High precision modeling method of involute helical gear

A modeling method and involute technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems affecting manufacturing and simulation analysis, approximate modeling methods are rough and inaccurate, and avoid errors , the effect of fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

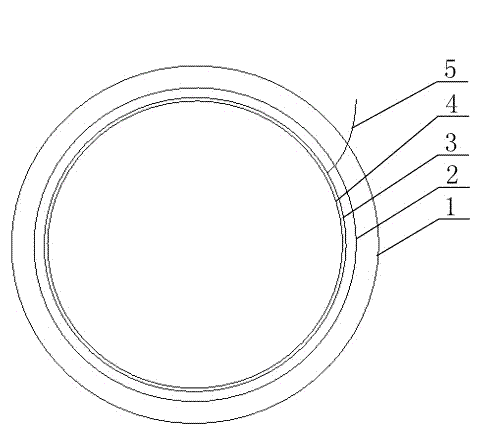

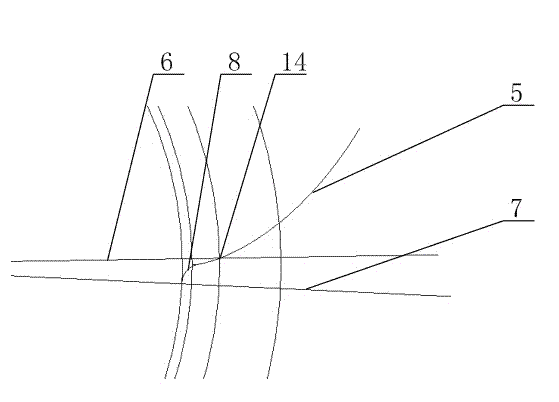

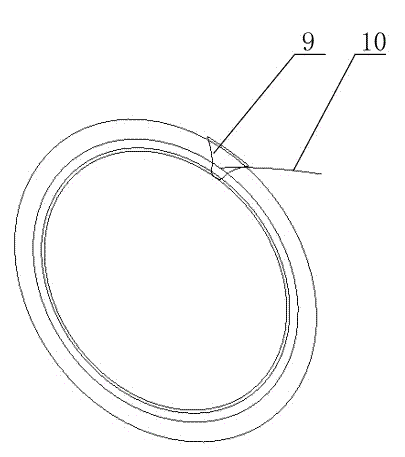

Image

Examples

Embodiment Construction

[0036] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0037] The high-precision modeling method of the involute helical gear of the present invention comprises the following steps:

[0038] 1) Set related parameters

[0039] Define the relevant parameters in the 3D modeling software to adjust the model accuracy to 0.001mm. The required input parameters include:

[0040] face modulus

[0041] normal pressure angle

[0042] Coefficient of displacement

[0043] Coefficient of face tooth height

[0044] Normal addendum coefficient

[0045] Helix angle

[0046] Number of teeth

[0047] Corner rounding radius factor

[0048] tooth width

[0049] According to the basic formula of helical gear, the end modulus can be deduced , end face pressure angle , the coefficient of radial variation , according to these parameters can be calculated addendum circle diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com