Method for processing blind hole by laser

A laser processing and blind hole technology, applied in laser welding equipment, metal processing equipment, removing conductive materials by mechanical methods, etc., can solve the problem of small contact area between electroplated copper and copper layer at the bottom of the hole, decreased scanning speed, and the bottom of the blind hole. Increase the unevenness and other problems to achieve the effect of improving the quality and success rate of blind holes, eliminating the decrease in scanning speed, and eliminating the distortion of scanning trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

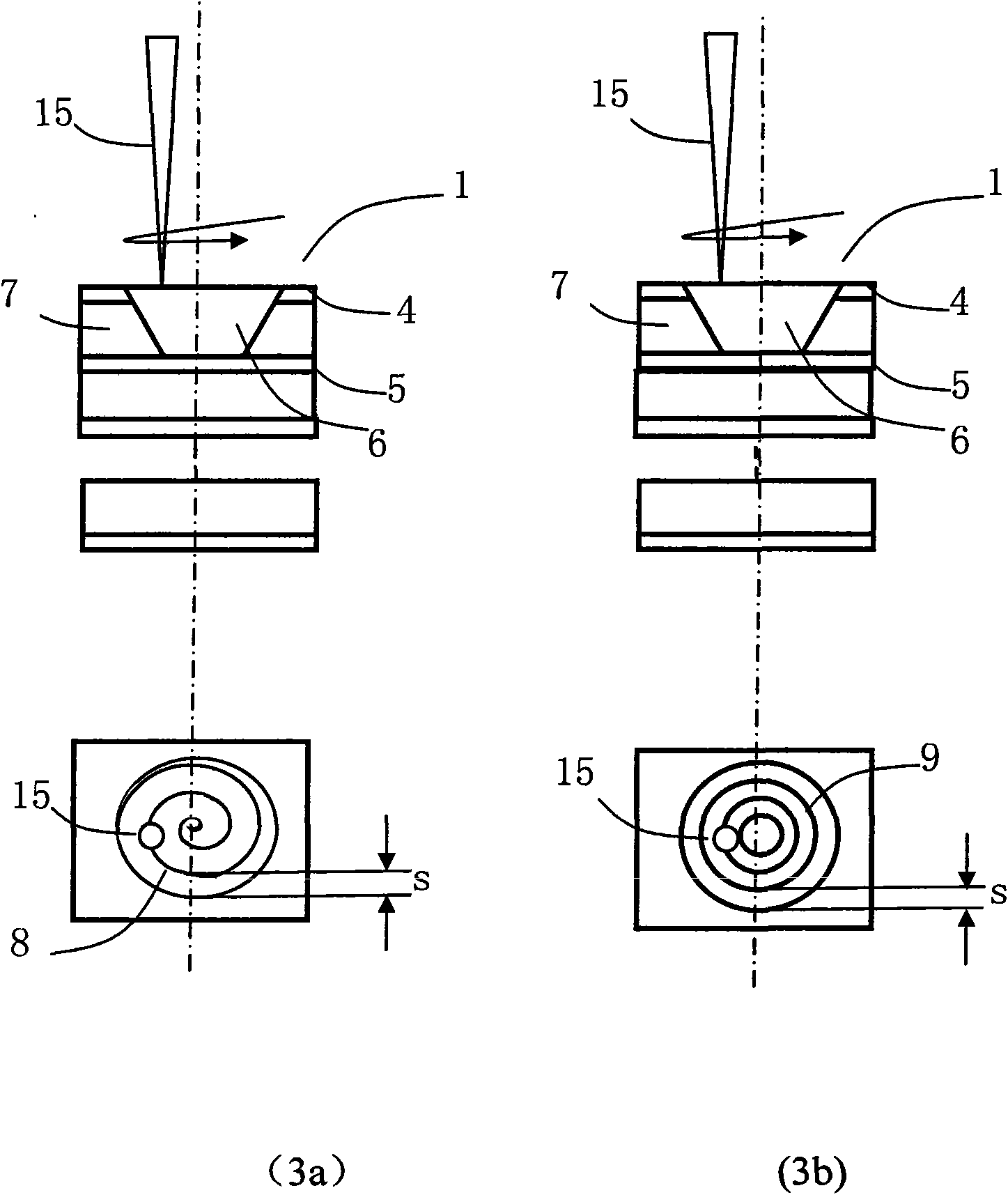

[0030] The present invention adopts the Awave-355-8W-25K model all-solid-state Q-switched ultraviolet laser produced by American Lightwave Company, the output wavelength is 355nm, the average power is from 0 to 10 watts, the frequency is set to 80kHz, and the structure is 4 layers of copper layers (thickness of 18 microns) and 3 layers of insulating material (thickness of 50 microns) composed of polyimide and epoxy resin adhesives (thickness of 50 microns) alternately laminated flexible circuit board (FCB) for drilling diameter of 200 microns The first-order blind hole machining. The processing parameters of the UV laser drilling blind holes are shown in Table 1. The verticality of the edge of the blind hole obtained by the invention is almost 90°, the copper recast layer is less than 0.89 micron, and the surface roughness of the copper layer at the bottom of the blind hole is 1.063 micron.

[0031] Table I

[0032]

[0033] second step

example 2

[0035] The present invention adopts the Awave-355-8W-25K model all-solid-state Q-switched ultraviolet laser produced by American Lightwave Company, the output wavelength is 355nm, the average power is from 0 to 10 watts, the frequency is set to 80kHz, and the structure is 4 layers of copper layers (thickness 35 microns) and 3 layers of insulating material (thickness 75 microns) composed of polyimide and epoxy resin adhesives (thickness 75 microns) alternately rolled flexible circuit board (FCB) for drilling diameter 100 microns The first-order blind hole machining. The processing parameters of the UV laser drilling blind holes are shown in Table 2. The verticality of the edge of the blind hole obtained by the invention is about 80°, the recasting layer of the copper layer is 0.95 micron, and the surface roughness of the copper layer at the bottom of the blind hole is 1.89 micron.

[0036] Table II

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com