Novel mechanical sealing performance testing apparatus

A technology of mechanical seal and test device, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, by measuring the acceleration and deceleration rate of fluid, etc., which can solve the problem of unbalanced axial force and increase the connection structure between the power input shaft and the power device. The complexity and the inability of the measured sealing surface to adjust the proportional pressure, etc., can reduce the influence of the inaccurate measurement of torque and leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the content, characteristics and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

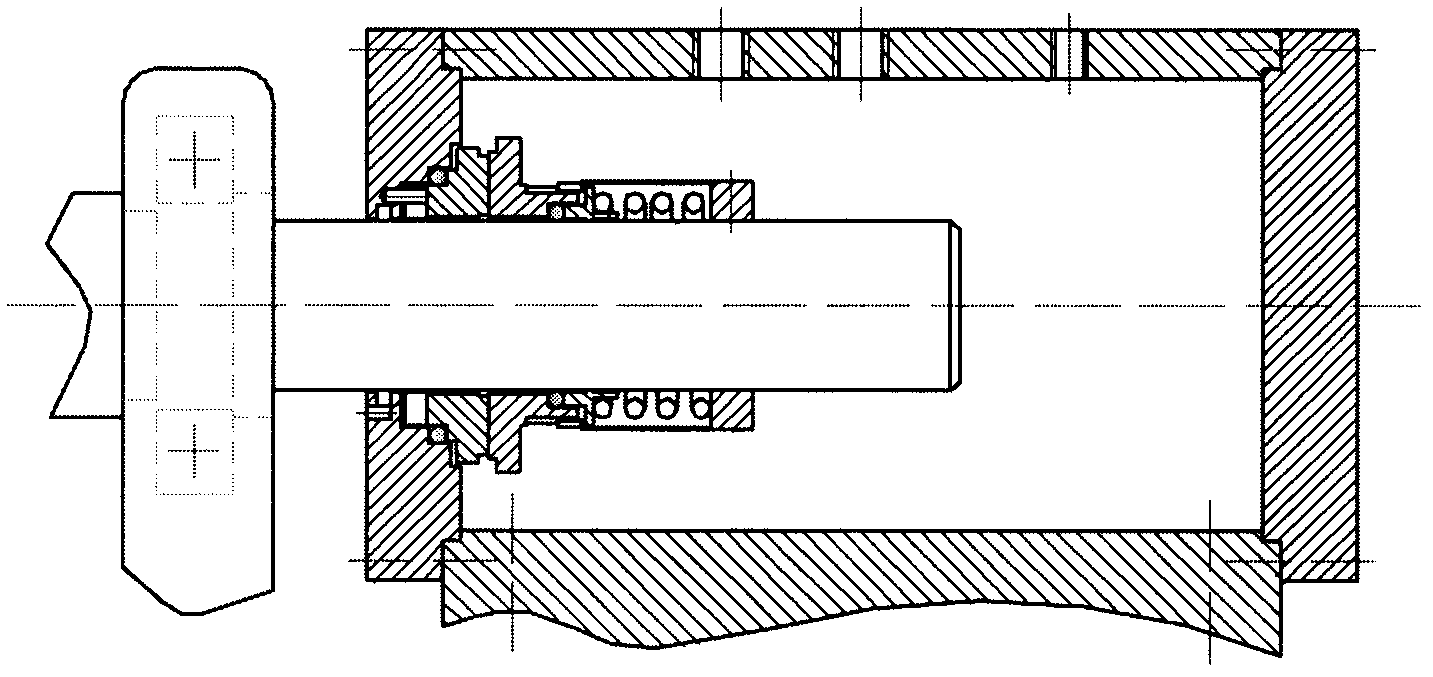

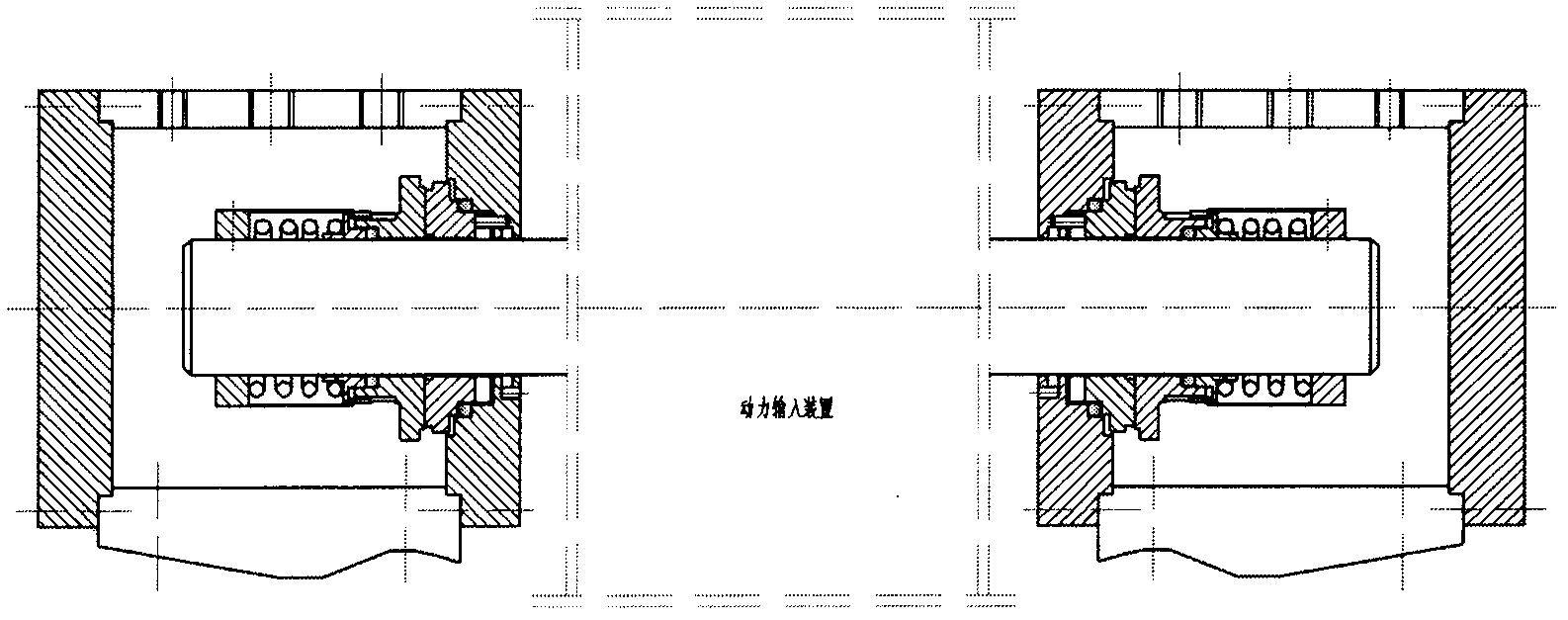

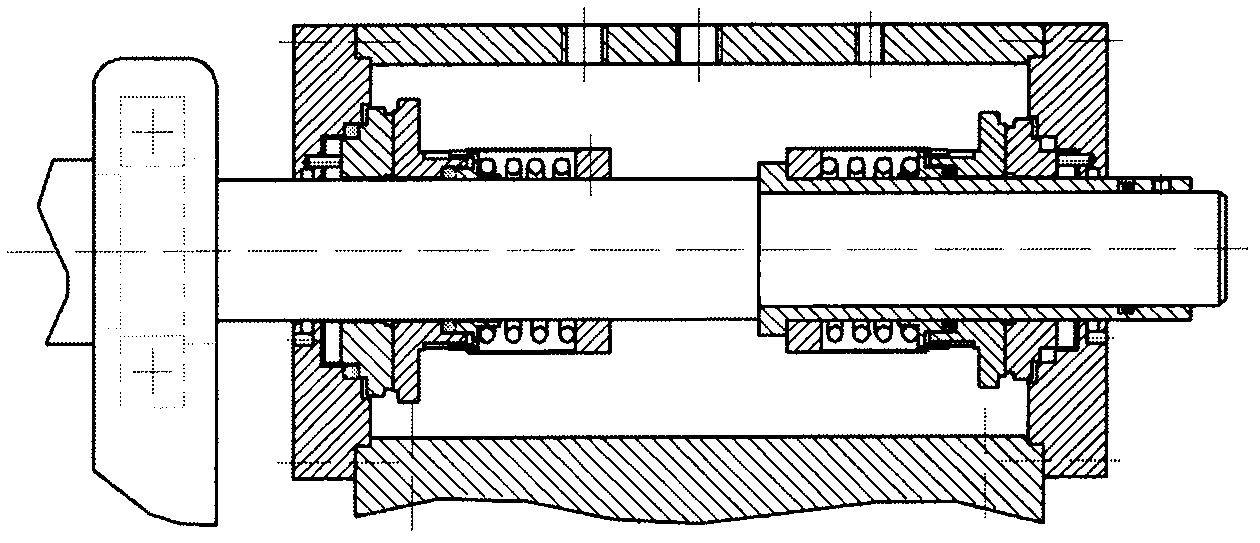

[0021] When installing two pairs of tested seal rings, first install the static ring 7 into the left end cover 6, and at the same time insert one end of the pin 5 into the hole of the left end cover 6, and the other end is stuck in the groove on the end surface of the static ring 7 to prevent the two Relative rotation (e.g. Figure 4 (Shown), then put the left end cover 6 and the static ring 7 in it on the main shaft 4 together, move the carriage 20 to drive the sealed chamber housing 19 to the left to lock it, and lock the left end cover 6 with the sealed chamber housing 19 Fix with screws; the assembly sequence of the remaining parts on the main shaft 4 is: moving ring 8, compression spring seat 9, compression spring 10, moving ring seat 11, pin shaft II21 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com