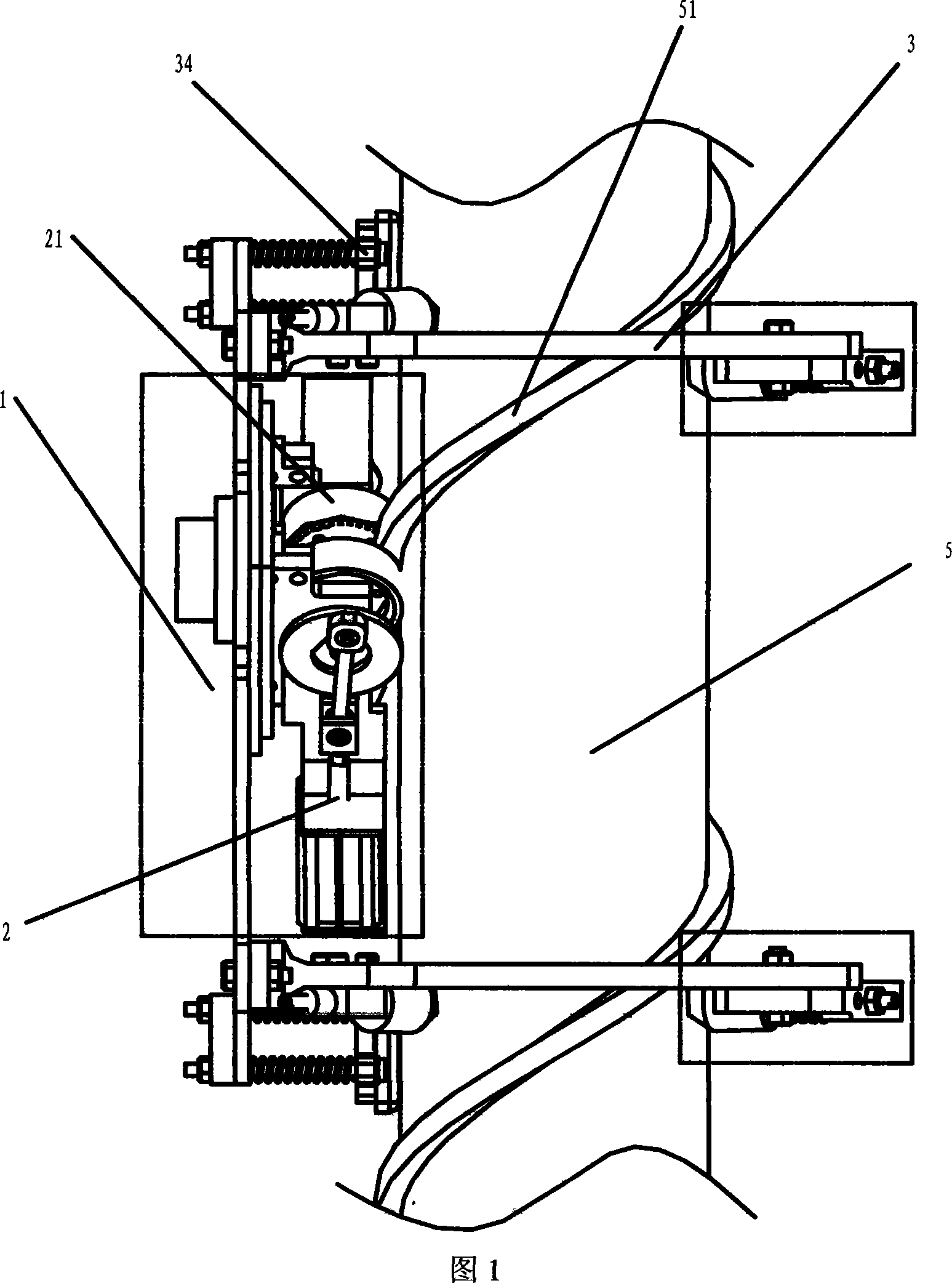

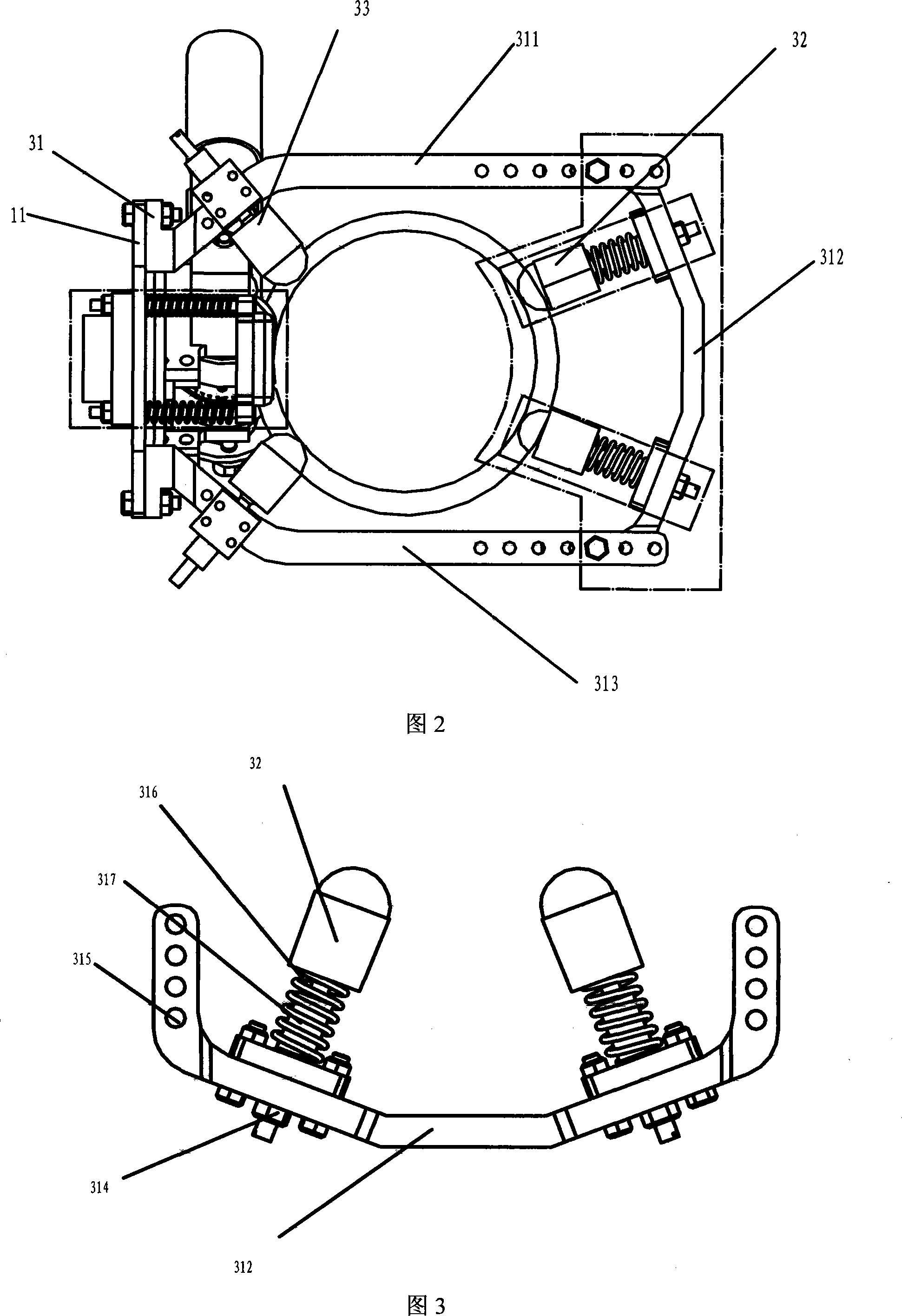

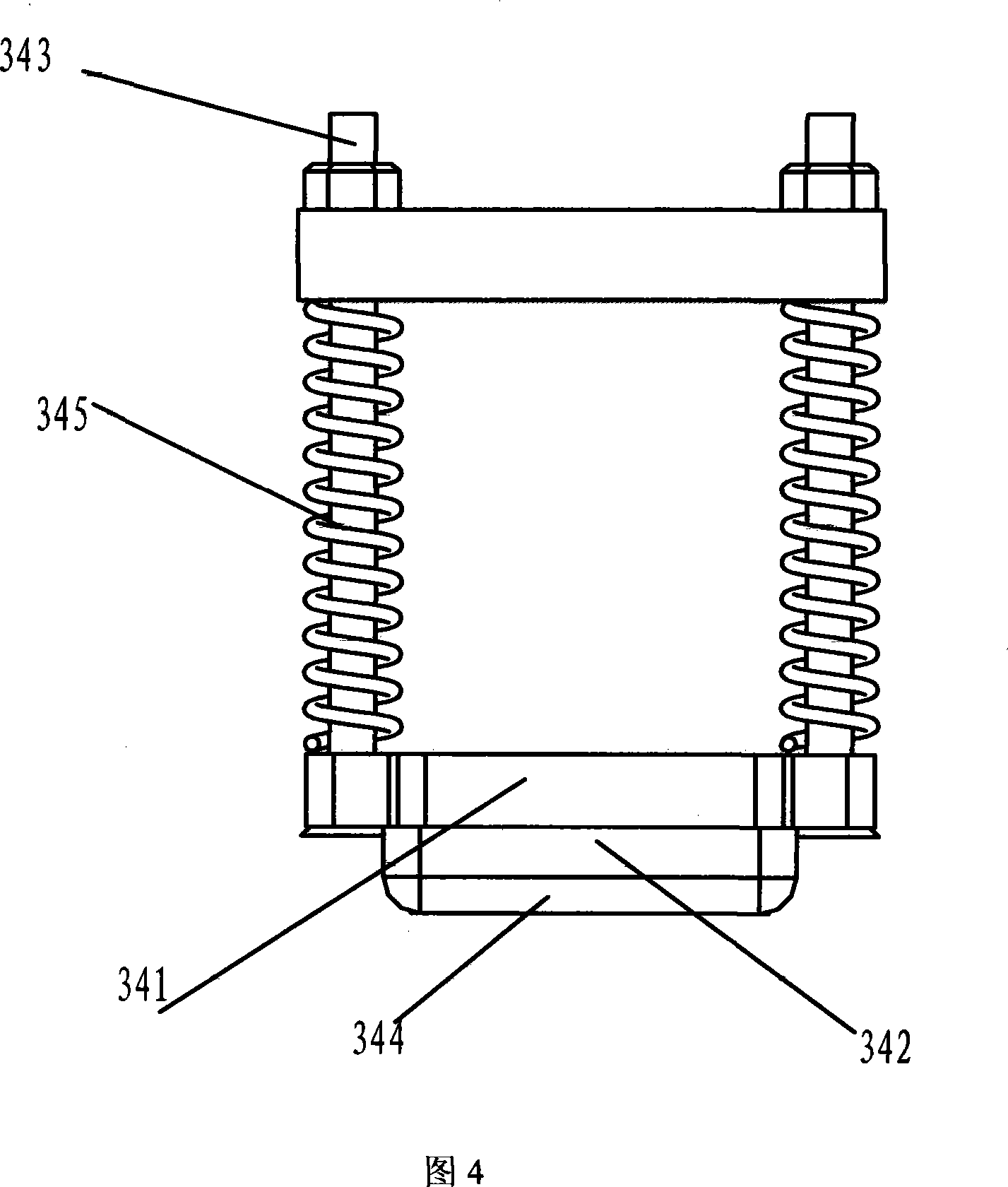

[0031] Shown in Fig. 1, Fig. 2 is the overall structural diagram of the spiral cable detection robot of the present invention, comprises a trolley 1 that is arranged along the circumferential direction of cable 5 and is arranged on trolley 1 upper end and lower end and is used for trolley 1 support The gripping device 3 tightly on the cable 5, the trolley at least includes a climbing mechanism 2 with a drive wheel 21, the drive wheel 21 forms an angle with the axial direction of the cable 5, and the angle is in line with the helix 51 of the cable 5. same helix angle. Described driving wheel 21 is arranged on the driving wheel axle 22, is also provided with a first bevel gear 23 on this driving wheel axle 22, and a motor 6 drives and is provided with the second bevel gear 24 that cooperates with the first bevel gear 23 The gear shaft, the driving wheel 21 realizes transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com