A method for processing floral and fruity-flavored non-bitter and astringent yellow tea by using fresh summer and autumn tea leaves

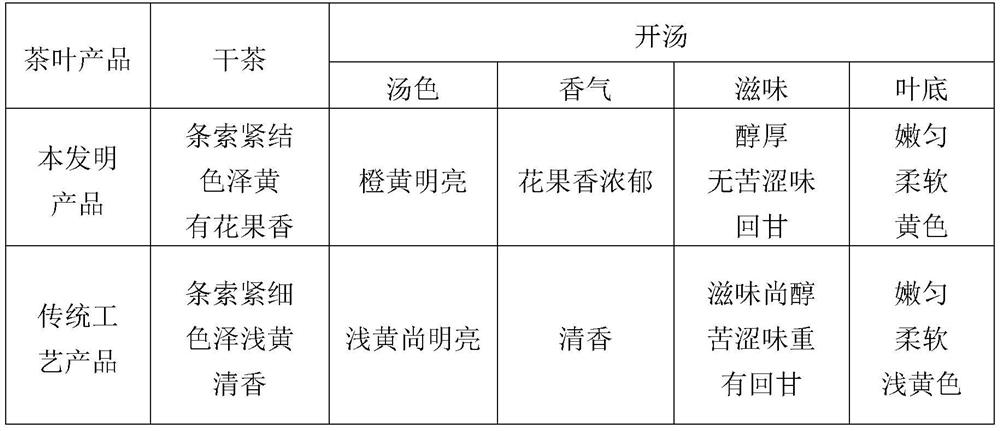

A technology of fresh tea leaves and bitter taste, which is applied in the field of processing floral and fruity-flavored non-bitter and astringent yellow tea with fresh leaves of summer and autumn tea, which can solve the problems of waste of summer and autumn tea resources, uncharacteristic aroma of yellow tea products, heavy bitter taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The summer one bud and one leaf fresh leaf of the Bixiang morning tea tree variety is selected as the raw material.

[0034]Spread the fresh leaves of Bixiang early summer with one bud and one leaf on an indoor disc, and spread them for 1 hour at a relative humidity of 60%, a room temperature of 35°C and good ventilation. The thickness of the spread leaves is 1-1.5cm. The surface loses luster, the leaf color turns dark green, the leaves are soft and have a slight fragrance; put the above-mentioned spread leaves under weak sunlight (5:30-6:30 pm) and dry them outdoors for 10 minutes, and transfer them after drying Spread the green leaves indoors for 10 minutes; at 25° C. and a relative humidity of 70%, use a tea shaker to shake the green leaves for 6.5 minutes at a speed of 10 rpm until the leaves are wrinkled, soft to the touch, and form a ball when held. The tender stems are folded continuously, the leaves are dark green without reddening, and exude a strong floral and...

Embodiment 2

[0037] Choose the fresh leaves of one bud and one leaf in autumn of Bixiang morning tea tree variety as raw material.

[0038] Spread the fresh leaves of Bixiang with one bud and one leaf in early autumn on an indoor disc for 1.5 hours at a relative humidity of 70%, a room temperature of 25°C and good ventilation. The thickness of the spread leaves is 1-1.5cm, until The leaves lose their luster, the leaf color turns dark green, and the leaves are soft and slightly fragrant; put the above-mentioned spread leaves under weak sunlight (8:00-9:00 in the morning) and dry them outdoors for 15 minutes. Transfer to indoor airing for 5 minutes; shake the above-mentioned green leaves at 20°C and relative humidity of 85% with a tea shaker at a speed of 10 rpm for 5.5 minutes until the leaves are wrinkled, soft to the touch, and the leaves form a ball , the tender stems are folded continuously, the leaves are dark green without reddening, and exude a strong floral and fruity fragrance; aft...

Embodiment 3

[0041] The summer one-bud one-leaf fresh leaf of the Jianbo yellow tea tree variety is selected as the raw material.

[0042] Spread the fresh leaves of Jianbohuang with one bud and one leaf in summer on an indoor disc for 1.25 hours at a relative humidity of 65%, a room temperature of 30°C and good ventilation. The thickness of the spread leaves is 1-1.5cm, until The leaf surface loses its luster, the leaf color turns dark green, the leaf quality is soft and has a slight fragrance; put the above-mentioned spread leaves under weak sunlight (5:30-6:30 pm) and dry them outdoors for 12 minutes. Transfer to indoor airing for 8 minutes; shake the above-mentioned green leaves at 23°C and relative humidity of 80% with a tea shaker at a speed of 10 rpm for 6.0 minutes until the leaves are wrinkled, soft to the touch, and the leaves form into agglomerates , the tender stems fold continuously, the leaf color is dark green without reddening, and exudes a strong floral and fruity fragranc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com