Hank tie knotting device used for hank reeling machine

A technology of knotting device and spinning machine, which is applied in knotting, other manufacturing equipment/tools, textiles and papermaking, etc. It can solve the difficulty in achieving consistent lengths of twisted strands, cracked finger skin, and poor quality of manual twisting. and other issues to achieve the effect of improving the efficiency and quality of stranding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

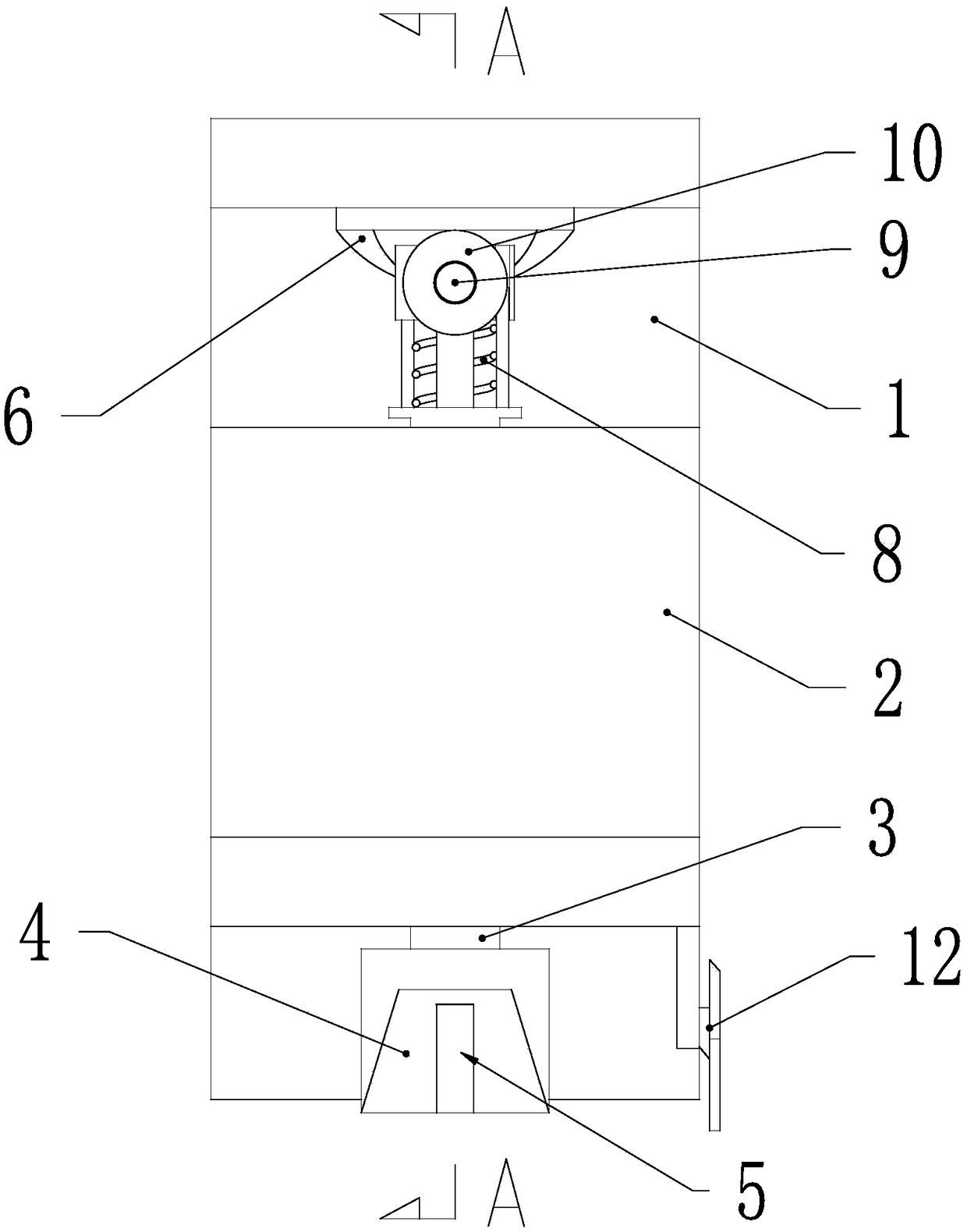

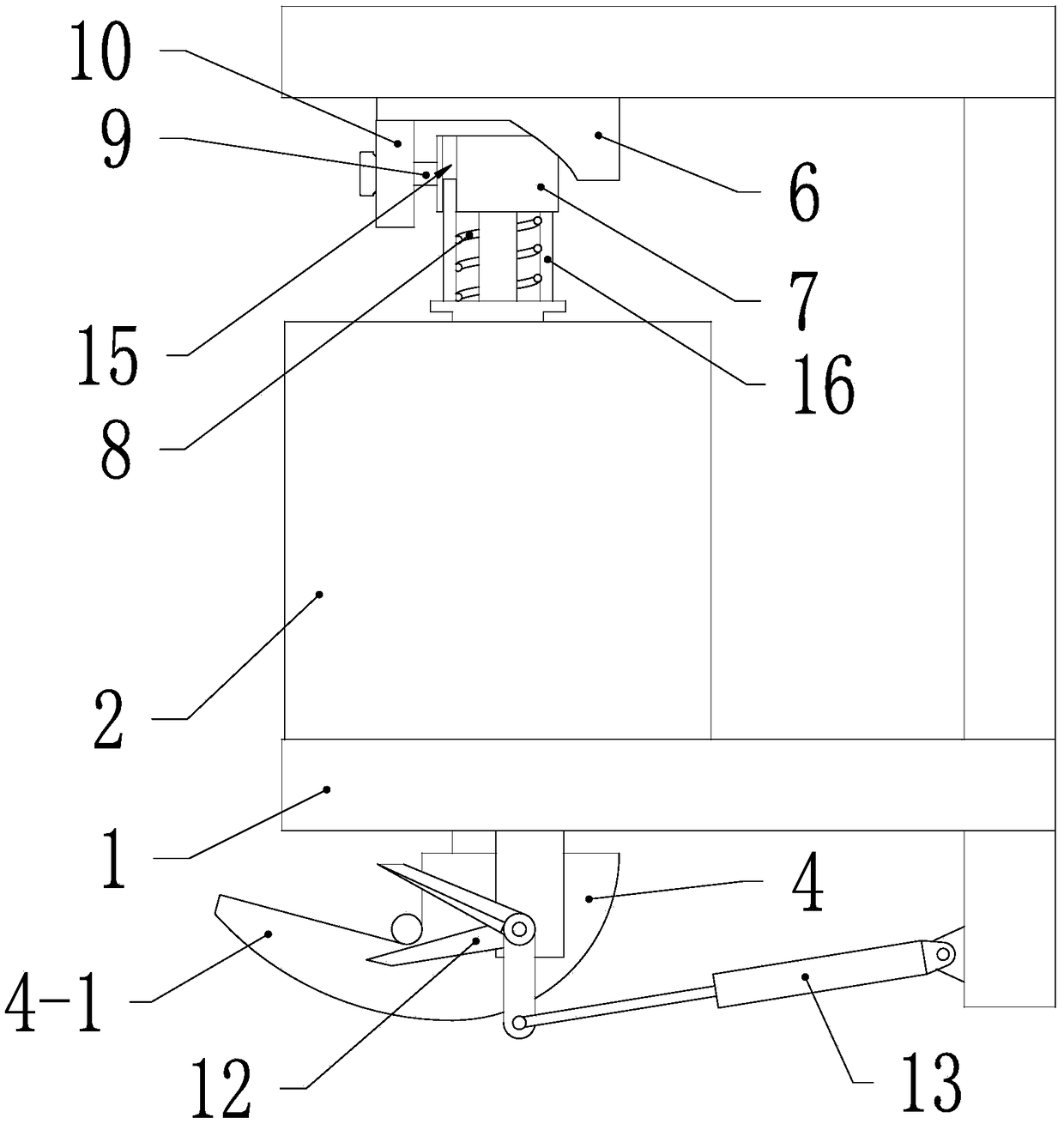

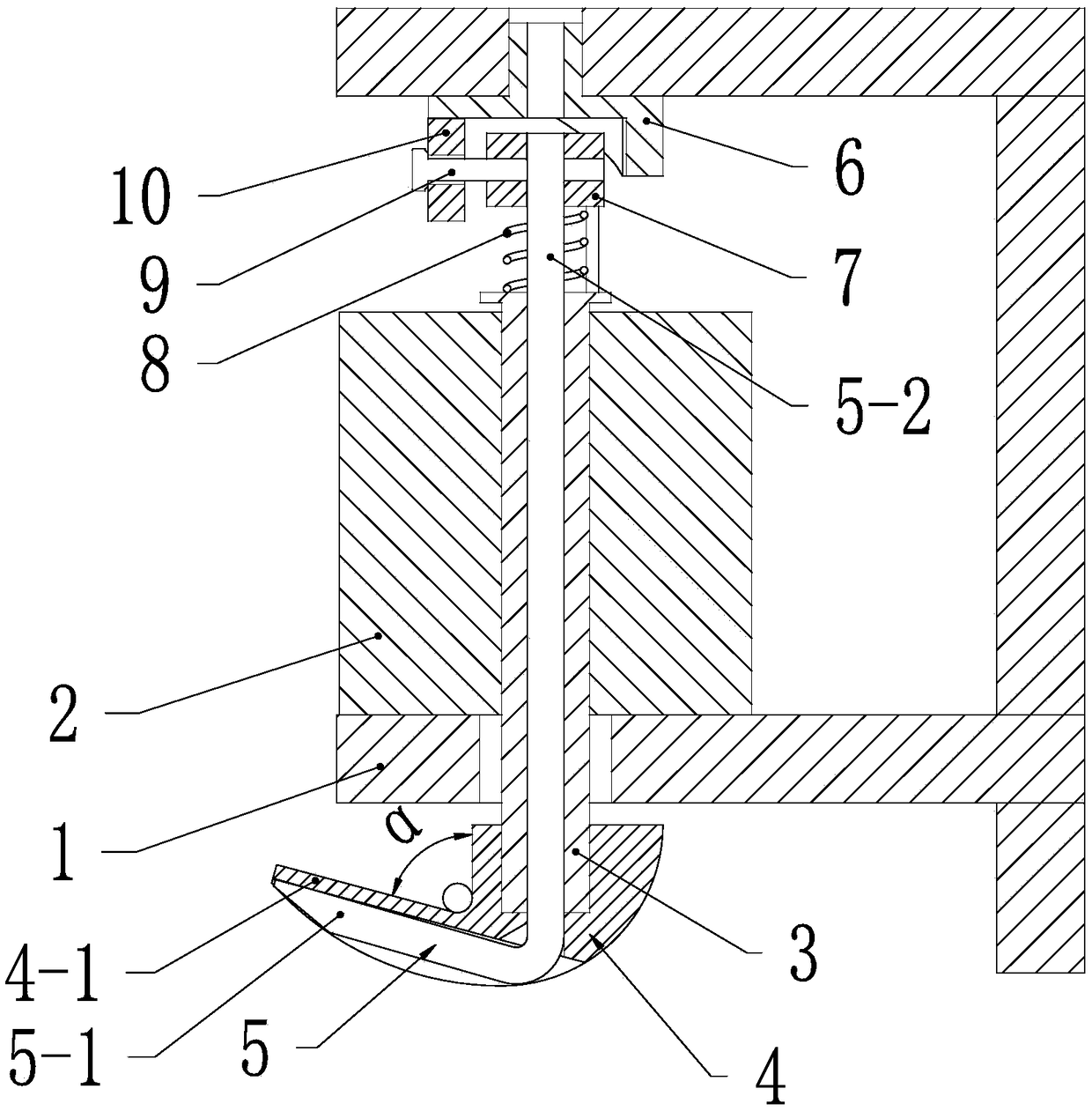

[0029] Such as Figure 1 ~ Figure 4 Shown is a twisted wire knotting device applied to a spinning machine, including a frame 1, a hollow shaft motor 2 is fixedly connected to the frame 1, and the motor 2 is a servo motor or a stepping motor or an ordinary motor with an encoder. The motor, the rotating shaft 3 of the motor 2 is a hollow shaft, and one end of the rotating shaft 3 of the motor 2 is connected with a knotting hook 4, the angle α between the inner surface of the fixed hook head 4-1 of the knotting hook 4 and the rotating shaft 3 is an acute angle, and the rotating shaft 3 is coaxially provided with a clamping hook 5, which includes a movable hook head 5-1 and a hook handle 5-2 connected to each other, and the hook handle 5-2 can be axially slidably plugged in the In the central hole, both ends of the hook handle 5-2 are stretched o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com