Soy milk making machine

A soymilk maker and pulping technology, which is applied to milk substitutes, beverage preparation devices, household appliances, etc., can solve the problems of insufficient suction, difficult cleaning, and easy wear and tear, and achieve the effect of fine slurry, convenient use, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

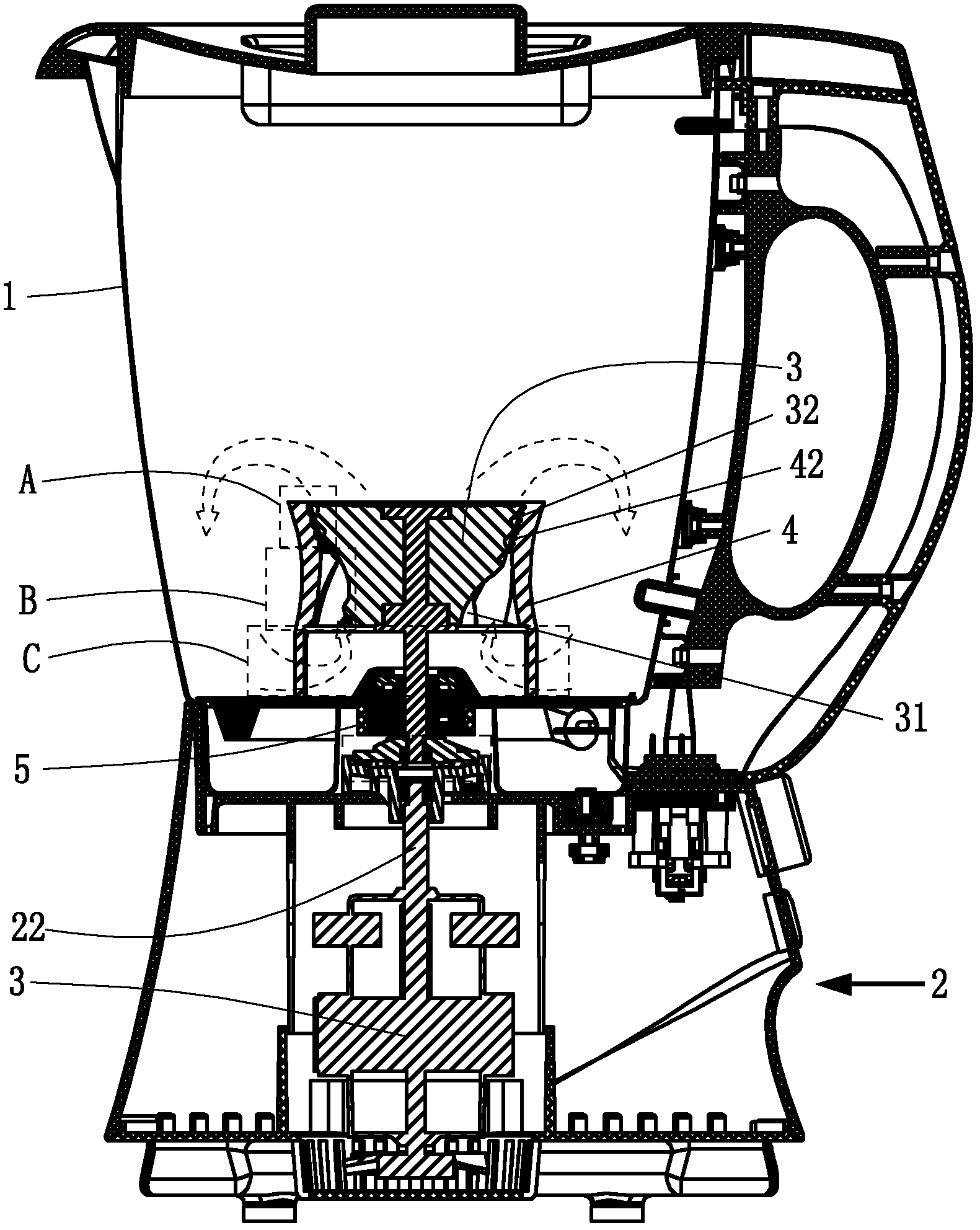

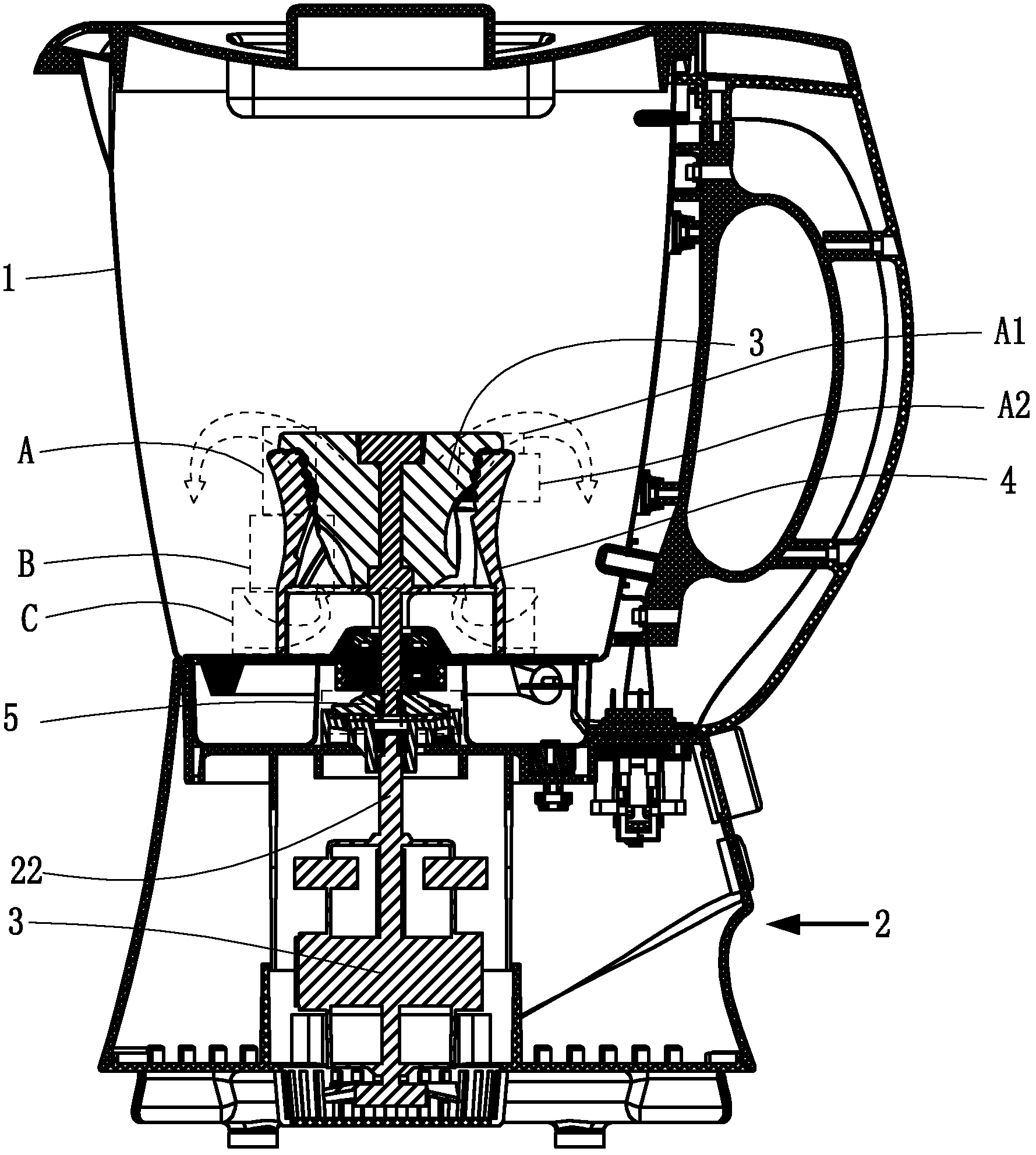

[0058] See attached Figure 2~4 , The dynamic and static grinding heads of this embodiment are different from those of Embodiment 1, and have the same technical effects as Embodiment 1 in other places, so they will not be repeated here.

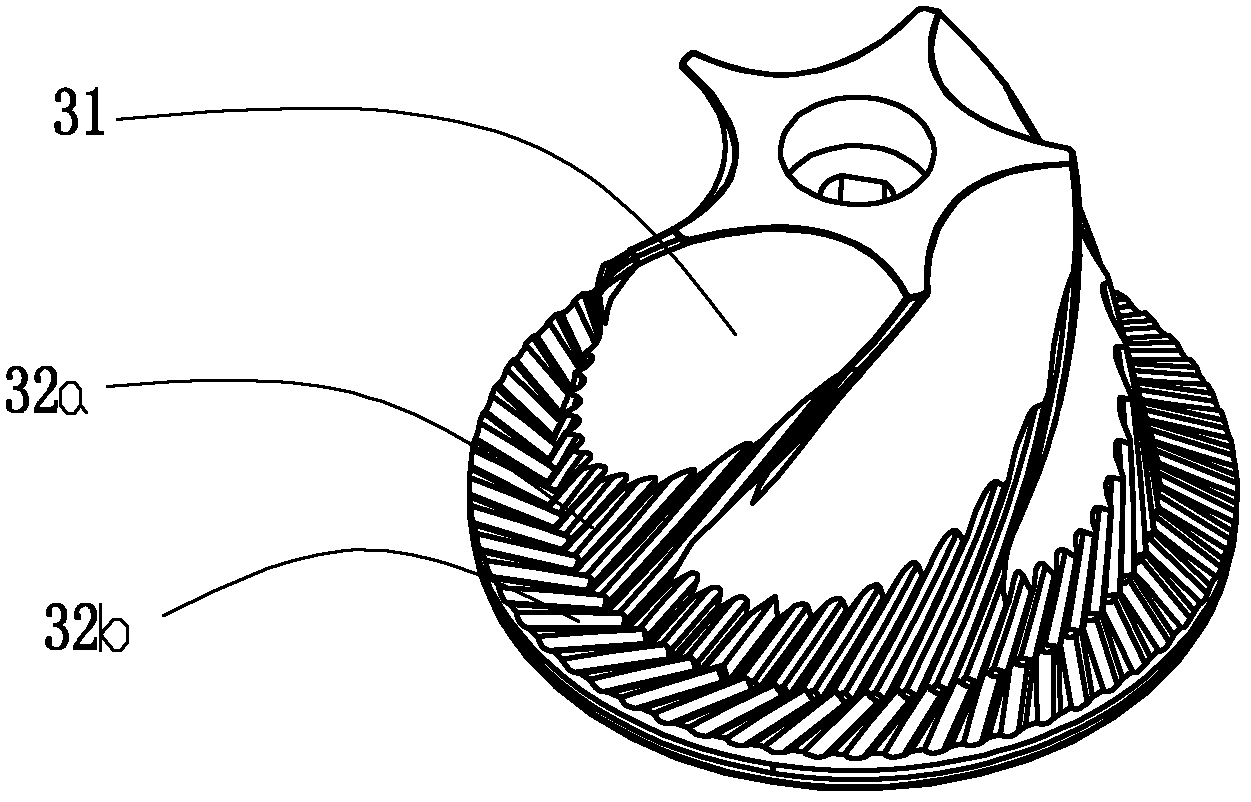

[0059] In this embodiment, the dynamic and static grinding heads are further divided into a rough grinding part A1 and a fine grinding part A2 in the grinding part A, and the moving grinding head 3 is respectively provided at the guide part B, the rough grinding part A1 and the fine grinding part A2. There are movable grinding guide teeth 31, dynamic grinding coarse grinding teeth 32a and dynamic grinding fine grinding teeth 32b.

[0060] The static grinding head 4 is provided with a static grinding guide tooth 41 , a static grinding rough grinding tooth 42 a and a static grinding fine grinding tooth 42 b at the material guide part B, the rough grinding part A1 and the fine grinding part A2 respectively.

[0061] The dynamic grinding guide t...

Embodiment 3

[0064] See attached Figure 5~7 , The dynamic and static grinding heads of this embodiment are different from those of Embodiment 1, and have the same technical effects as Embodiment 1 in other places, so they will not be repeated here.

[0065] In this example,

[0066] The movable grinding guide tooth 31 is a rotating member capable of generating liquid flow when rotating, specifically, the movable grinding guide tooth 31 is a propeller-shaped blade.

[0067] The working surfaces of the movable grinding head 3 and the static grinding head 4 at the grinding part A are roughly disc-shaped.

[0068] The dynamic grinding head 3 is provided with a dynamic grinding material guide hole 33 connecting the working surface with the outside. When grinding, when encountering large particles or materials that are difficult to grind and pulverize, the materials will be sent to the dynamic grinding material guide hole 33 and then flow out of the grinding area. It prevents the motor from ...

Embodiment 4

[0070] See attached Figure 8~10 , The dynamic and static grinding heads of this embodiment are different from those of Embodiment 1, and have the same technical effects as Embodiment 1 in other places, so they will not be repeated here.

[0071] In this embodiment, the dynamic grinding guide teeth 31, the dynamic grinding coarse grinding teeth 32a, the dynamic grinding fine grinding teeth 32b, the static grinding guide teeth 41, and the static grinding coarse grinding teeth 42a are provided on the dynamic and static grinding heads. The structure of the static grinding and fine grinding teeth 42b is generally a corresponding spiral tooth shape, and the gap between the moving grinding head 3 and the static grinding head 4 between the working surfaces of the rough grinding part A1 and the fine grinding part A2 is from bottom to bottom. gradually becomes smaller, and the gap between the moving grinding head 3 and the static grinding head 4 on the working surface of the material g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com