Textile reeling automatic splitting tie knotting device and splitting tie knotting method

A knotting device, automatic technology, applied in knotting, textile and papermaking, other manufacturing equipment/tools, etc., can solve the problems of unguaranteed product quality, no factory adoption, slow work progress, etc., to achieve convenient operation. , Easy installation and maintenance, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

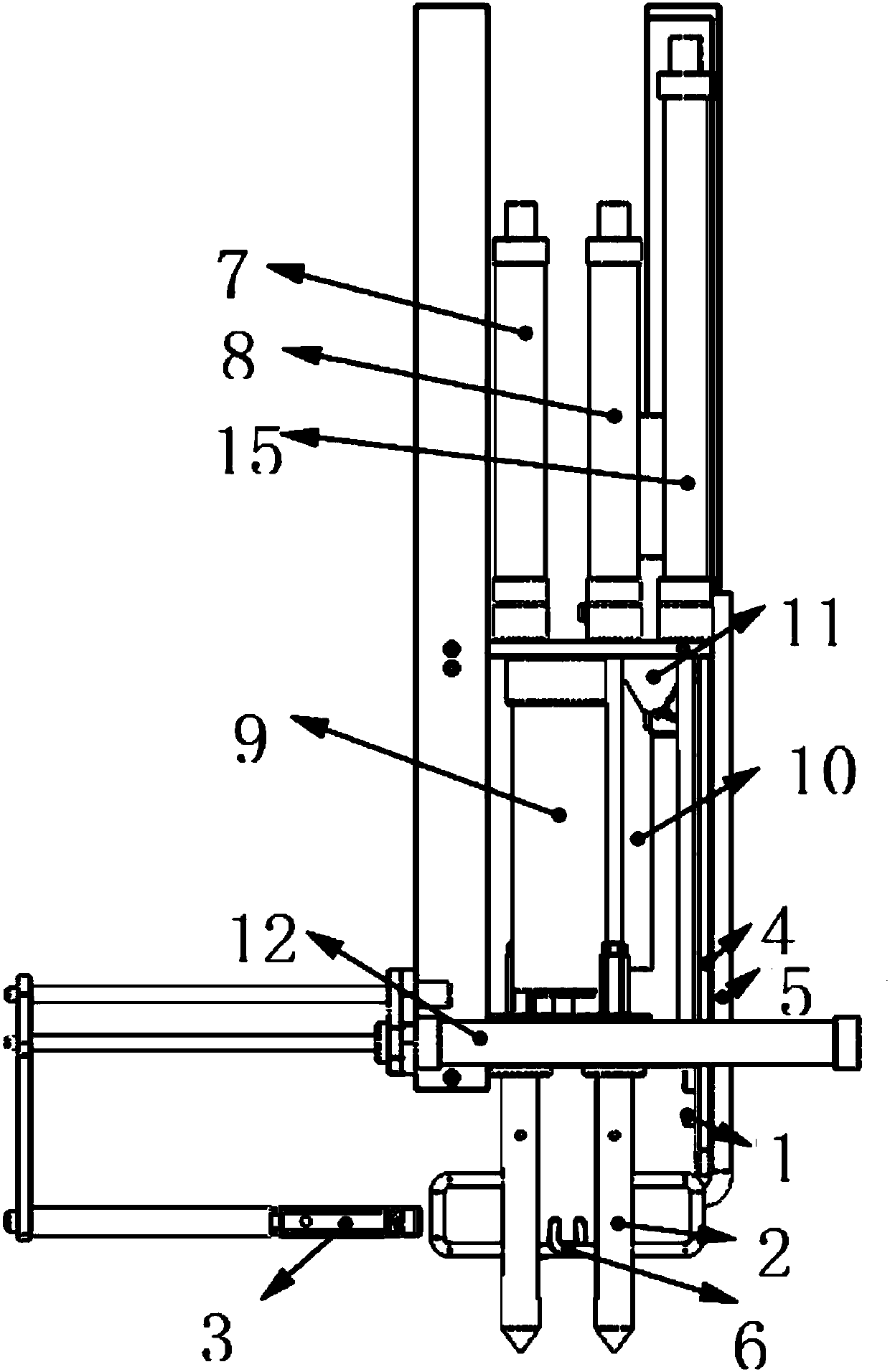

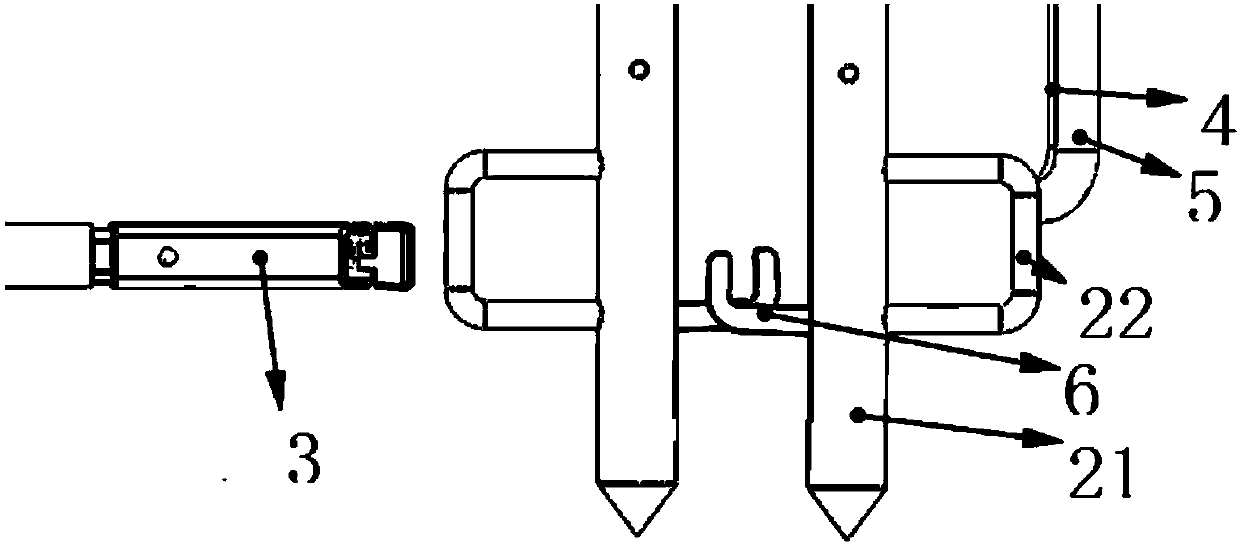

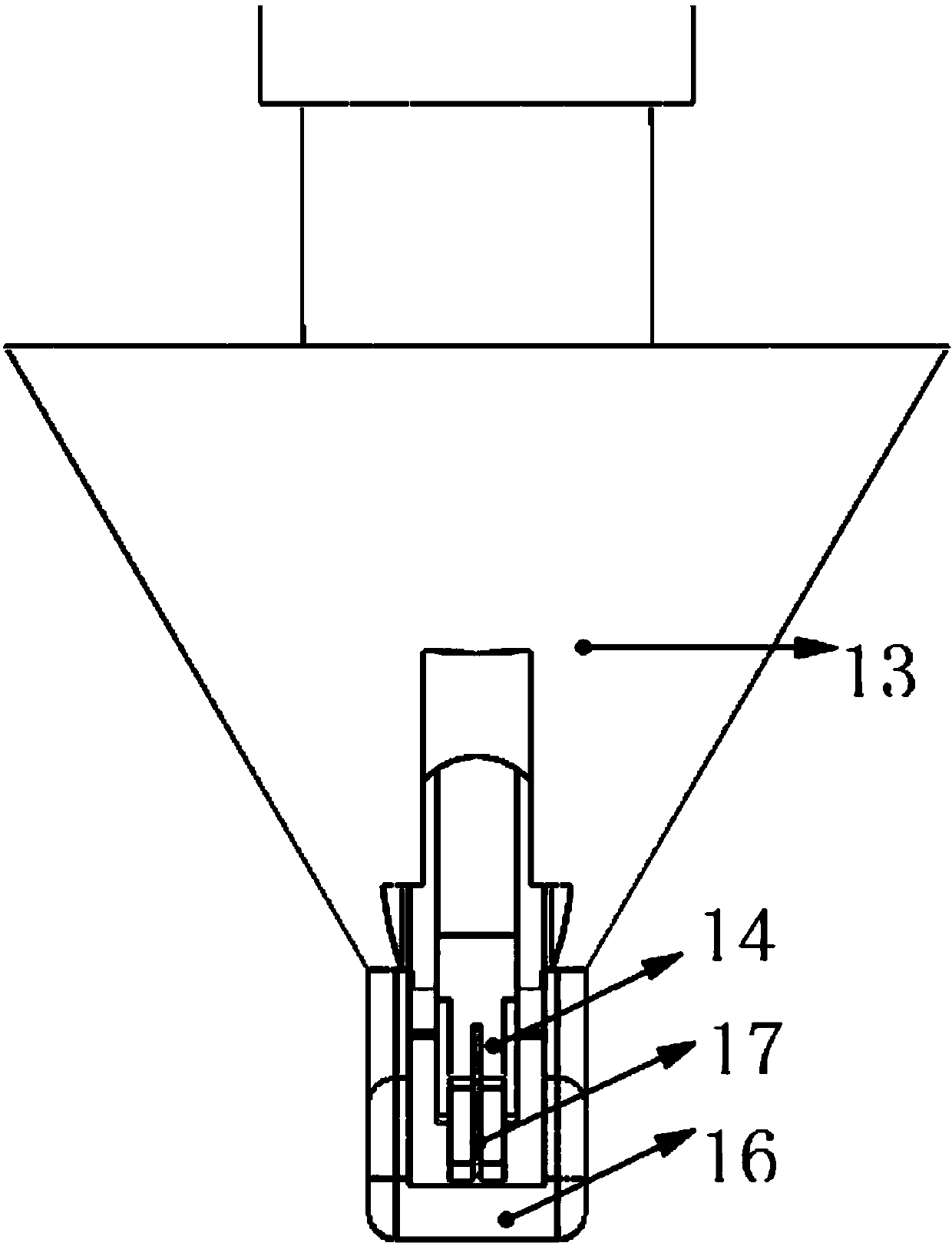

[0017] Referring to the accompanying drawings, an automatic splitting, twisting, and knotting device for textile shaking and twisting includes a thread lifting device 1. The outer side of the thread lifting device 1 is provided with a thread pressing device 2. The outer end surface of the yarn machine A wire clamping device 3 is provided, and a vacuum copper tube A4 and a vacuum copper tube B5 are respectively arranged side by side on the side of the wire lifting device 1. The bottom of the wire pressing device 2 is symmetrically provided with a wire lifting hook 6 respectively. The top of the crimping device 2 is respectively provided with a cylinder A7, a cylinder B8, the cylinder A7, the cylinder B8 are respectively connected with two wire lifting hooks 6, and the crimping device 2 is provided with a motor A9, and the One side of the motor A9 is provided with a motor B10, the motor B10 is connected with the knotter 11, and the outside of the wire crimping device 2 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com