Juice squeezing machine for producing ginger black tea

A technology of juicer and mountain ginger black tea, which is applied in the fields of application, juice extraction, food science, etc., can solve the problems of poor juicing effect and easy residues, etc., and achieve the effect of increasing the time of juicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

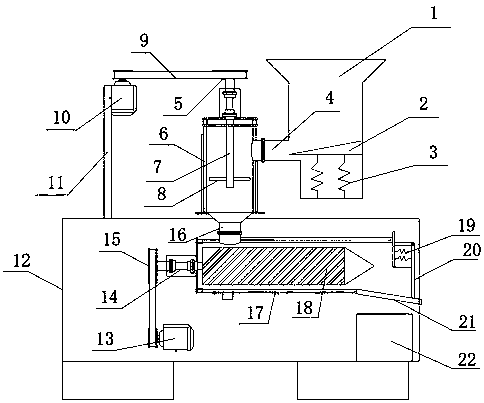

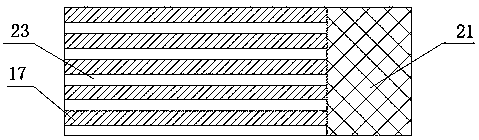

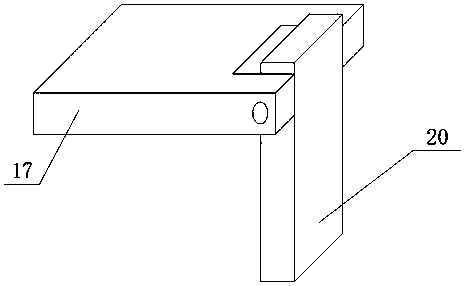

[0023] see Figure 1-3 As shown, a juice extractor for producing Shiwanshanjiang black tea comprises a body 12, a bracket 11 is installed on the top of the body 12, a first motor 10 is arranged on one side of the bracket 11, a belt 9 is arranged on one side of the first motor 10, and a belt 9 A first pulley 5 is arranged on one side, and a rotating shaft 7 is installed inside the first pulley 5, and a cutting edge 8 is arranged on the side wall of the rotating shaft 7, thereby driving the cutting edge 8 to rotate. A second discharge port 16 is provided at the bottom, a feed port 1 is provided on one side of the cutting cylinder 6, a base plate 2 is provided below the feed port 1, the bottom of the base plate 2 is connected to a first spring 3, and a first discharge port 4 is provided on one side of the base plate 2. The body 12 is provided with a juice extractor 17, and the juice extractor 17 is provided with a grinding rod 18, one end of the grinding rod 18 is equipped with a...

Embodiment 2

[0025] read on Figure 1-3 , the difference with Embodiment 1 is: the cross-sectional shape of the bottom plate 2 is triangular, and the bottom plate 2 is inclined from right to left, and there is a fixed connection between the bottom plate 2 and the first spring 3, so that the amount of ginger entering the cutting cylinder 6 can be controlled. Be movably connected between the movable plate 20 and the juice extractor 17, and be fixedly connected between the second spring 19 and the movable plate 20, and then the movable plate 20 can regulate the discharge of ginger residue; The cylinders 17 are tightly connected, and the inside of the deflector 21 is provided with a filter screen, and then the ginger juice is filtered out; the side wall of the grinding rod 18 is provided with a left-handed spiral blade, and the shape of the tail end of the grinding rod 18 is Conical shape, and then allow the ginger residue to move to the right with the rotation of the grinding rod 18; between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com