Grinding soymilk machine with multifunctional operation mode and its speed-regulating grinding method

An operation mode, the technology of soybean milk machine, applied in milk substitutes, beverage preparation devices, household utensils, etc., can solve problems such as difficult to clean, affect the health of drinkers, cleanliness, food hygiene and safety issues, etc., and achieve the effect of fine slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

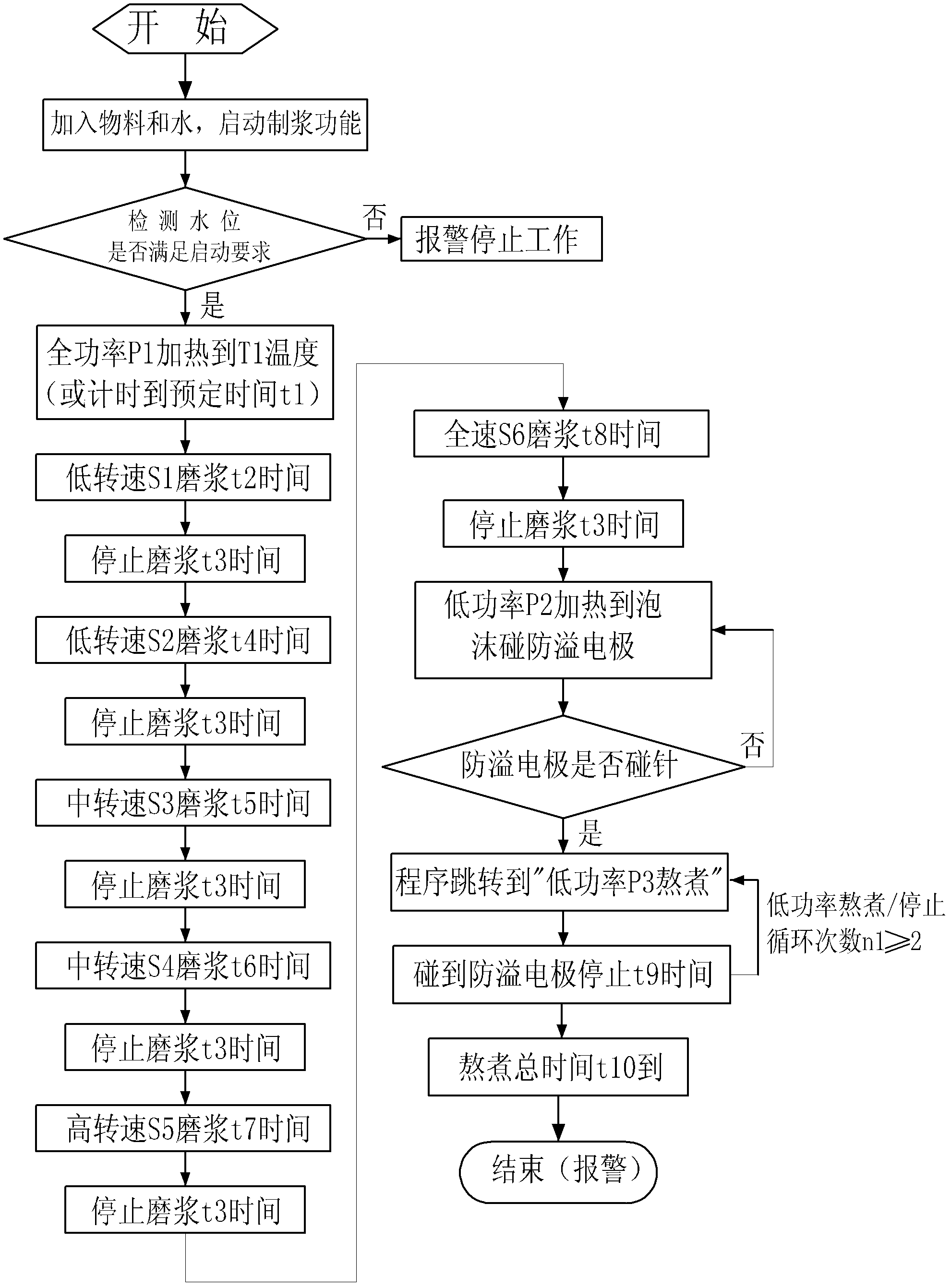

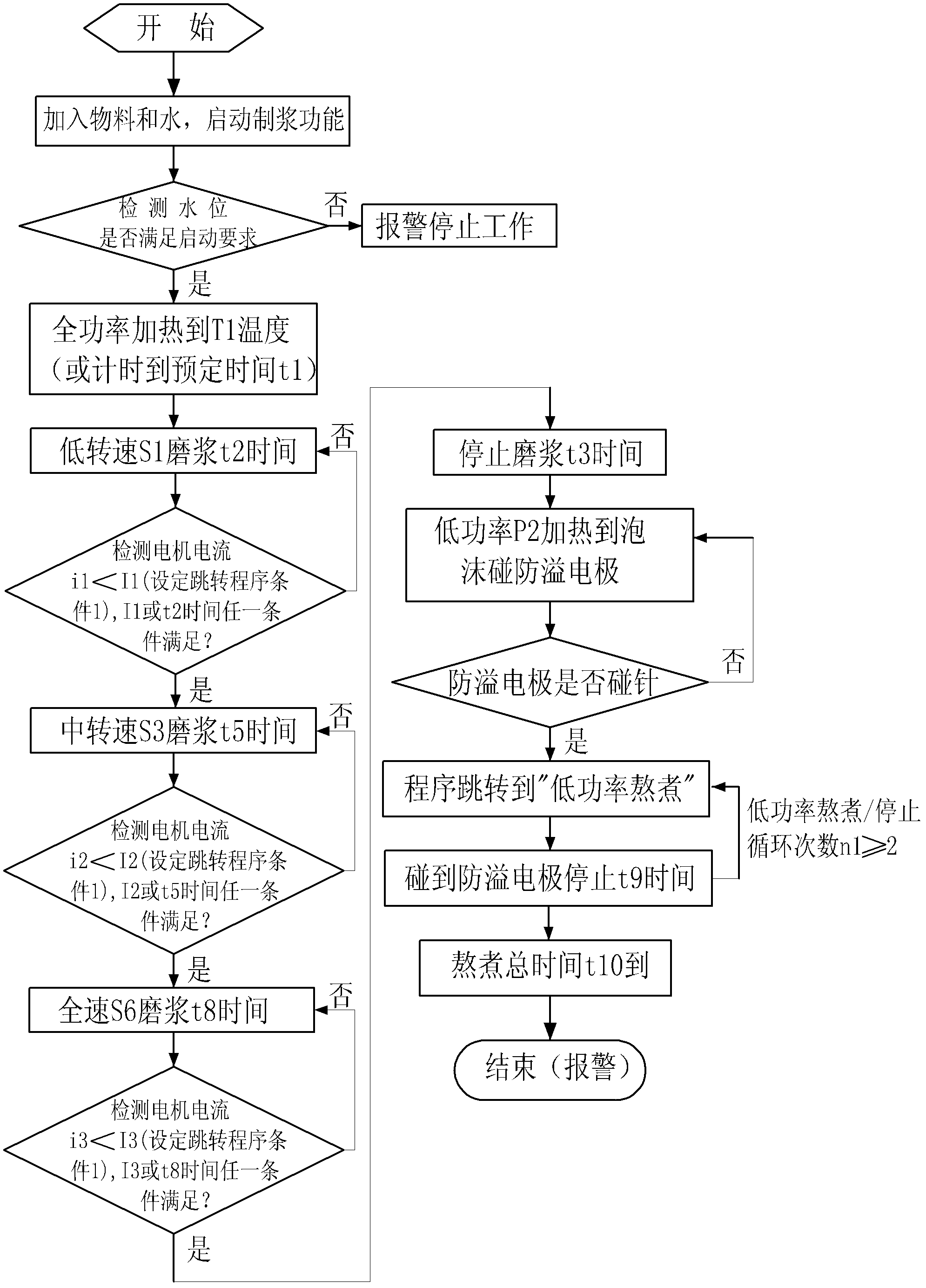

Examples

Embodiment 2

[0079] The low-speed operation S1, low-speed operation S2, medium-speed operation S3, medium-speed operation S4, high-speed operation S5, and full-speed operation S6 in the speed-regulating refining stage are performed cyclically. The remaining steps are the same as the first embodiment.

Embodiment 3

[0081] The c). preheating stage H1 and the d). speed-adjusting refining stage are carried out sequentially. The other steps are the same as the first embodiment.

Embodiment 4

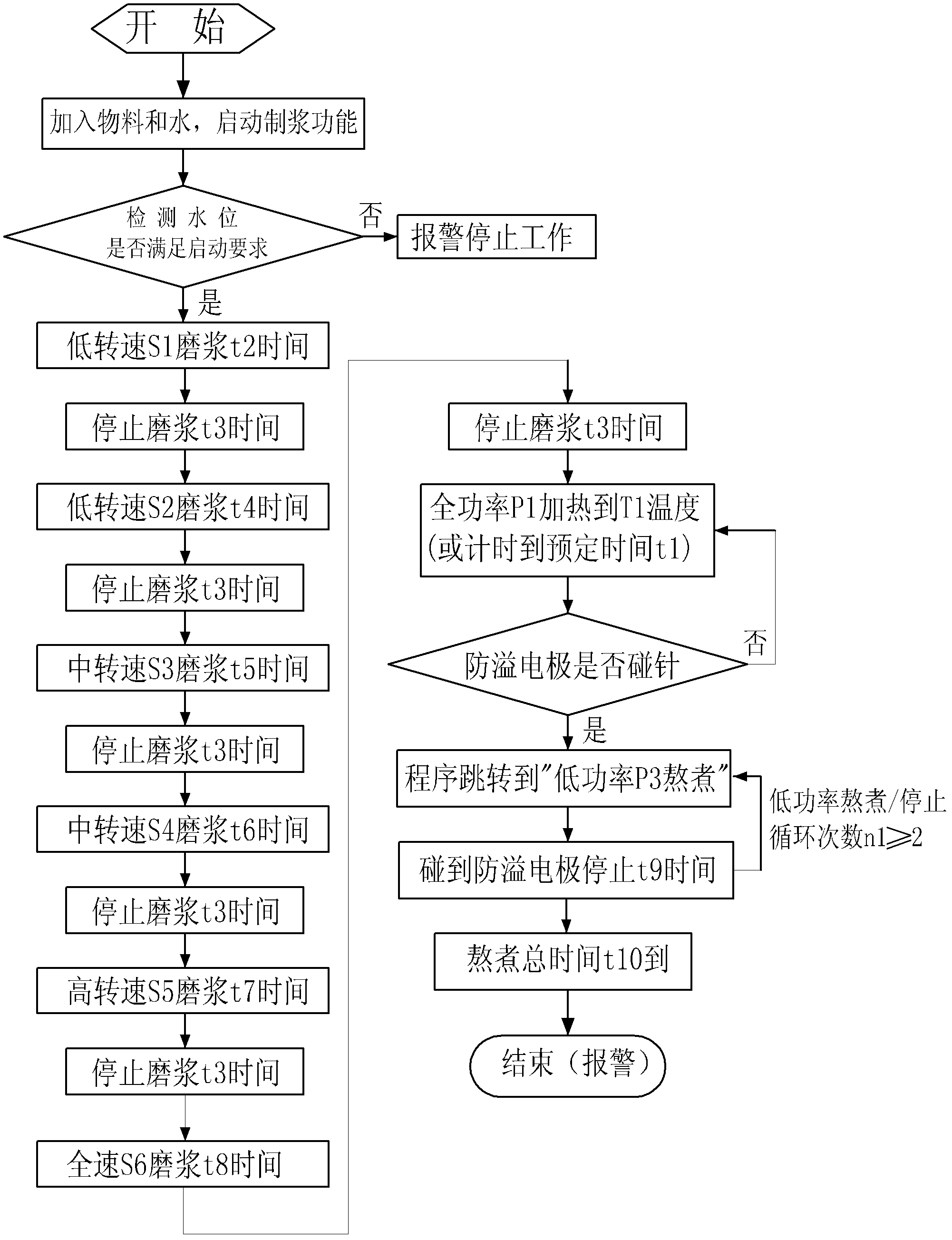

[0083] See attached figure 2 When the wet material is added, the heating stage H1 can be moved to after the speed adjustment refining, that is, after the refining is completed, the heating stage H1 is entered, and the ground slurry is heated with full power P1 to prevent overflow Electrode, skip the heating stage H2 and enter the next cooking stage H3, until the pulping is completed and alarm. The other steps are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com