A kind of processing method of fungus-scented black tea

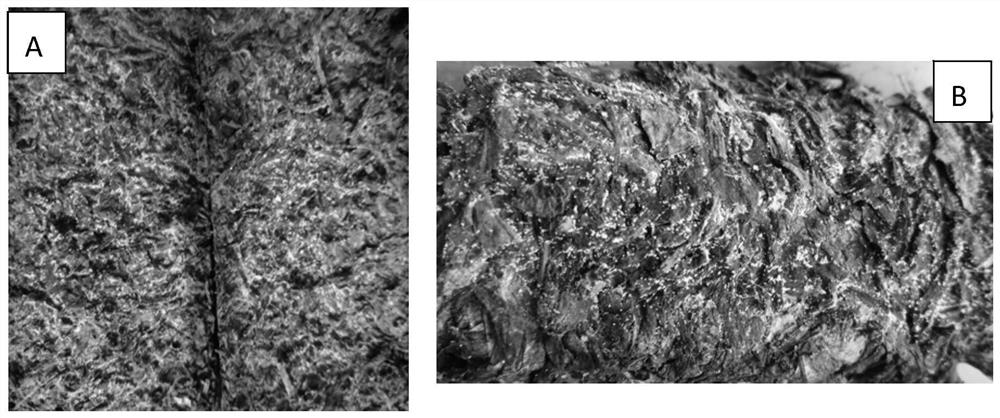

A processing method and technology of mushroom-flavored black tea, applied in the processing field of mushroom-flavored black tea, can solve the problems of insufficient taste concentration, strength and freshness, waste of tea resources in summer and autumn, and lack of characteristics, etc., to achieve fresh color, uniform particles, Golden flower lush effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The summer one-bud three-leaf tea fresh leaves of the tea tree species Castanopsis qi are selected as raw materials.

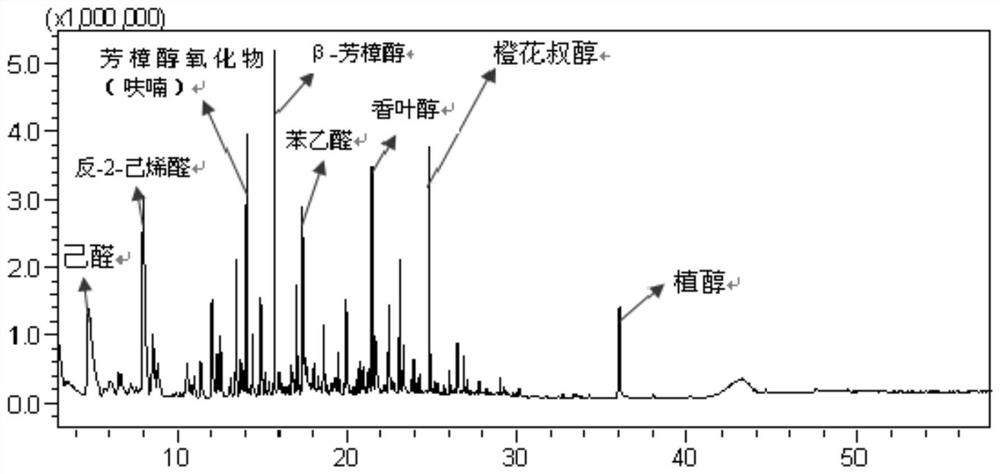

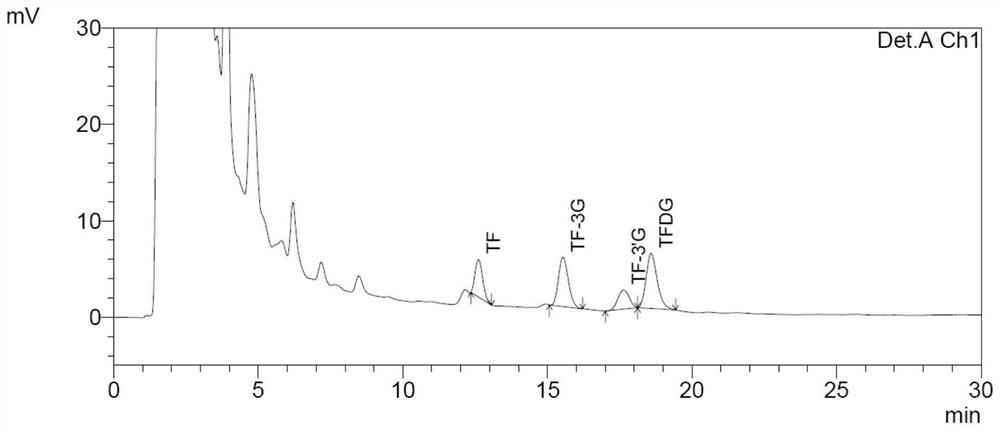

[0042] Place the fresh one-bud three-leaf tea leaves of Castanopsis chinensis in summer in a withering trough with a thickness of 3-5cm. The first withering is carried out at a temperature of 28°C and a humidity of 65%. During this period, it is turned twice until the grass gas disappears. , The water content of the leaves is 66%; the fresh leaves after the first withering are placed in a well-ventilated outdoor environment with a light intensity of 2000-40000lx sunlight for 10 minutes. During this period, they are turned twice until the leaves lose their luster and the leaves are soft. When it has a clear fragrance, move it to a cool and ventilated place indoors for 20 minutes, then shake it for 60 revolutions with a green shaker, and let it stand for 50 minutes until the water content is 60%, no redness, and a strong floral fragrance; after withering Pla...

Embodiment 2

[0046] Choose the tea tree variety Taoyuan Daye's autumn one-bud four-leaf tea fresh leaves as raw materials.

[0047] Put the autumn one-bud four-leaf tea fresh leaves of the tea tree variety Taoyuan Daye in a withering trough with a thickness of 3-5cm. The first withering is carried out at a temperature of 32°C and a humidity of 75%. During this period, it is turned twice until the grass disappears. The water content of the leaves is 62%; the fresh leaves after the first withering are placed in a well-ventilated outdoor environment with a light intensity of 20000-40000lx sunlight for 20 minutes. During this period, they are turned twice until the leaves lose their luster and the leaves are soft. When it has a clear fragrance, move it to a cool and ventilated place indoors for 40 minutes, then shake it for 100 revolutions with a green shaker, and let it stand for 70 minutes until the water content is 58%, no redness, and a strong floral fragrance; after withering Place the fresh...

Embodiment 3

[0051] The summer one-bud three-leaf and one-bud four-leaf tea fresh leaves of Bixiangzao are selected as raw materials.

[0052] Place the fresh three-leaf to four-leaf tea leaves of Bixiangzao in summer in a withering trough with a thickness of 4cm. The first withering is carried out at a temperature of 30°C and a humidity of 70%. During this period, the tea leaves are turned twice to reach the green grass. Disappearing, the water content of the leaves is 64%; the fresh leaves after the first withering are placed in a well-ventilated outdoor environment with a light intensity of 20000-40000lx sunlight for 15 minutes, during which they are turned twice, until the leaves lose their luster and the leaves are soft When it has a refreshing fragrance, move it to a cool and ventilated place indoors for 30 minutes, then shake it for 80 revolutions with a green shaker, and let it stand for 60 minutes until the water content is 59%, no redness, and a strong floral fragrance; it will withe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com