Automatic tying machine of overhand knot and application method thereof

An automatic knotting and single knotting technology, applied in knotting, textile and papermaking, etc., can solve the problems of low efficiency, time-consuming and laborious, and achieve the effect of liberating labor, reducing labor intensity, and being applicable to a wide range of occasions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

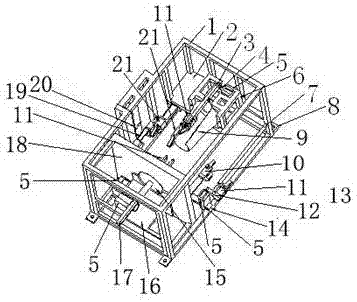

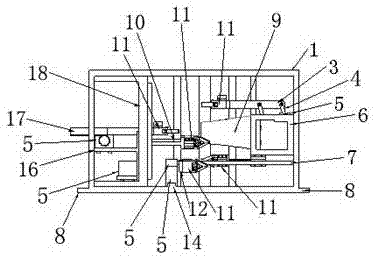

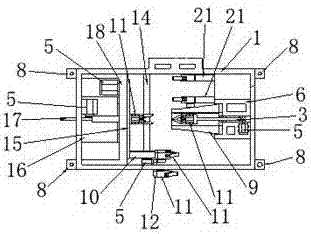

[0036] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0037] A fixed single-knot automatic knotting machine, including a frame 1, the shape of the frame 1 can be designed according to the needs, as a preferred embodiment, the frame 1 adopts a rectangular structure, in order to facilitate fixing, the four corners of the frame 1 are respectively set Be used for the fixing foot 8 of fixing, can offer bolt hole on the fixing foot 8. Frame 1 is provided with limit hole 20 on the side that cutter 19 is installed, is used for rope introduction in frame 1 and knots, and the vertical height of limit hole 20 is consistent with the traction mechanical arm 13 height on the guide rail 14, convenient Gripping of the rope.

[0038] Described frame 1 is fixed with the knotting cover 9 that is perpendicular to this side direction in its side, and the knotting mechanical arm 3 that can stretch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com