Lithium battery thickness automatic detection machine

An automatic detection and lithium battery technology, which is applied in sorting and other directions, can solve the problems of large errors and low efficiency, and achieve the effect of improving detection efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

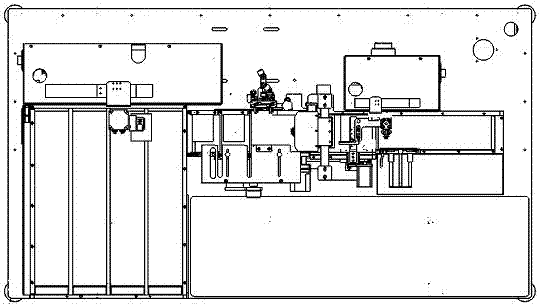

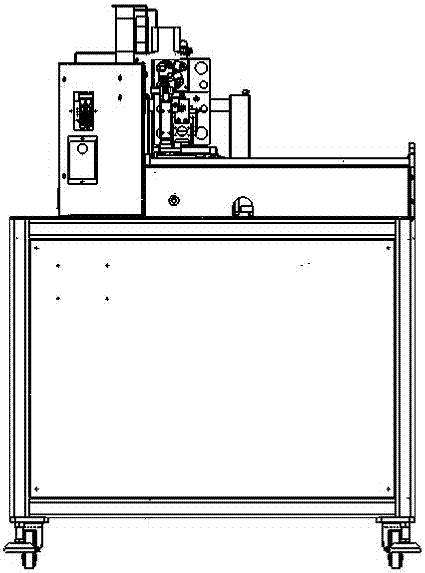

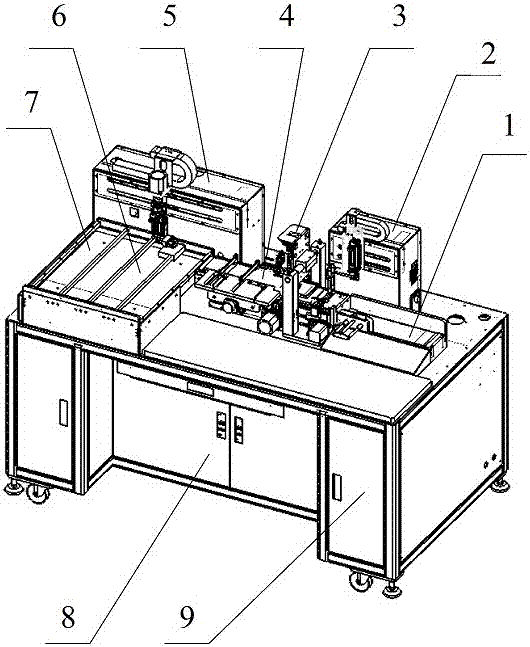

[0045] specific implementation plan

[0046] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0047] Put a group of lithium batteries into 1, the lithium battery input mechanism, 1, the lithium battery input mechanism transports the lithium battery group to a 11, blocking plate at the front end of the 1, lithium battery input mechanism and locate it.

[0048] Further, 2. The feeding moving mechanism uses 10. Vacuum suction cups to pick up and place each lithium battery successively on 4. The middle conveyor belt assembly.

[0049] Further, 4, the central conveyor belt assembly transports the lithium battery to 3, the thickness detection assembly, 3, 12, the cylinder on the thickness detection assembly starts, 3, 13, the thickness detection plate of the thickness detection assembly moves down, and detects the lithium battery 14. The displacement sensor records the thickness value of the lithium battery an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com