Automatic sorting method of large-array resistance strain gages

A technology of resistive strain and resistive strain gauges, applied in sorting and other directions, can solve the problems of unfavorable product quality stability control, error-prone, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

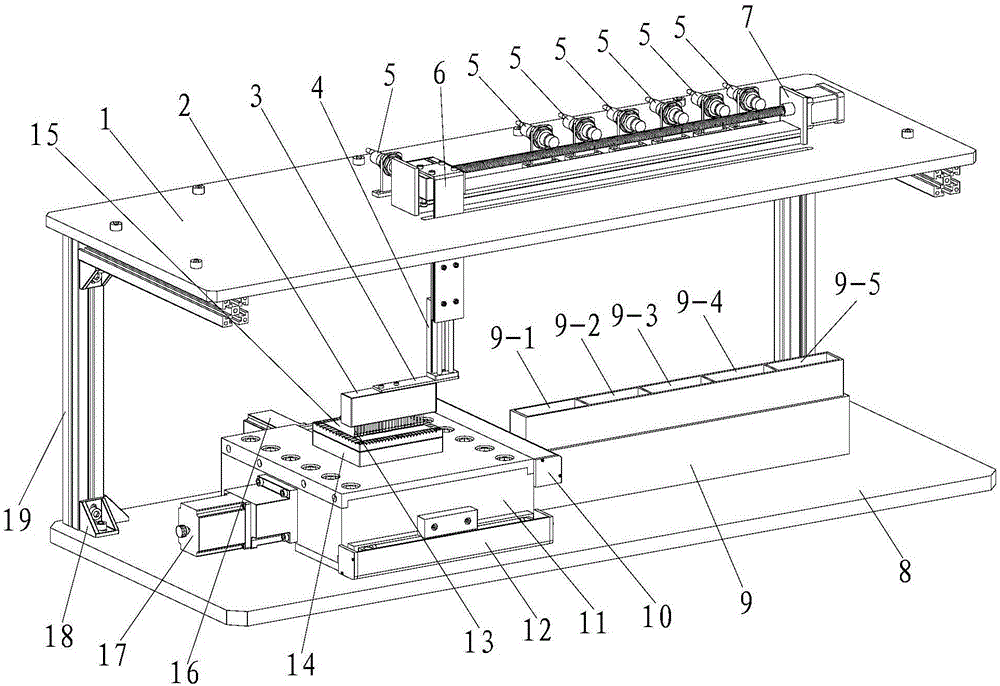

[0088] like figure 1 and Figure 8 As shown, the large-array resistance strain gauge automatic sorting device of the present invention includes a frame, a positioning and fixing mechanism, an adsorption sorting mechanism, a positioning sorting mechanism and a computer 37, and the computer 37 is connected with a data acquisition board 38 , the signal output terminal of the data acquisition board 38 is connected with an output amplifier board 39;

[0089] The frame includes an upper top plate 1 and a lower bottom plate 8 arranged at intervals up and down, and a pillar supported between the upper top plate 1 and the lower bottom plate 8;

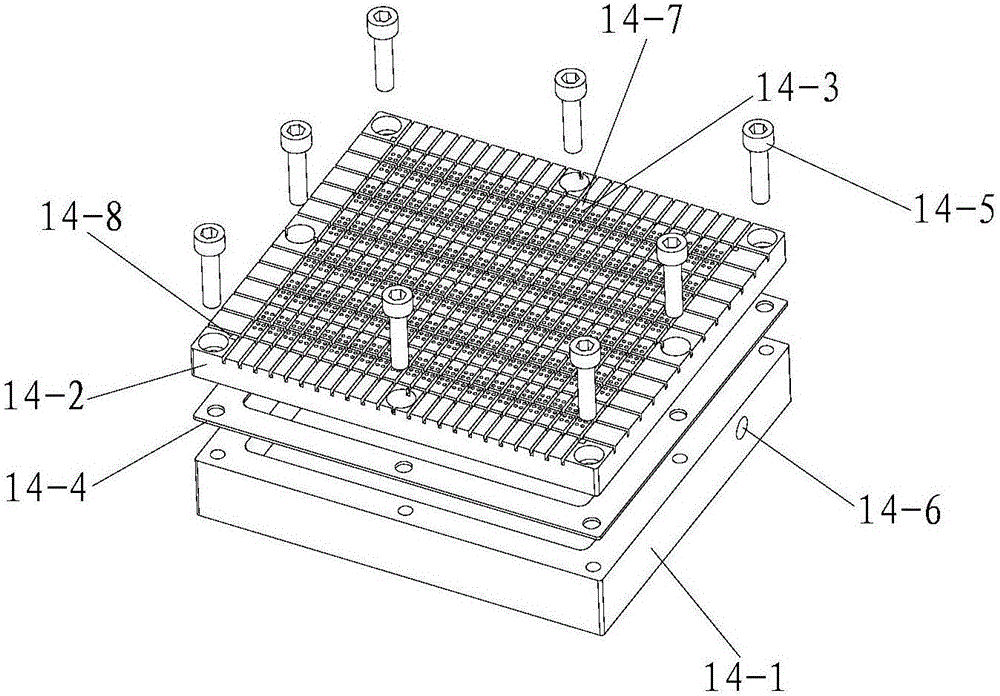

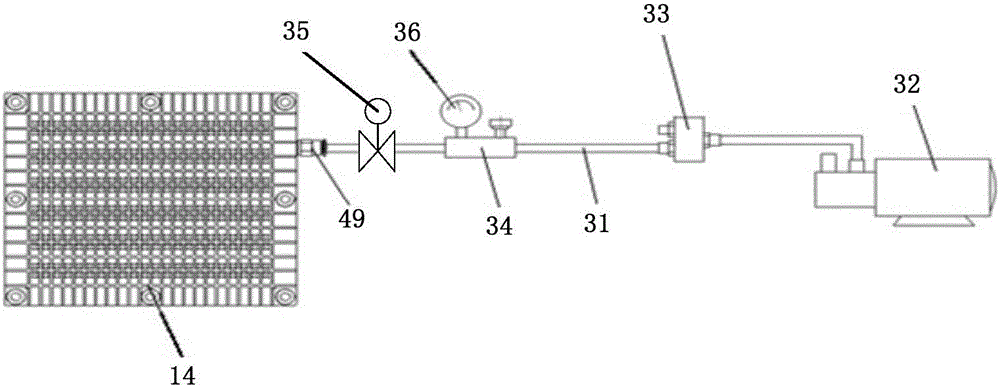

[0090] The positioning and fixing mechanism includes a two-dimensional mobile platform 11 installed on the top of the lower bottom plate 8, a vacuum adsorption table 14 installed on the top of the two-dimensional mobile platform 11, and a first vacuum adsorption circuit for evacuating the vacuum adsorption table 14. The two-dimensional movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com