Glass three-dimensional columnar hole laser cutting method

A cutting method, hole laser technology, applied in the direction of laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of affecting laser transmittance, laser can not cut, not widely used, etc., to improve cutting efficiency , Conducive to slag discharge, reduce the effect of refraction and reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

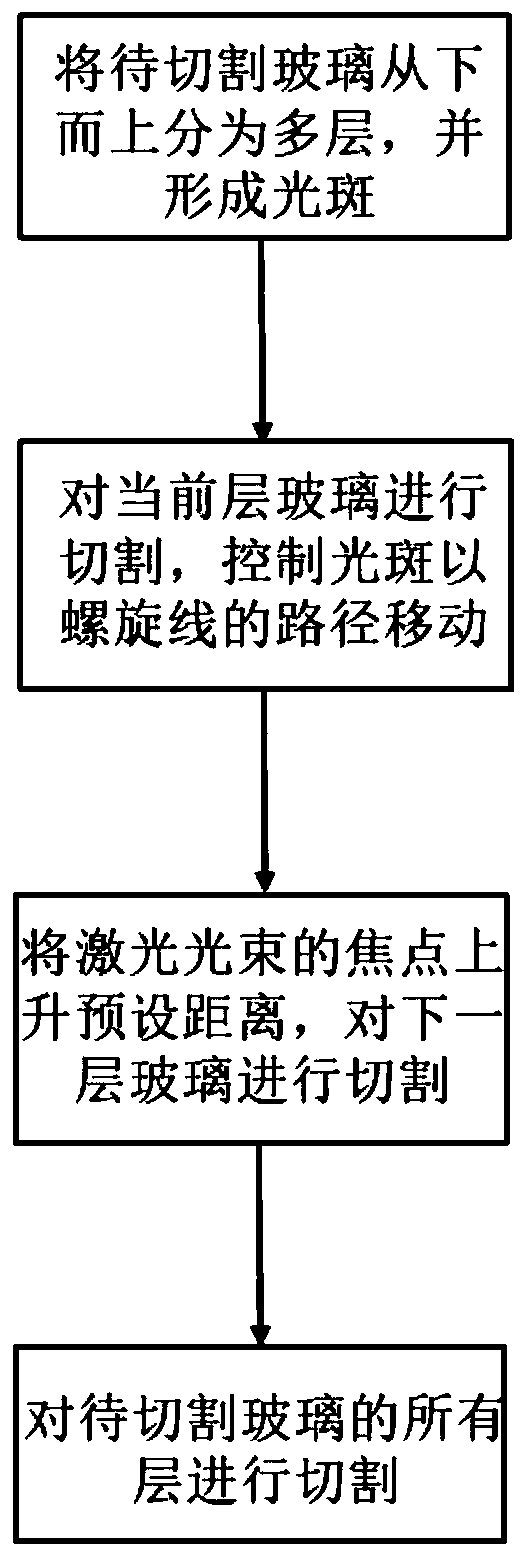

Method used

Image

Examples

Embodiment 1

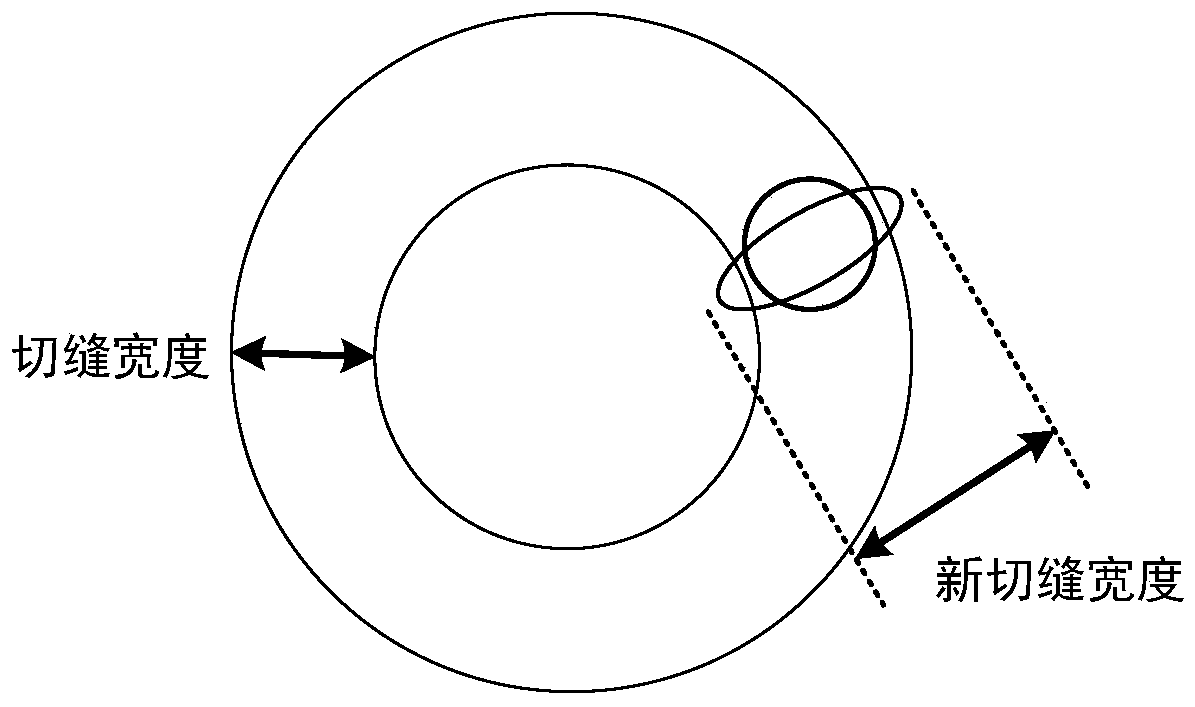

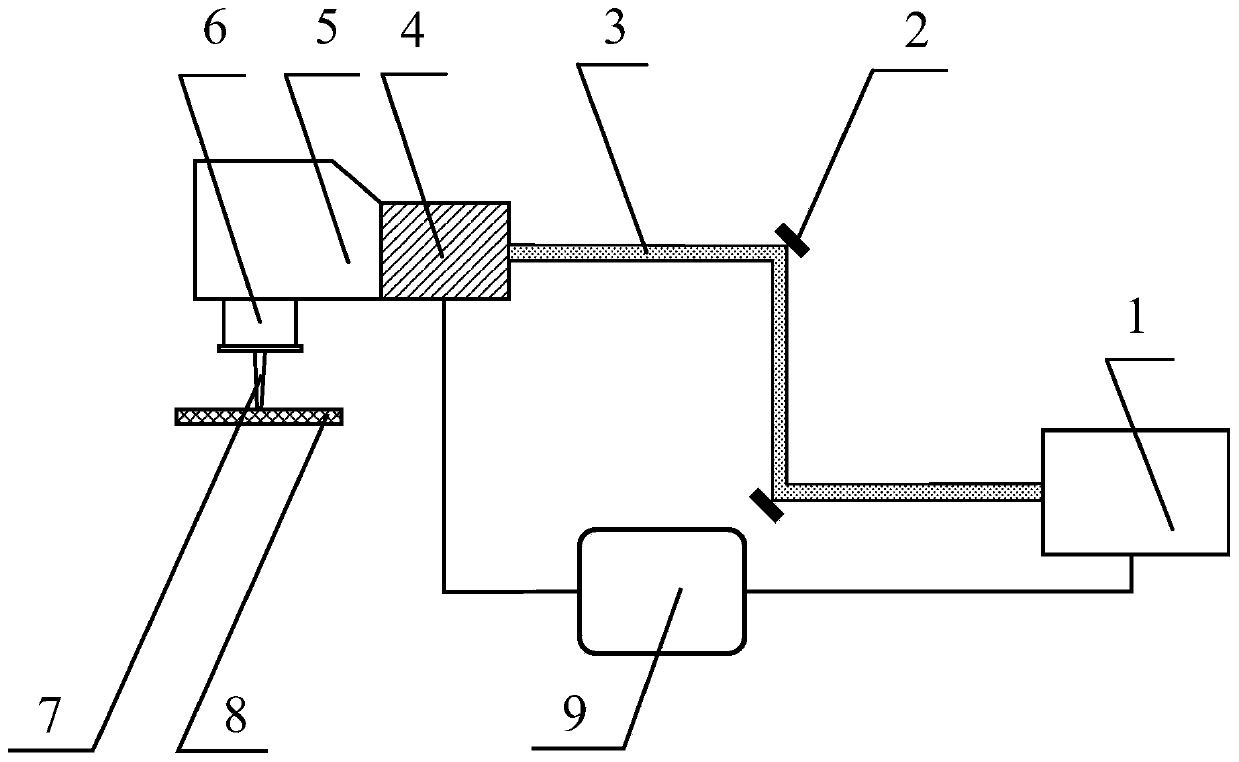

[0047] A 40W green laser is selected to emit a laser beam, which is expanded 1.5 times by the galvanometer and then focused by a telecentric field lens to form an elliptical spot. A cylindrical hole with a diameter of 10mm is cut on a float glass with a thickness of 2.5mm, and the scanning is set. The speed is 320mm / s, the rising distance of each layer is 0.8 times the depth of focus, the width of the helix is 0.47mm, and the overlap rate of the helix is 70%. By adopting the above method parameters, a three-dimensional columnar hole with high incision quality can be obtained efficiently.

Embodiment 2

[0049] A 20W green laser is selected to emit a laser beam, which is expanded 3 times by a galvanometer and then focused by a telecentric field lens to form an elliptical spot. A cylindrical hole with a diameter of 10mm is cut on a float glass with a thickness of 2.5mm, and the scan is set. The speed is 300mm / s, the rising distance of each layer is 0.9 times the depth of focus, the width of the helix is 0.5mm, and the overlap rate of the helix is 80%. By adopting the above method parameters, a three-dimensional columnar hole with high incision quality can be obtained efficiently.

Embodiment 3

[0051] A 35W green laser is selected to emit a laser beam, which is expanded 5 times by the galvanometer and then focused by a telecentric field lens to form an elliptical spot. A cylindrical hole with a diameter of 10mm is cut on the embossed glass with a thickness of 2.5mm. First, the glass Evenly spray transparent liquid on the upper surface to pave it, and set the scanning speed to 150mm / s, the rising distance of each layer is 0.5 times the focal depth, the width of the helix is 0.4mm, and the overlap rate of the helix is 65%. By adopting the above method parameters, a three-dimensional columnar hole with high incision quality can be efficiently obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com