Sleeve cylinder surface inspection device

A technology of appearance inspection and sleeve parts, which is applied in the direction of measuring devices, optical devices, and optical testing for flaws/defects, etc. It can solve the problems of high subjectivity in manual inspection, reduce production efficiency, and prone to false inspections, etc., and achieve the degree of automation Large size, improved production efficiency, and high picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

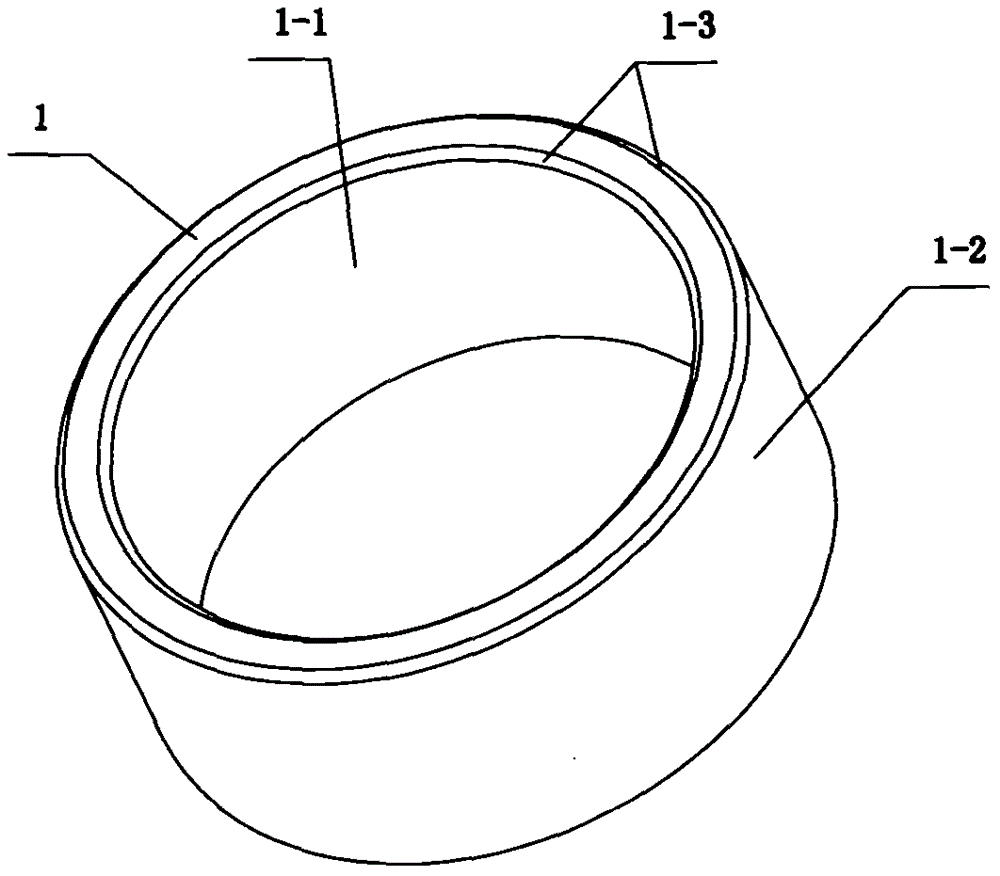

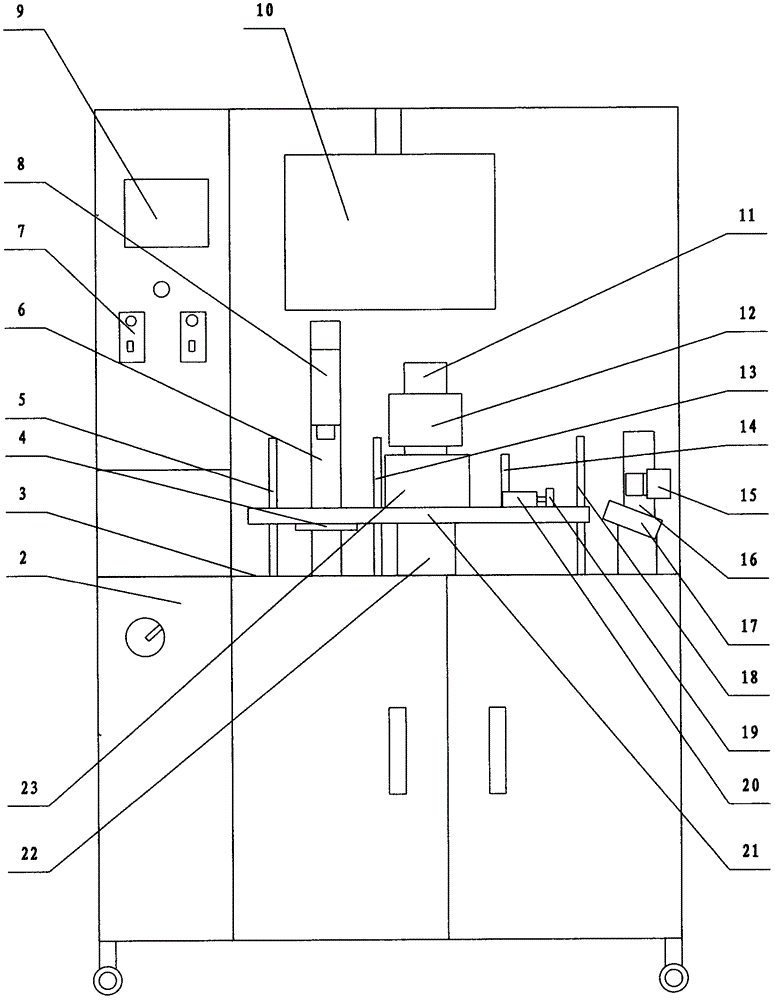

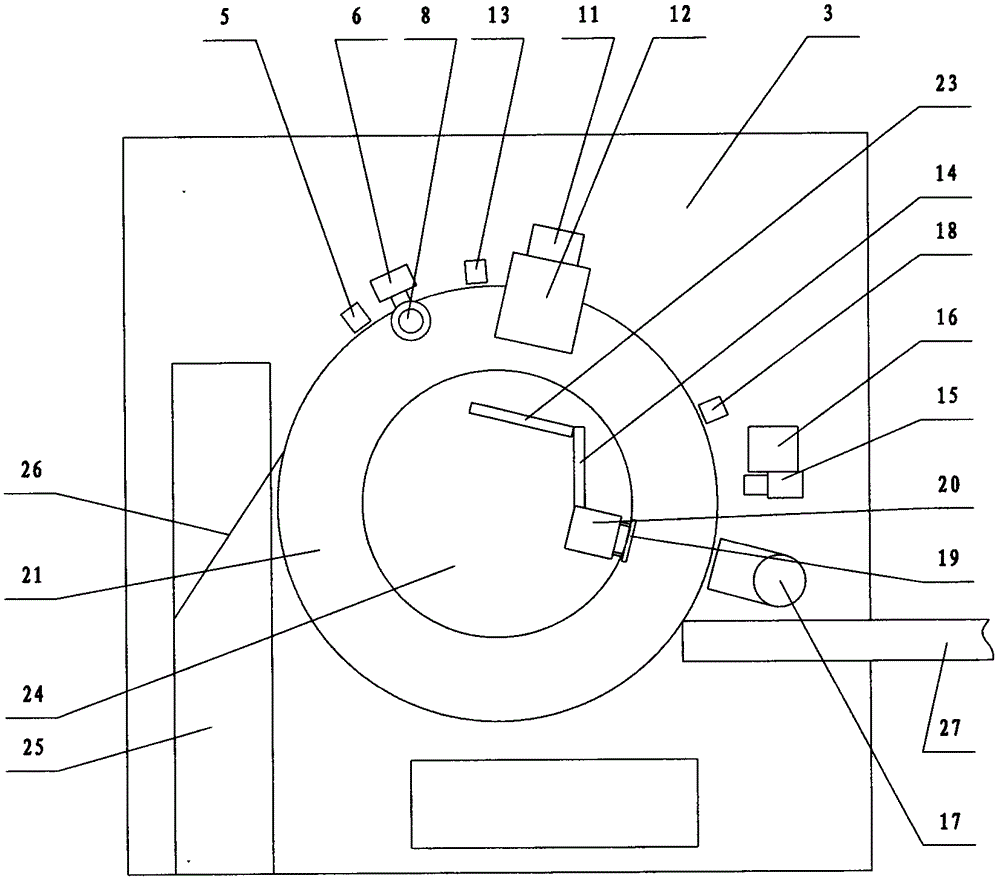

[0023] Depend on Figure 1 ~ Figure 3 As can be seen from the schematic diagram of the structure of the sleeve part appearance detection device of the present invention, it includes a frame 2 with a workbench 3, a control assembly, a central fixed table 24, a light-transmitting glass turntable 21 made of glass, and is used to detect sleeves. The surface defect detection mechanism for the surface defect of the barrel 1, the chamfer defect detection mechanism for detecting the inner and outer chamfer defects of the sleeve 1, the height defect detection mechanism for detecting the height dimension of the sleeve 1 and the transfer mechanism for the sleeve 1. The control assembly is connected to the frame 2, the central fixed table 24 is connected to the worktable 3, the glass turntable 21 is circular and is located on the outer ring of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com