Large gantry polar-coordinate digital-control milling, hobbing and grinding gear combined machine

A compound machine tool and polar coordinate technology, applied in gear cutting machines, large fixed members, gear teeth, etc., can solve the problems of difficulty in ensuring the accuracy of the turntable center, time-consuming and labor-intensive problems, and achieve the effects of stable machining accuracy, reduced manufacturing costs and difficulty in assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

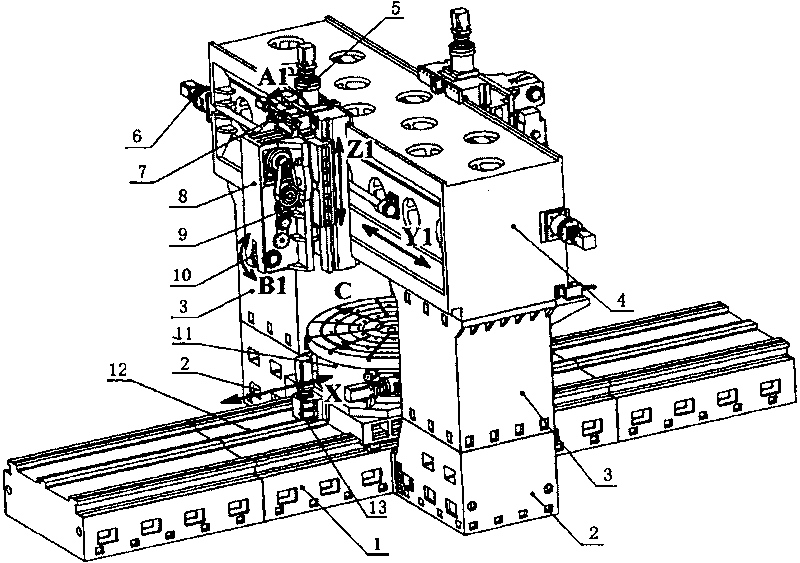

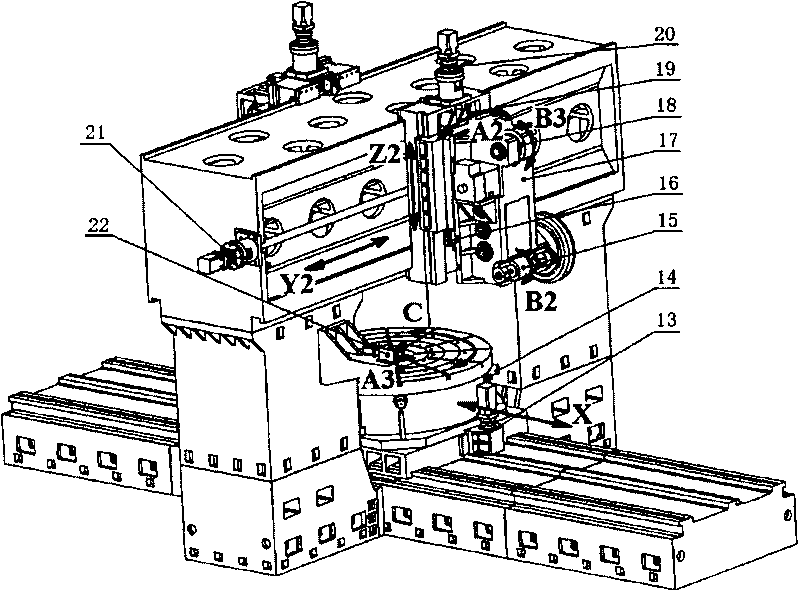

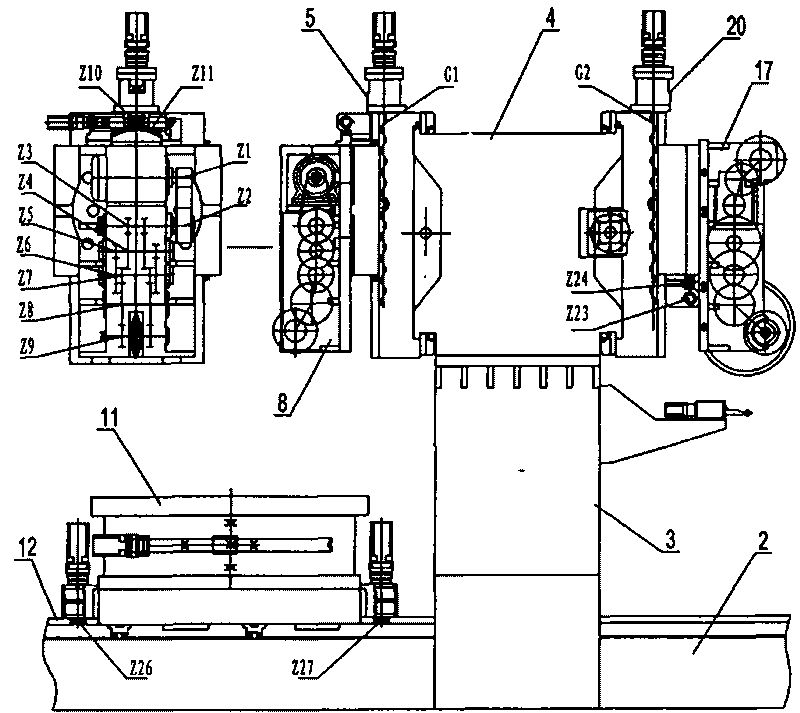

[0037] Below in conjunction with accompanying drawing, technical content of the present invention is described:

[0038] Such as figure 1 , figure 2 , a large-scale gantry polar coordinate CNC milling, rolling and grinding compound machine tool, comprising a bed 1, a base 2 located on both sides of the bed 1, a column 3 placed on the upper part of the base 2, a beam 4 arranged on the column 3, the bed 1 is equipped with a rack 12 and a double servo drive system 13 for X-direction feed of the turntable, and a CNC static pressure turntable 11 is provided on the double-servo drive system 13 for X-direction feed of the turntable; The hobbing tooth horizontal carriage, the milling tooth horizontal carriage and the hobbing tooth horizontal carriage are respectively equipped with a milling tooth vertical carriage and a hobbing tooth vertical carriage, and the milling tooth horizontal carriage is connected to the milling tooth Y-direction feed system 6 The ball screw pair of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com