Patents

Literature

125results about "Weaver's tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

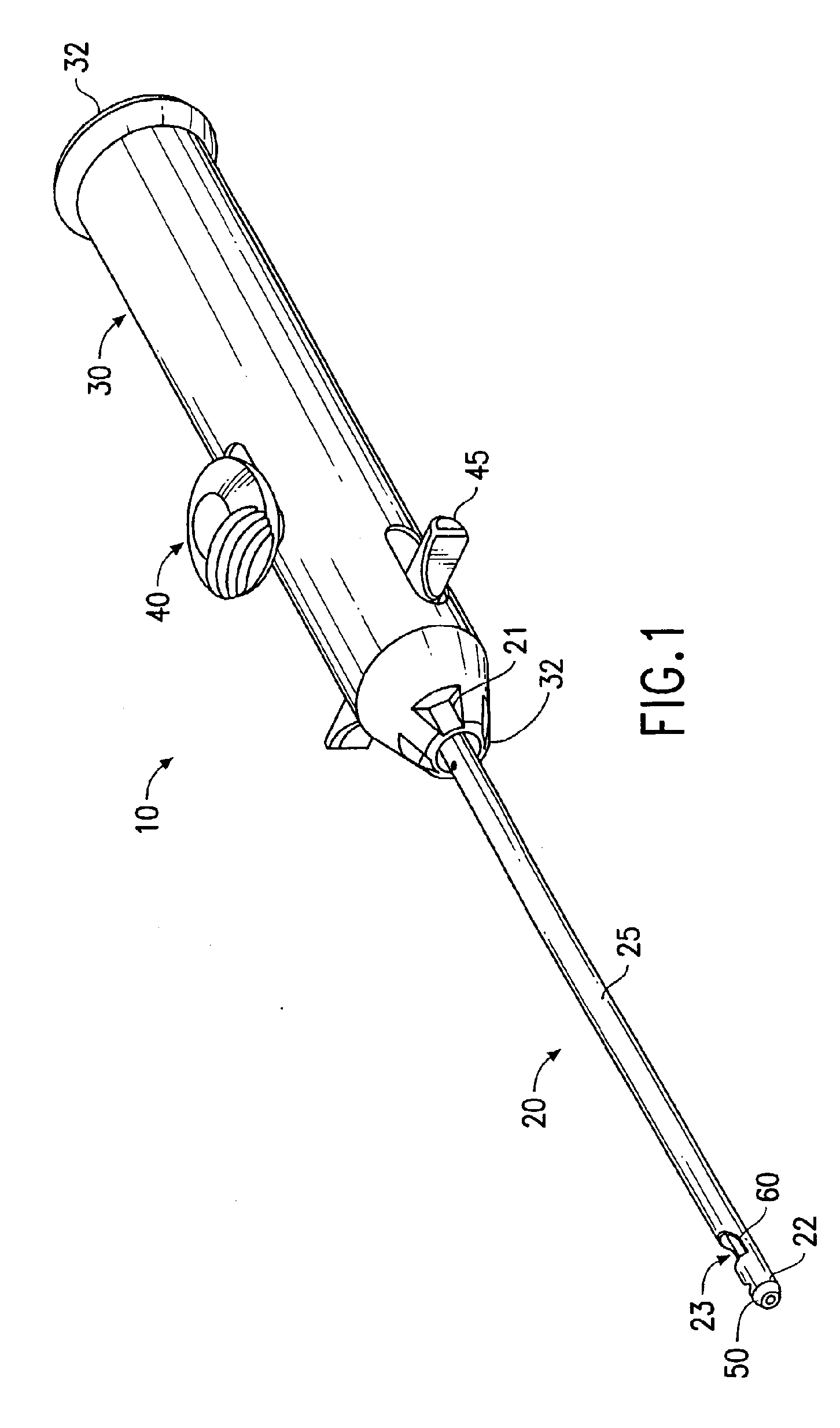

Surgical filament snare assemblies

ActiveUS8814905B2Reduce in quantitySmall sizeSuture equipmentsSurgical needlesEngineeringBiomedical engineering

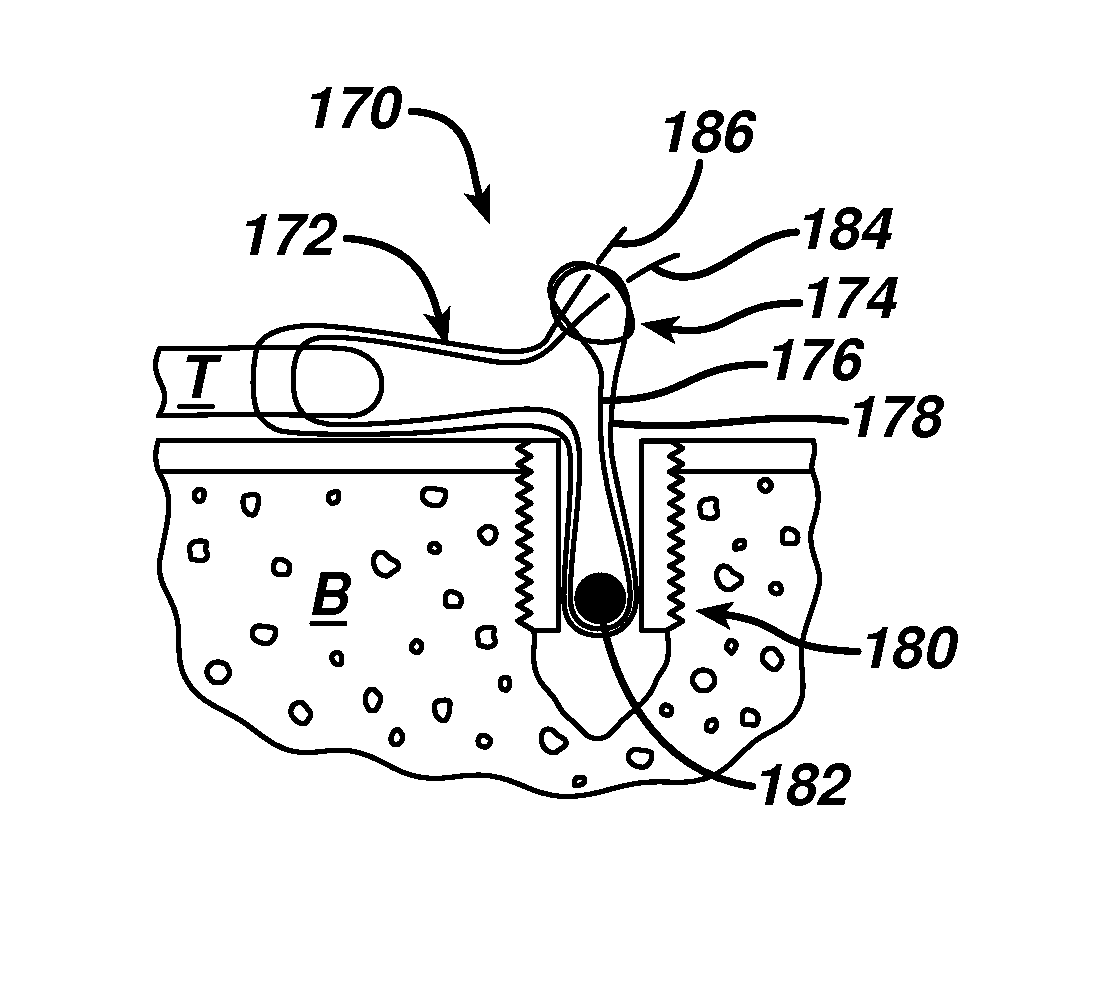

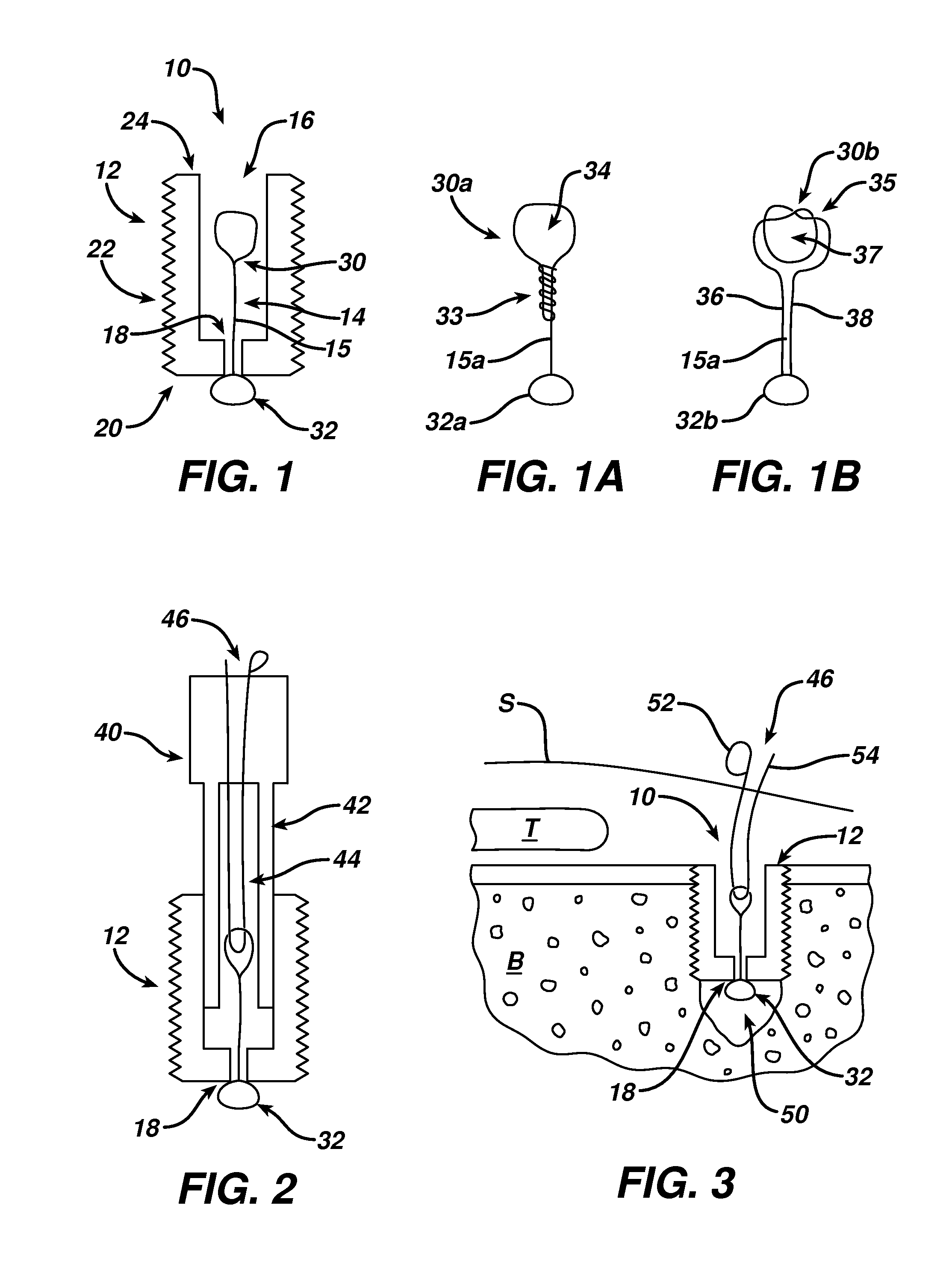

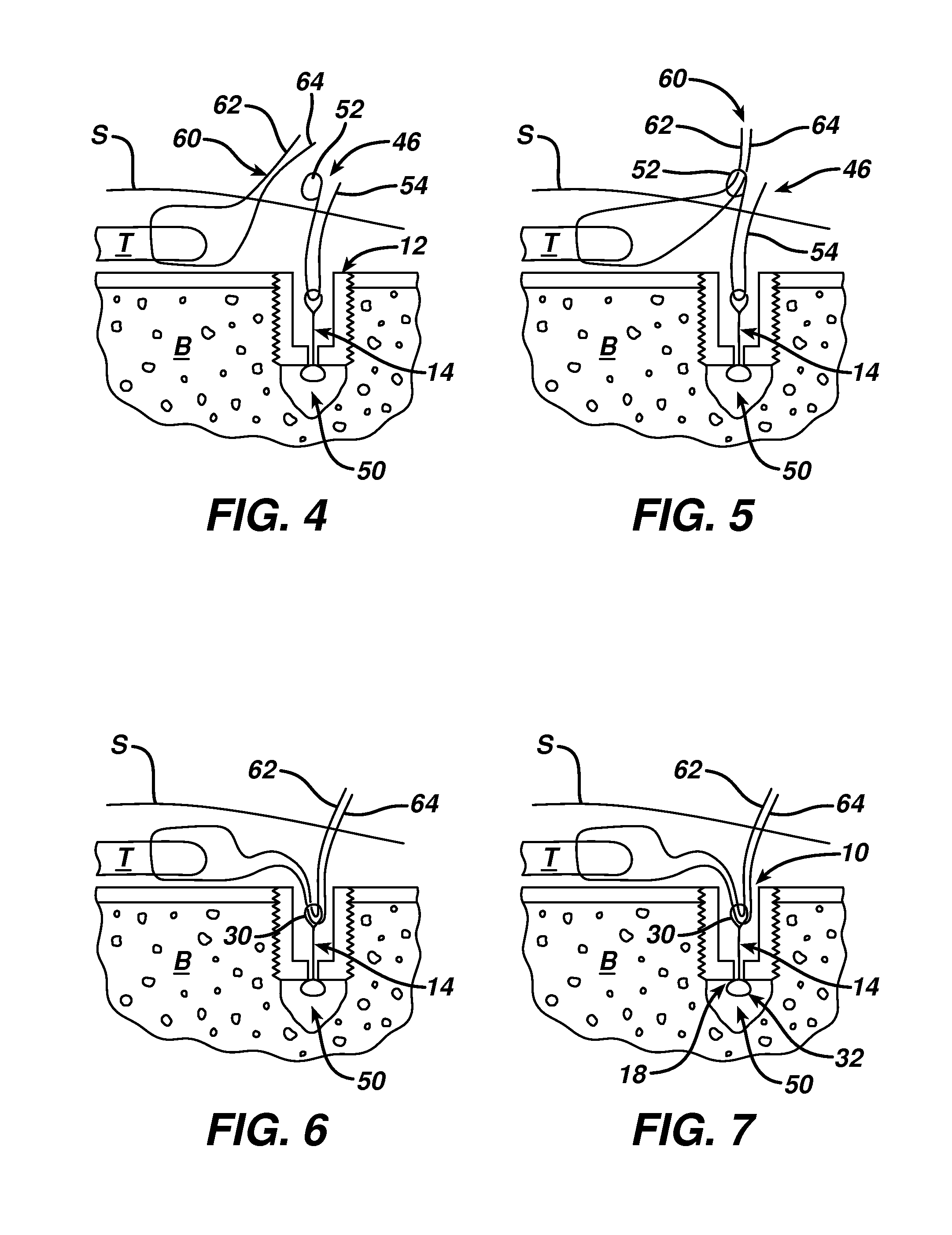

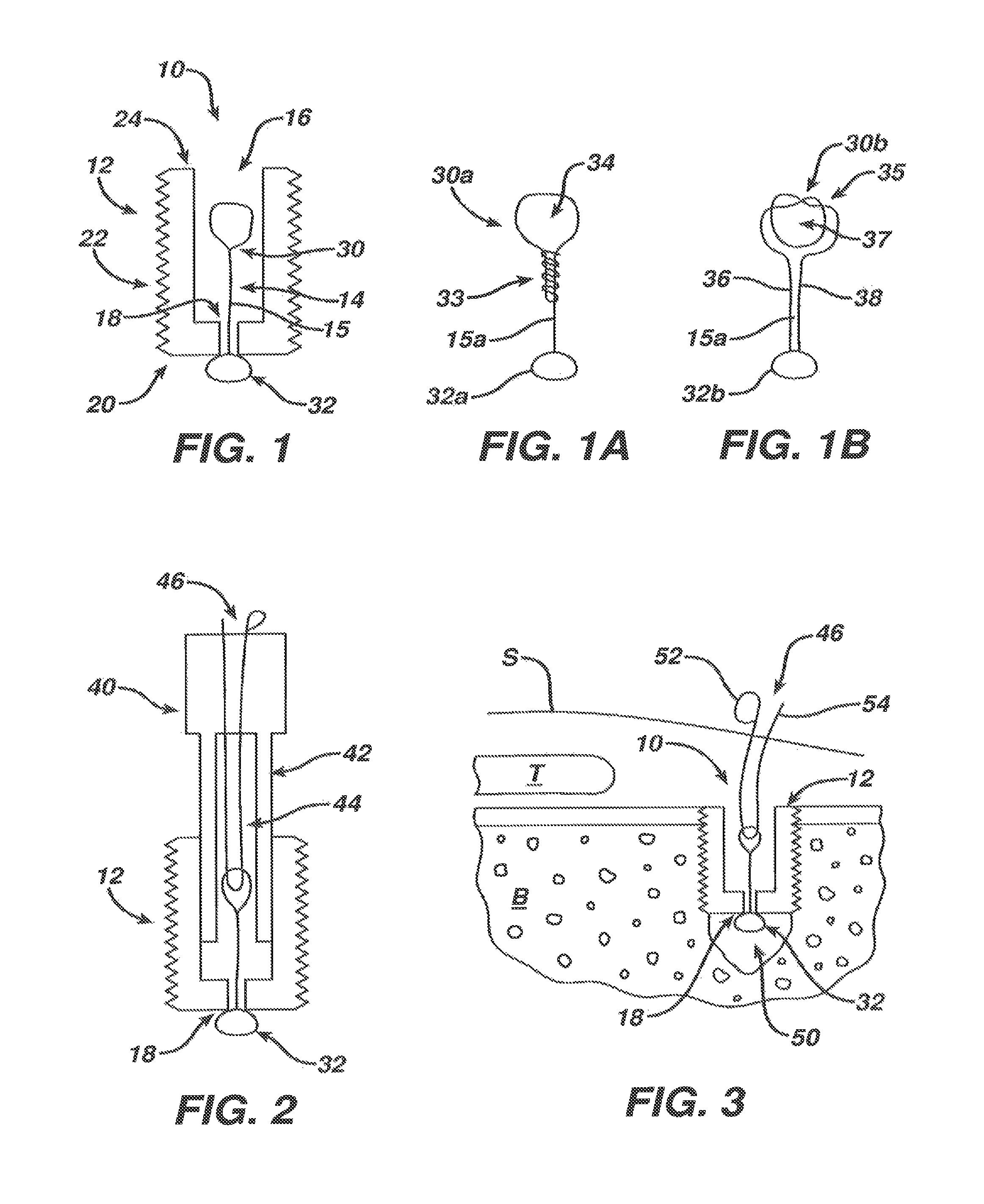

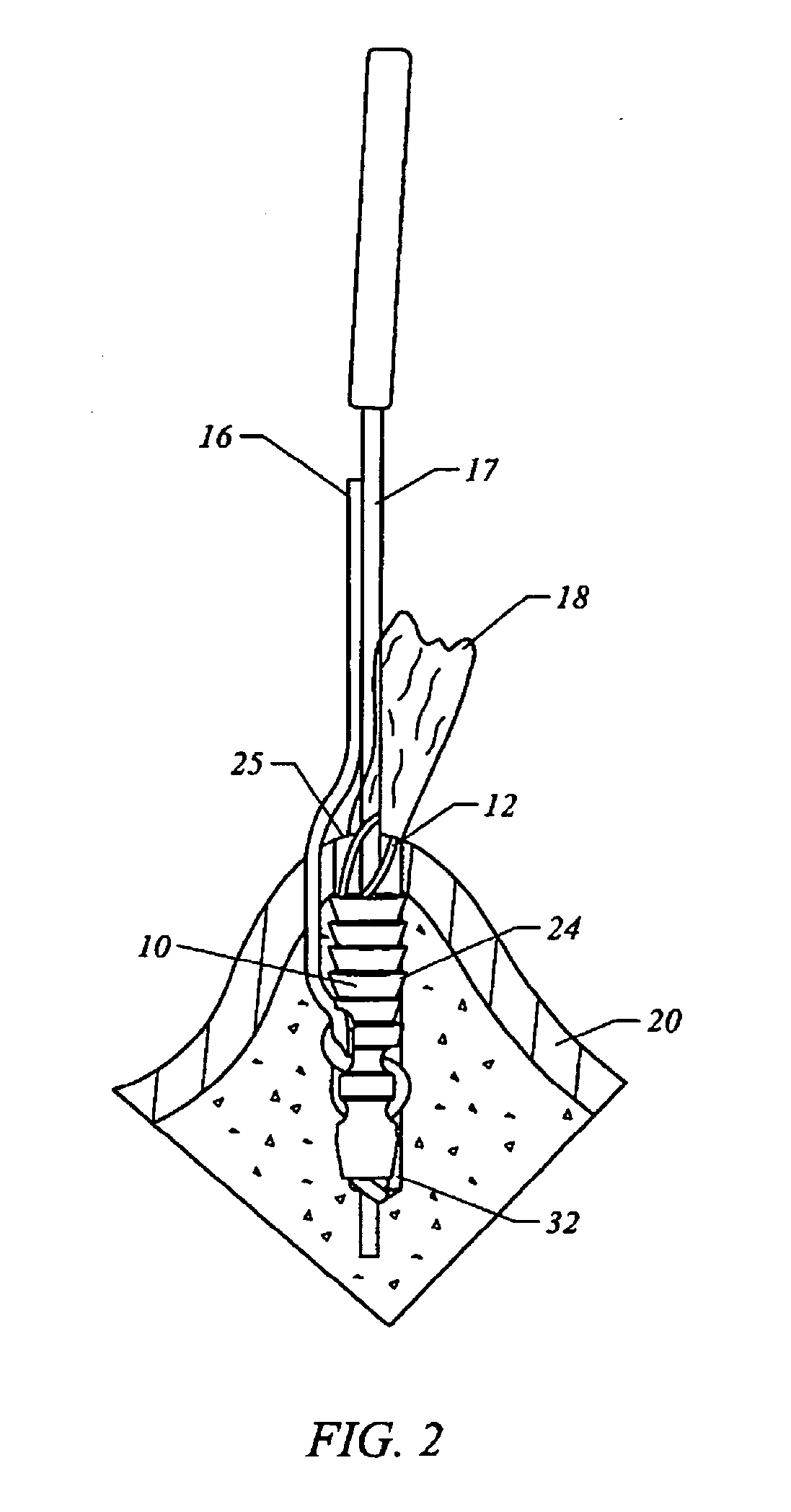

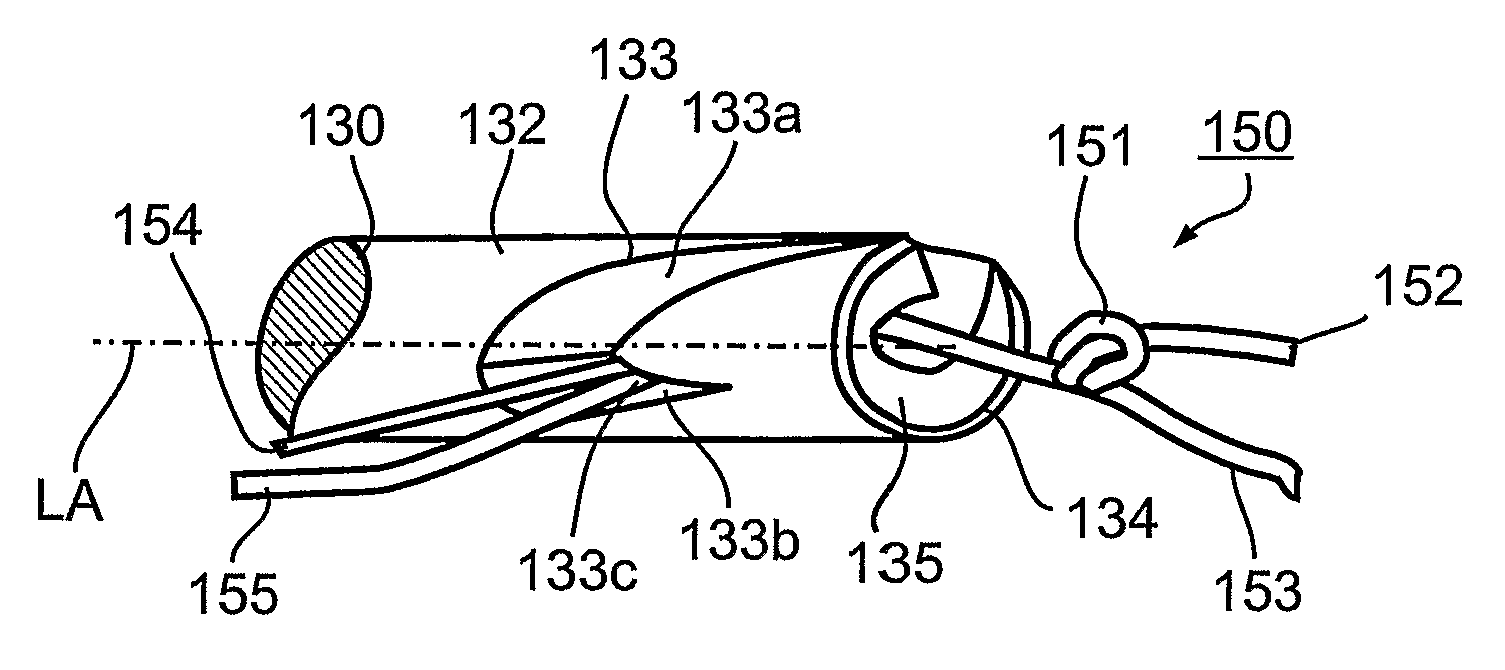

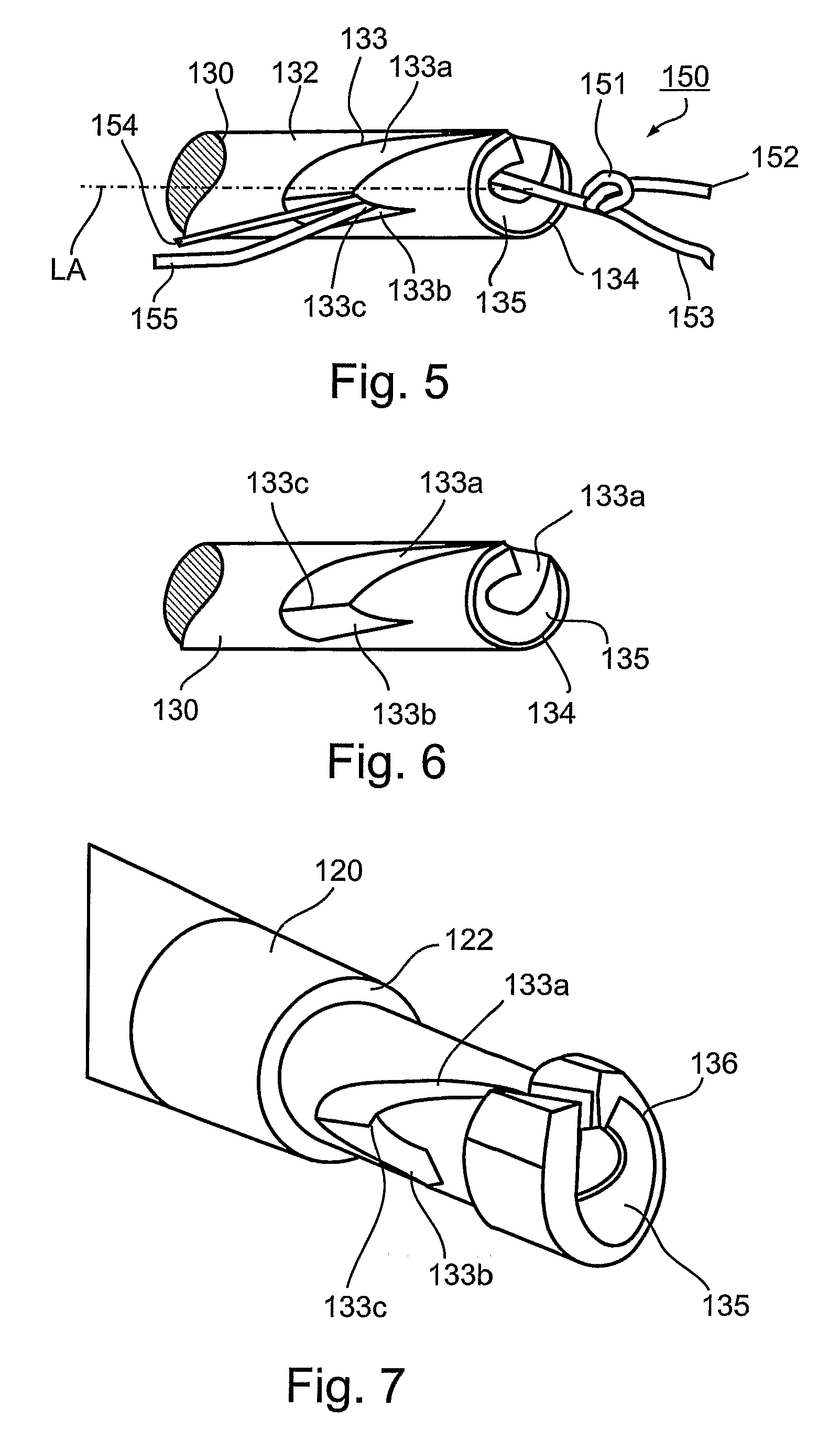

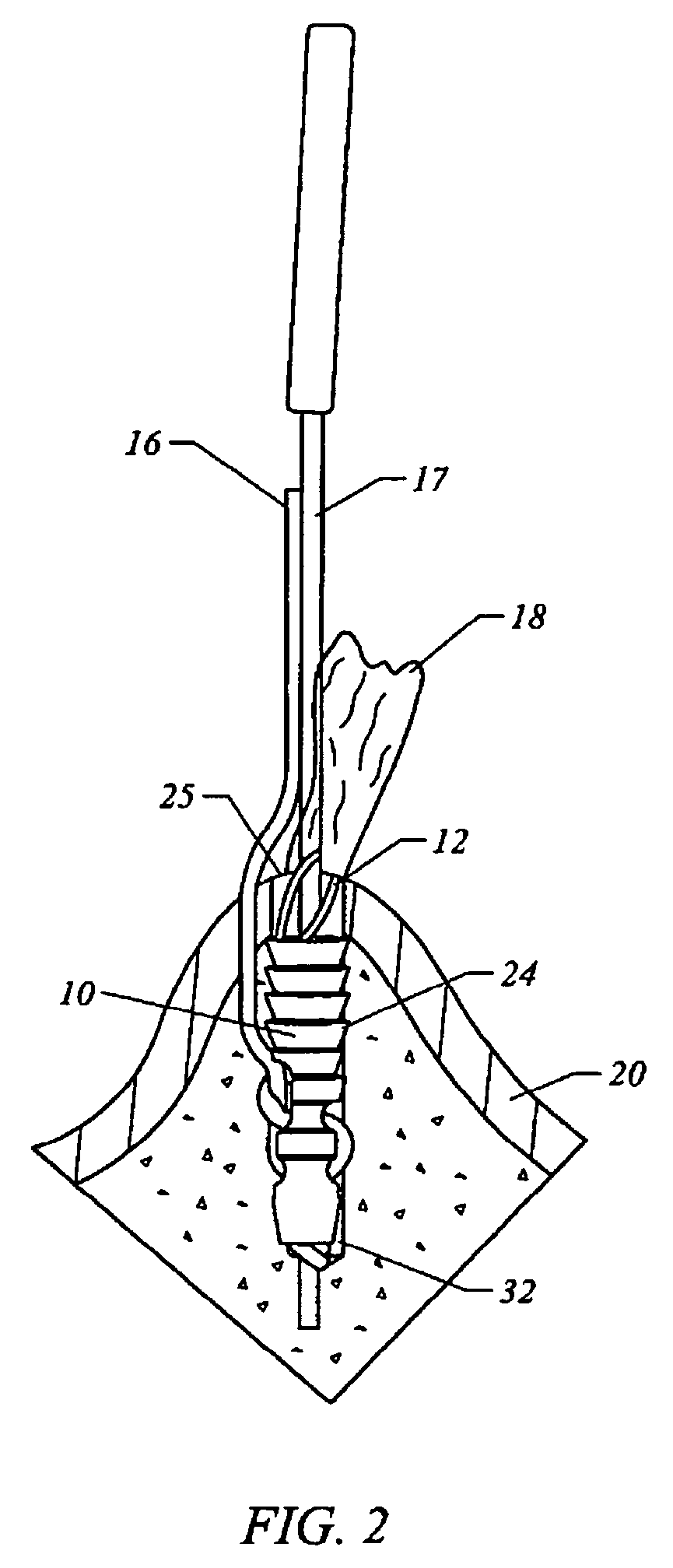

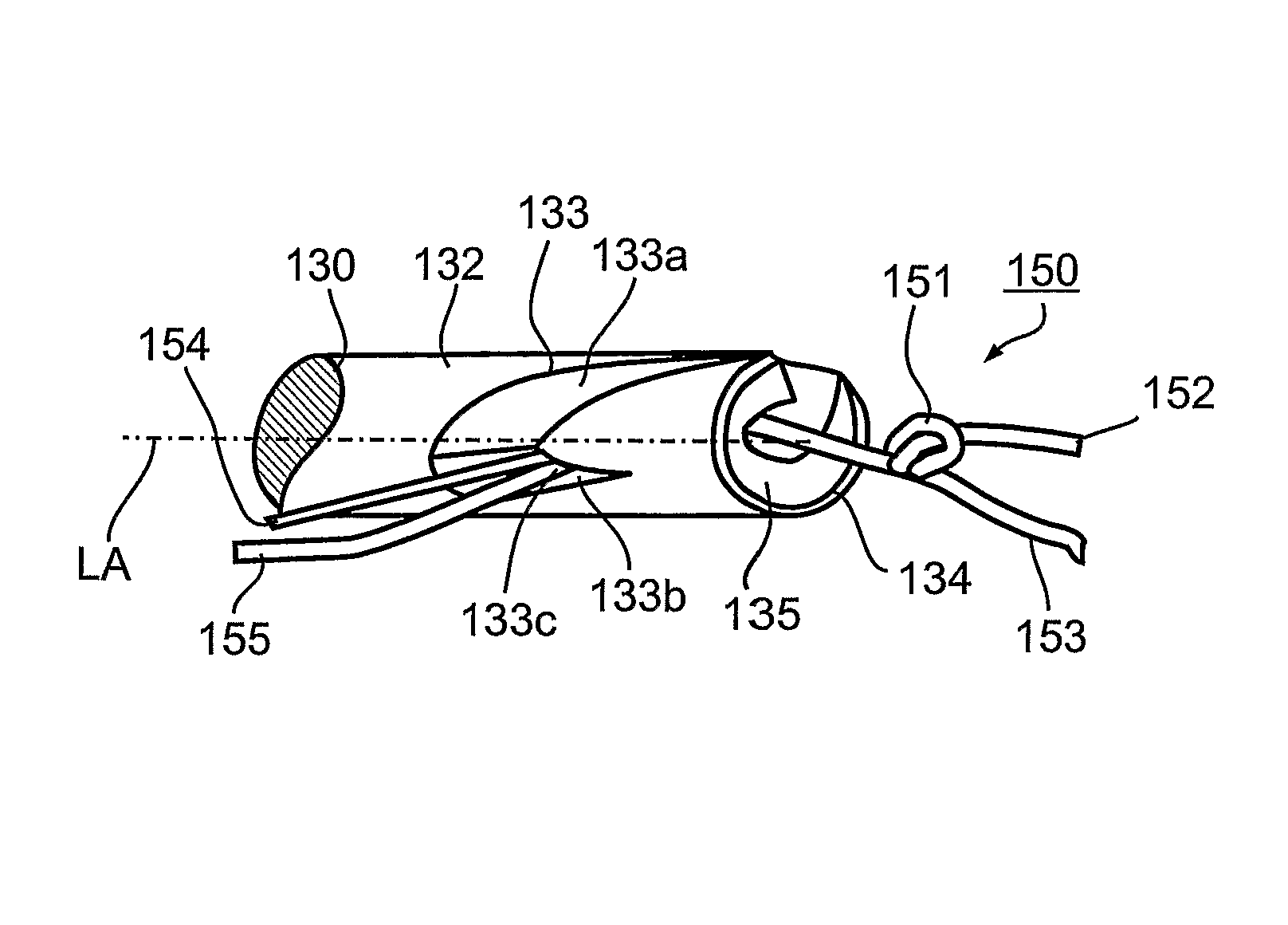

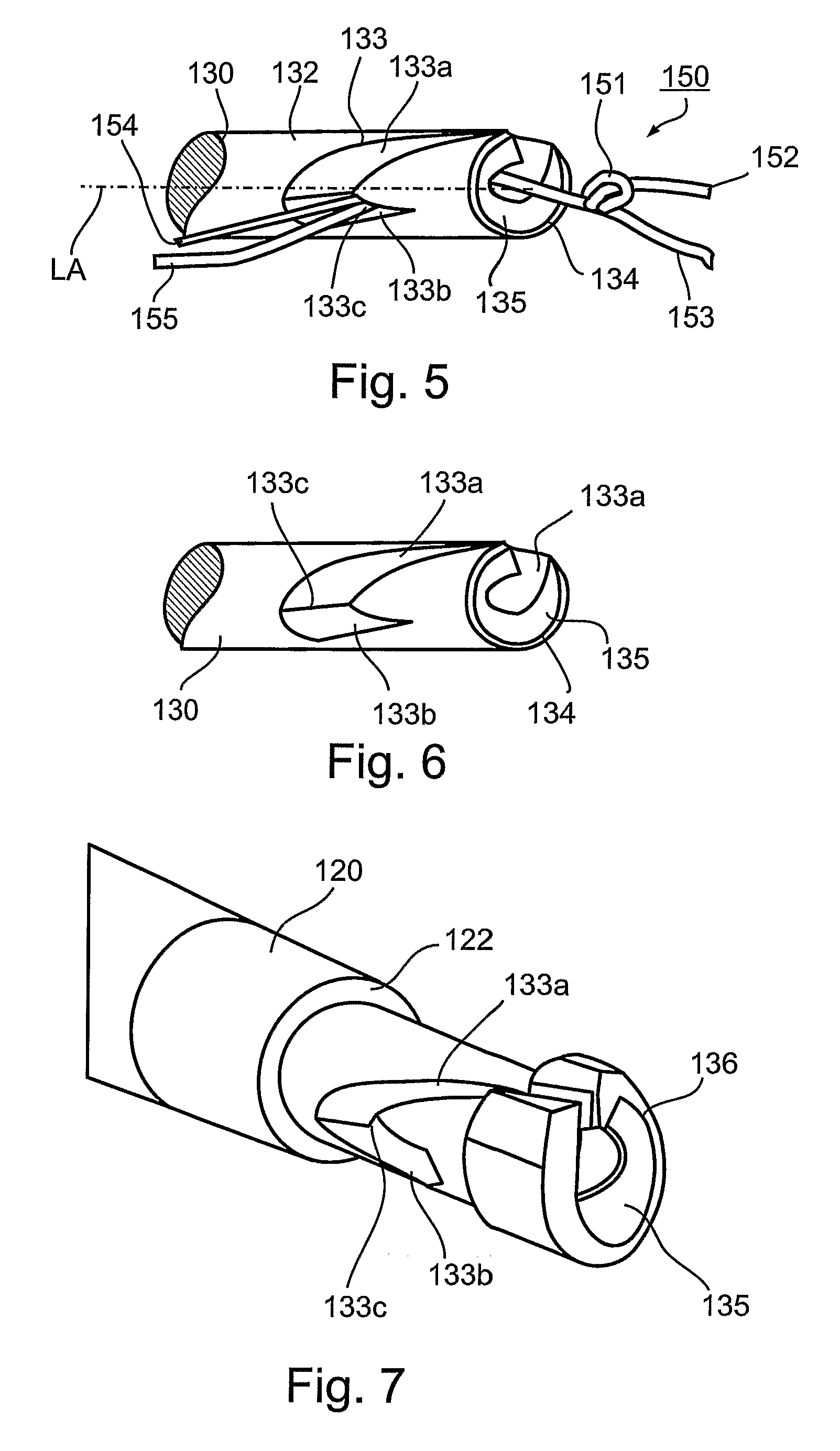

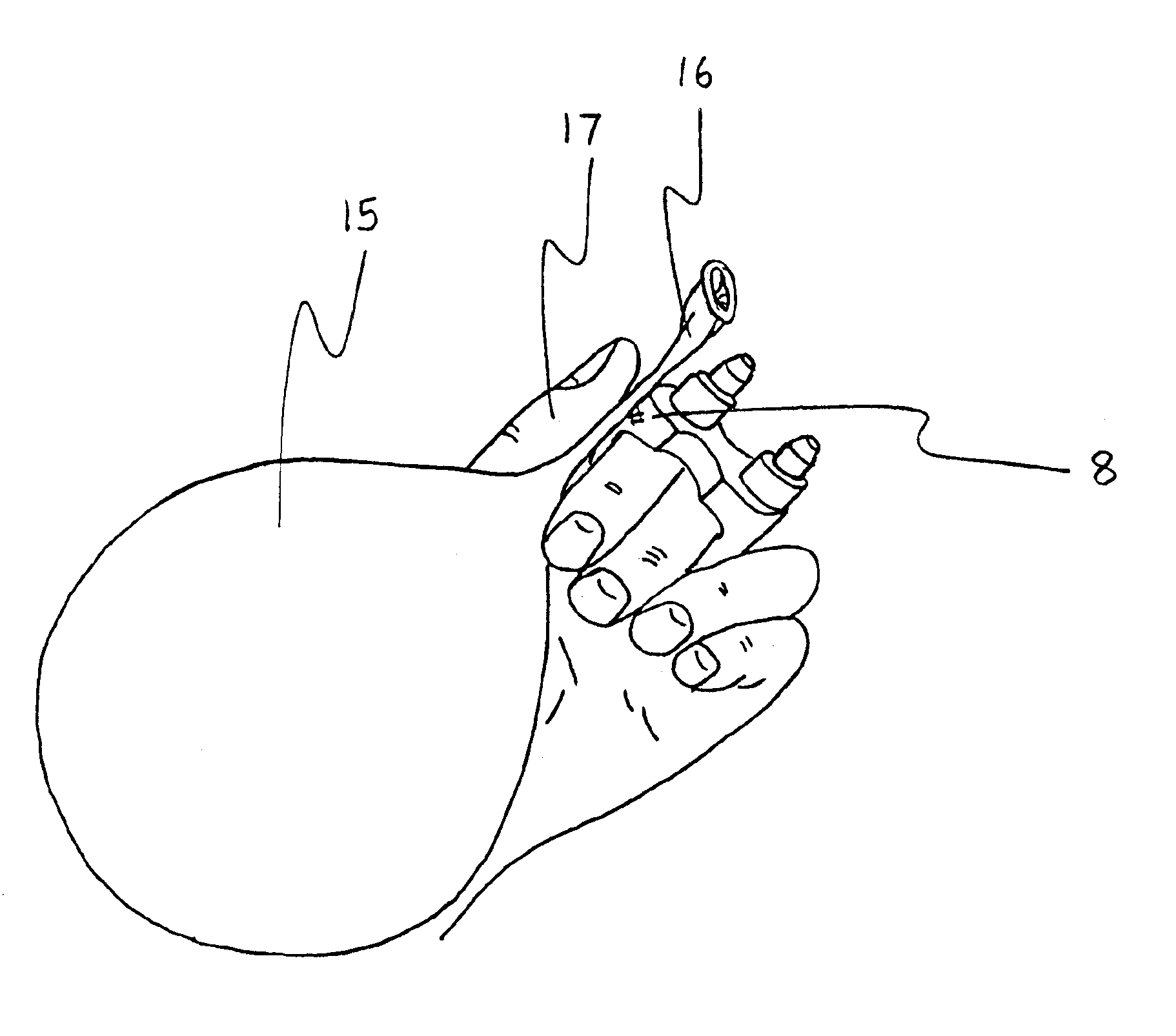

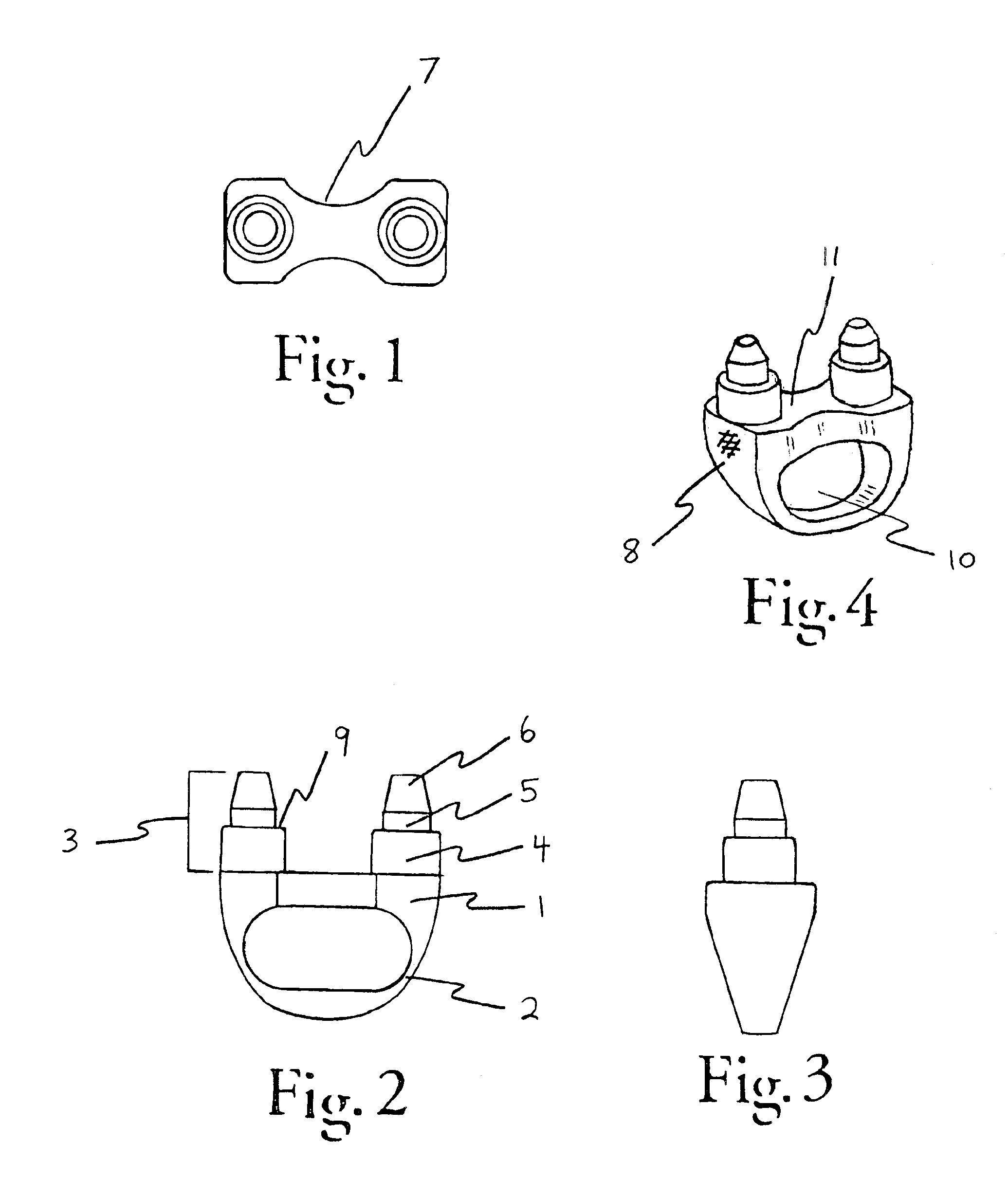

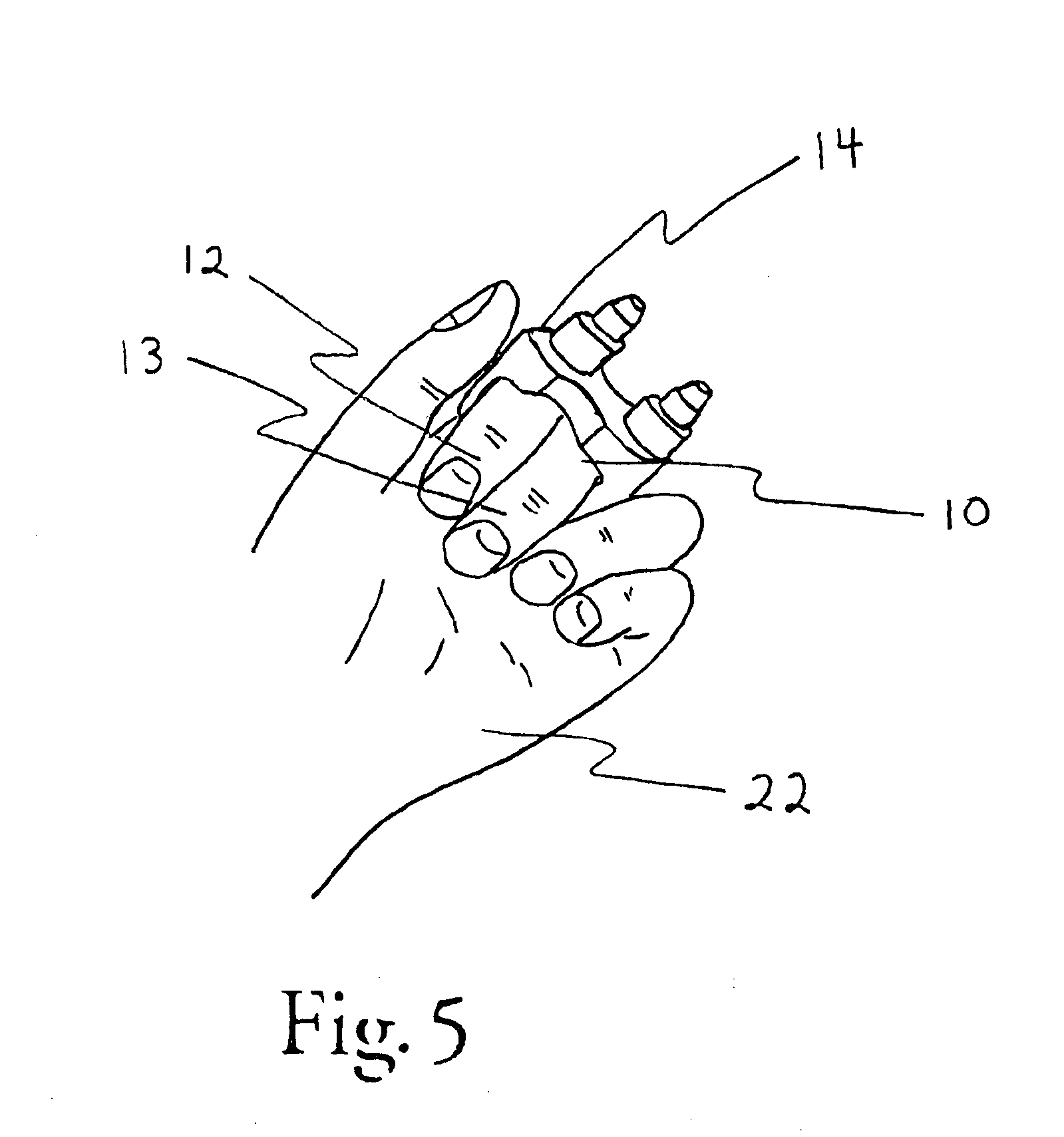

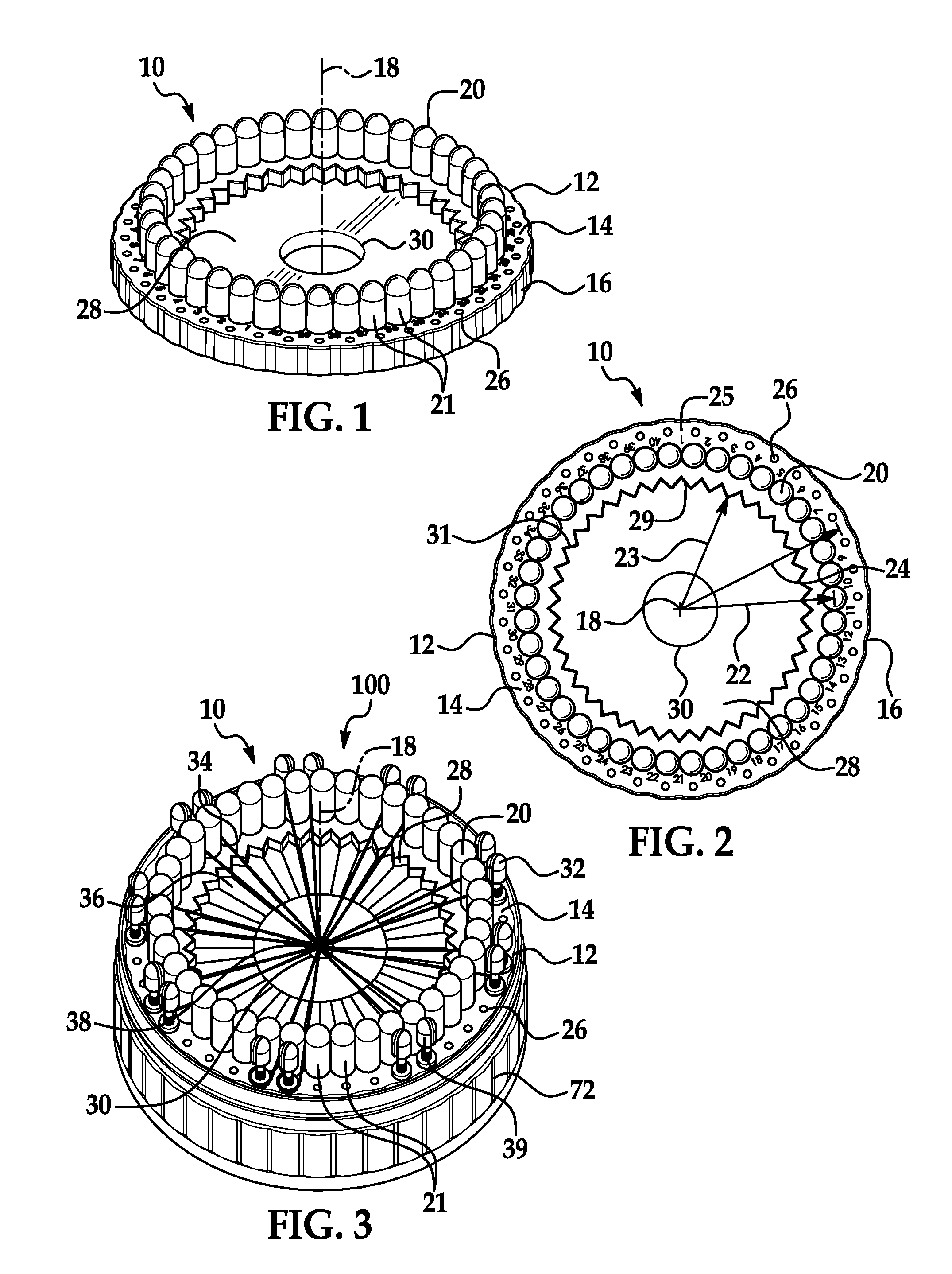

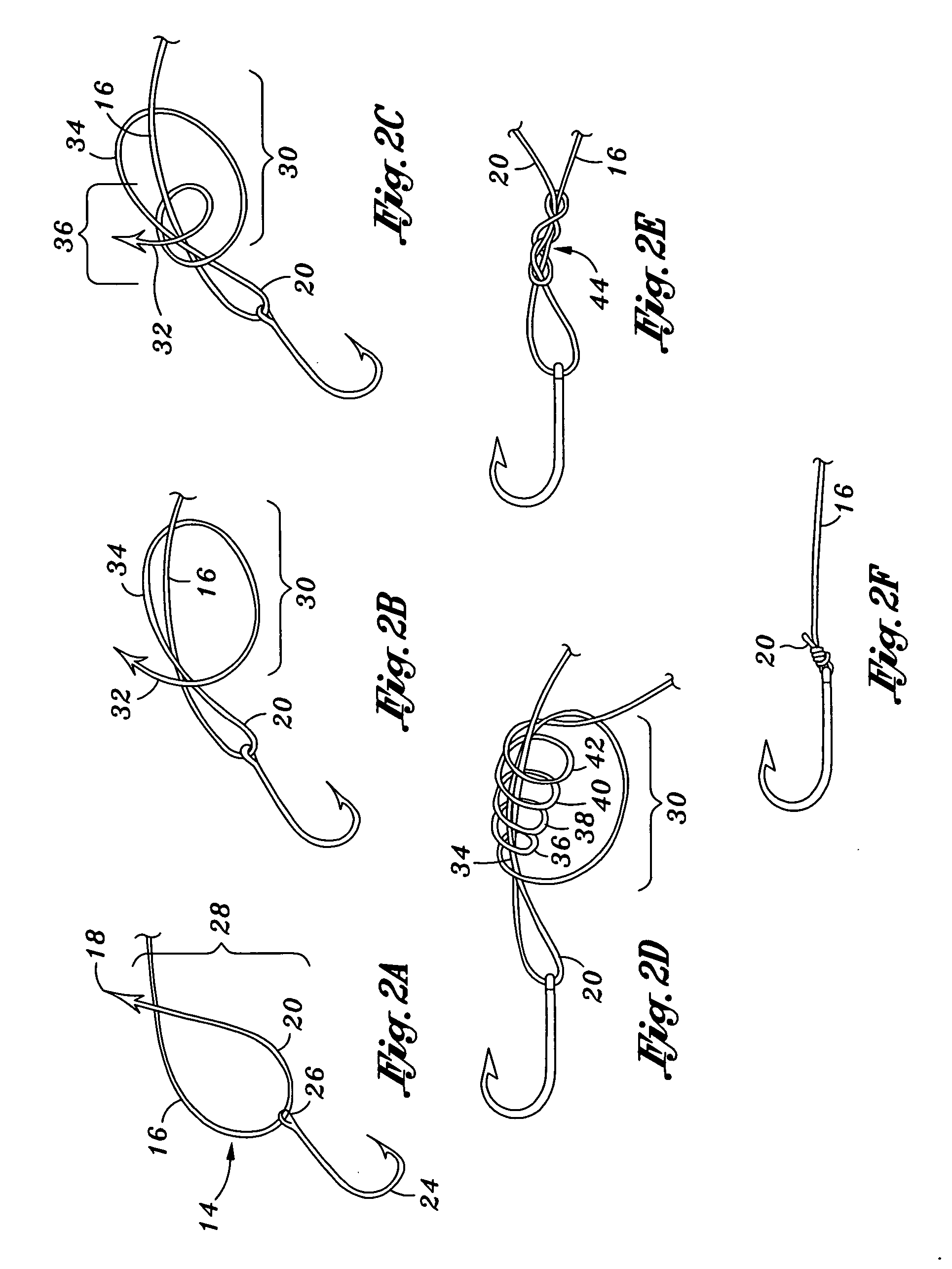

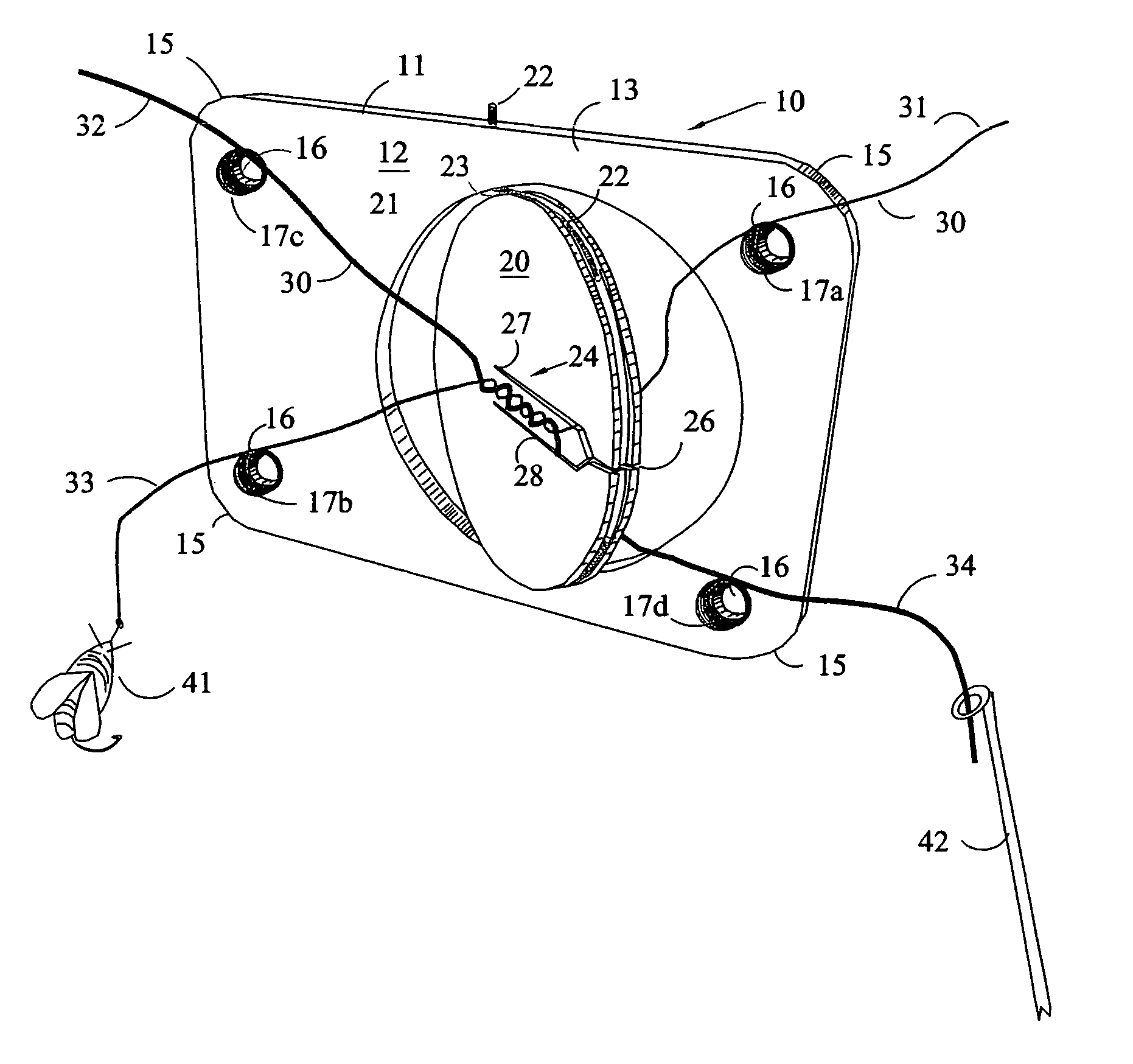

A surgical filament snare assembly including an anchor capable of being fixated in bone and having a filament engagement feature. A first filament has a noose on a first portion of at least a first limb and has a second portion connected to the filament engagement feature of the anchor. Preferably, at least one free filament limb, which in some embodiments is a length of the first filament and in other embodiments is a second filament, is capable of being passed through tissue to be repaired and has at least one end passable through the noose to enable incremental tensioning of the tissue after the anchor is fixated in bone. The noose strangulates the free filament limb when tension is applied to at least one of the free filament limb and the noose.

Owner:MEDOS INT SARL

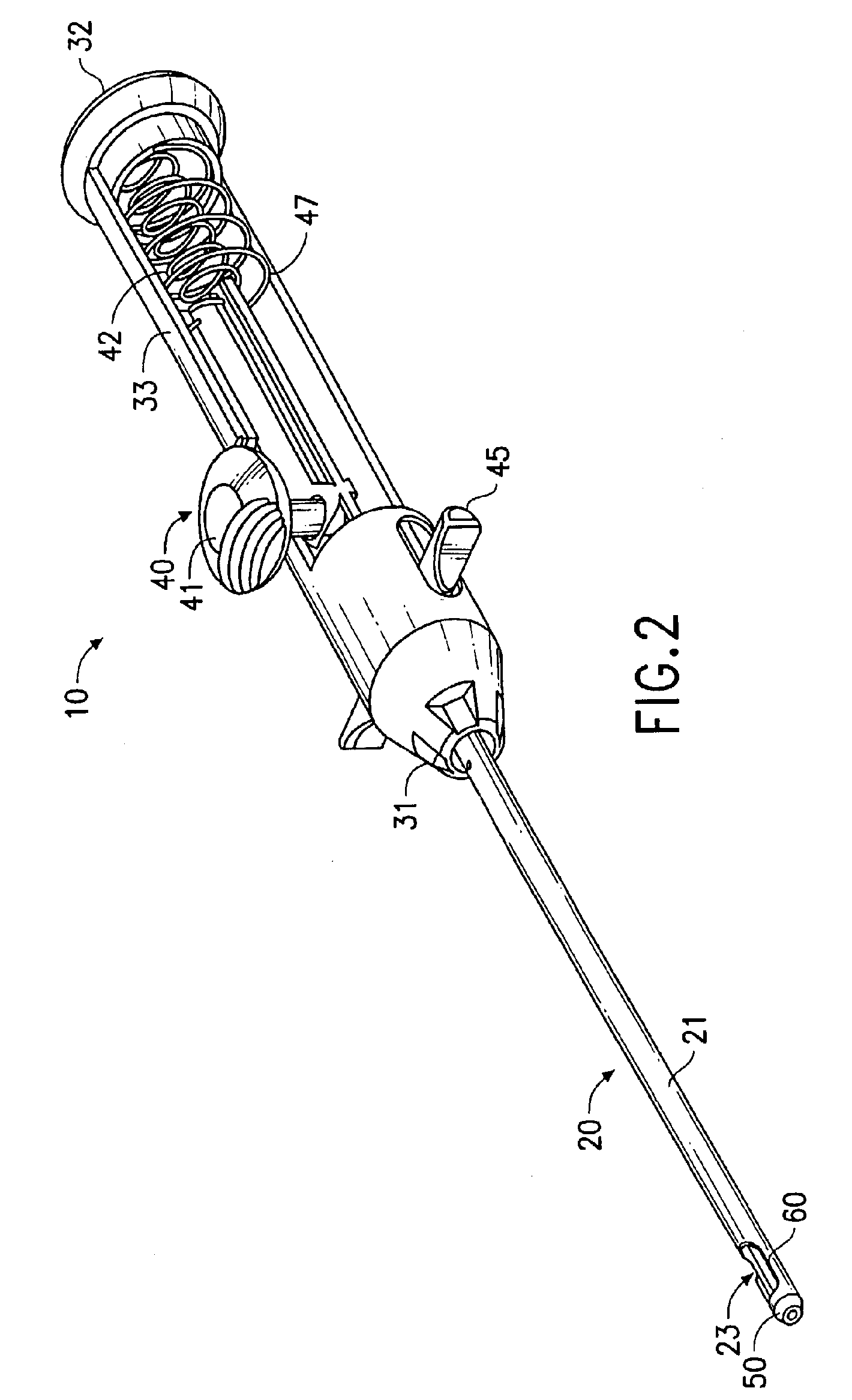

Surgical filament snare assemblies

ActiveUS8821544B2Reduce in quantitySmall sizeSuture equipmentsDiagnosticsEngineeringSurgical department

A surgical filament snare assembly including an anchor capable of being fixated in bone and having a filament engagement feature. A first filament has a noose with first and second noose limbs connected, preferably slidably, to the filament engagement feature. The first and second noose limbs emerge from the anchor as first and second free filament limbs that are capable of being passed through tissue to be repaired and then passable through the noose. The noose is capable of receiving the free filament limbs and strangulating them when tension is applied to at least one of the free filament limbs and the noose to enable incremental tensioning of the tissue after anchor fixation. Preferably, the snare assembly further includes a flexible sleeve joining at least some portion of the first and second free filament limbs to facilitate passing of the free filament limbs as a single unit.

Owner:MEDOS INT SARL

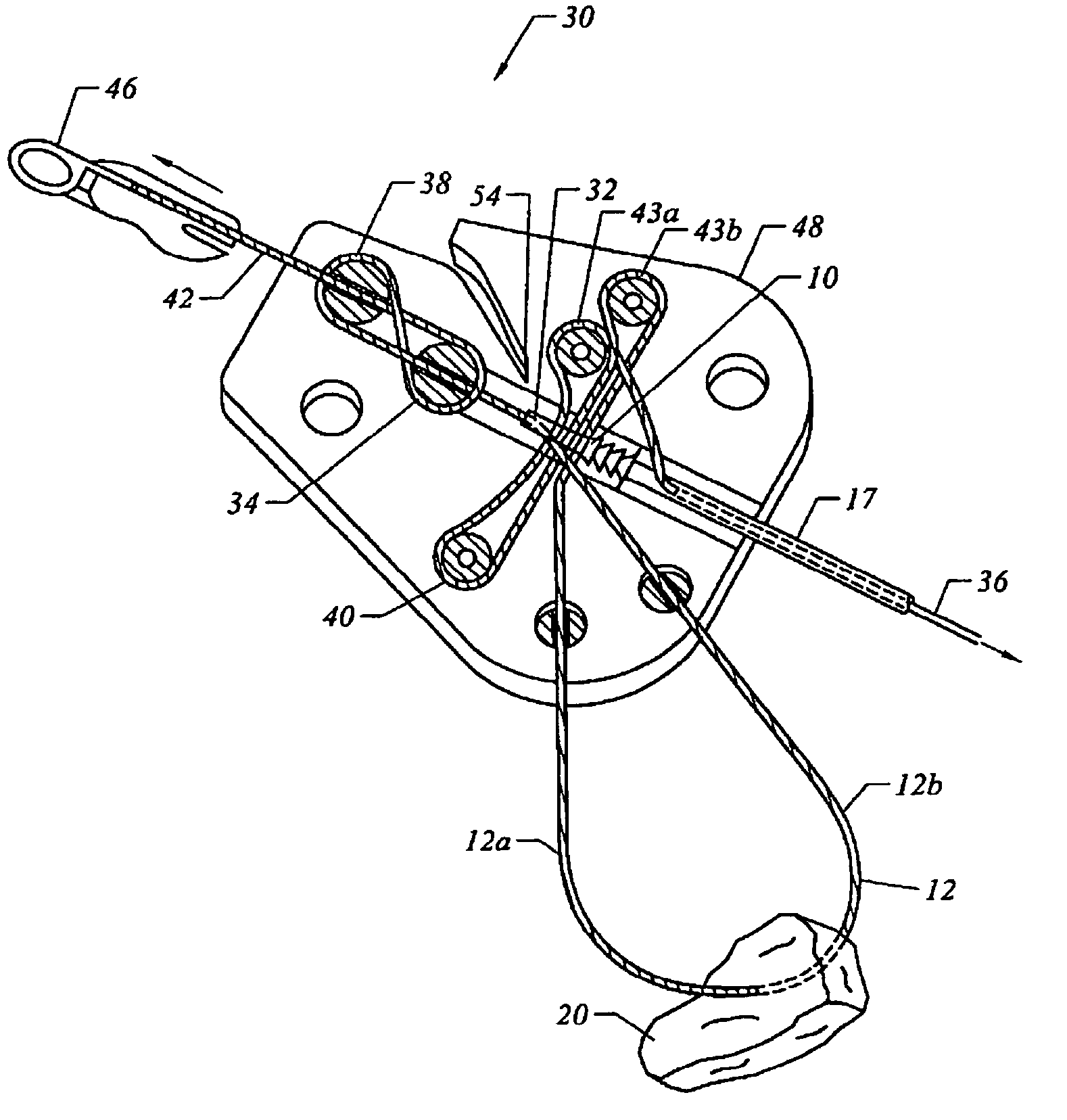

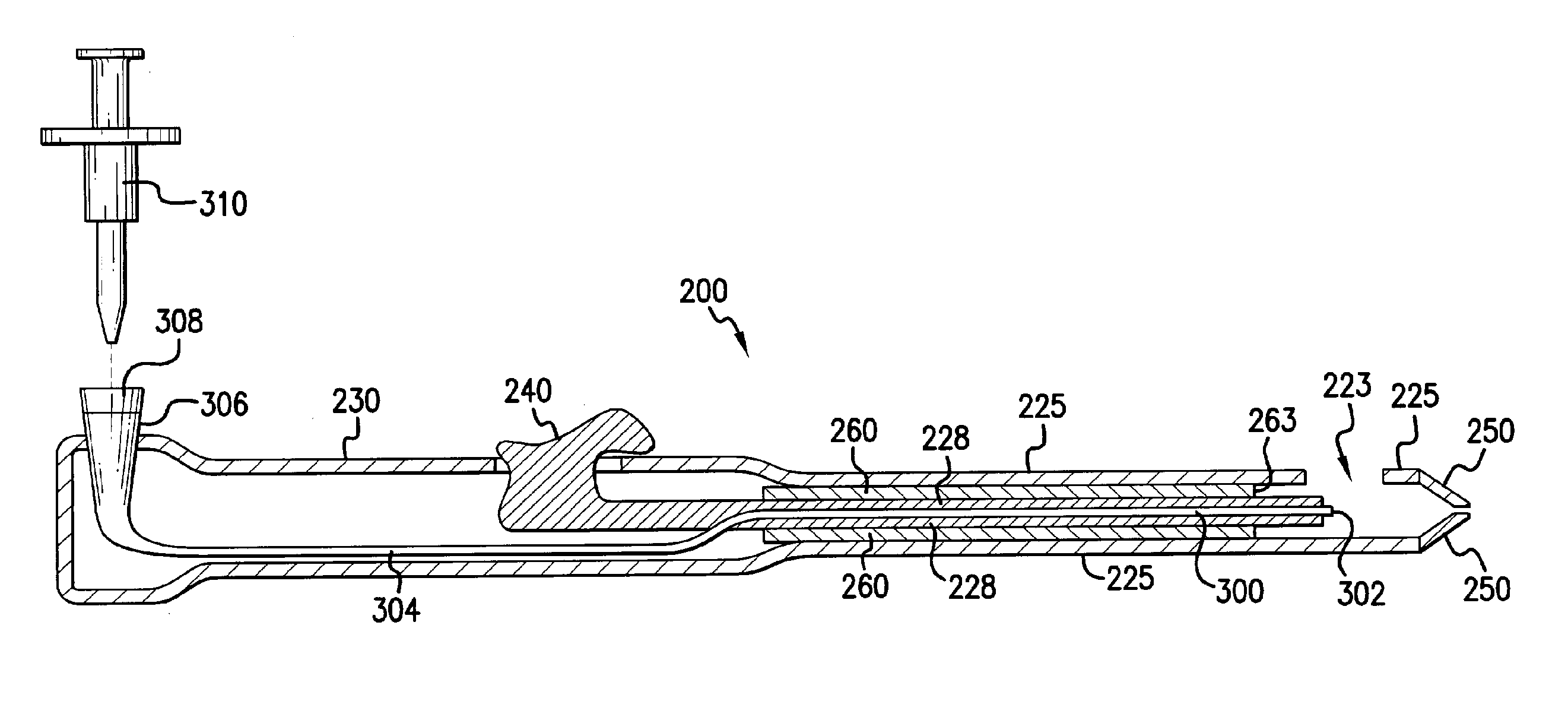

Bone anchor suture-loading system, method and apparatus

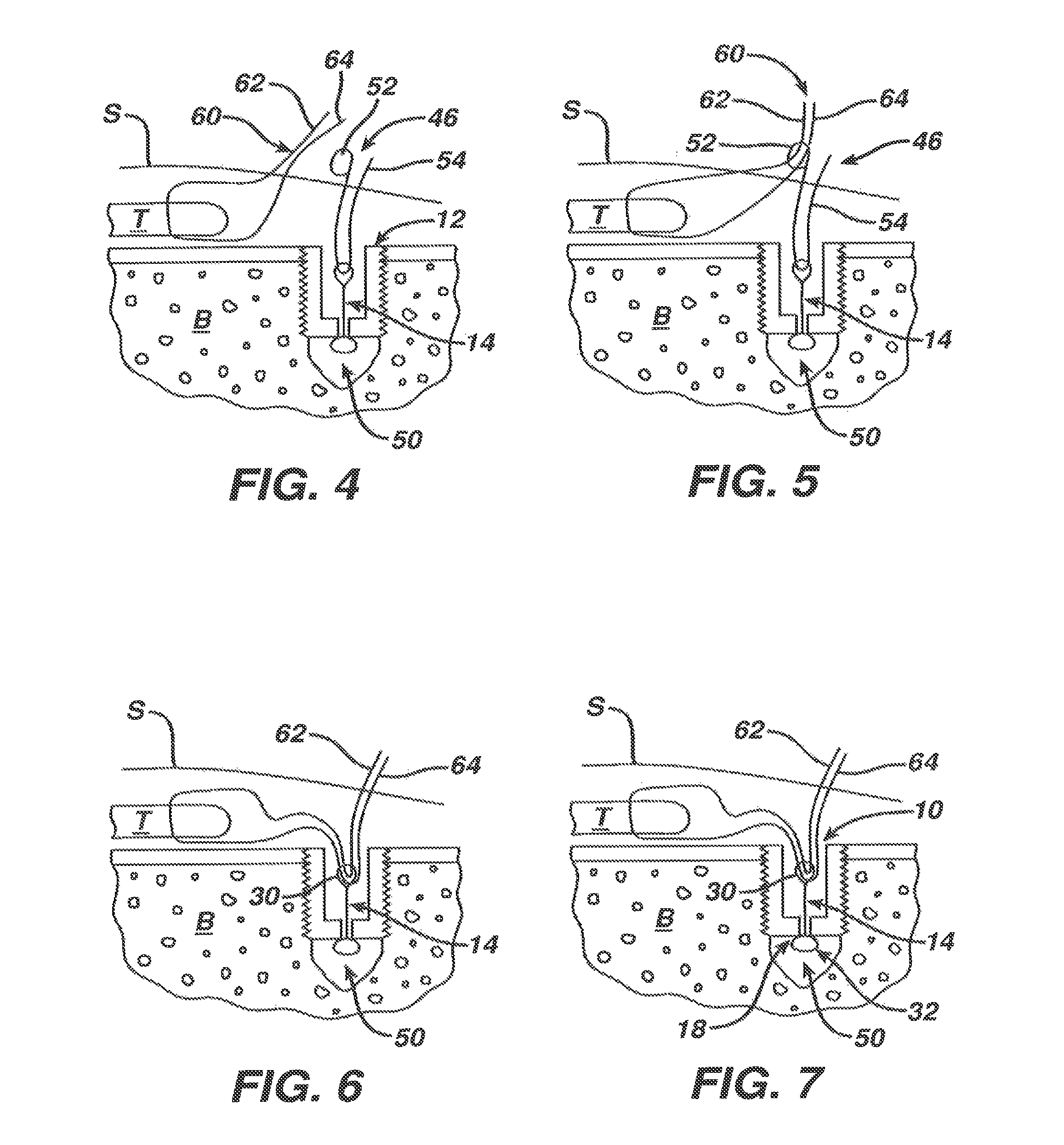

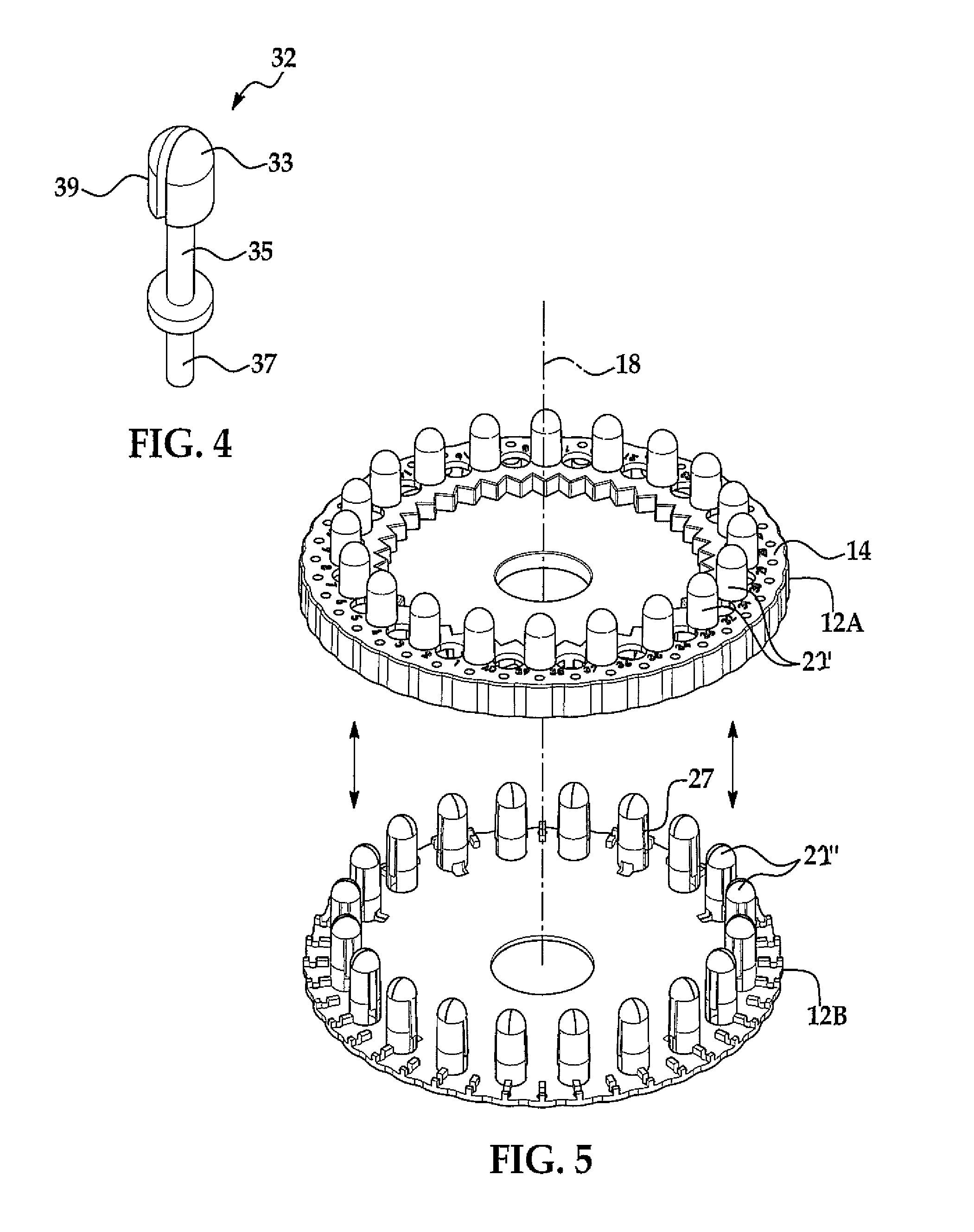

A suture-loading system, method and apparatus for loading a suture onto a bone anchor, the system comprising: a bone anchor comprising a suture leg-anchoring structure and a plurality of body holes on the anchor; a suture comprising a standing end portion and a working end portion; a standing end trackway to guide the standing end portion of the suture through the suture leg-anchoring structure; and a working end trackway to guide the working end portion of the suture through the body holes in the anchor.

Owner:ARTHROCARE

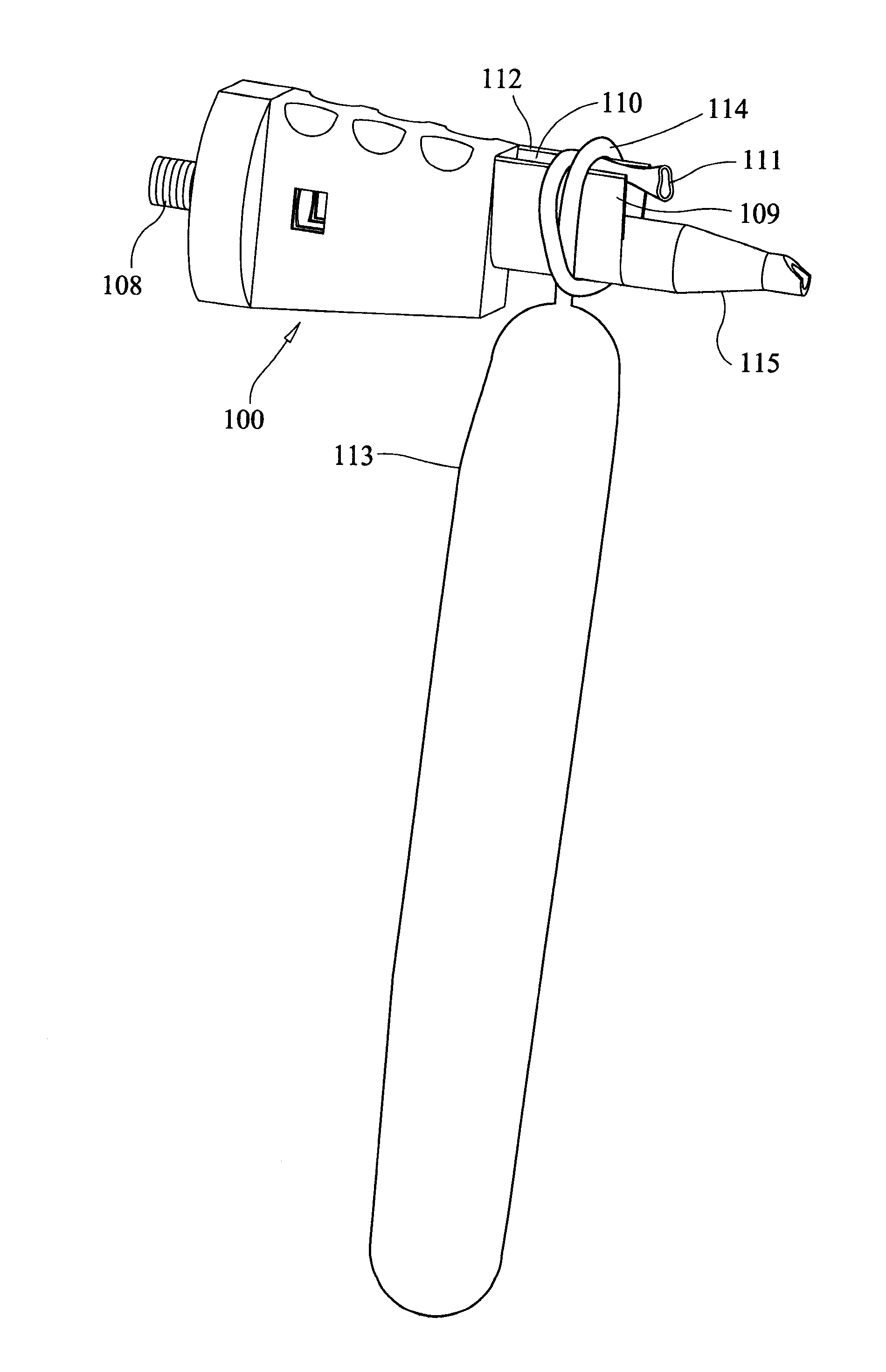

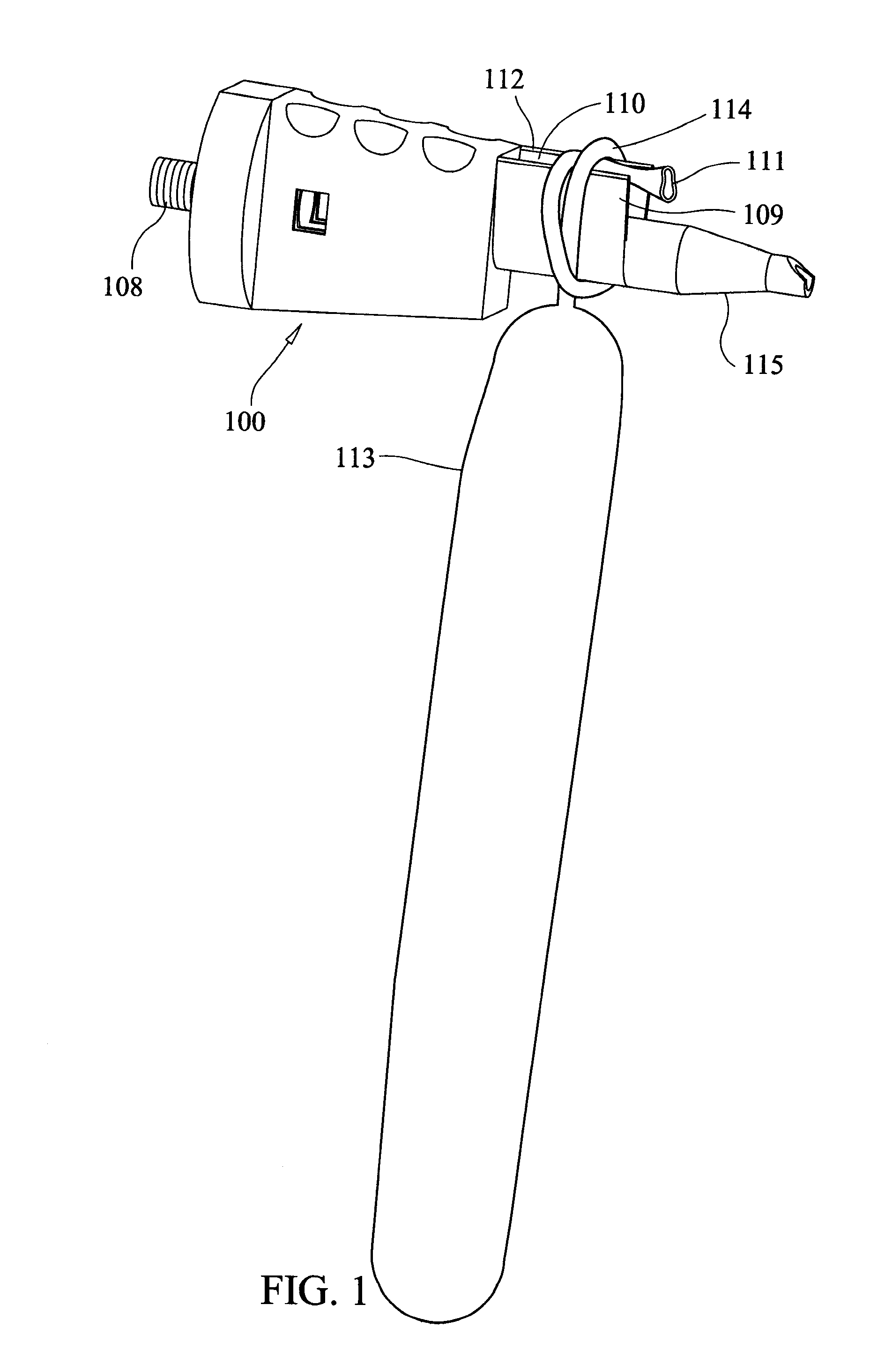

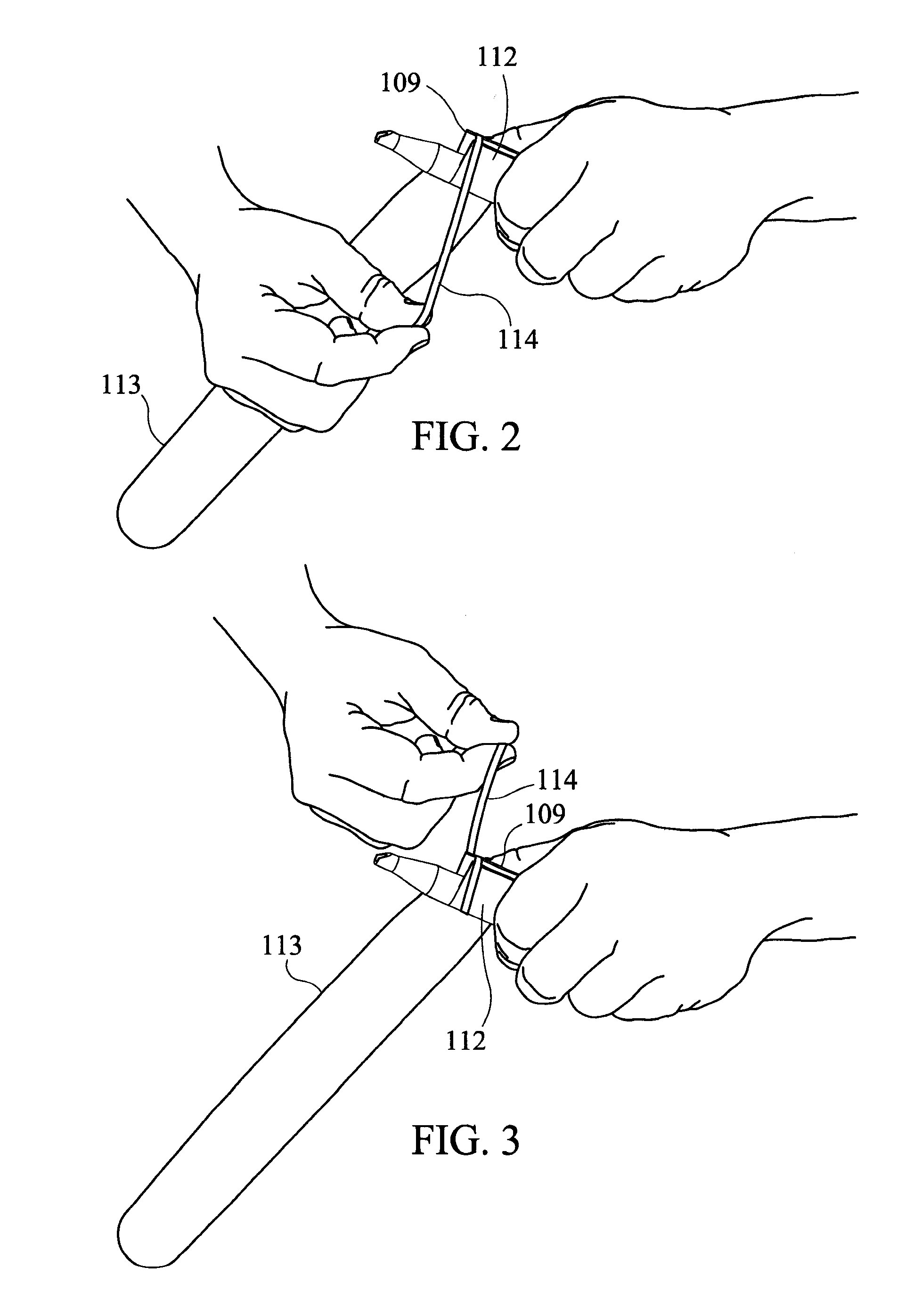

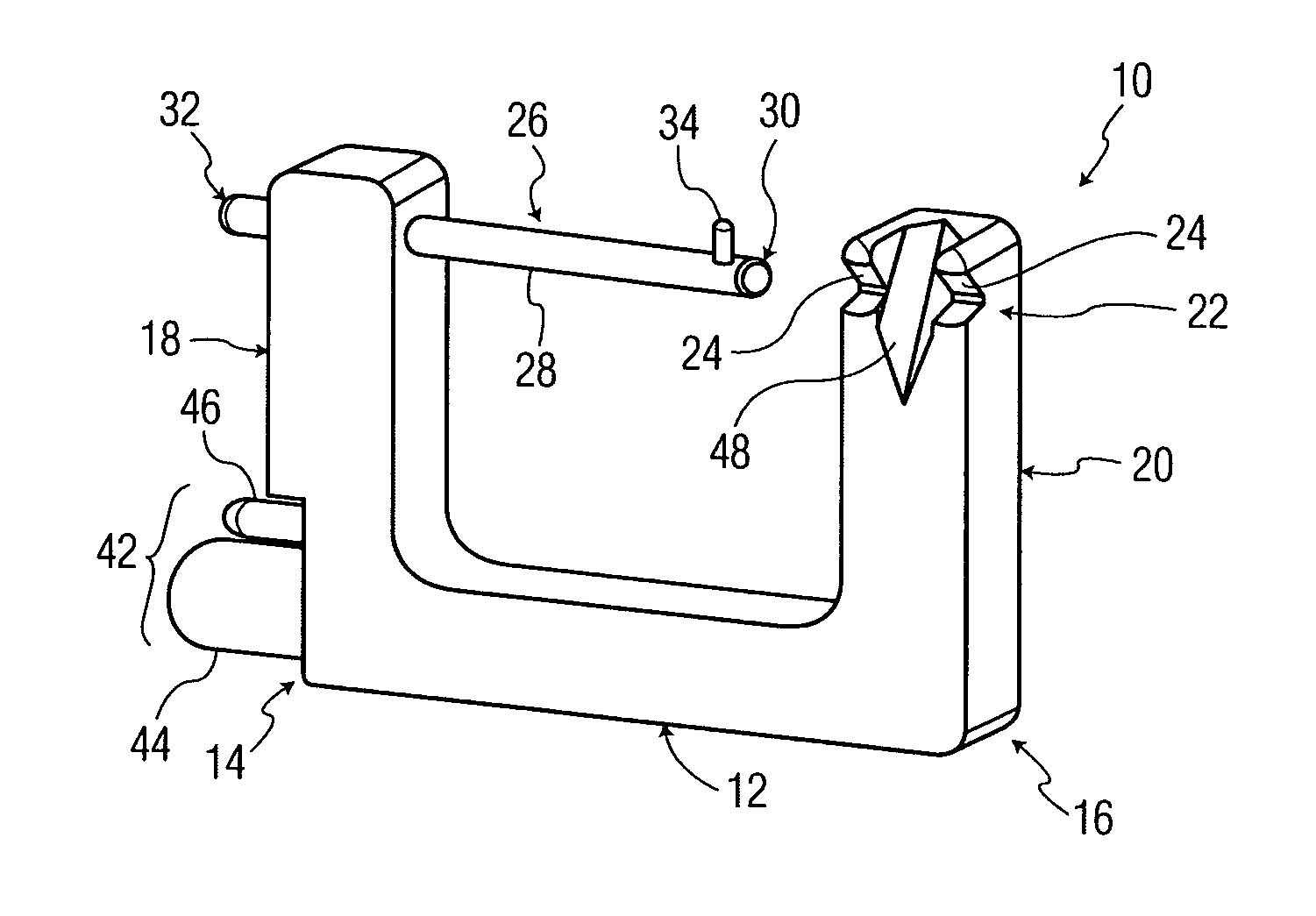

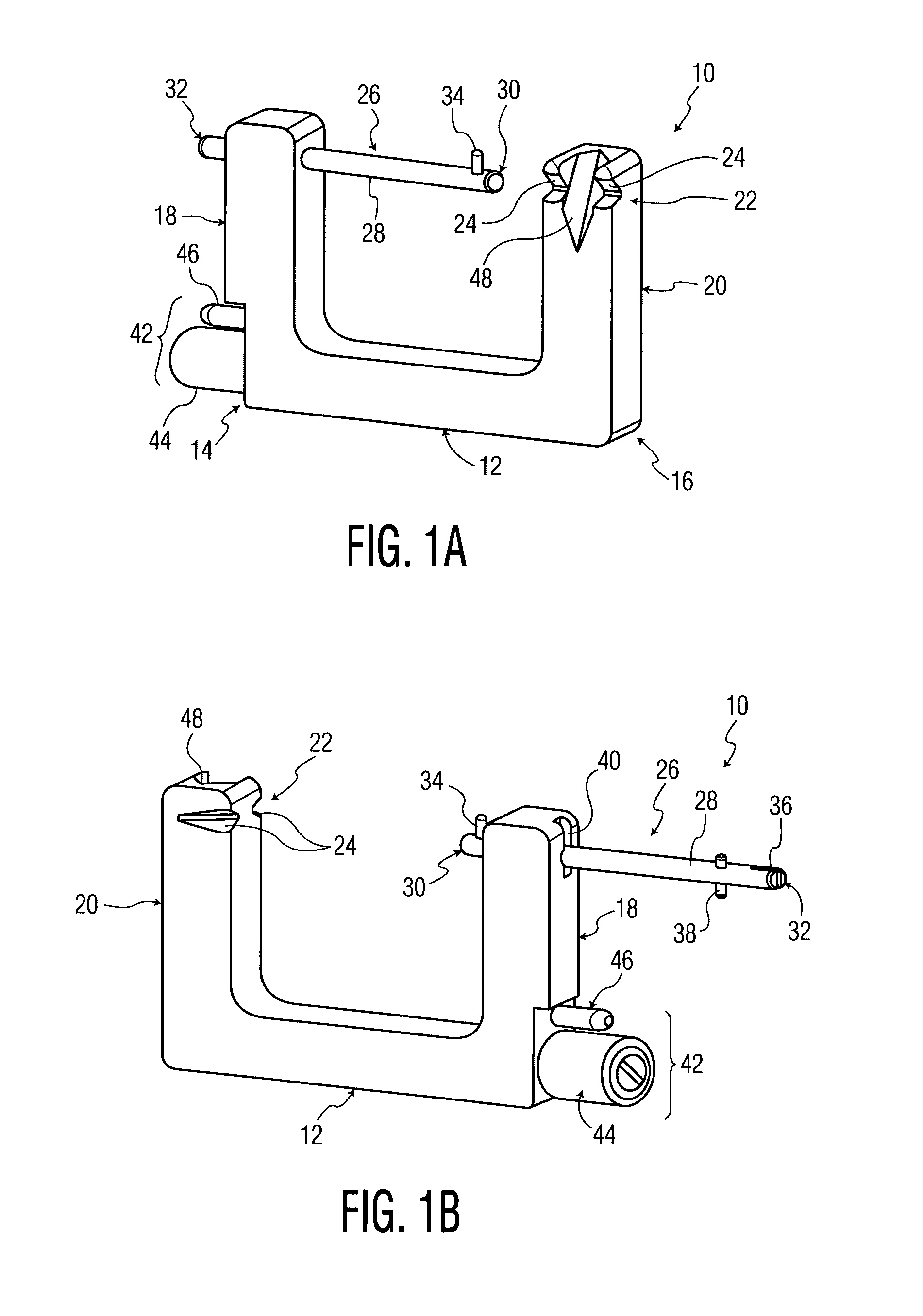

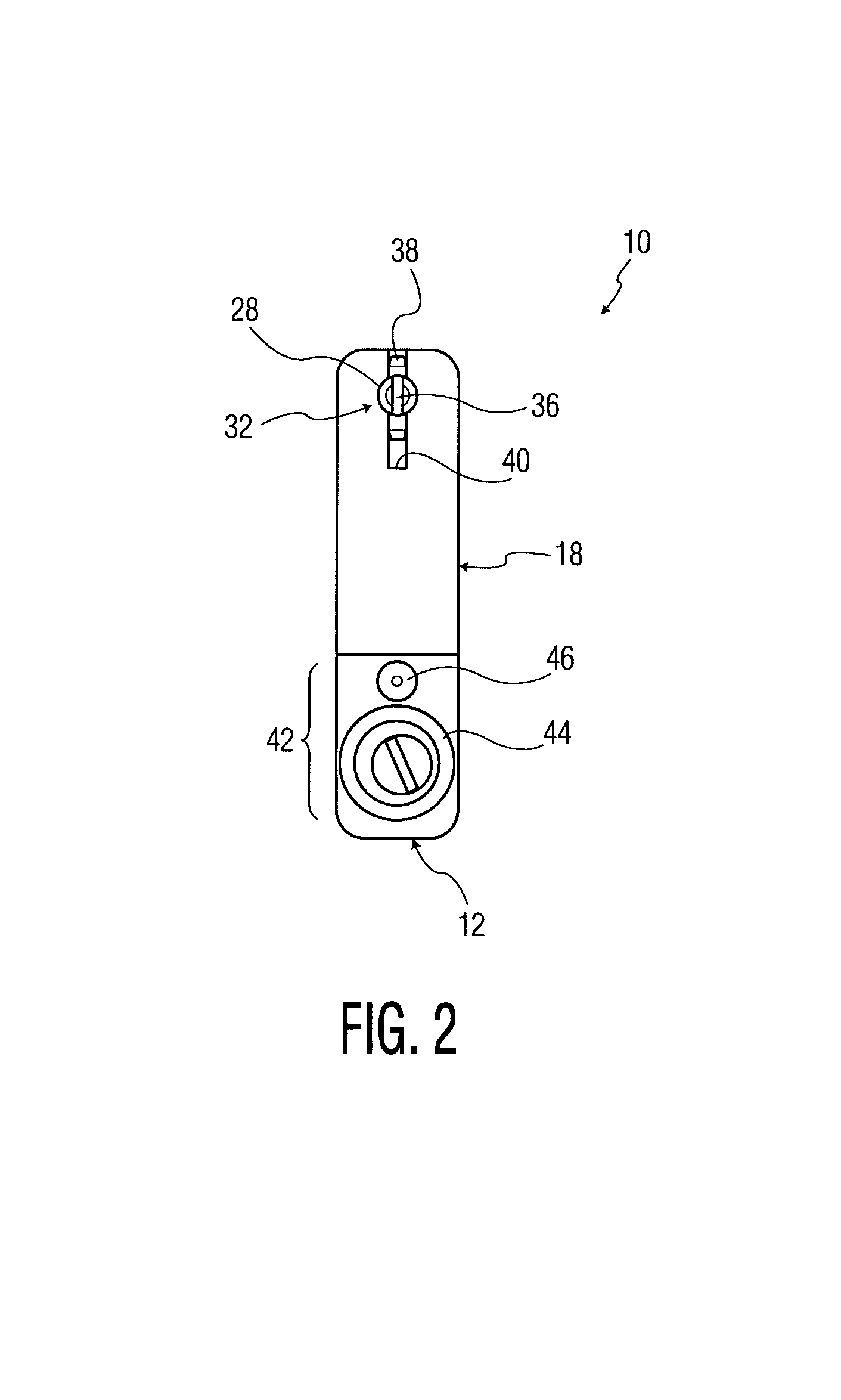

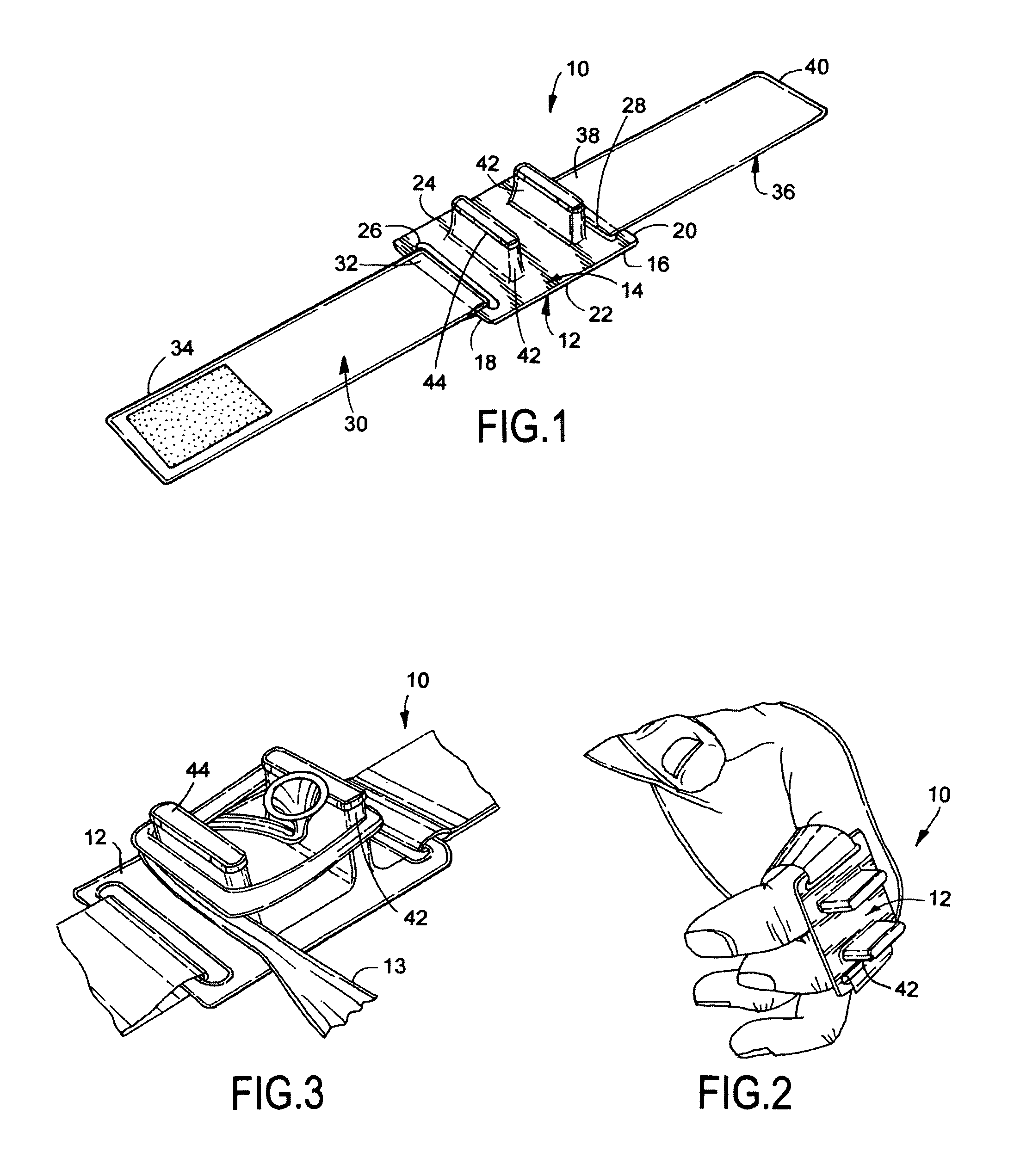

Suture manipulating and/or cutting implement

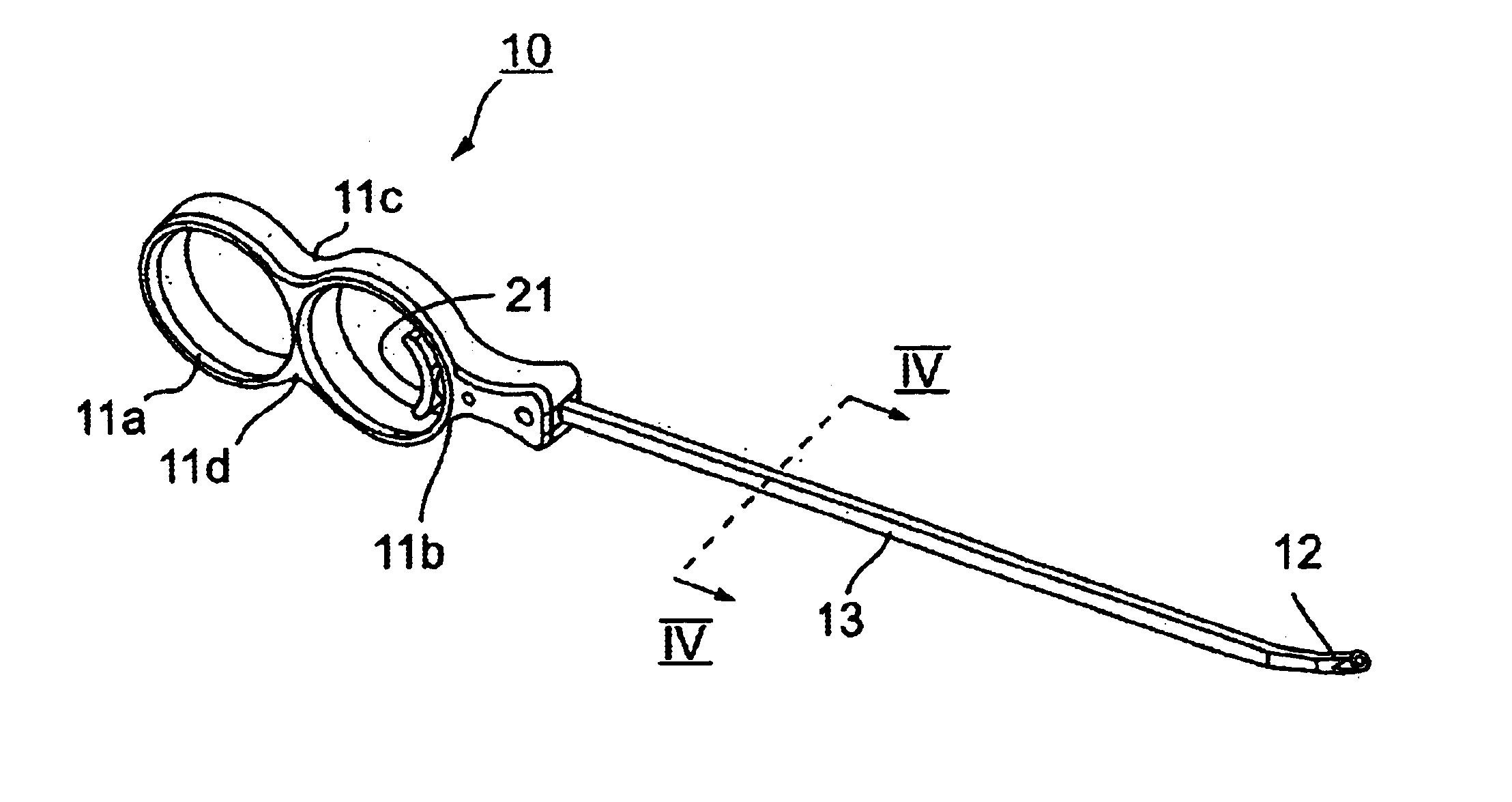

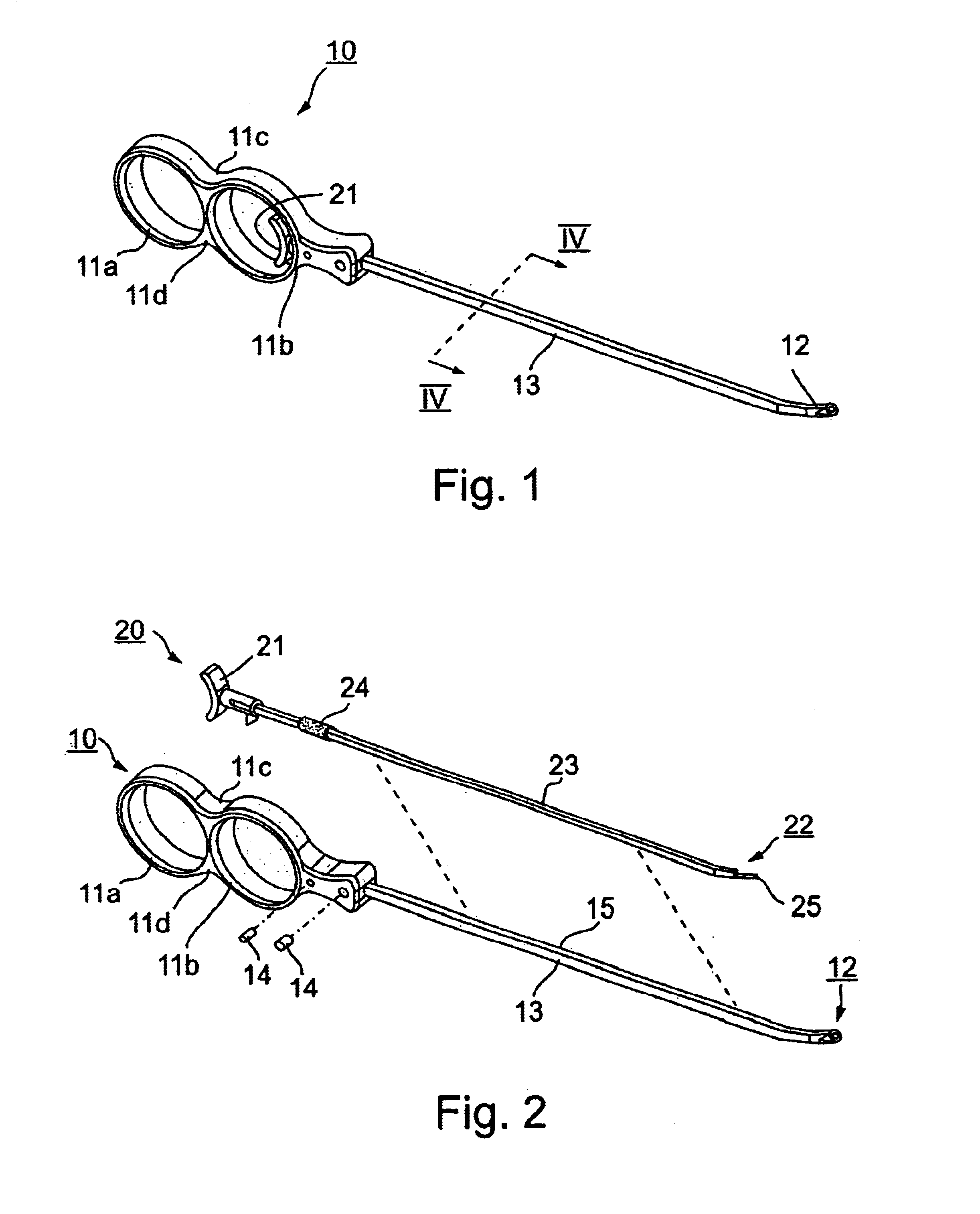

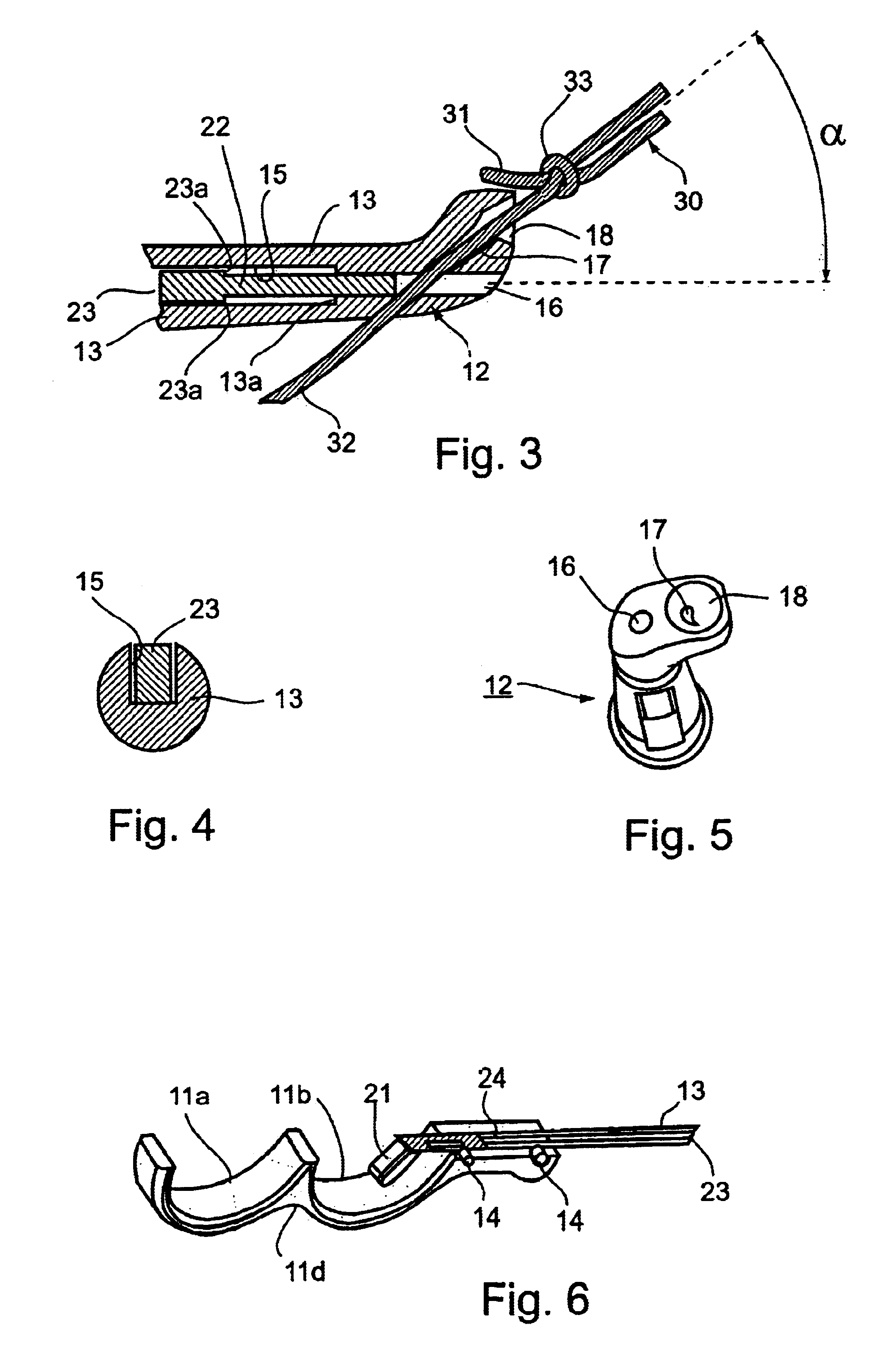

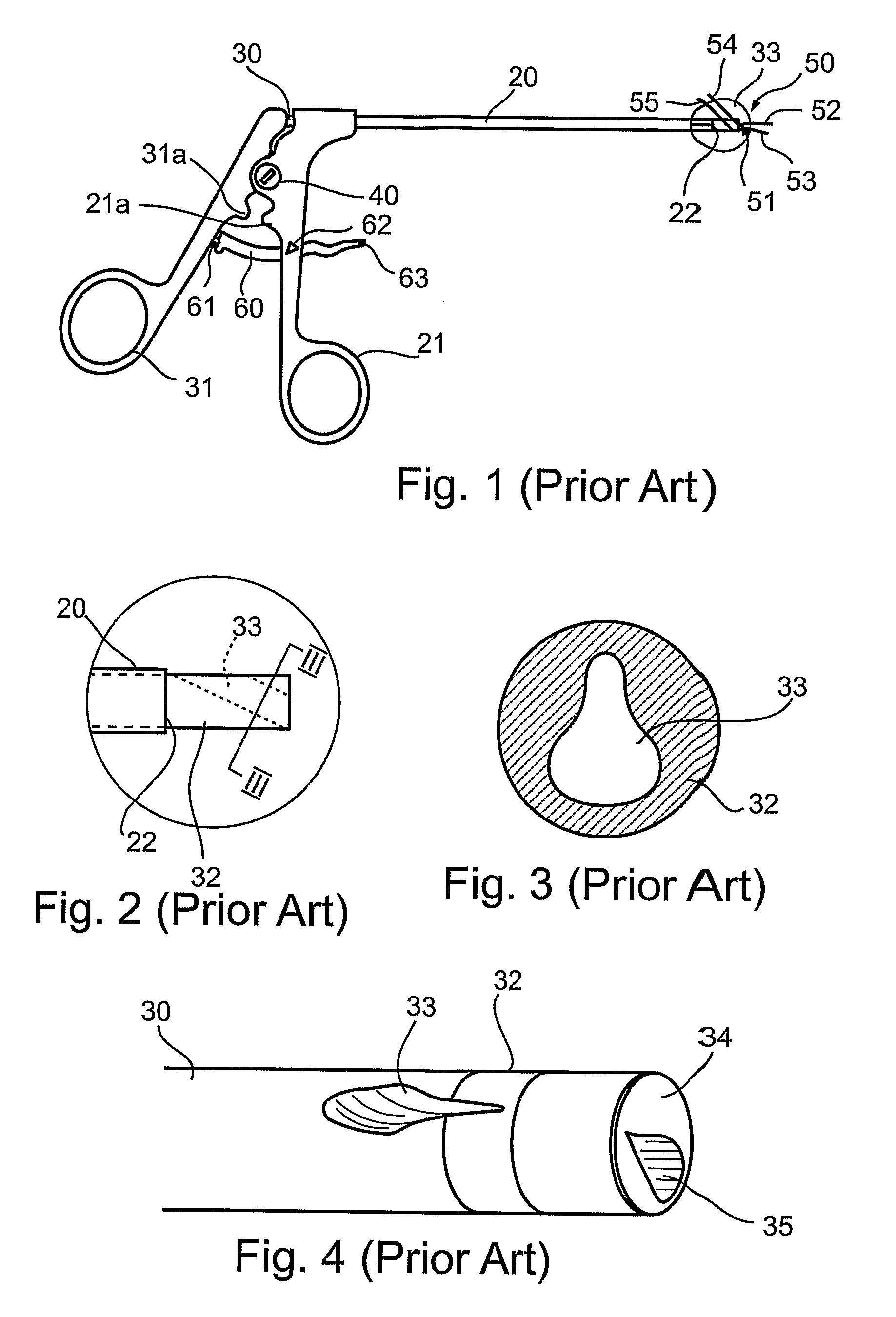

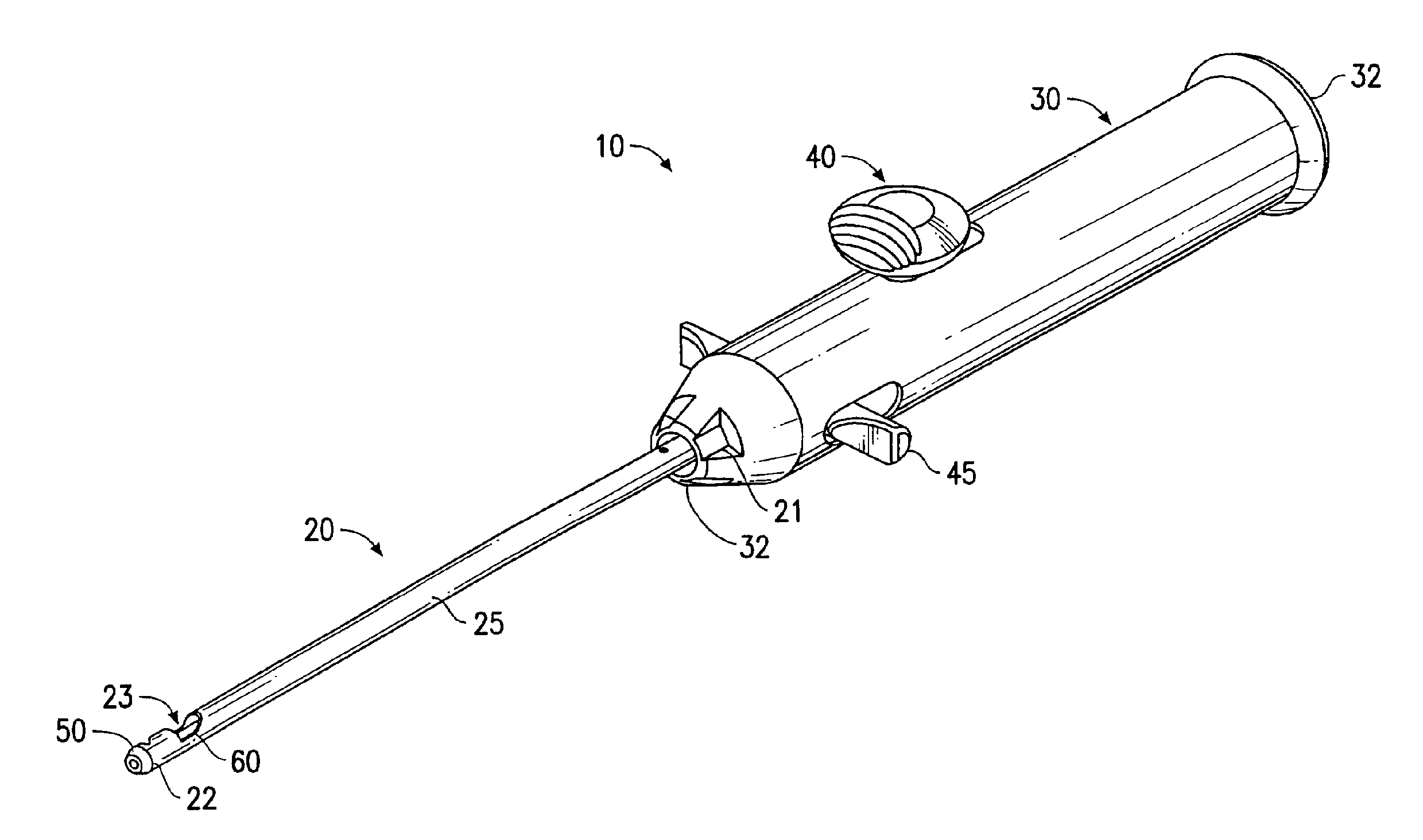

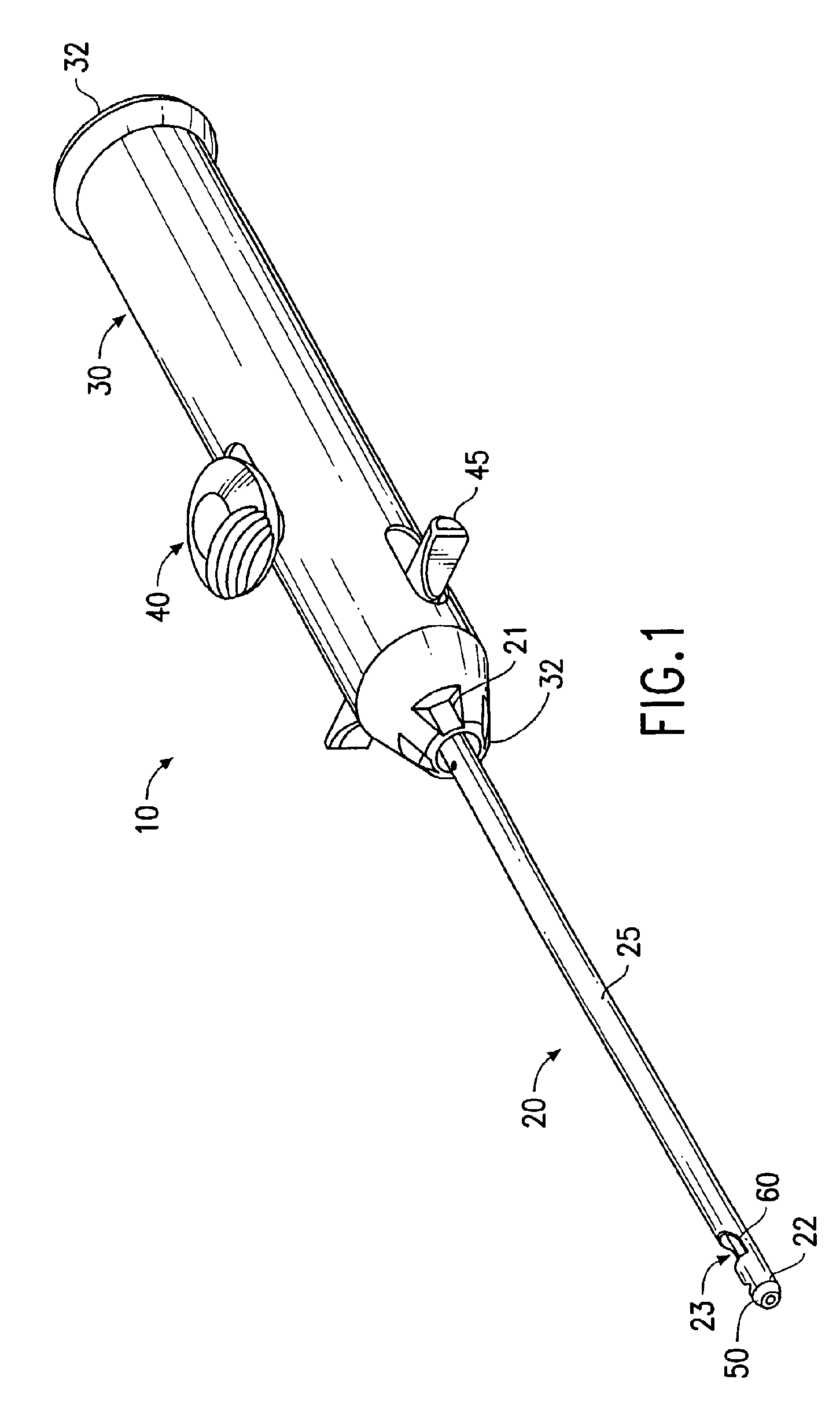

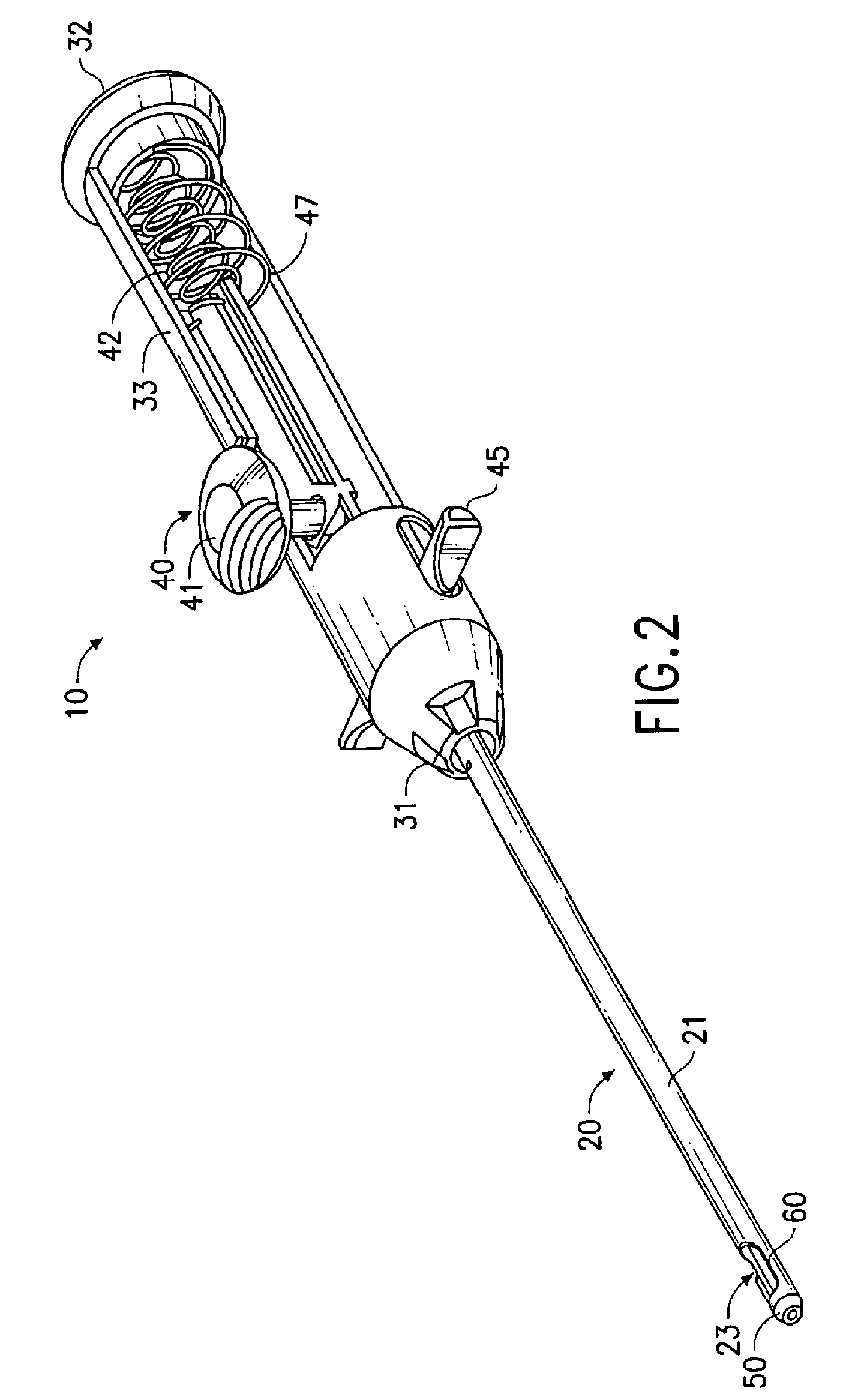

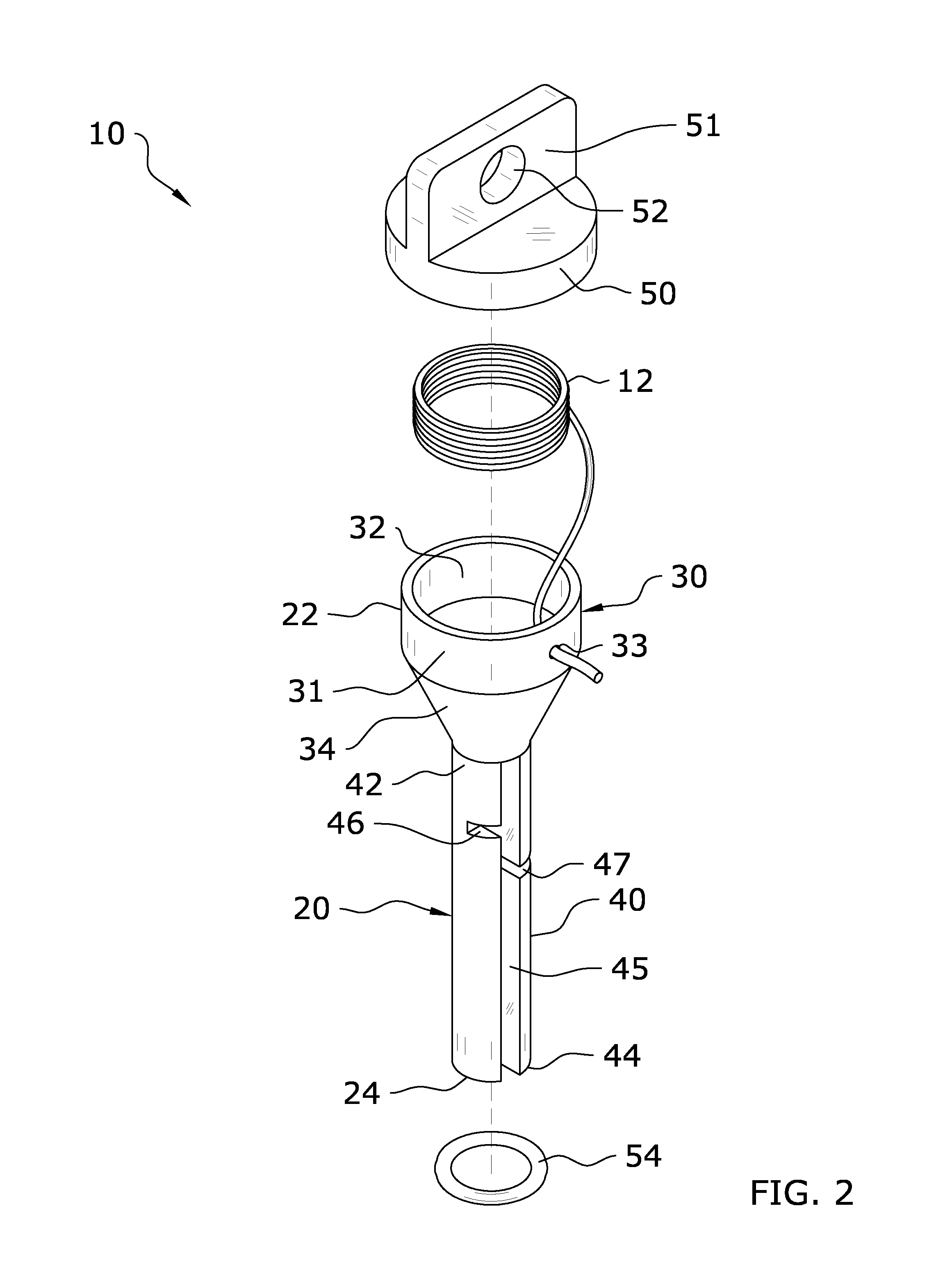

InactiveUS20040122450A1Easy to operateExcessive removalSuture equipmentsWeaver's toolsEngineeringMechanical engineering

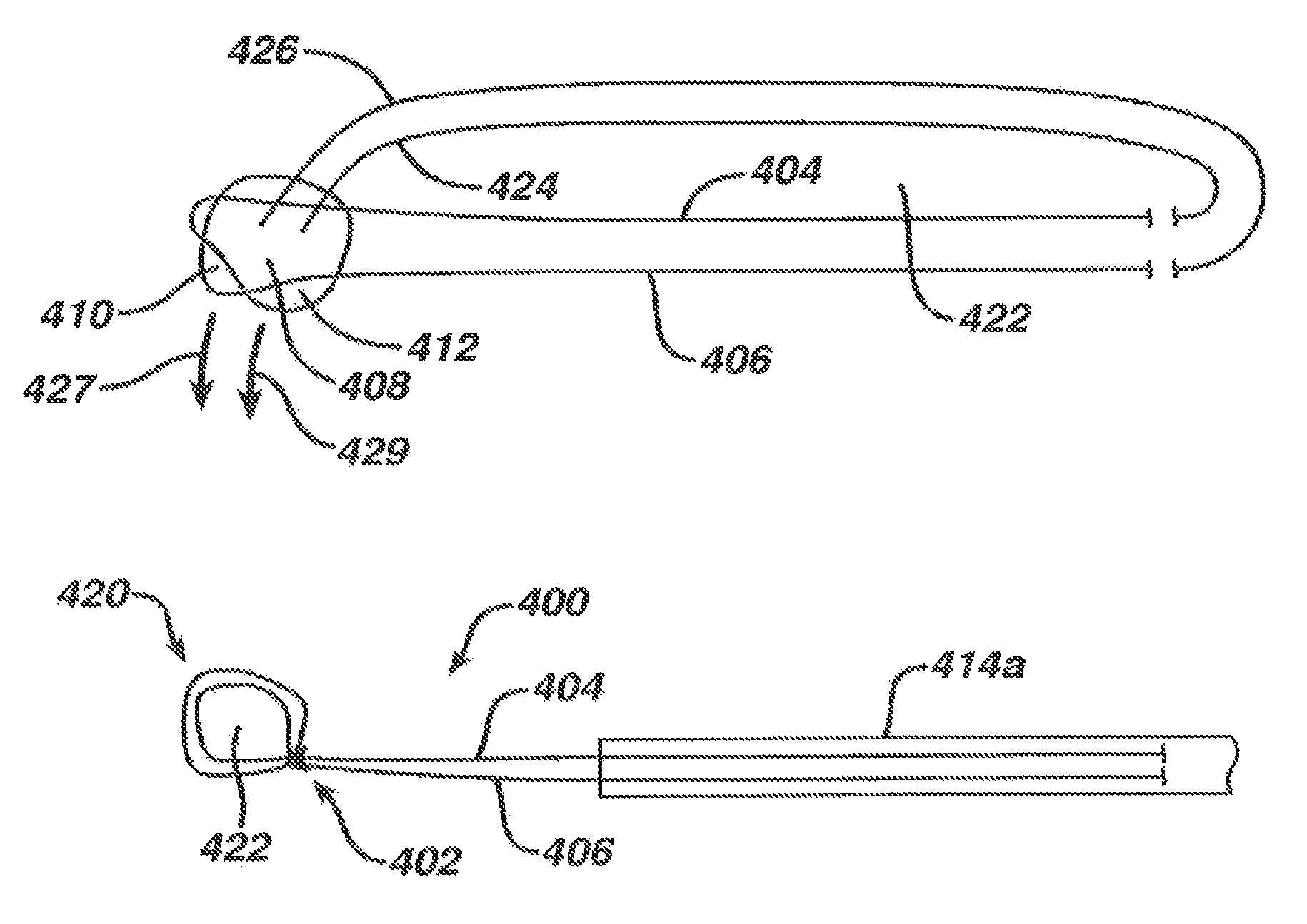

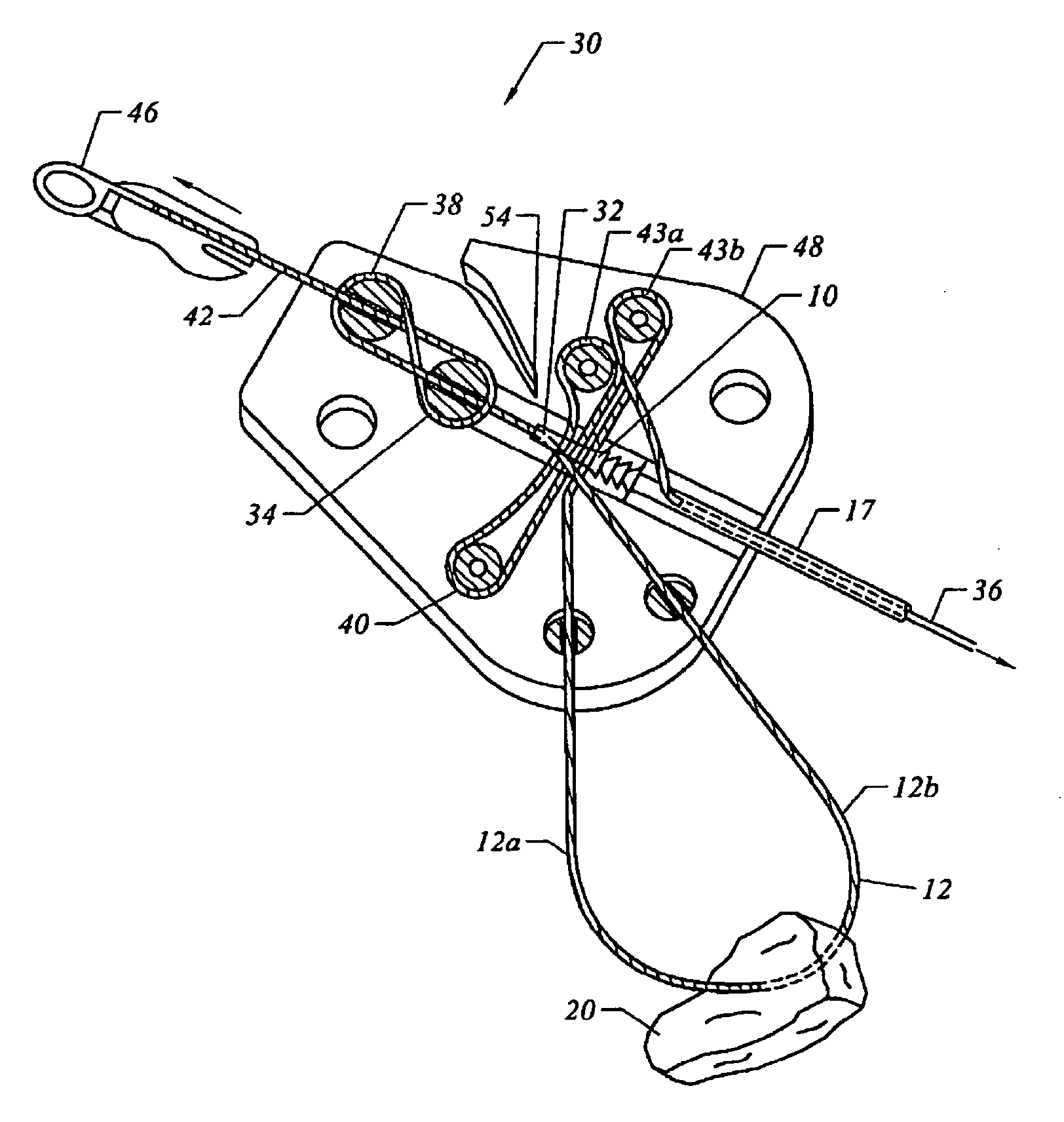

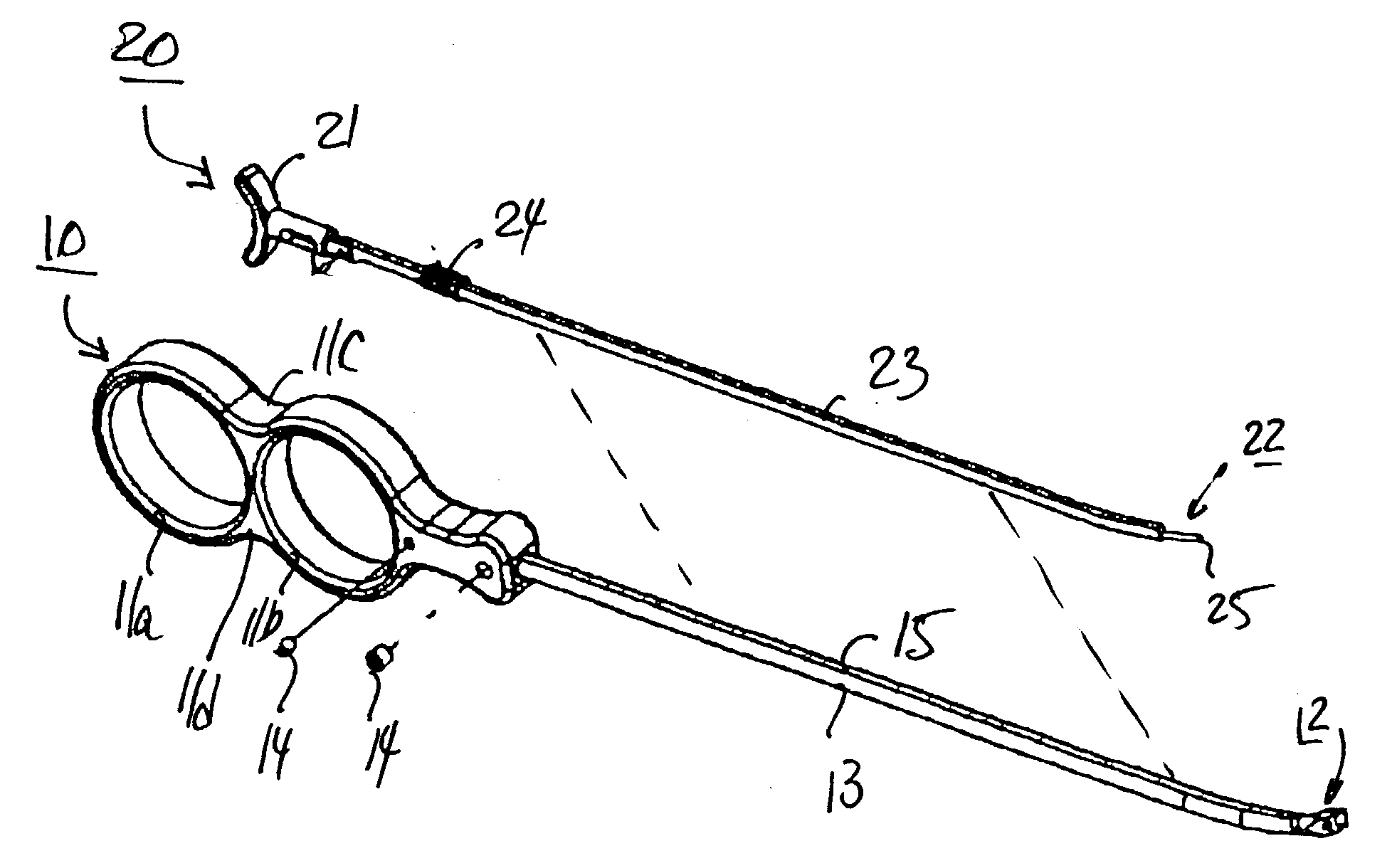

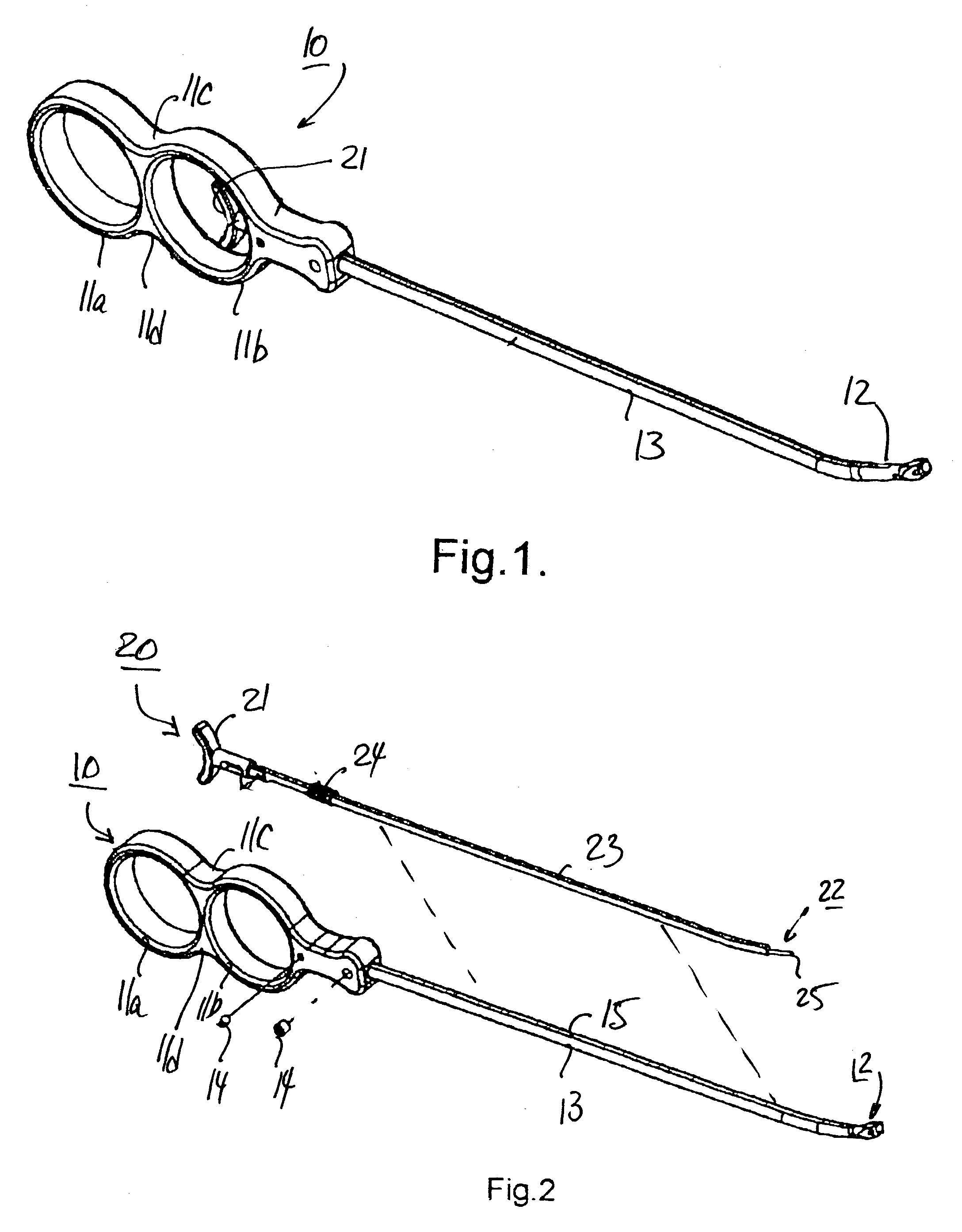

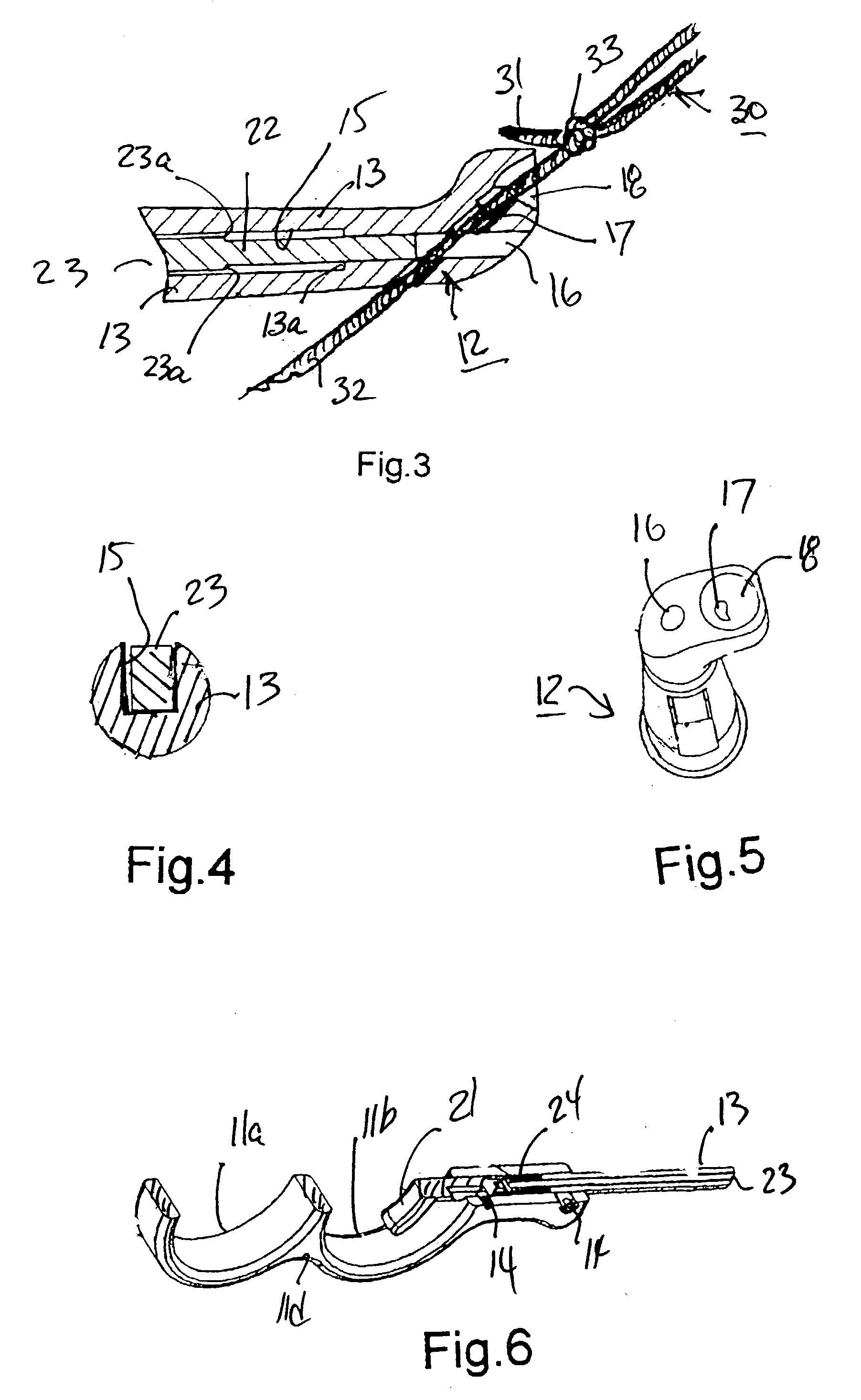

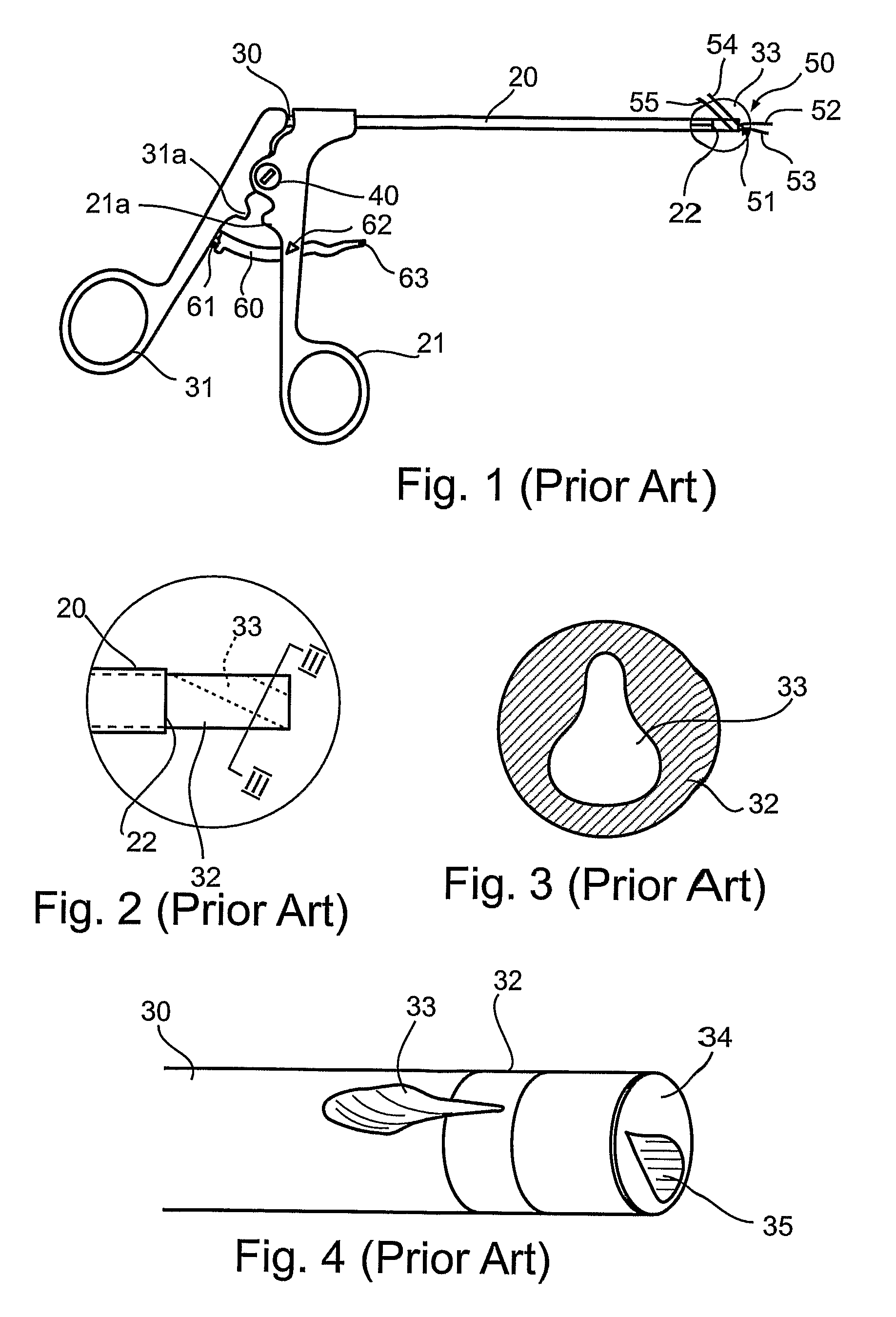

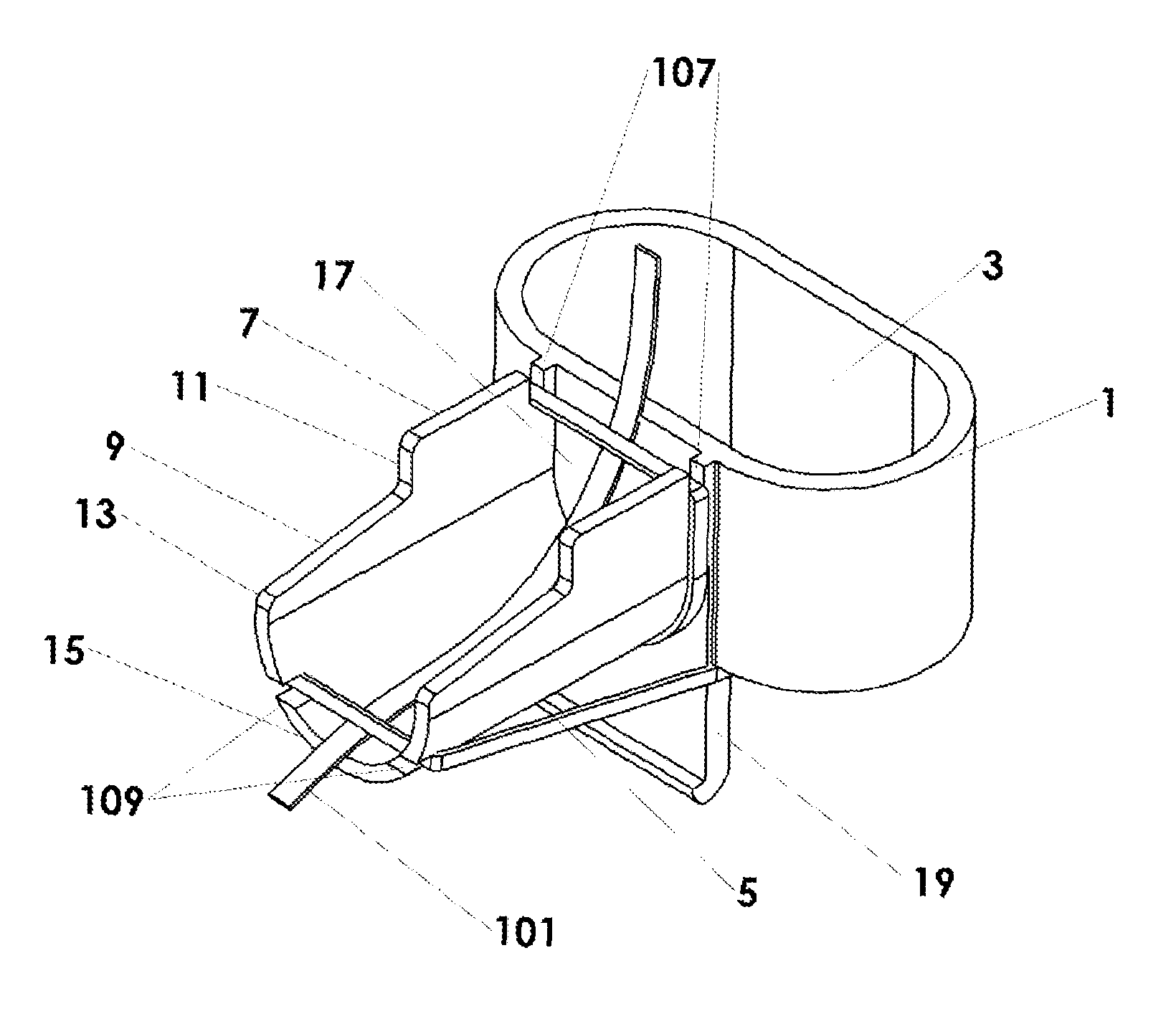

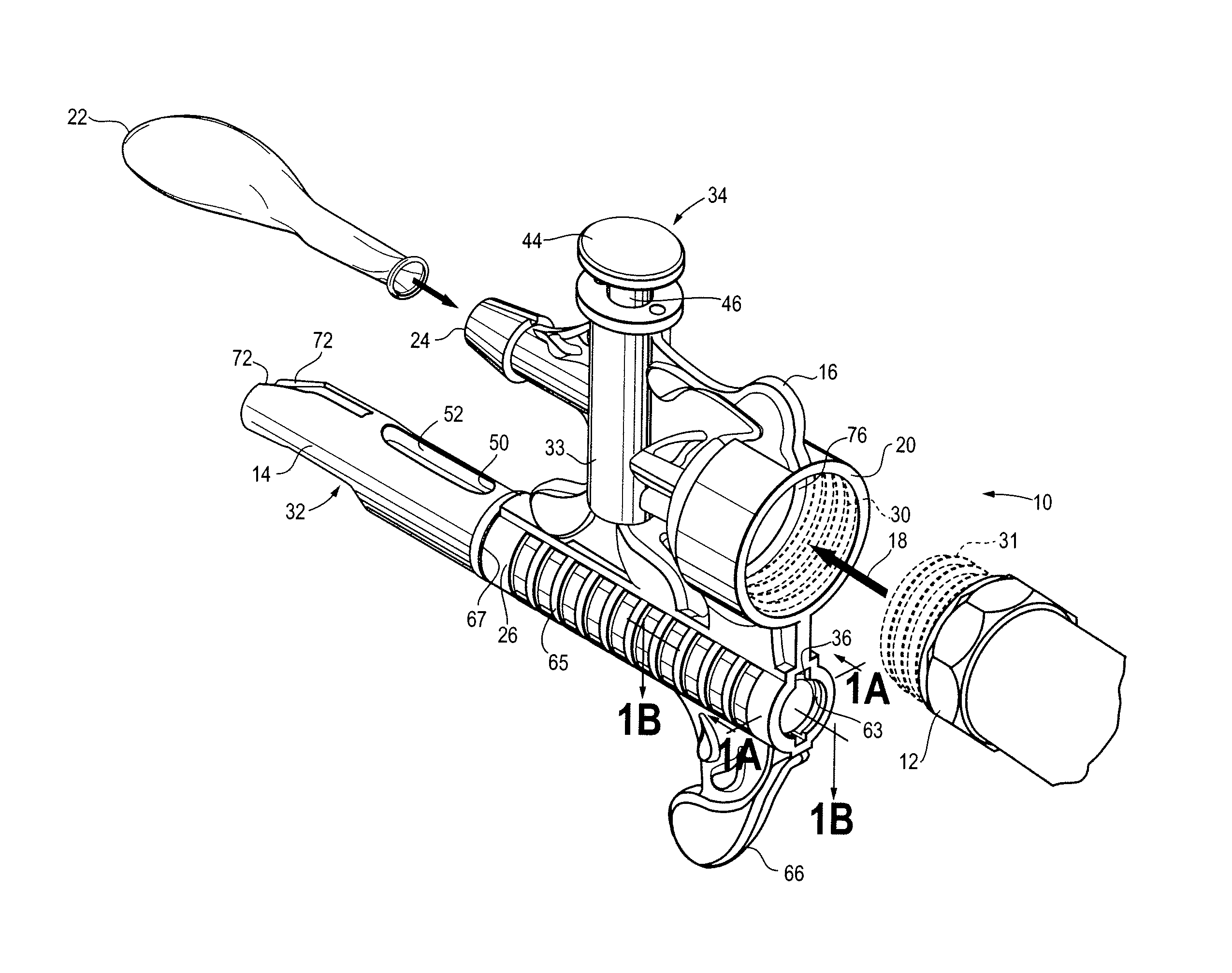

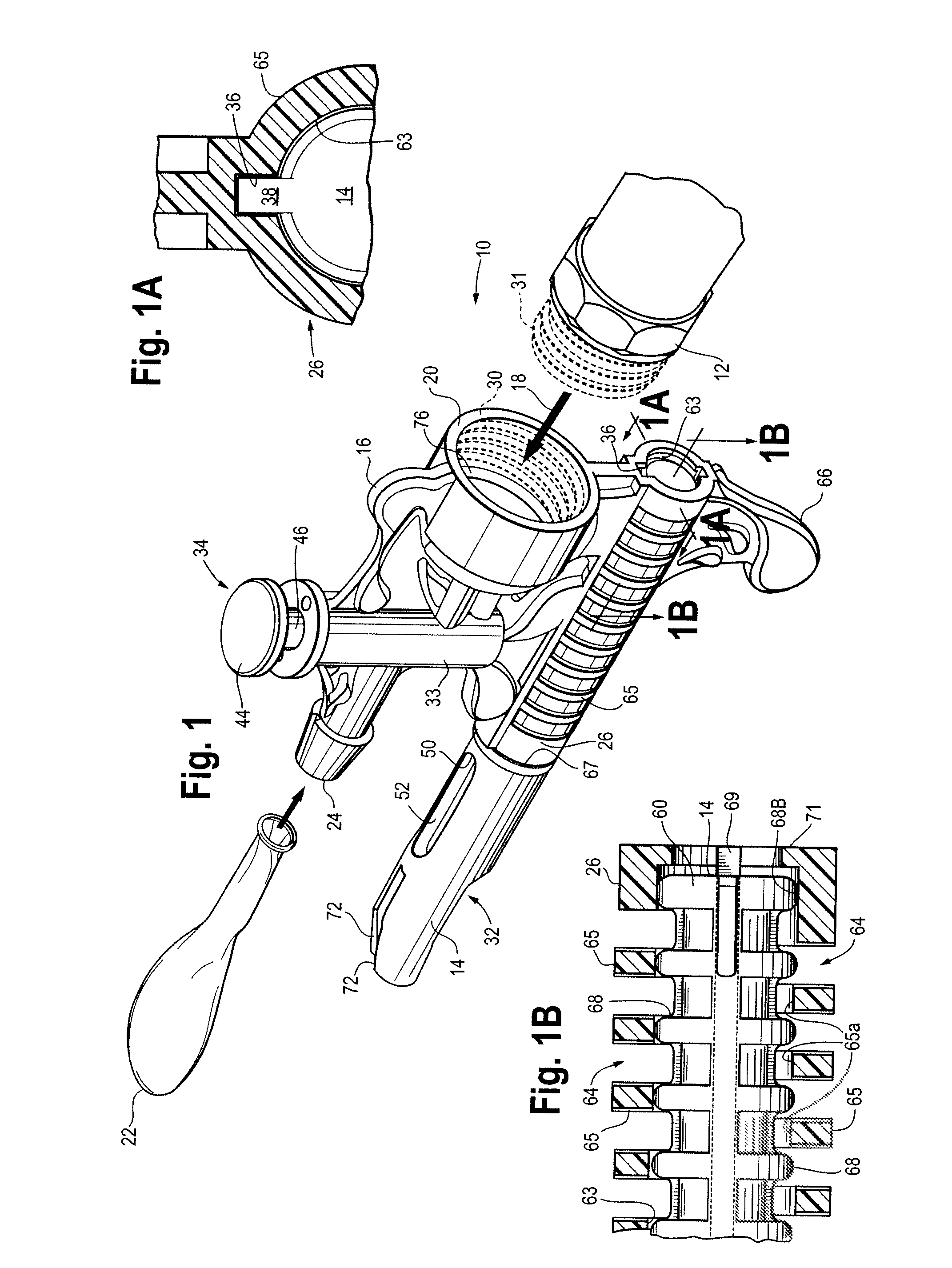

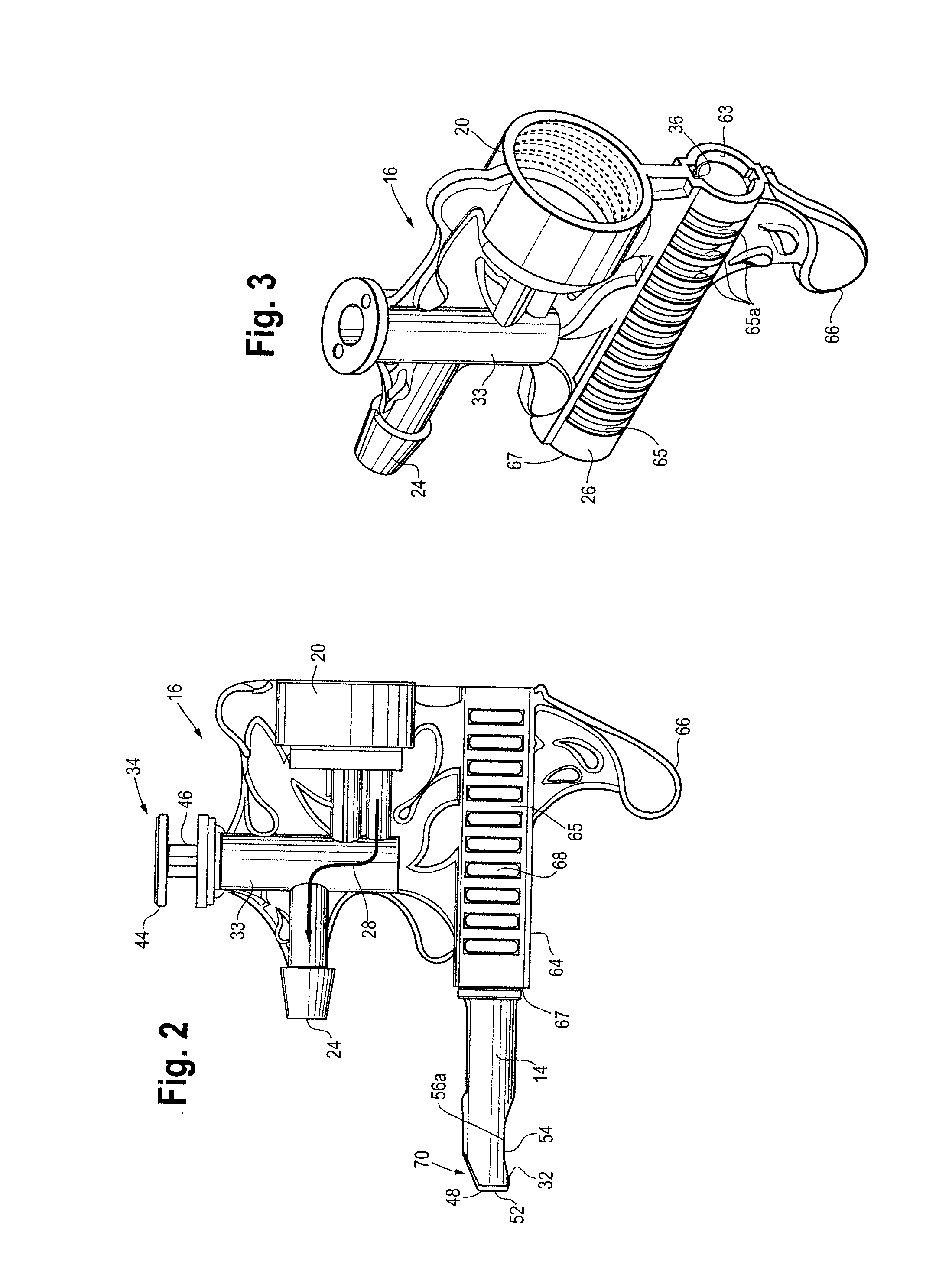

An implement for manipulating and cutting a knotted suture includes a body member having a handle at one end, and a knot-engageable section at the opposite end for engaging the knotted suture to be cut; and a cutting member carried by the body member and having an end portion formed with a cutting edge for cutting the knotted suture at a predetermined distance from the knot. The cutting member is movable along its longitudinal axis from a normal position to an actuated position for cutting the knotted suture. The knot-engageable section of the body member is formed with an axial bore for receiving the end portion of the cutting member when the cutting member is moved to its actuated position, and with an angled bore intersecting the axial bore at an angle to the longitudinal axis for receiving the knotted suture. The knot is located at one side of the angled bore and the suture to be cut extends through the angled bore to the opposite side, such as to permit hand-tensioning the knot and then cutting the suture by moving the cutting member to its actuated position.

Owner:T MEDICAL DEVICES AGRI COOP

Suture manipulating and/or cutting implement

InactiveUS6866673B2Easy to operateExcessive removalSuture equipmentsWeaver's toolsEngineeringMechanical engineering

An implement for manipulating and cutting a knotted suture includes a body member having a handle at one end, and a knot-engageable section at the opposite end for engaging the knotted suture to be cut; and a cutting member carried by the body member and having an end portion formed with a cutting edge for cutting the knotted suture at a predetermined distance from the knot. The cutting member is movable along its longitudinal axis from a normal position to an actuated position for cutting the knotted suture. The knot-engageable section of the body member is formed with an axial bore for receiving the end portion of the cutting member when the cutting member is moved to its actuated position, and with an angled bore intersecting the axial bore at an angle to the longitudinal axis for receiving the knotted suture. The knot is located at one side of the angled bore and the suture to be cut extends through the angled bore to the opposite side, such as to permit hand-tensioning the knot and then cutting the suture by moving the cutting member to its actuated position.

Owner:T MEDICAL DEVICES AGRI COOP

Suture manipulating and cutting implement

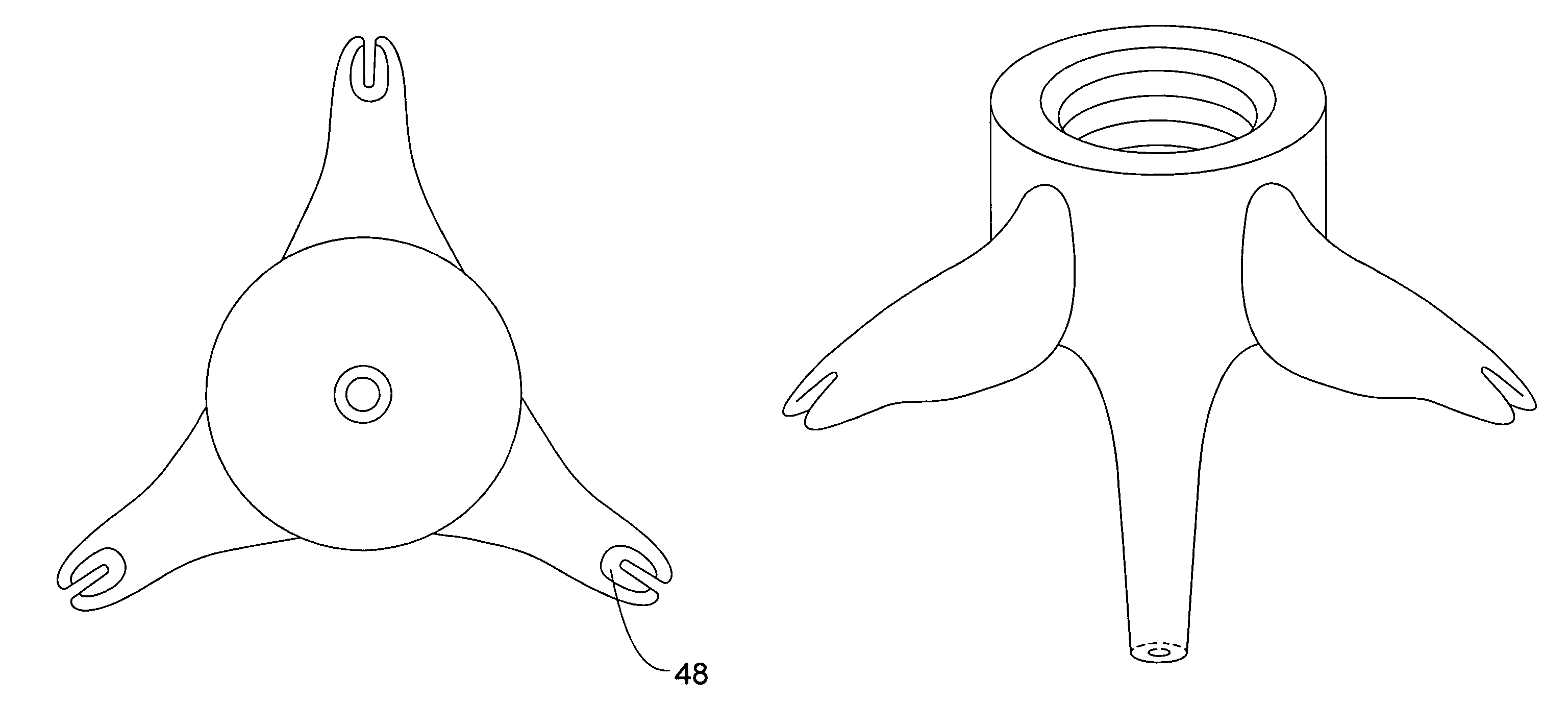

ActiveUS20070173865A1Conveniently executedLittle or no accommodationSuture equipmentsWeaver's toolsSurgical proceduresGeneral surgery

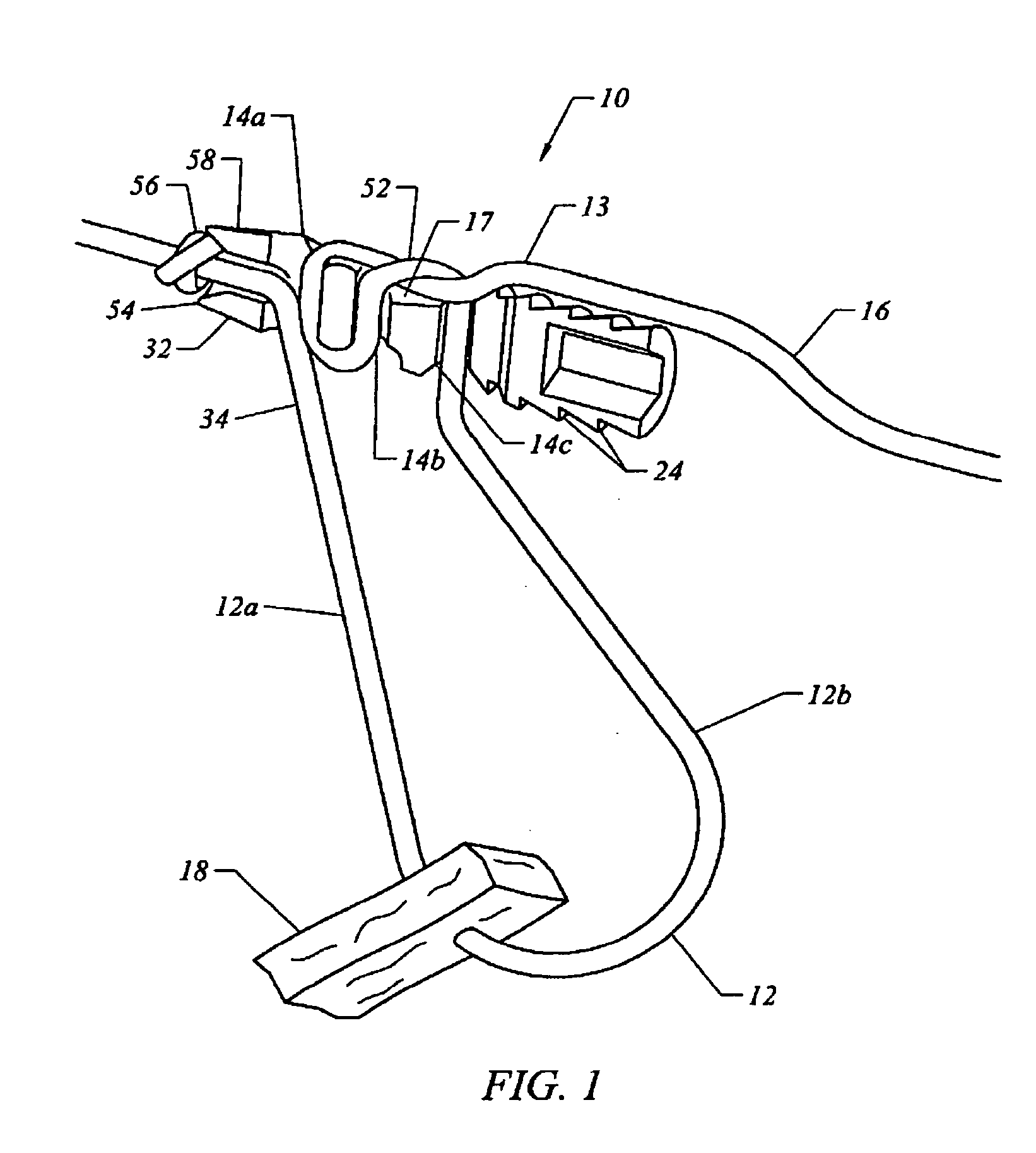

An implement for manipulating a knotted suture during a surgical procedure, includes an elongated shaft having a proximal end engageable by the user for manipulating the instrument, and a distal end engageable with the knotted suture to be manipulated. The distal end of the elongated shaft has an end face formed with a recess for receiving the knot of the suture. The distal end of the elongated shaft is formed with an open slot starting from a location spaced from the end face and leading to the recess in the end face, such as to enable the knotted suture to be introduced into the slot and the recess by effecting a sidewise movement. The implement further includes a tubular cutter member enclosing the elongated shaft and formed with an annular cutting edge engageable with a suture in the open slot of the shaft upon movement of the elongated shaft with respect to the tubular cutter member, or by vice-versa.

Owner:T MEDICAL DEVICES AGRI COOP

Bone anchor suture-loading system, method and apparatus

A suture-loading system, method and apparatus for loading a suture onto a bone anchor, the system comprising: a bone anchor comprising a suture leg-anchoring structure and a plurality of body holes on the anchor; a suture comprising a standing end portion and a working end portion; a standing end trackway to guide the standing end portion of the suture through the suture leg-anchoring structure; and a working end trackway to guide the working end portion of the suture through the body holes in the anchor.

Owner:ARTHROCARE

Suture manipulating and cutting implement

ActiveUS8282659B2Easy to implementLittle or no accommodationSuture equipmentsWeaver's toolsSurgical proceduresSuture line

Owner:T MEDICAL DEVICES AGRI COOP

Hand held balloon tier

A balloon knot tying device that has a base with dual rods provided for stretching the leading end of an inflated balloon around to assist in tying a permanent knot. Each rod having at least two diameters to provide a retaining edge so the balloon will not slide down onto the base during the knot tying operation. The base with dual rods can be attached to different holding devices such as a ring shaped device for inserting at least 1 finger or a handle shaped device for gripping. The knot tying operation consisting of holding the balloon against the side of the device and stretching the leading end around the rods to form a loop. The leading end is then crossed under the loop through a relief area and up between the two rods. The leading end is then pulled off of the rods to form a permanent knot.

Owner:MIZE KAREN JENNIFER

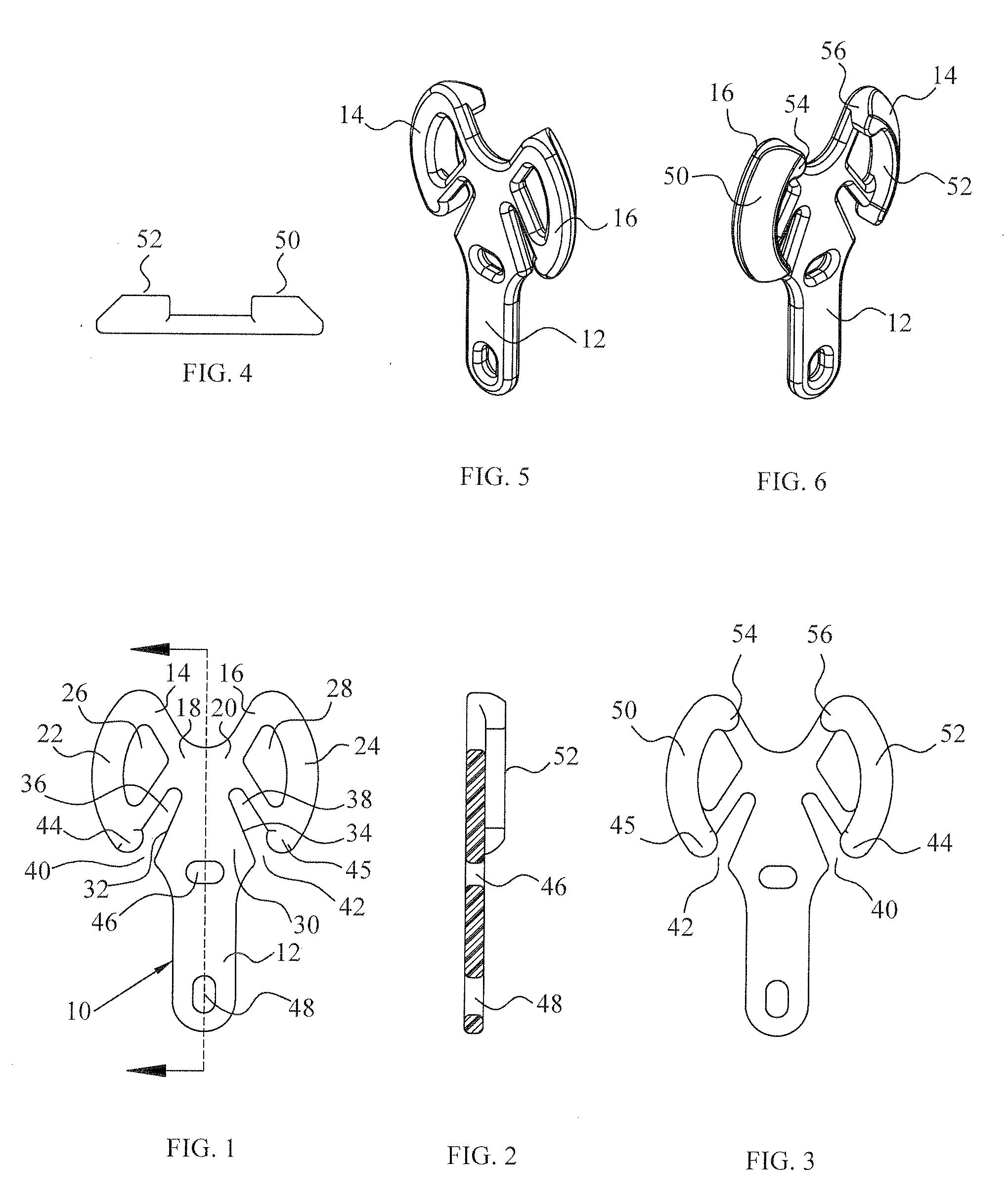

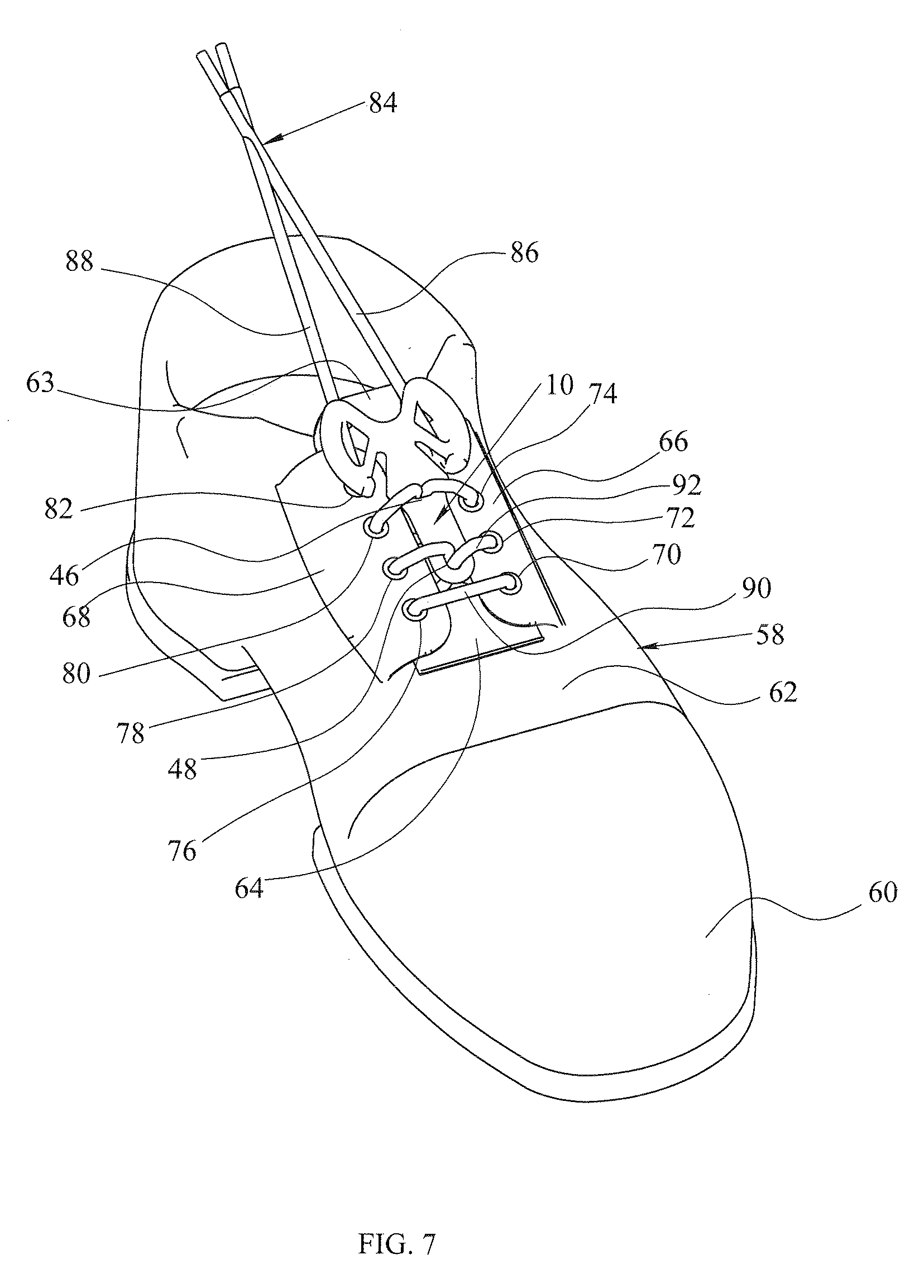

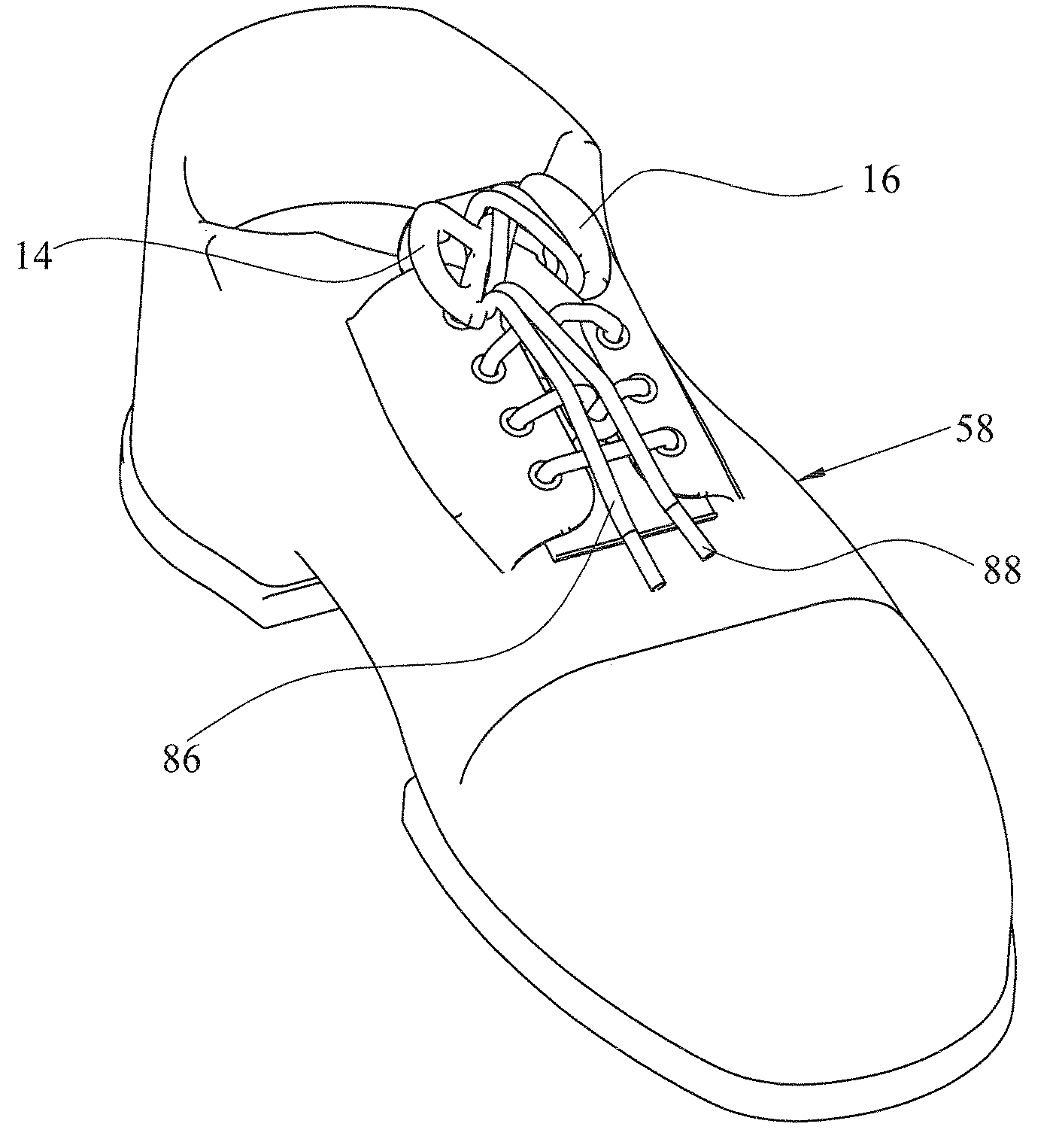

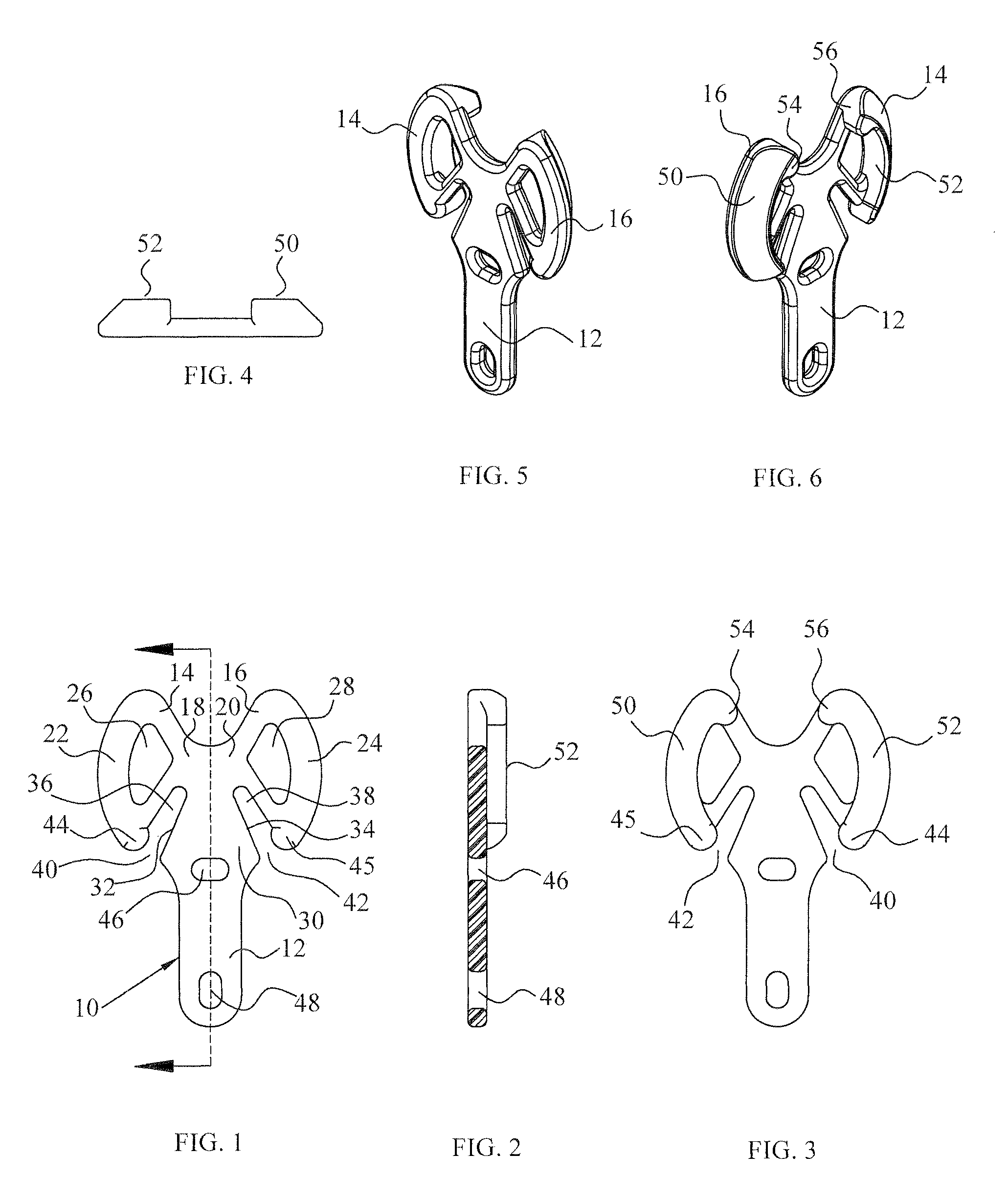

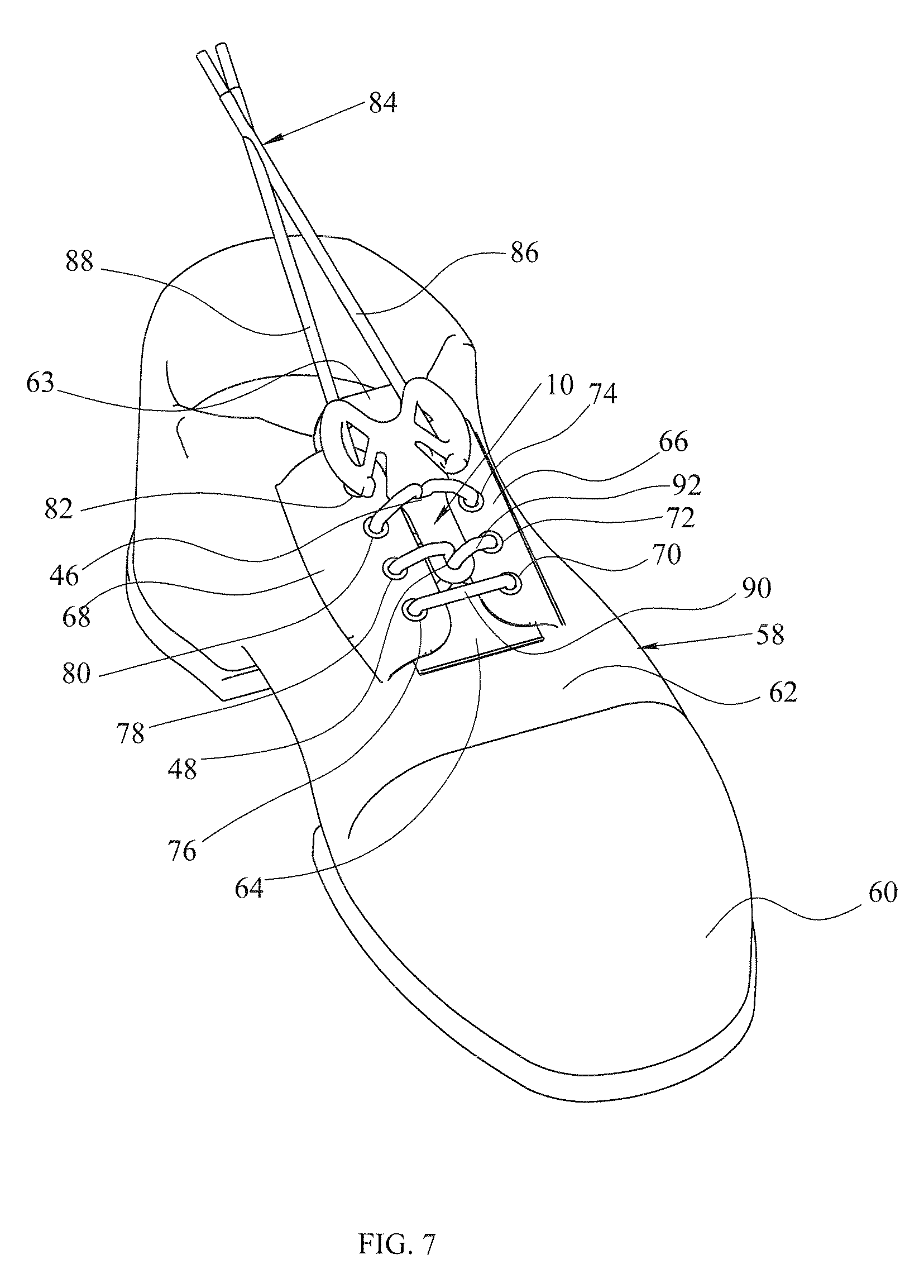

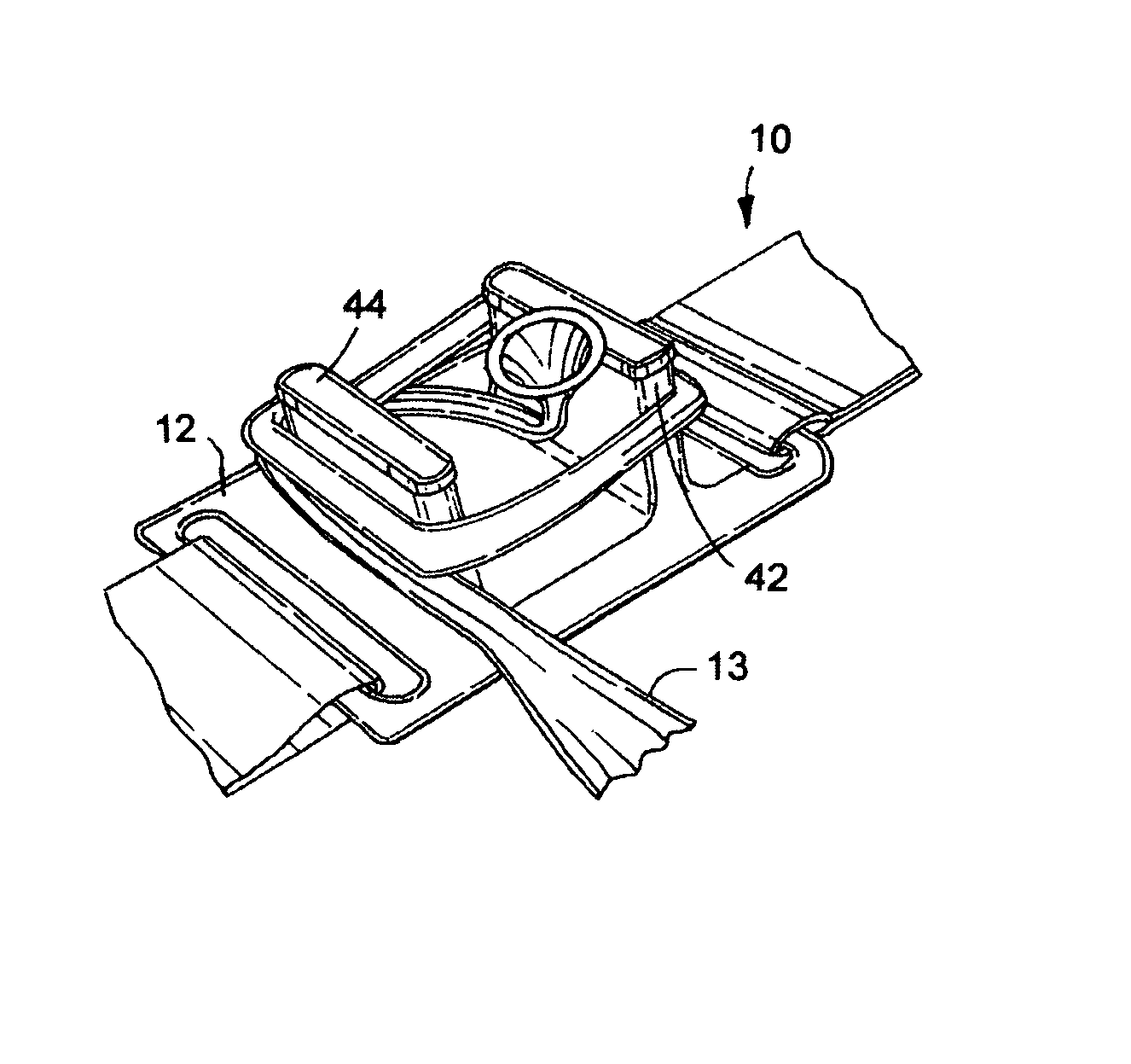

Shoe tying aid and method

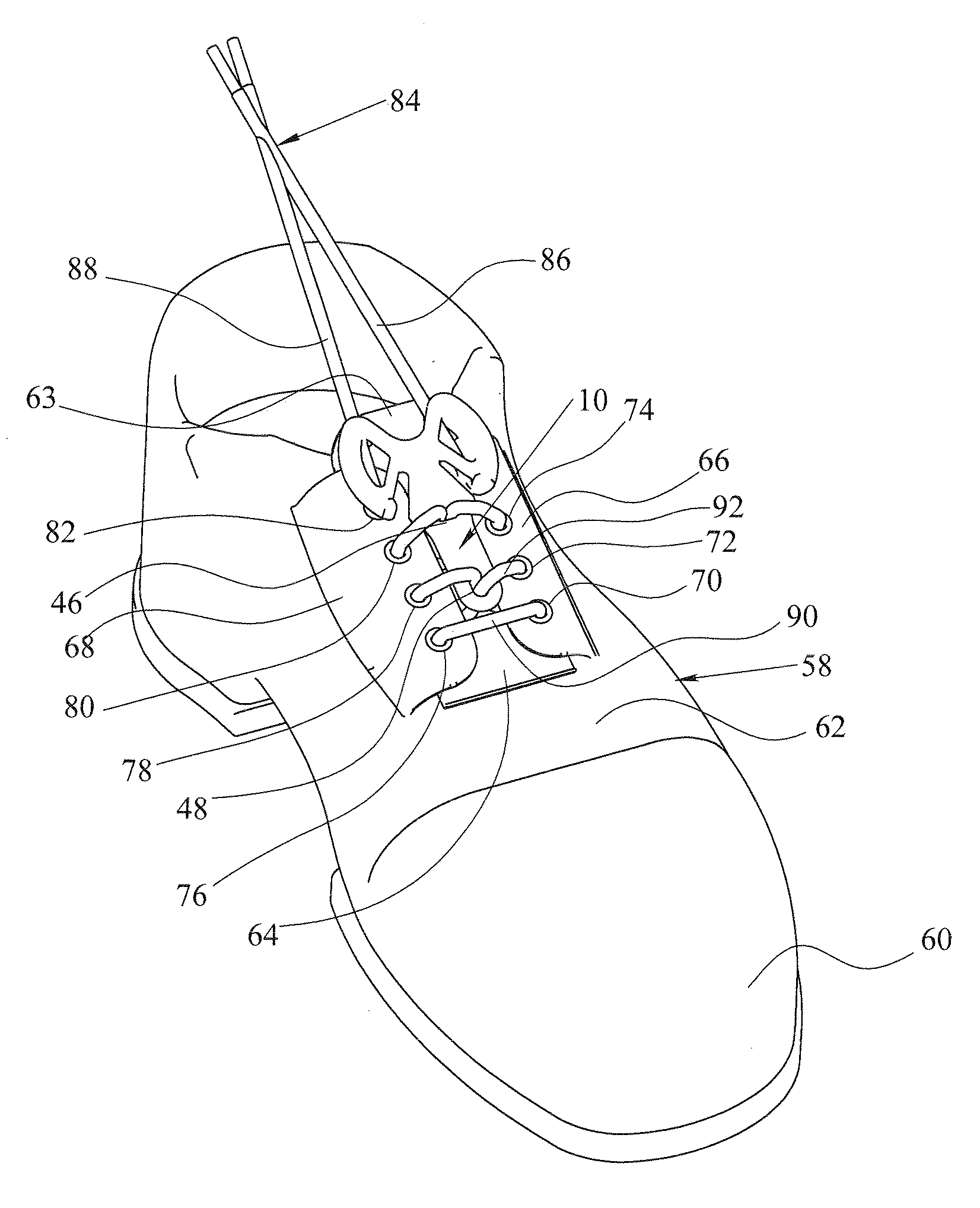

InactiveUS20100269373A1The process is simple and effectiveEasy to tieFilament handlingShoe lace fasteningsEngineeringMooring line

A shoe can be tied using only one hand if provided with a tying aid in the form of a generally T-shaped unit comprising a leg having two laterally extending ears. The leg is secured between rows of eyelets on the opposed flaps of the shoe by one or more of the lengths of lace extending across the gap between the flaps. The lengths of shoelace that would otherwise be tied in a bow are instead wrapped around the ears of the tying aid in alternating fashion, preferably twice around each ear, in a manner similar to the manner in which a mooring line is secured to the cleat of a boat.

Owner:THERM OMEGA TECH INC

Shoe tying aid and method

InactiveUS8056265B2The process is simple and effectiveEasy to tieFilament handlingShoe lace fasteningsEngineeringMooring line

A shoe can be tied using only one hand if provided with a tying aid in the form of a generally T-shaped unit comprising a leg having two laterally extending ears. The leg is secured between rows of eyelets on the opposed flaps of the shoe by one or more of the lengths of lace extending across the gap between the flaps. The lengths of shoelace that would otherwise be tied in a bow are instead wrapped around the ears of the tying aid in alternating fashion, preferably twice around each ear, in a manner similar to the manner in which a mooring line is secured to the cleat of a boat.

Owner:THERM OMEGA TECH INC

Uni-knot tying apparatus

Owner:CARRIER CALVIN

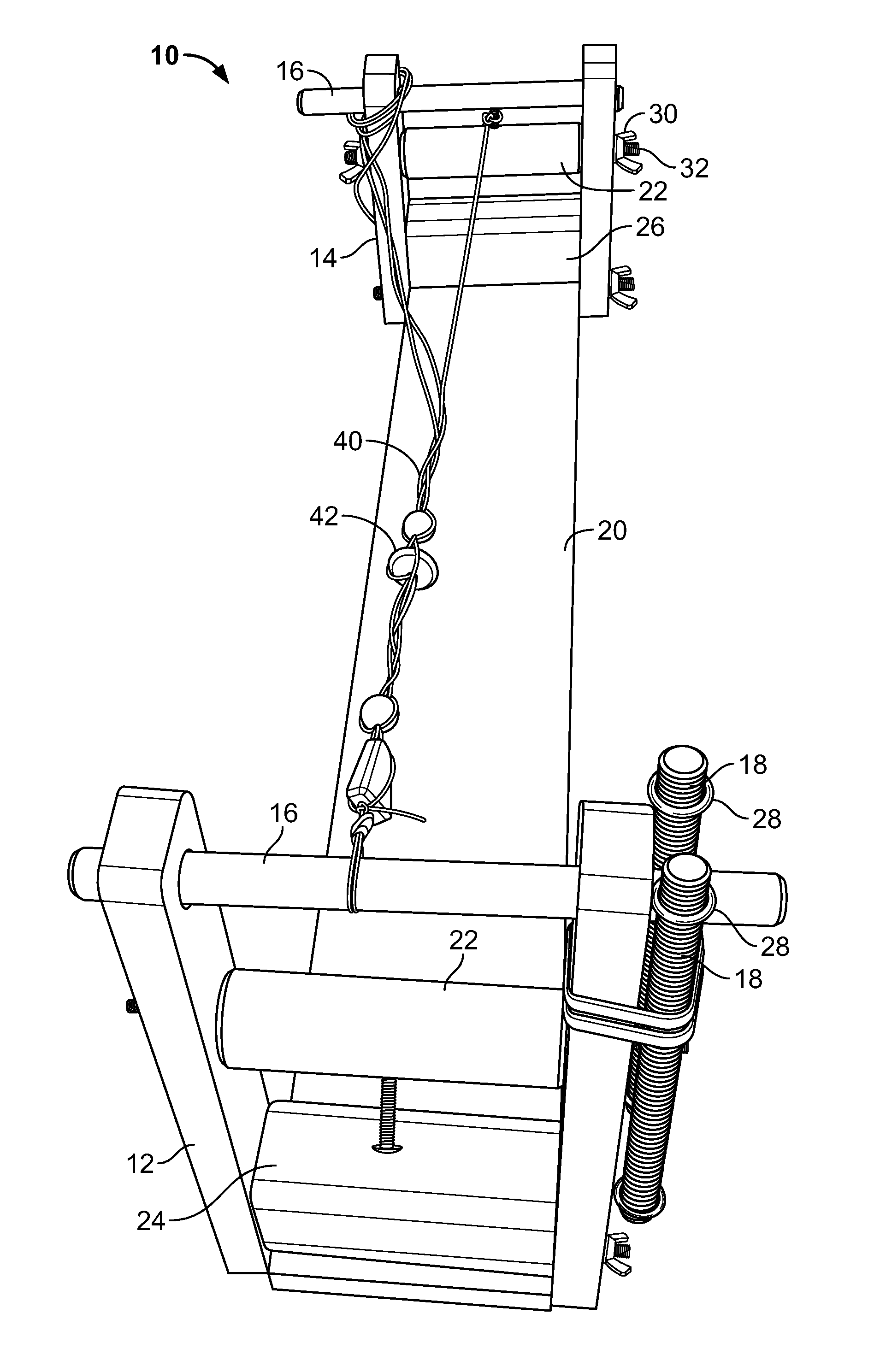

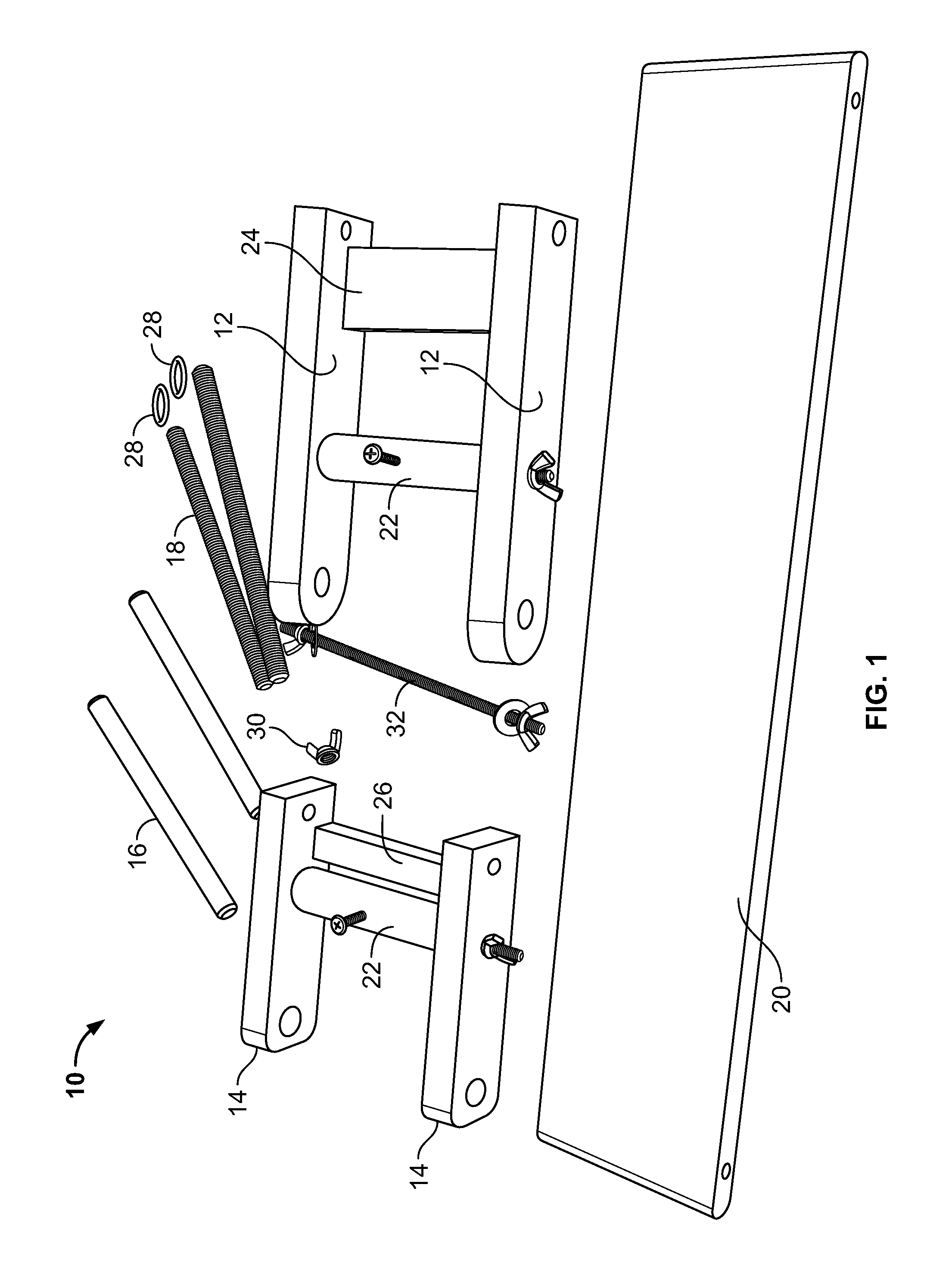

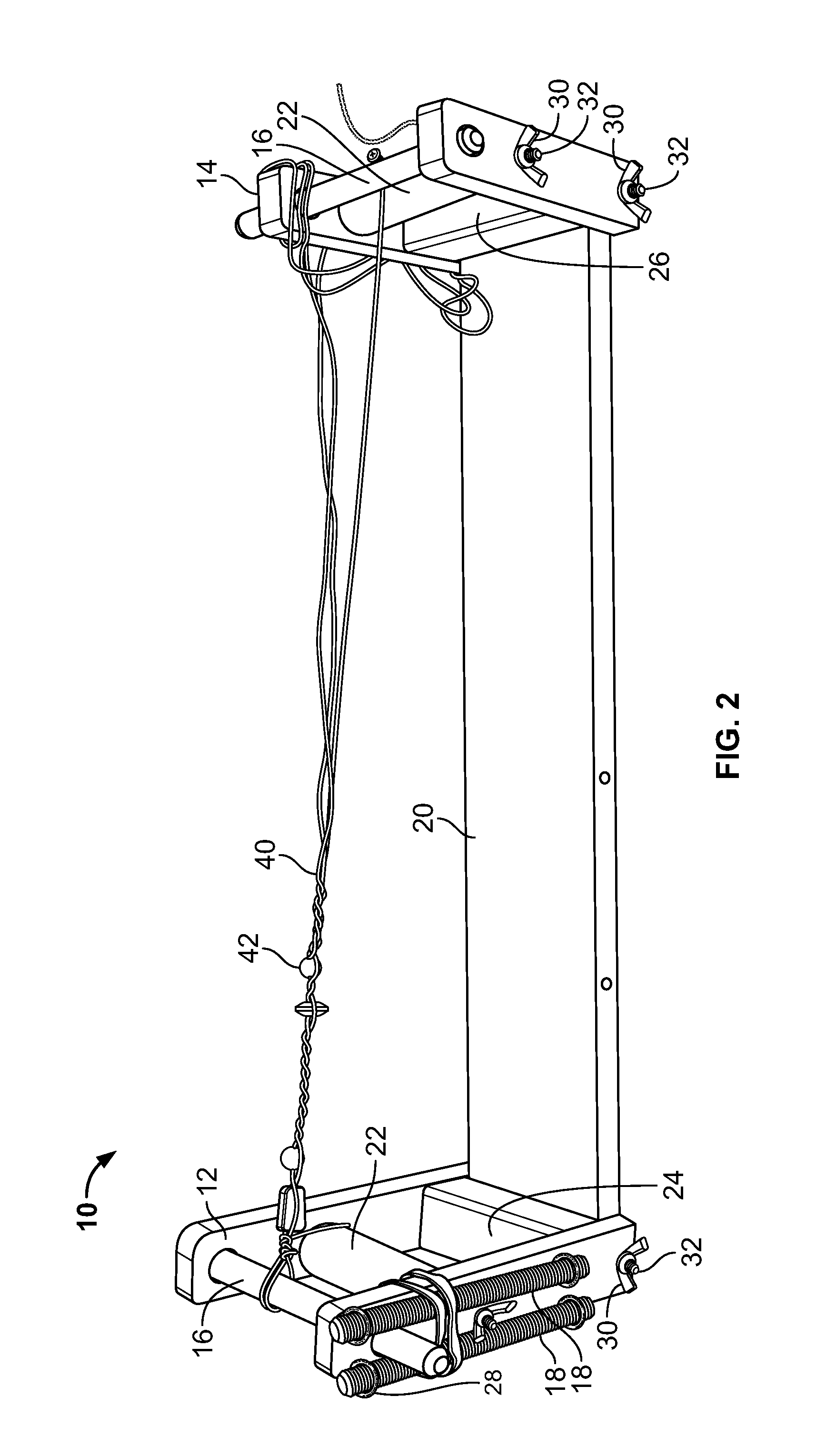

Unit for tying a balloon and securing a ribbon to the balloon

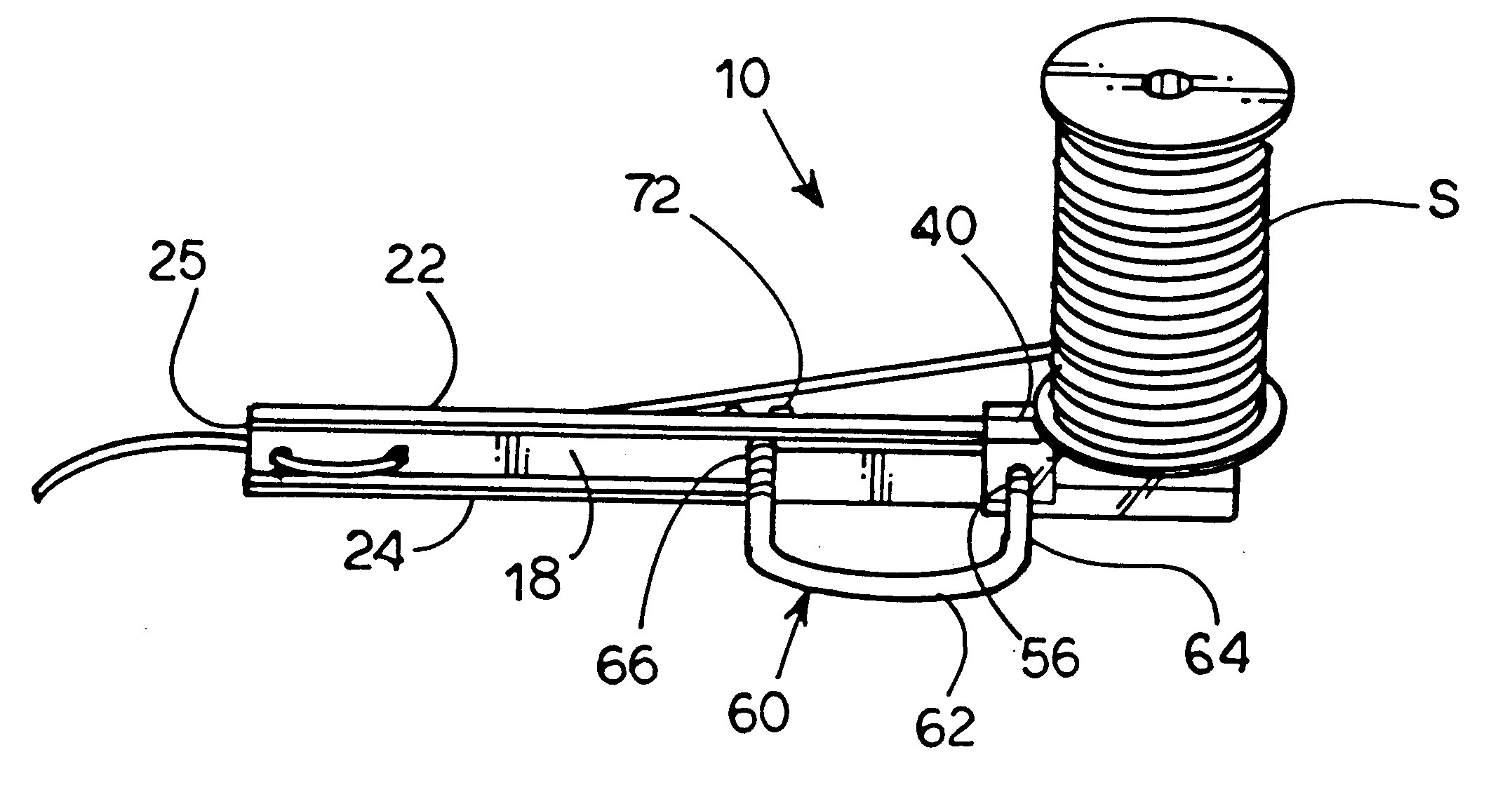

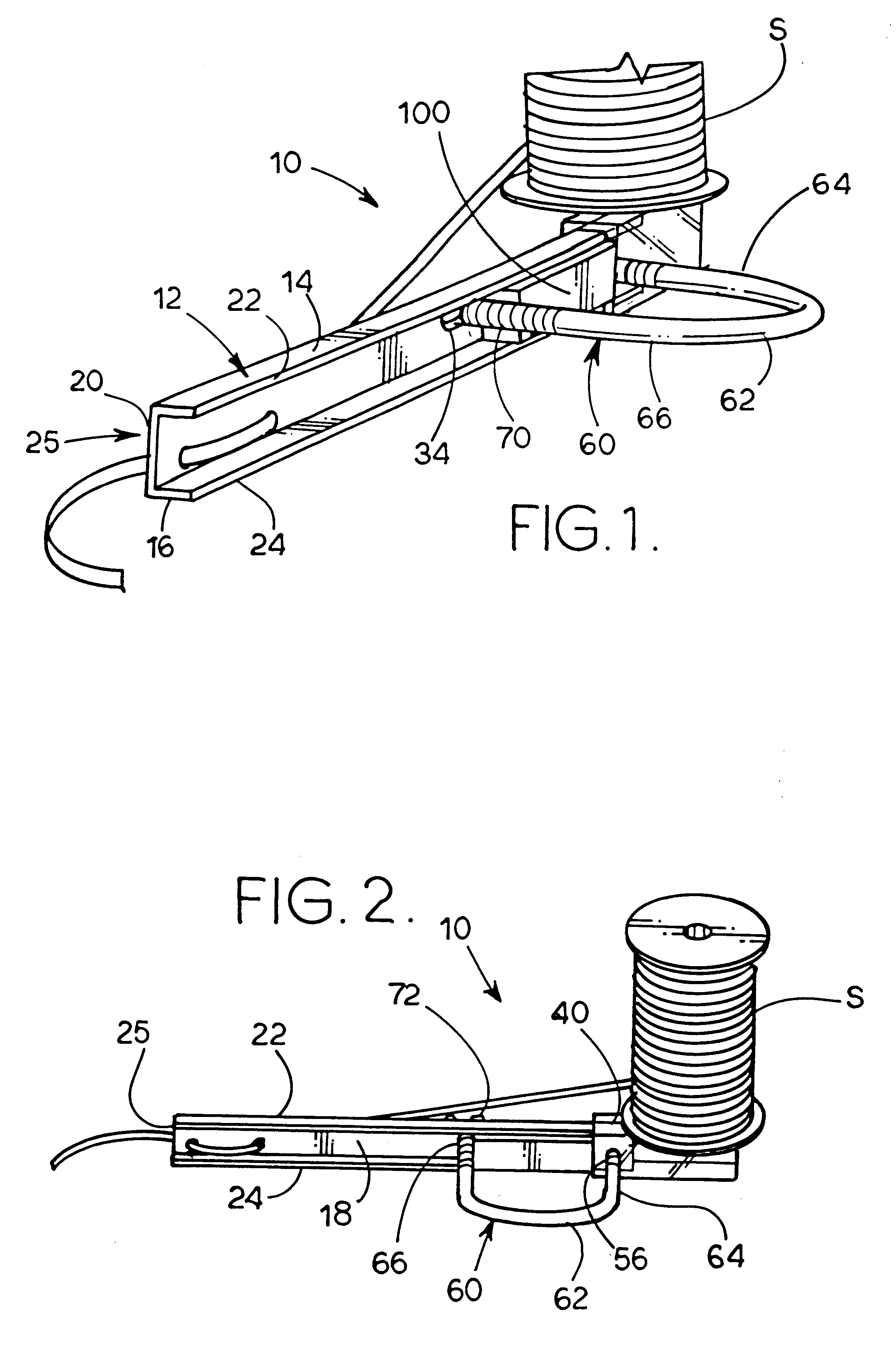

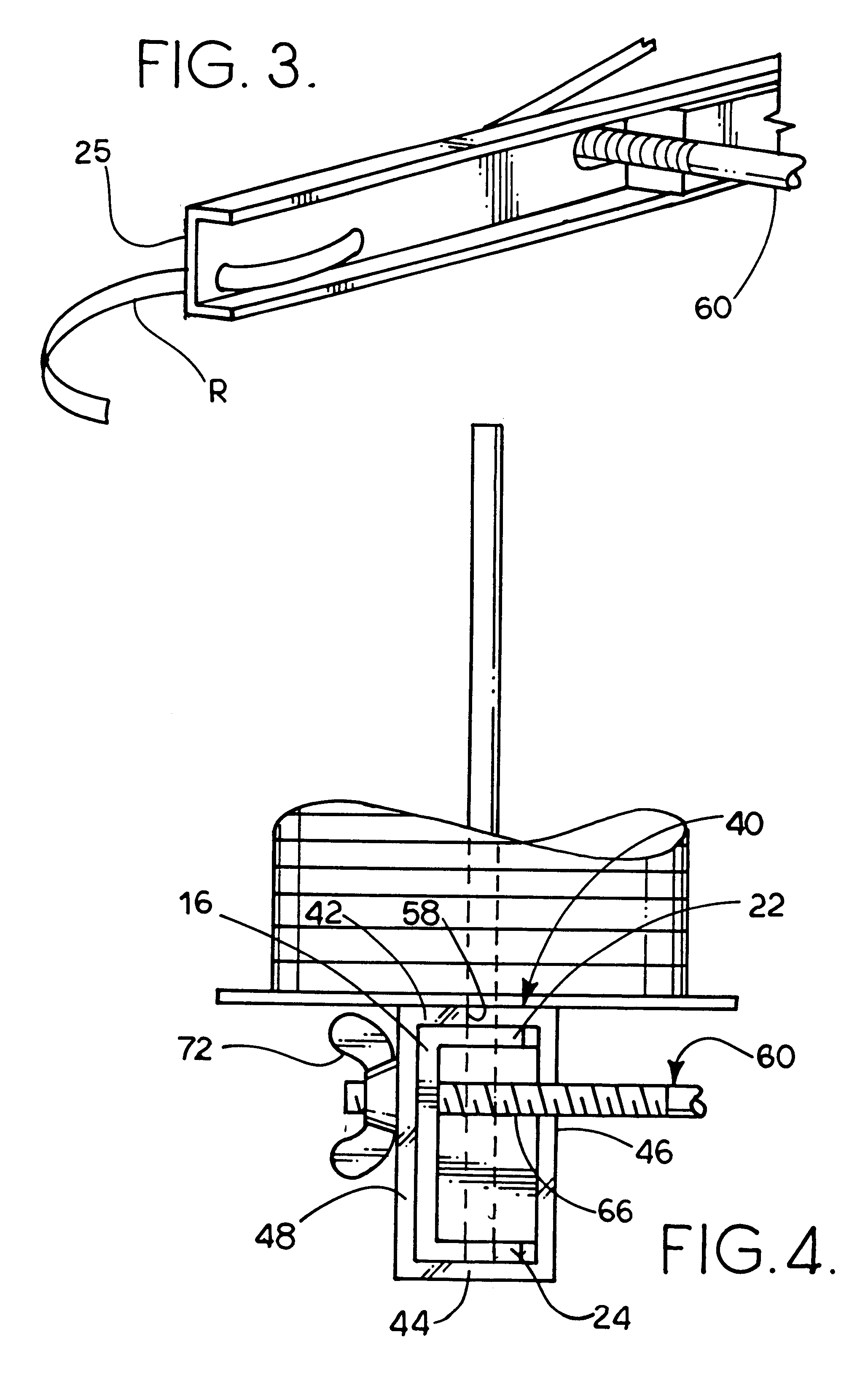

A unit is mounted directly on a tank of pressurized gas used to inflate a balloon and includes a supporting bracket having ribbon-accommodating holes defined through one end thereof and a support section on the other end. A ribbon supporting spool is rotatably mounted on the support section and ribbon drawn off the spool is threaded through the ribbon-accommodating holes to be captured in a knot formed in the neck of the balloon after that neck has been drawn around the supporting bracket and formed into a knot. A method of forming a knot in the balloon and capturing the ribbon therein is also disclosed.

Owner:CARLSON LELAND R

Device and kit for making knotted string accessories

Owner:CROREY DAVID J

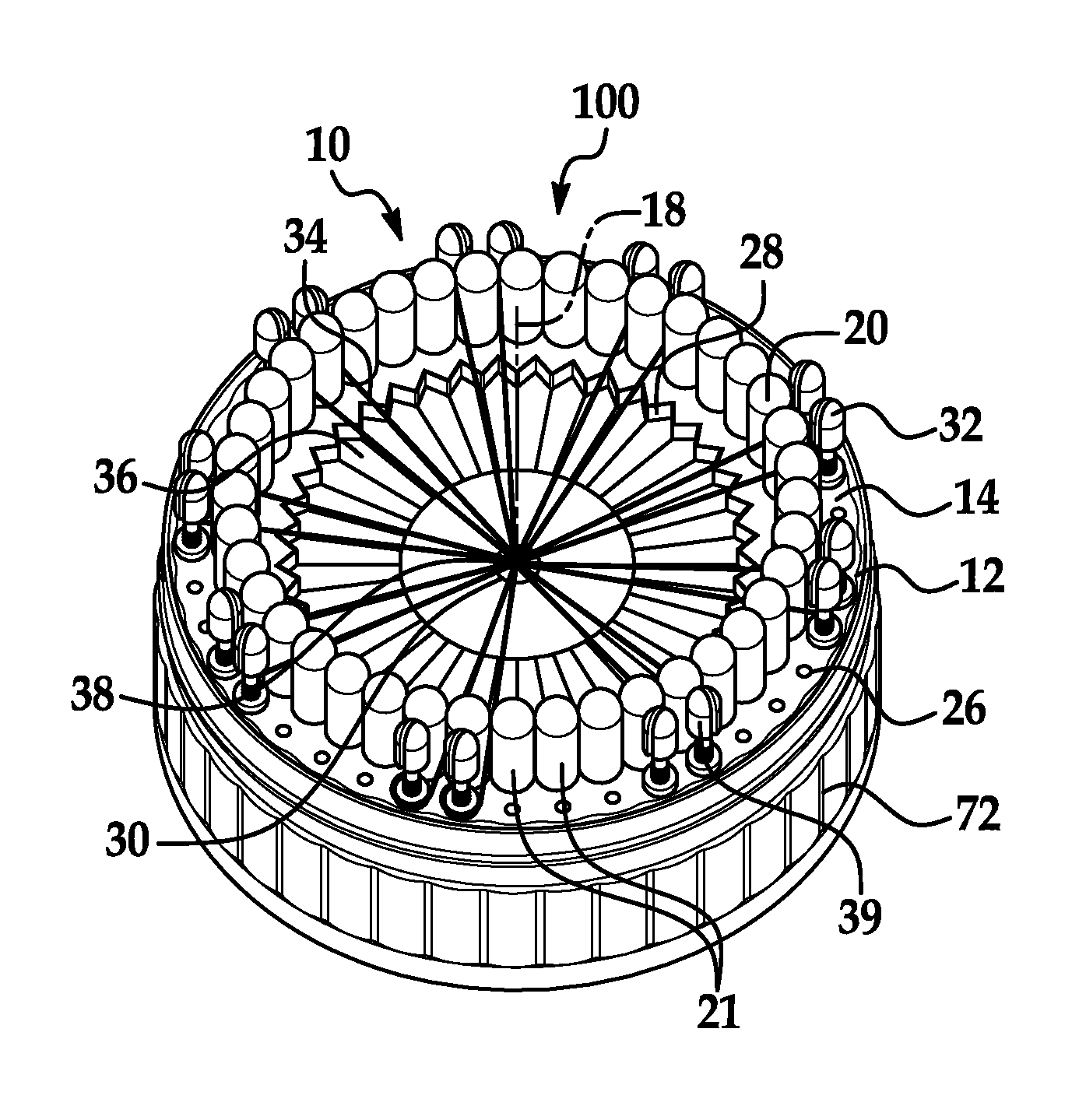

Portable balloon tying device, station and caddy

A balloon tying device has a base adapted for attaching to a support structure. A cantilever, supported by the base and protruding away from the support structure, is attached to the base. The cantilever has a U-shaped cross section and two ears defining generally parallel planes extending outwardly and terminating at the tip for retaining a loop of balloon material. Inside the U-shape of the cantilever is an axially oriented recess for passing ribbon and providing clearance for tucking the overhand knot. A brace tab extends downward from the lower edge of the base. A ribbon retainer is disposed on the device for integrating spooled or pre-cut ribbon into the balloon knot. The support structure can be human fingers, a station stanchion, a tank stand, or a caddy leg.

Owner:HERREN GERALD R

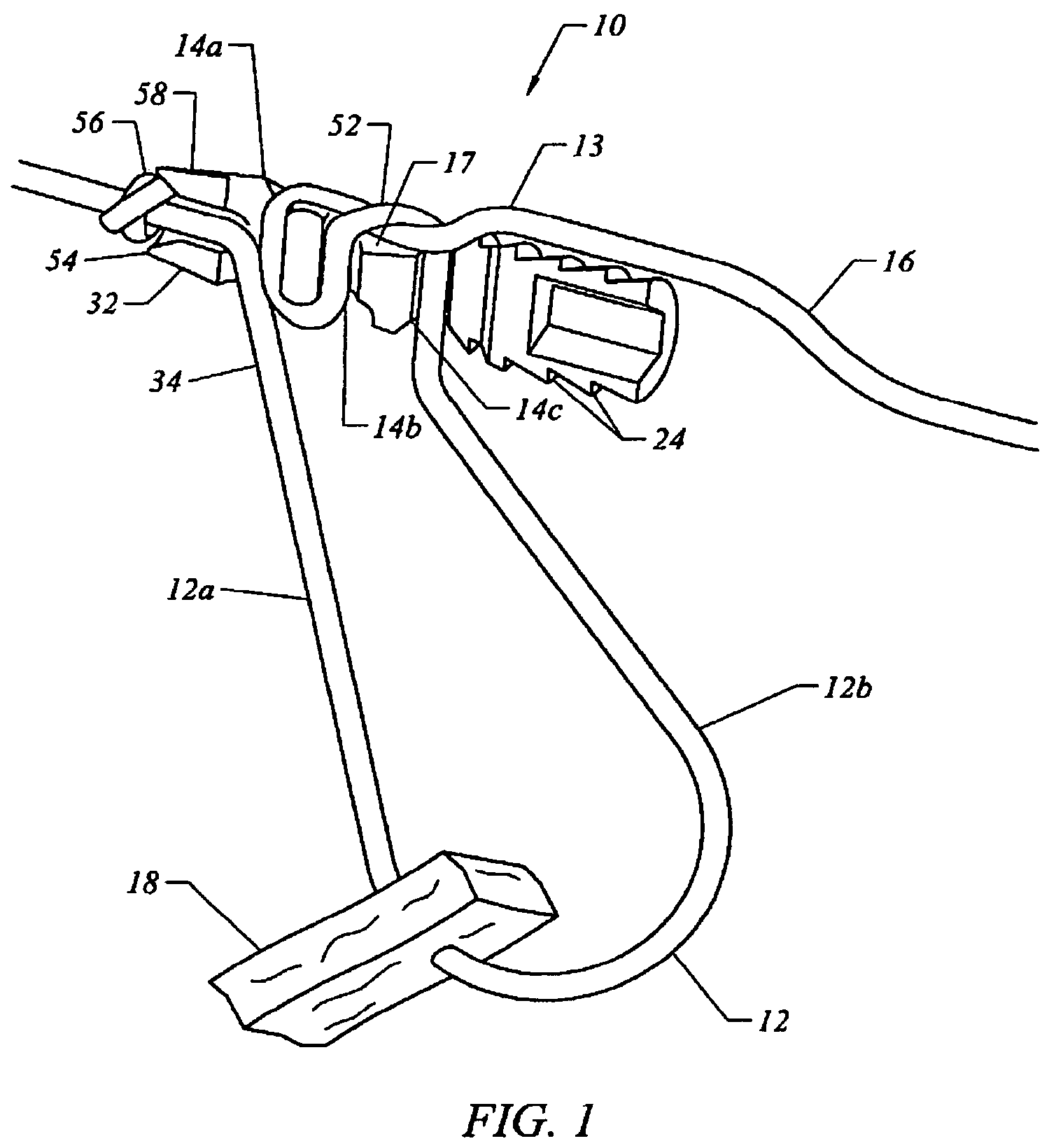

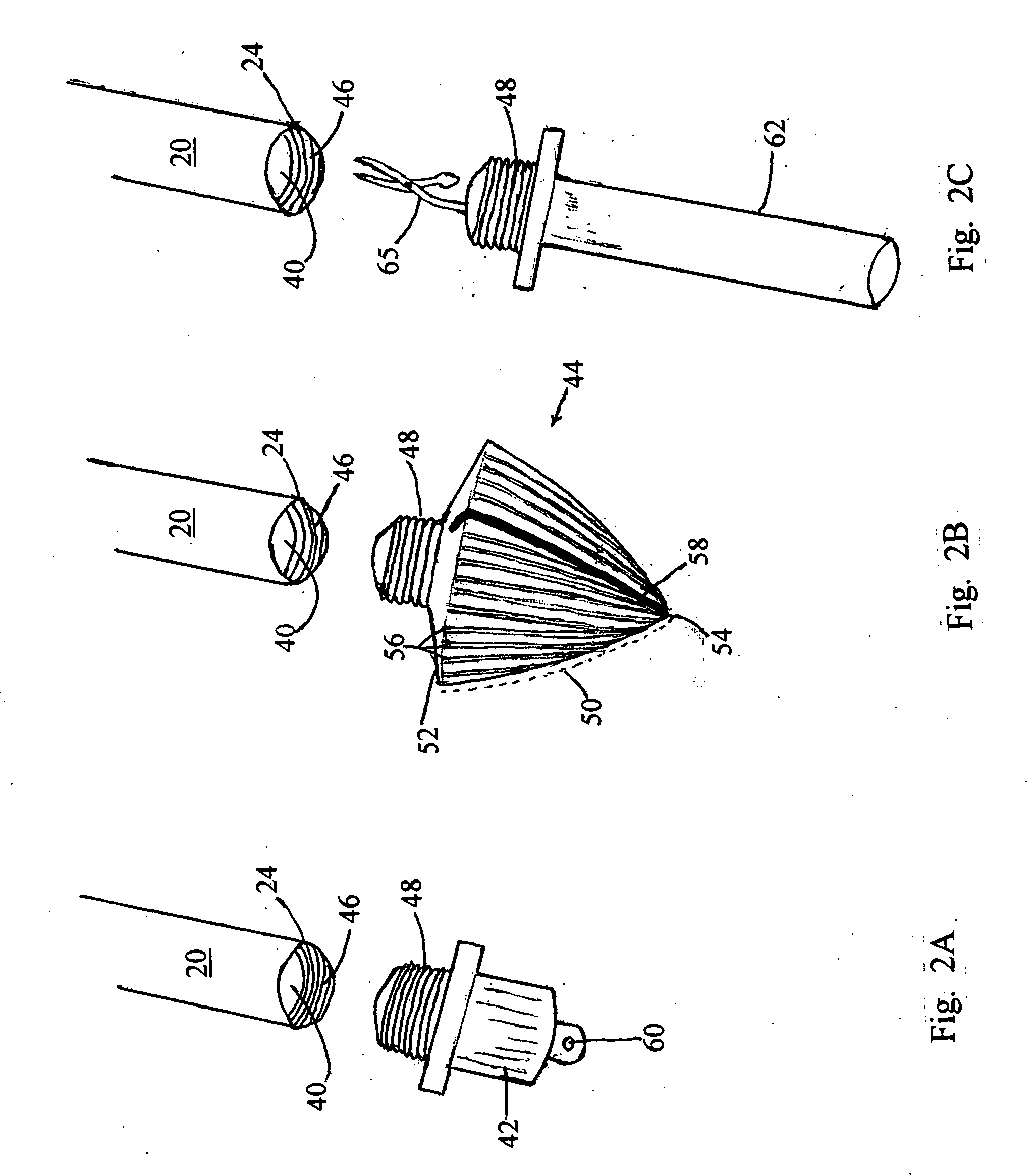

Suture Trimmer

A suture trimmer having a shaft with a groove formed in the side thereof, a cutting member movably disposed within the shaft, and a suture retainer slidably disposed within the shaft. The suture trimmer may be used to position knots formed within a suture loop prior to trimming the free end(s) of the suture loop, and to deliver an agent near the location where the suture is severed.

Owner:ABBOTT LAB INC

Suture trimmer

A suture trimmer having a shaft with a groove formed in the side thereof, a cutting member movably disposed within the shaft, and a suture retainer slidably disposed within the shaft. The suture trimmer may be used to position knots formed within a suture loop prior to trimming the free end(s) of the suture loop, and to deliver an agent near the location where the suture is severed.

Owner:ABBOTT LAB INC

Water balloon tool

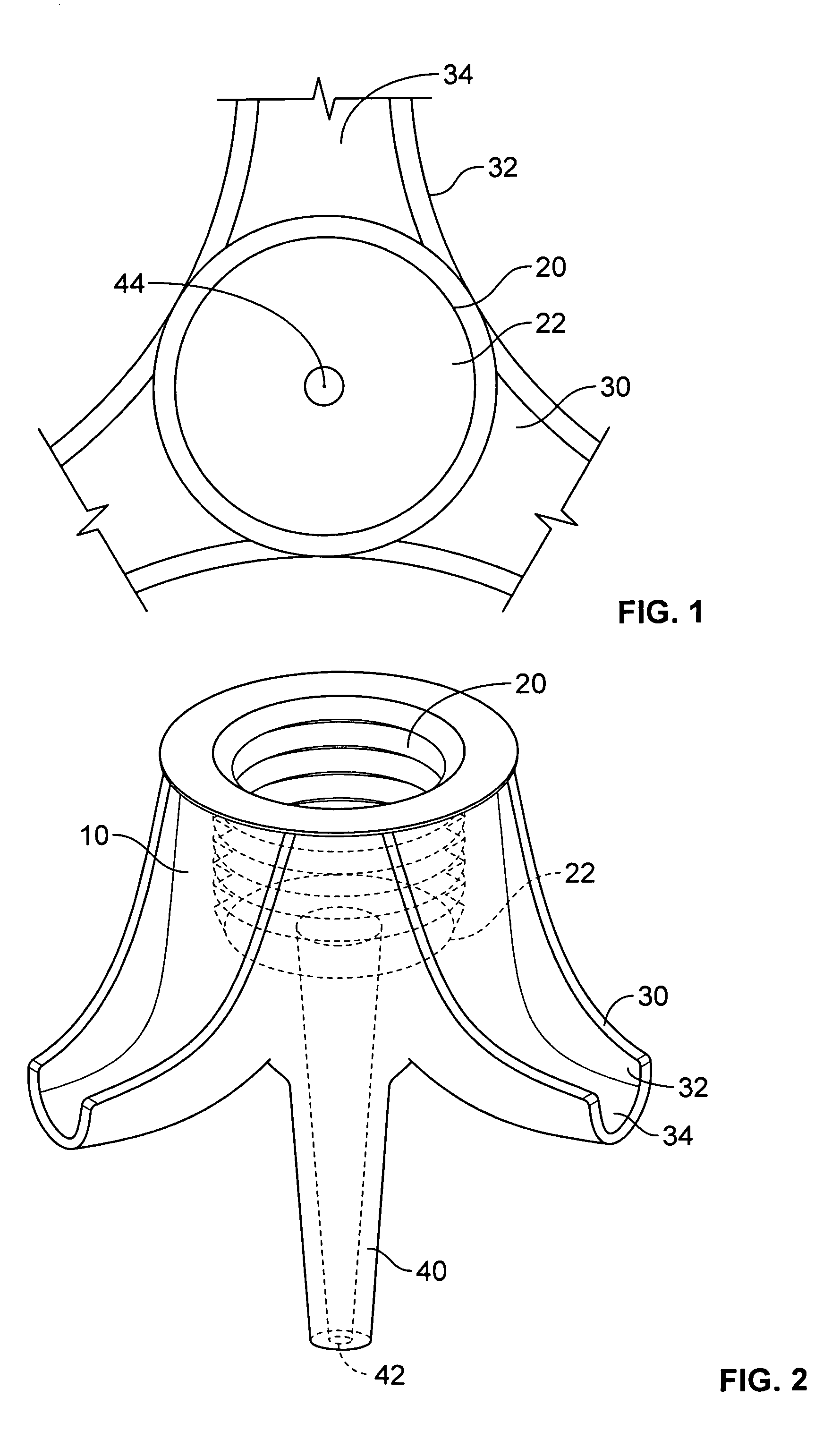

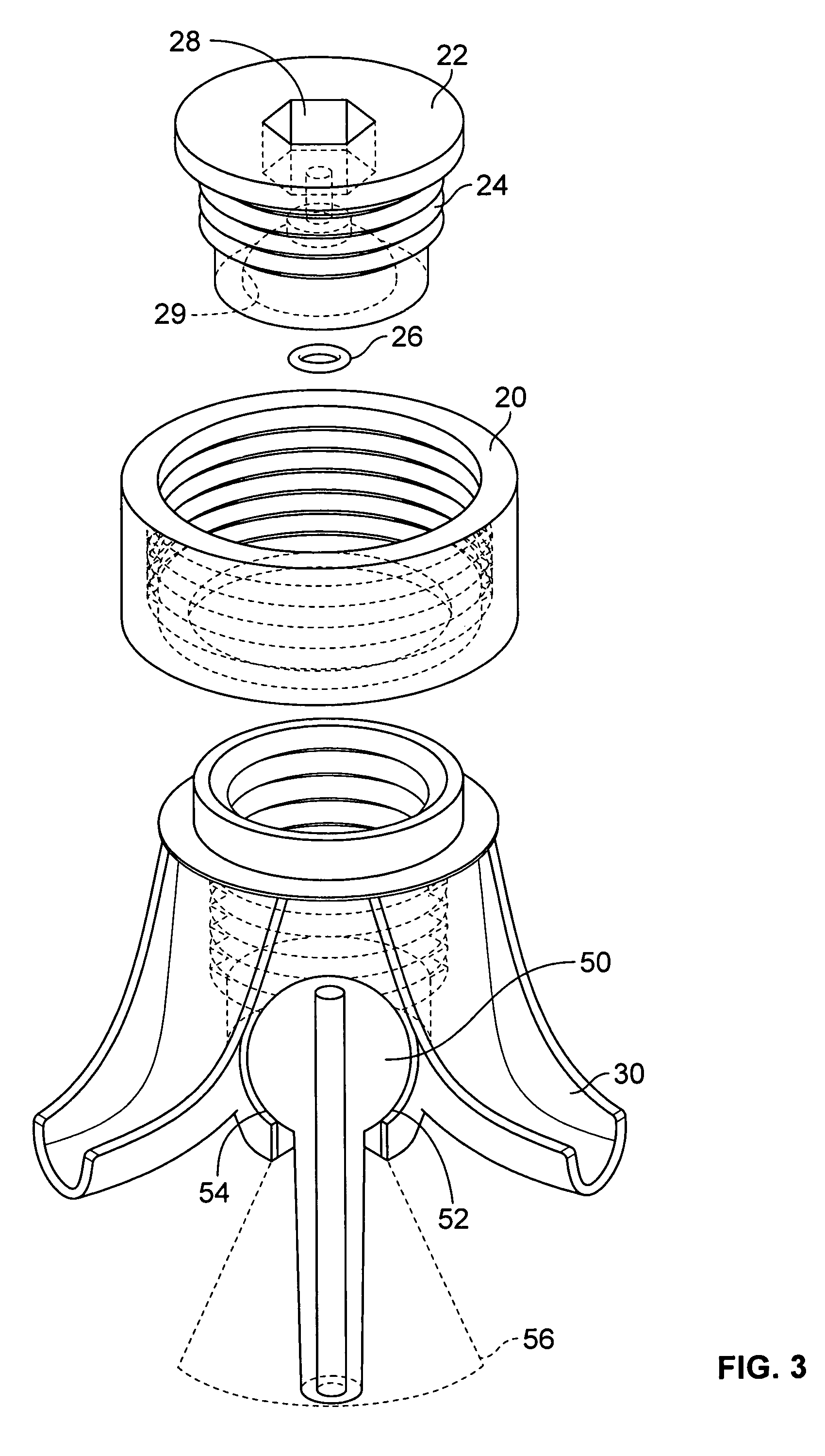

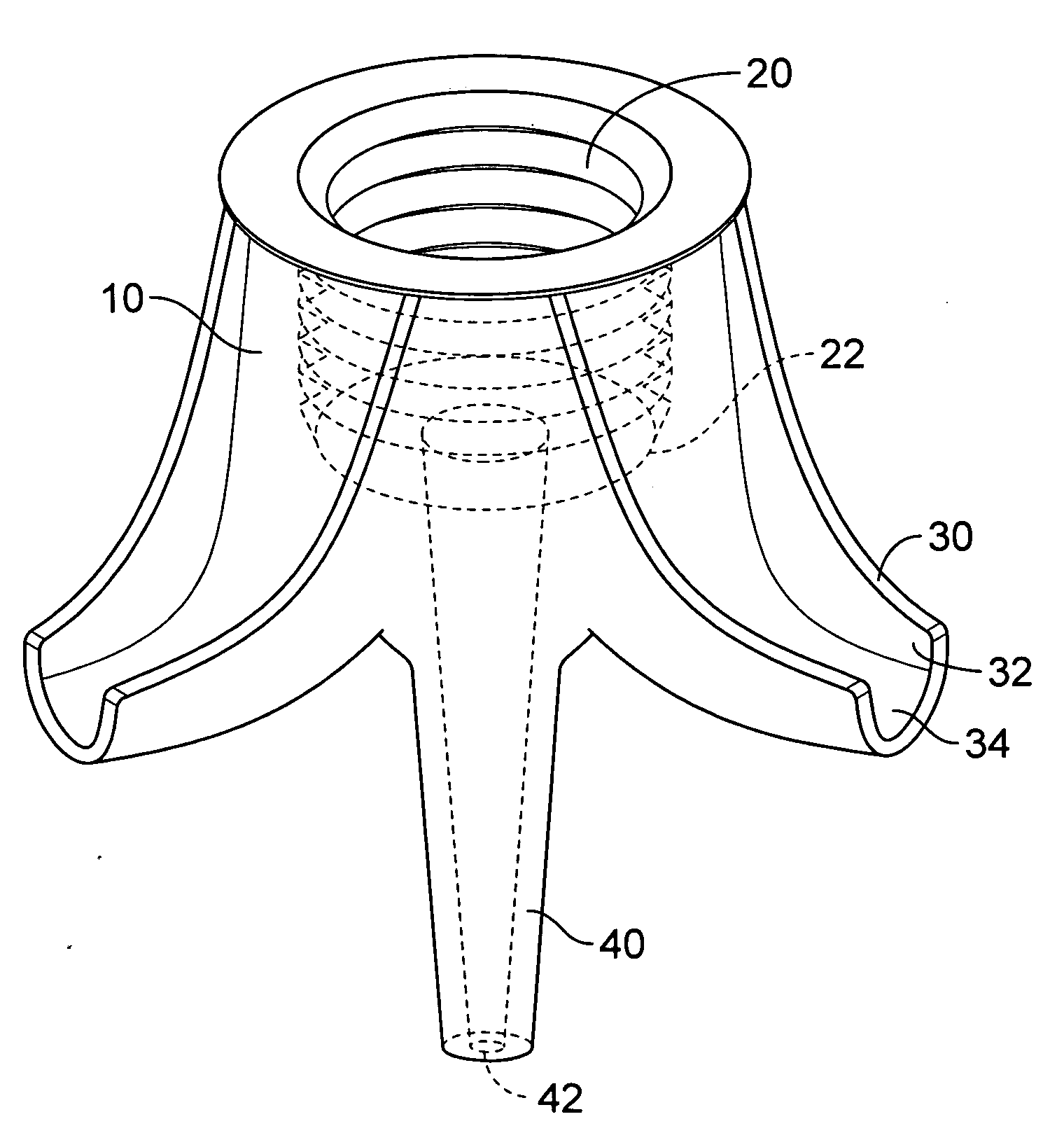

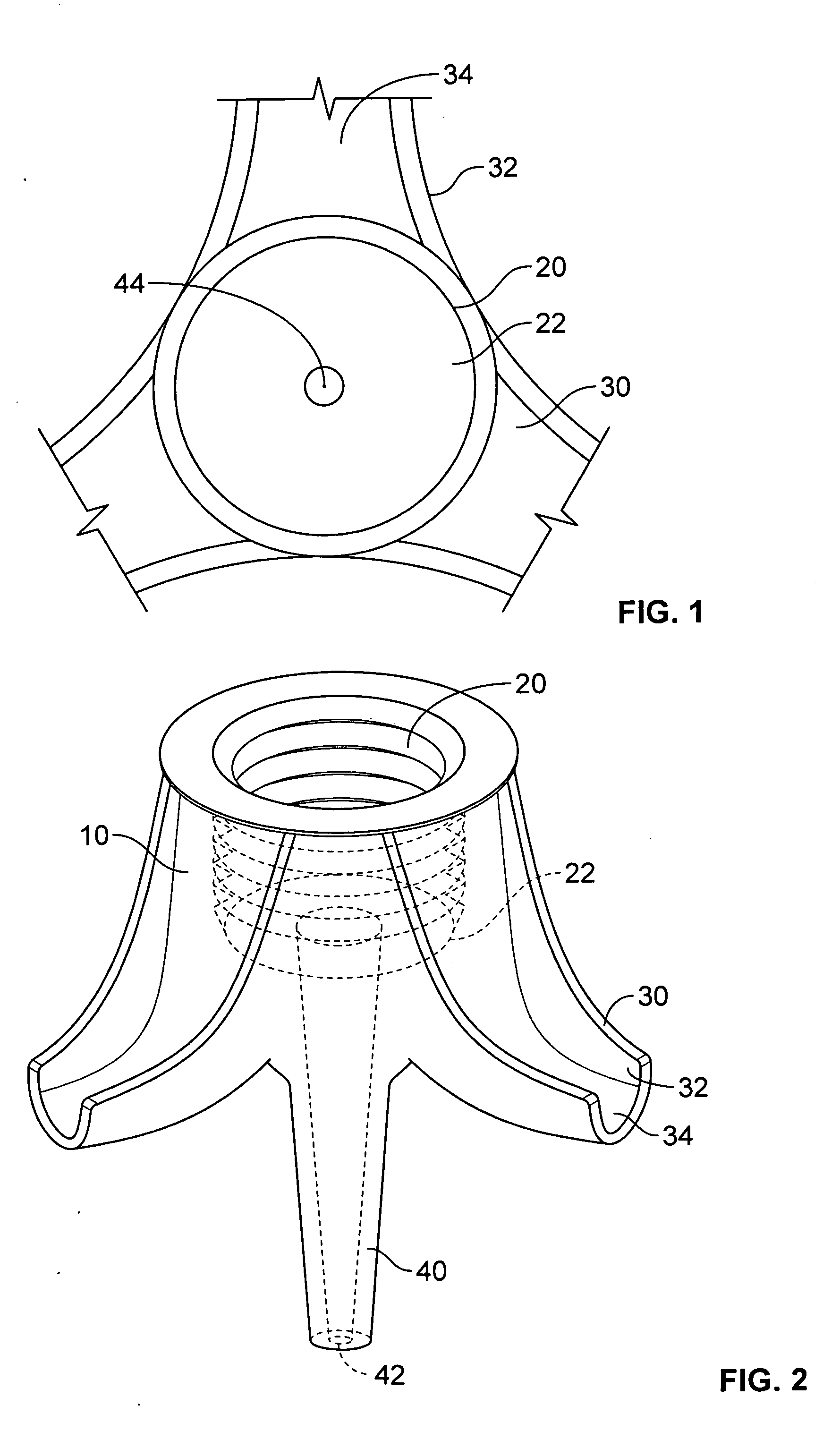

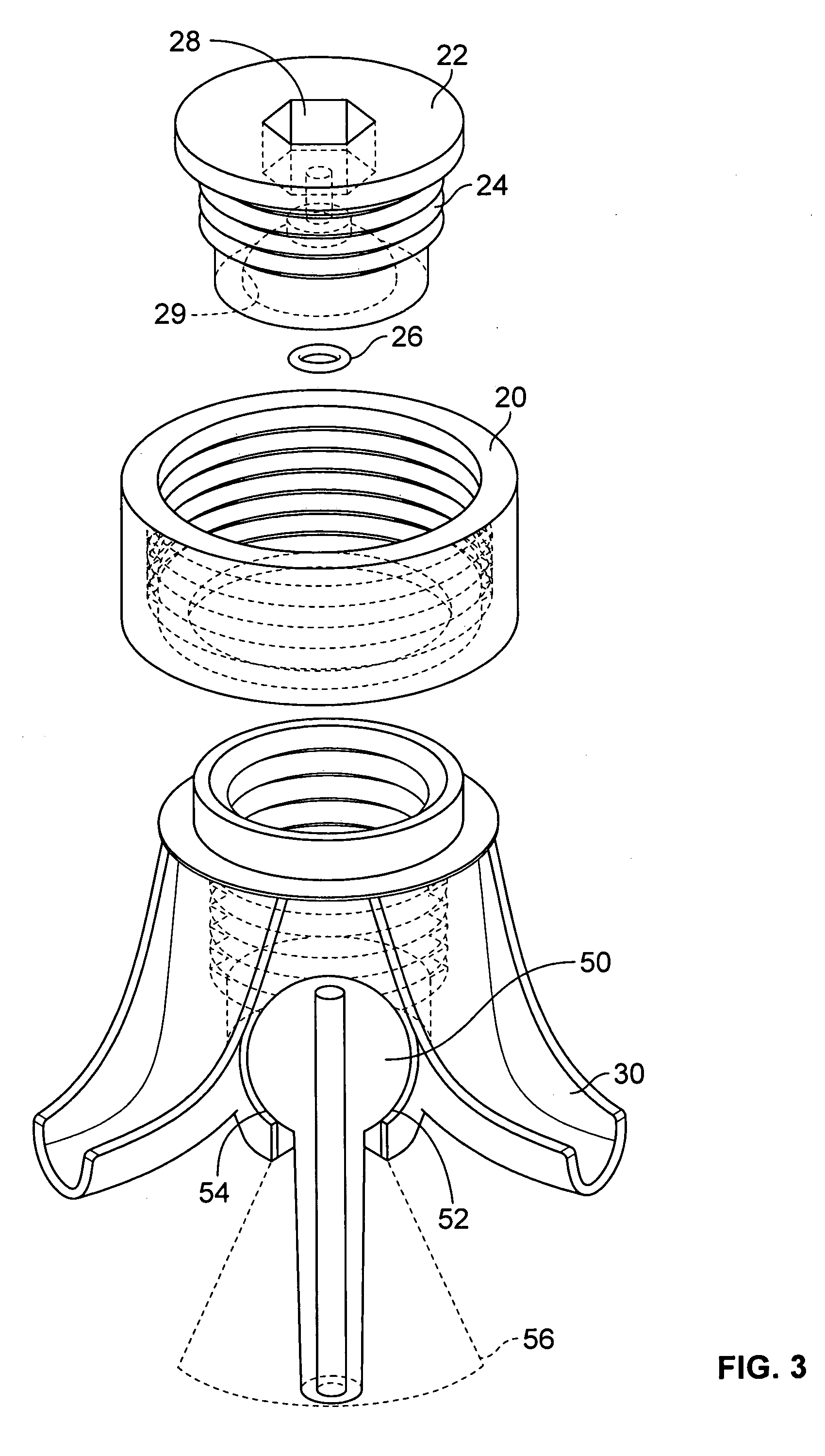

A water balloon fill and knot device has a housing, a hose connector disposed on the housing and also a connector base. A plurality of flanges or noses are disposed on the housing and flanges may include a flange sidewall and a flange bottom wall. A stem has a water channel formed through the stem terminating at a stem opening. The plurality of noses can be two noses placed at 120° from each other or three noses placed at 120° from each other. A ball pivot valve formed on the stem is ball shaped and forms a ball pivot face that pivots relative to a housing pivot lower face. A ball cap fits over the ball pivot valve, and the ball cap has a ball cap lower surface forming a ball cap face. The ball cap face is spherical in profile.

Owner:WANG CHIALEH

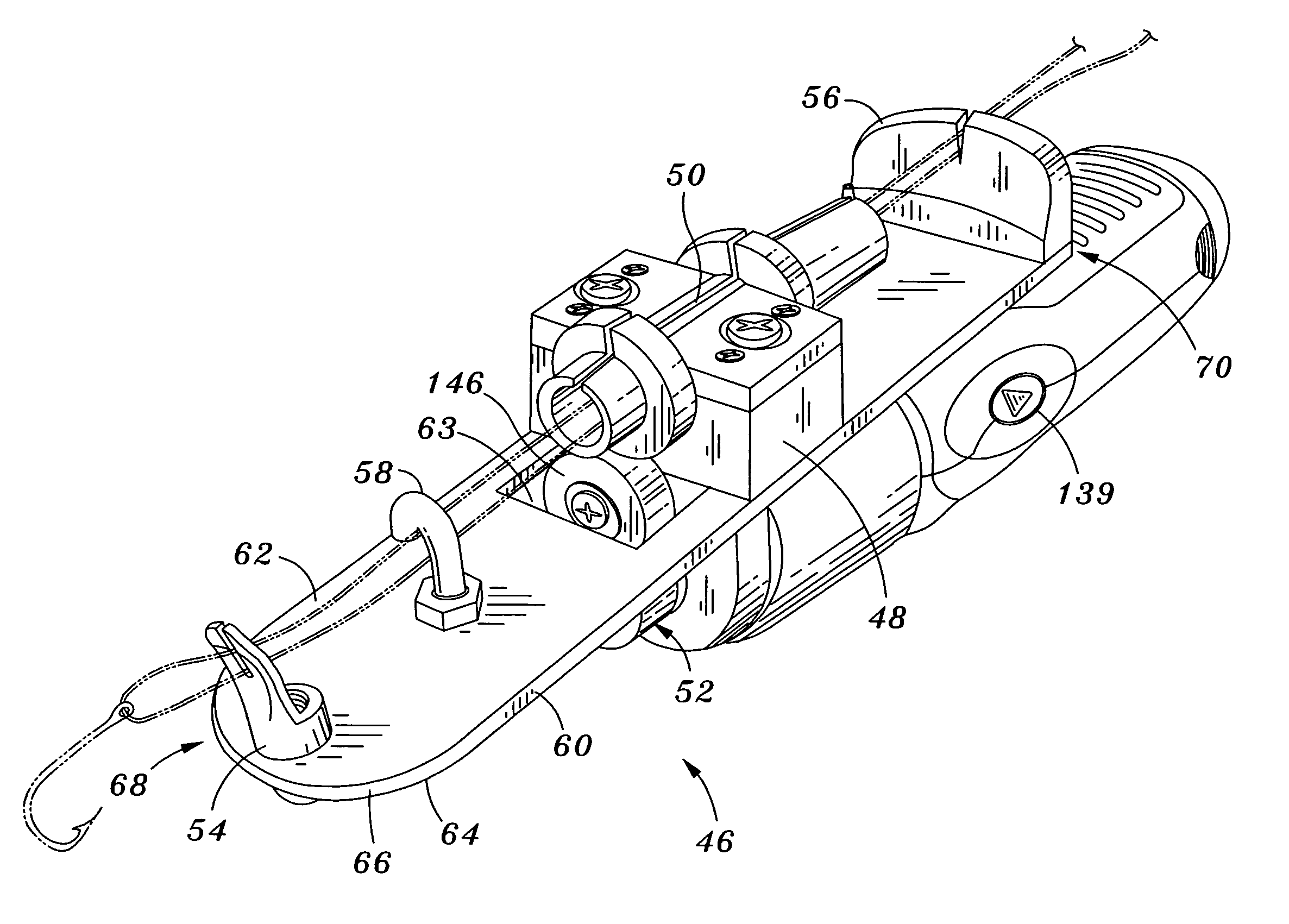

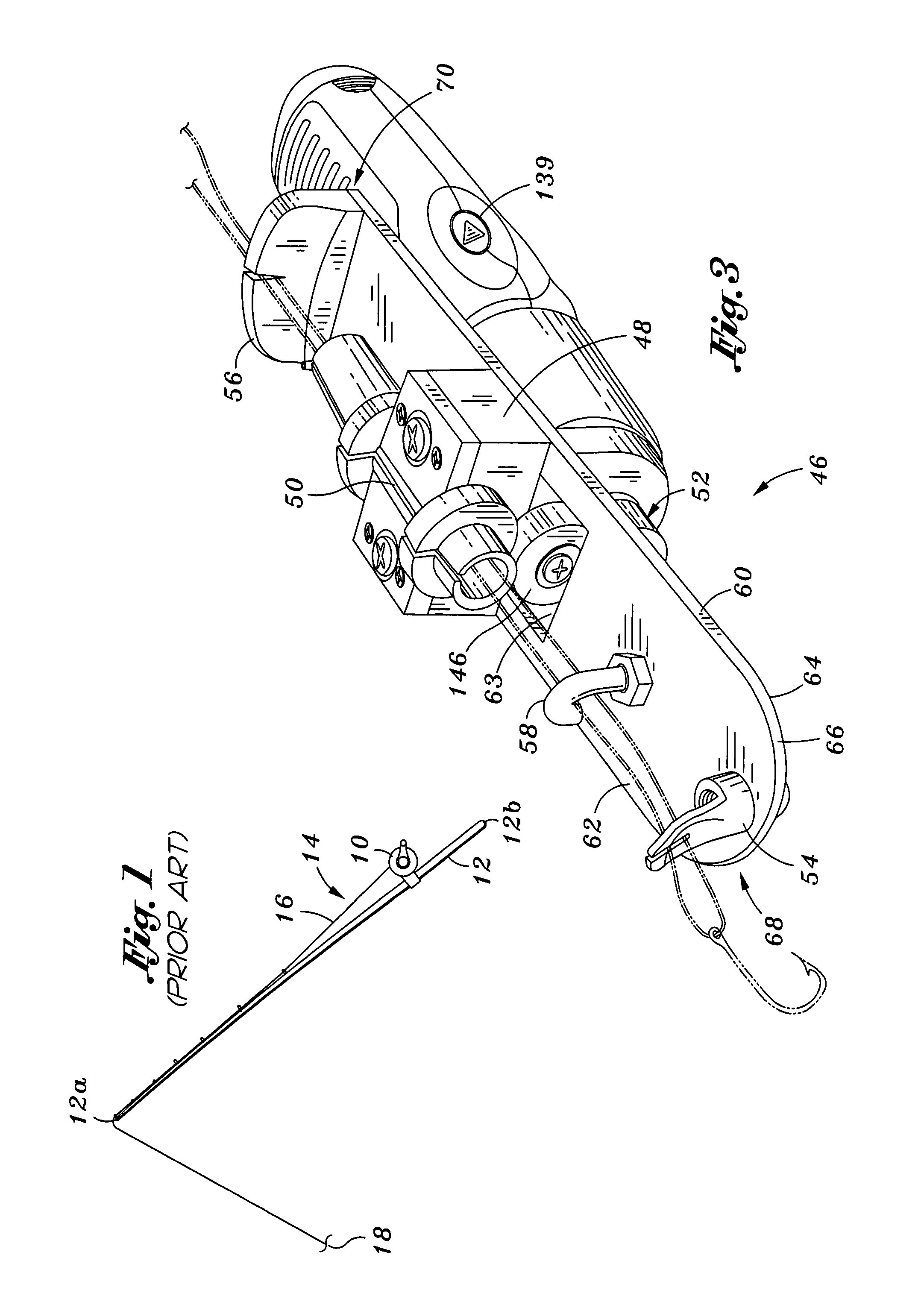

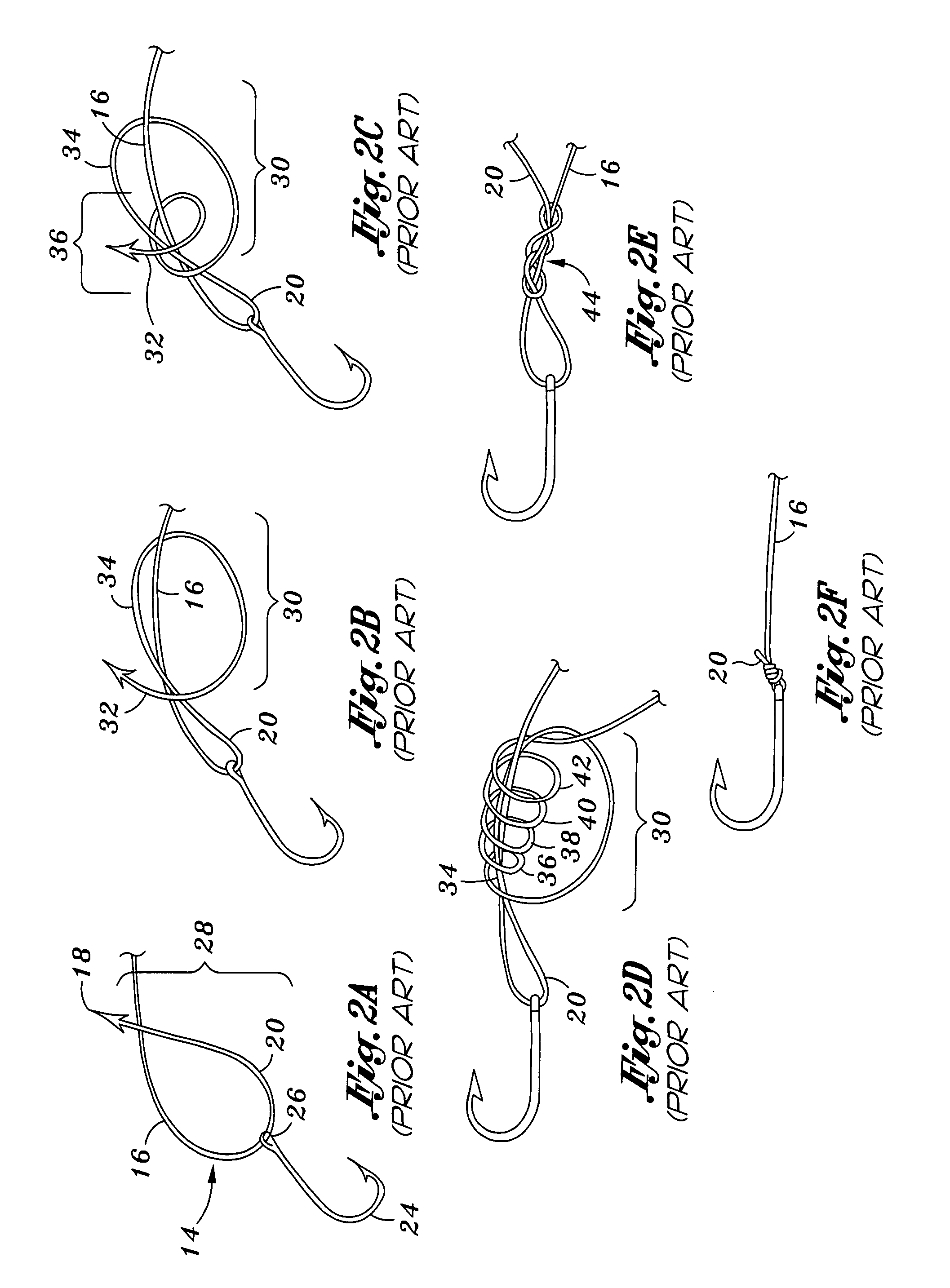

Uni-knot tying apparatus

Disclosed is a uni-knot tying device. The device includes a stator, a hollow cylindrical rotor which is rotatably mounted on the stator, and a rotating drive operatively coupled to the rotor. The rotor has a proximal end and a distal end, and includes a longitudinal slot extending from the proximal end to the distal end. The device also includes a line locking member facing the proximal end of the rotor, as well as a tackle securing member and a line centering member facing the distal end of the rotor. Fishing line is threaded through the hollow cylindrical rotor and then looped around the same, forming a uni-knot.

Owner:CARRIER CALVIN

Water balloon tool

A water balloon fill and knot device has a housing, a hose connector disposed on the housing and also a connector base. A plurality of flanges or noses are disposed on the housing and flanges may include a flange sidewall and a flange bottom wall. A stem has a water channel formed through the stem terminating at a stem opening. The plurality of noses can be two noses placed at 120° from each other or three noses placed at 120° from each other. A ball pivot valve formed on the stem is ball shaped and forms a ball pivot face that pivots relative to a housing pivot lower face. A ball cap fits over the ball pivot valve, and the ball cap has a ball cap lower surface forming a ball cap face. The ball cap face is spherical in profile.

Owner:WANG CHIALEH

Loom for weaving, macramé, and braiding with jewelry

A loom includes a first fork, having a first interchangeable anchor point for a cord; a second fork, having a second interchangeable anchor point for the cord; and a base to retain the first fork and the second fork at generally perpendicular angles to the base. The first and second anchor points are positioned so as to provide an area for a user's hands to be inserted underneath the cord and between the forks to allow the hands to manipulate jewelry items into the cord. A tall fork and a short fork support the attachment points perpendicular to the base. The interchangeable anchor points are selectable between dowels and threaded warp bolts.

Owner:SPEAR SHERRY

Balloon Tying Apparatus and Method

ActiveUS20110253255A1Efficient and fast processingEfficient retrievalLiquid fillingPackaging eggsGeneral surgery

Owner:DELLAQUILA PETER JAMES

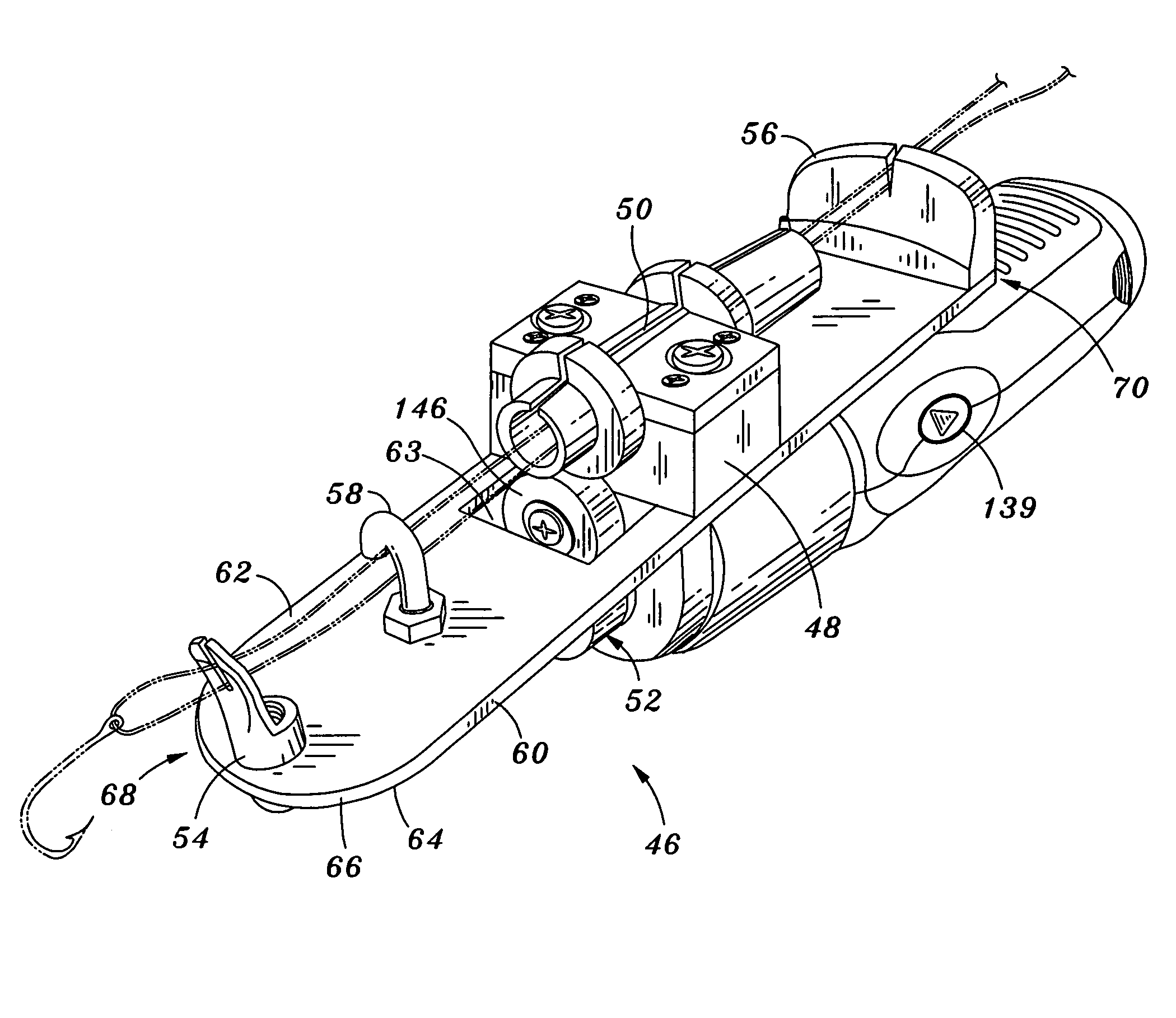

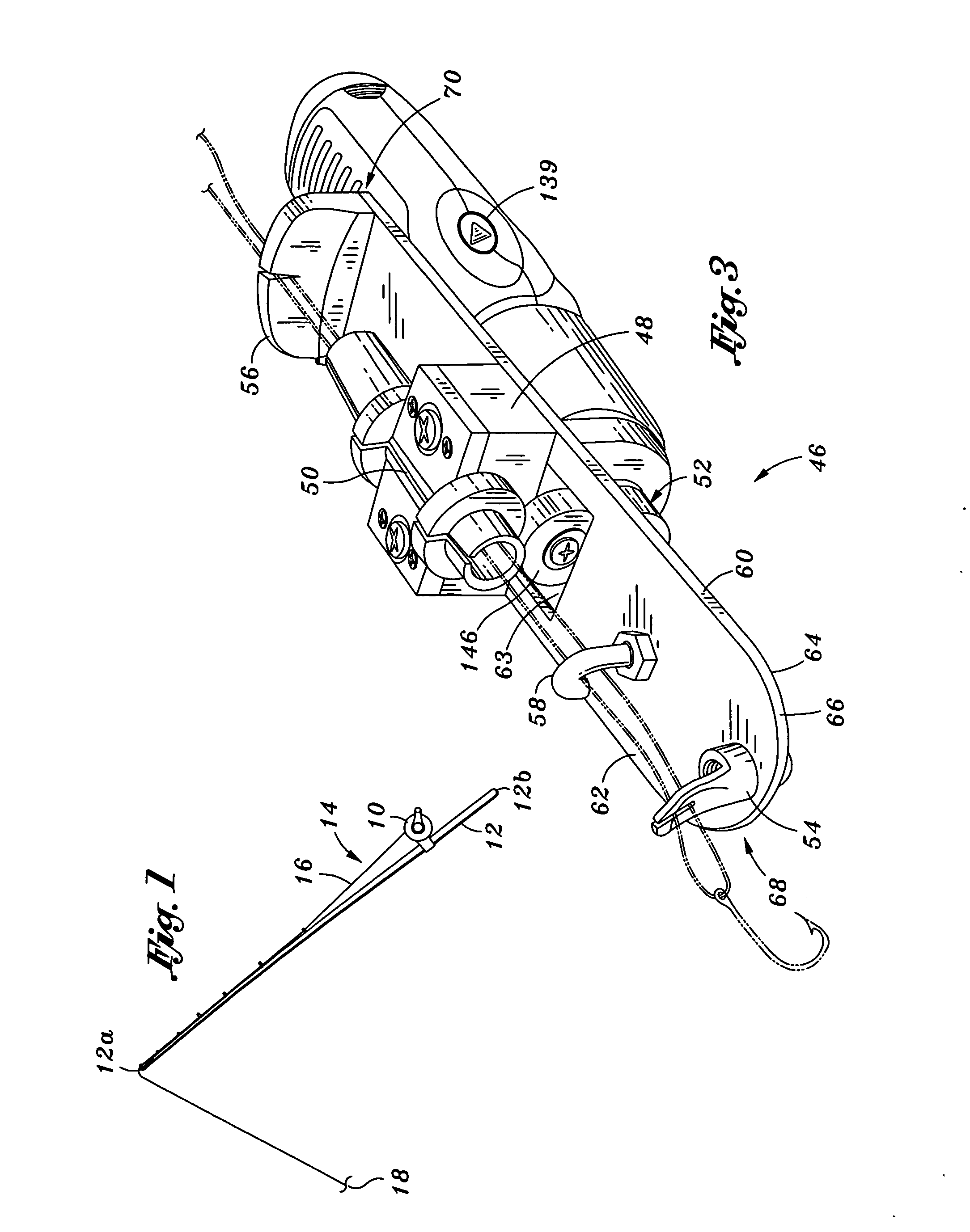

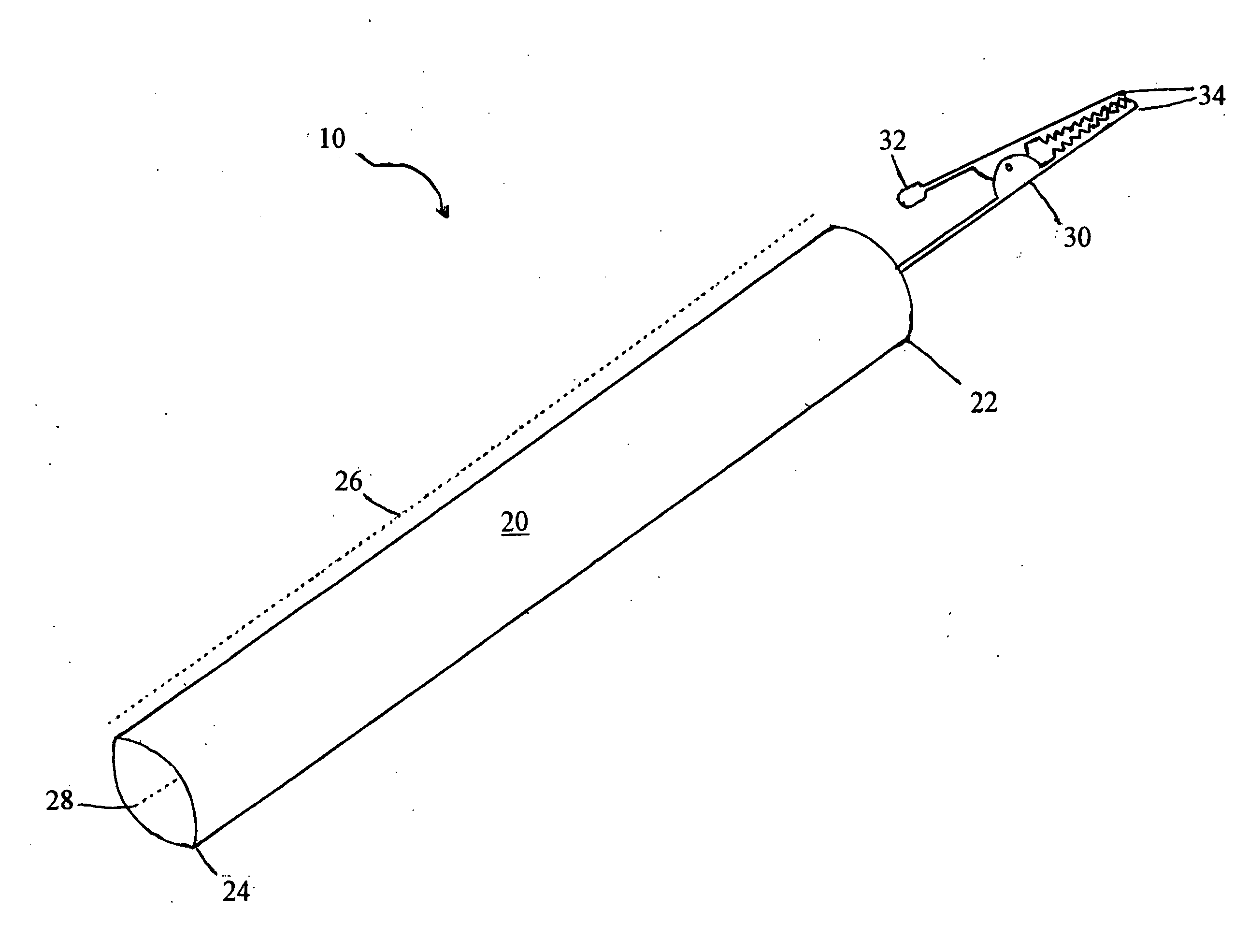

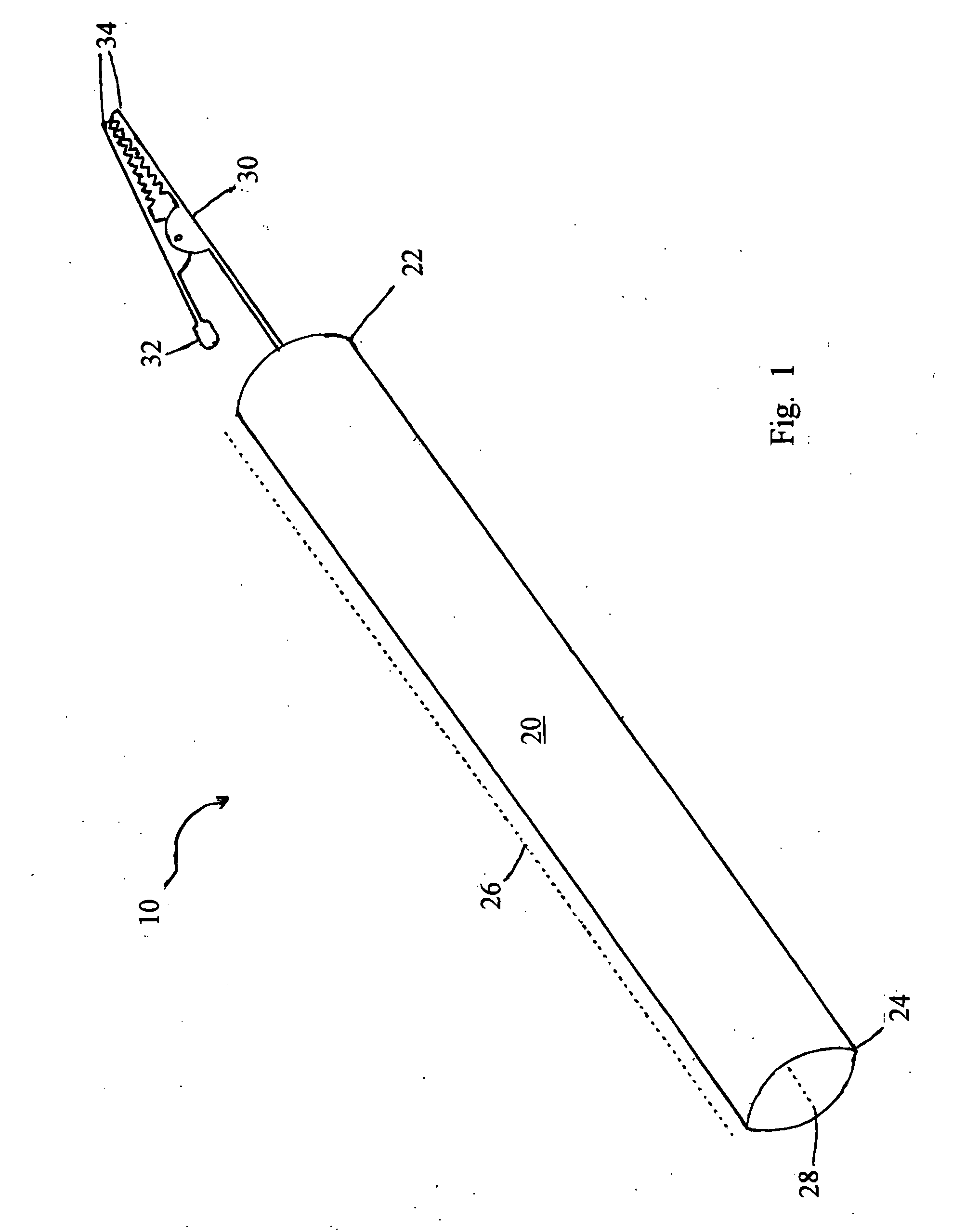

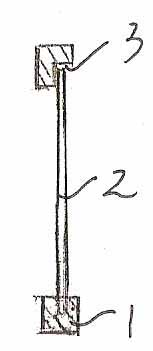

Apparatus for tying fishing line to fishing tackle and methods for use

InactiveUS20050116471A1Reduce effortReduce the amount of timeLinesWeaver's toolsEngineeringAlligator

An apparatus used to tie fishing line to fishing tackle, and the procedures developed to be used specifically with the apparatus to form certain knots used in sport fishing. The gross structure of the apparatus is a rod with a securing device, such as an alligator clip, attached to one end. The fishing tackle may be secured to the apparatus using the securing device. Then the fishing line may be threaded through the appropriate structure of the fishing tackle, and the apparatus manipulated to produce the desired knot.

Owner:MUIR MYRON R +2

Knot tying tool

A knot tying tool for tying knots in cords or lines of material including those for attaching the line to an eyelet of an object, includes a base member having first and second ends, a first post extending from the first end of the base member, a second post extending from the second end of the base member, a loop retainer operatively associated with the second post for retaining a portion of one loop of a line forming part of a knot being tied, wherein the line includes a working end and a standing end, a support member operatively associated with the first post, wherein the support member includes a catch positioned spaced apart from the loop retainer for holding a portion of the retained loop of the line, and a rotatably-actuated clamp assembly for receiving and releasably retaining the standing end of the line.

Owner:JOCHUM WOLFGANG

Balloon-tying device

A balloon-tying device for assisting in tying a balloon is provided, the balloon having a filling end. The balloon-tying device comprises a base having a top surface and a bottom surface substantially opposite the top surface. A pair of spaced tying prongs is provided with each having a base end and a top end and the base ends of the tying prongs secured to the top surface of the base. A ridge extends from the top end of each of the tying prongs wherein the filling end of the balloon is wrappable around the tying prongs and fed between the tying prongs and wherein the ridges maintain the filling end of the balloon from inadvertently slipping from the tying prongs during the tying process.

Owner:HEMINGWAY FR S

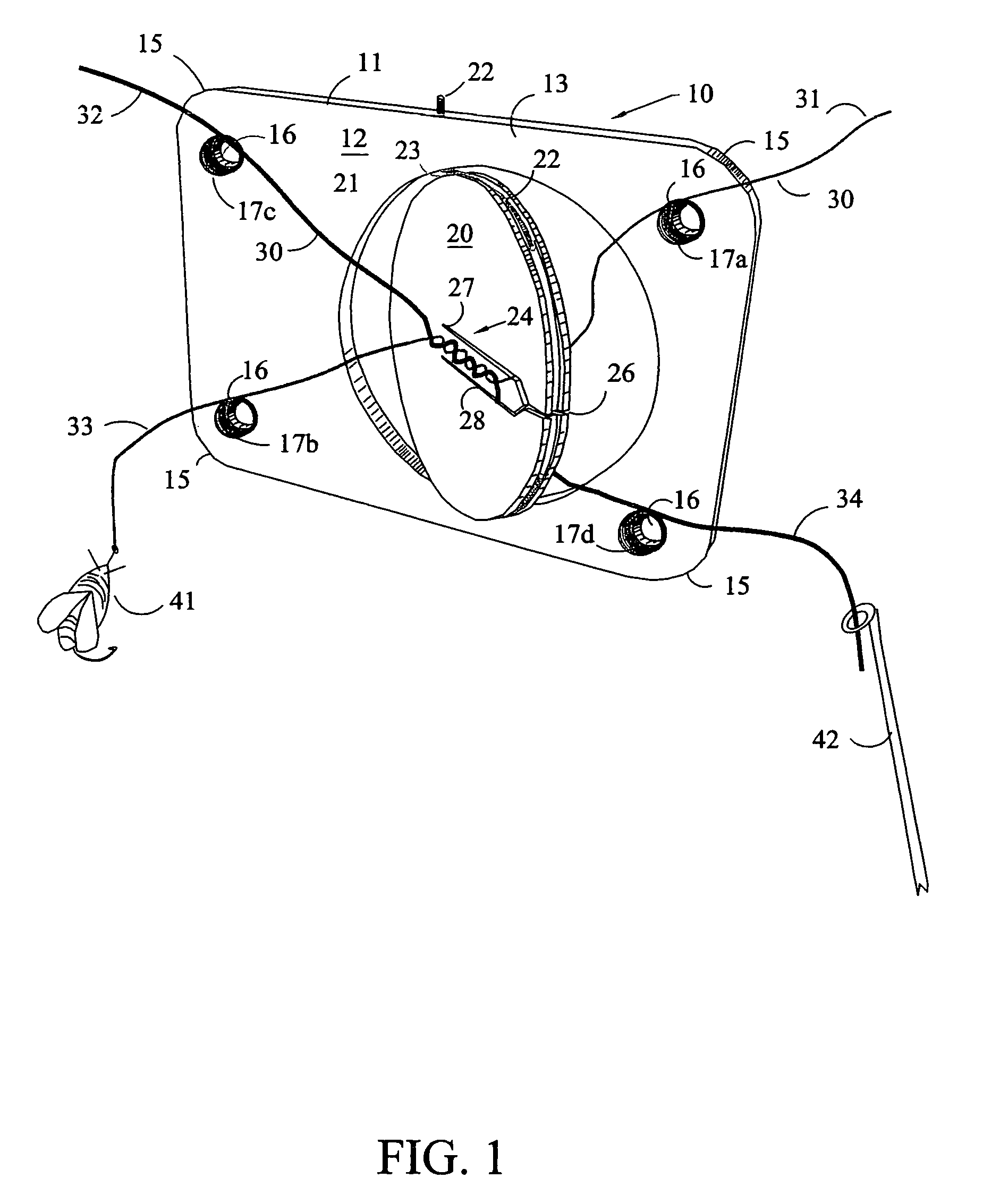

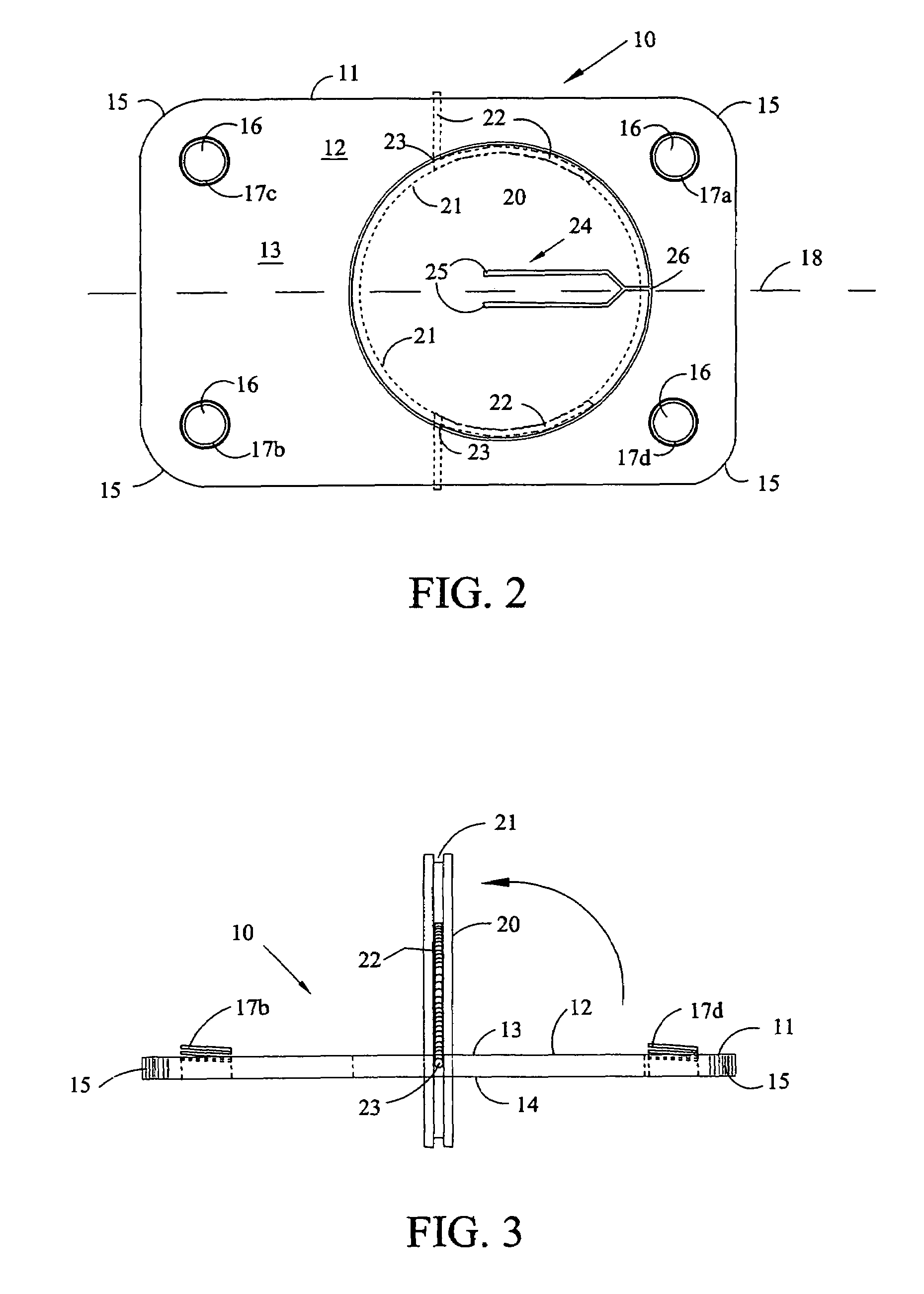

Knot-tying device for joining fishing leaders

A knot-tying device with a rectangular card body made of rigid, buoyant material, including a retaining means for entraining separate leader lines in crossing diagonal relation, and a swivel disc cut from said card body, adapted to pivot in the card body. The swivel disc contains a bifurcated slot having closed ends extending to a single open end, receiving separate leader lines, for easy manipulation by fishermen with limited dexterity. The device is not costly to manufacture, small and easily stored, with few movable parts and withstands vigorous use. The operator swivels the disc, entrains the tag ends of the leader lines as well as the remaining lines in the card body, and the lines in the swivel disc slots. The operator rotates the swivel disc, forming the knot, then threads the tag ends through the gap in the knot, completing the knot-tying process.

Owner:HOWELL CHARLES FRANCIS +1

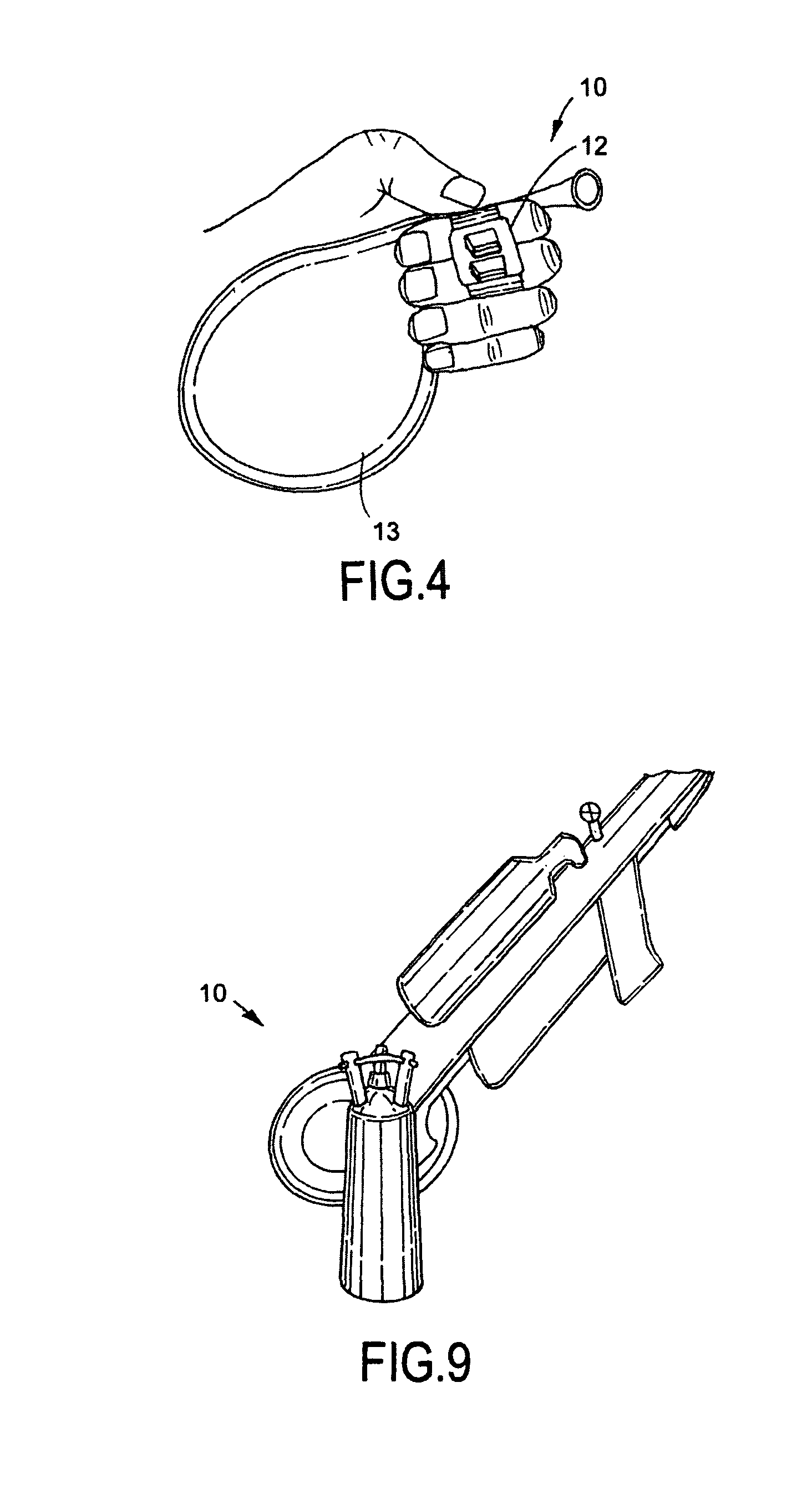

Stop knot tying device

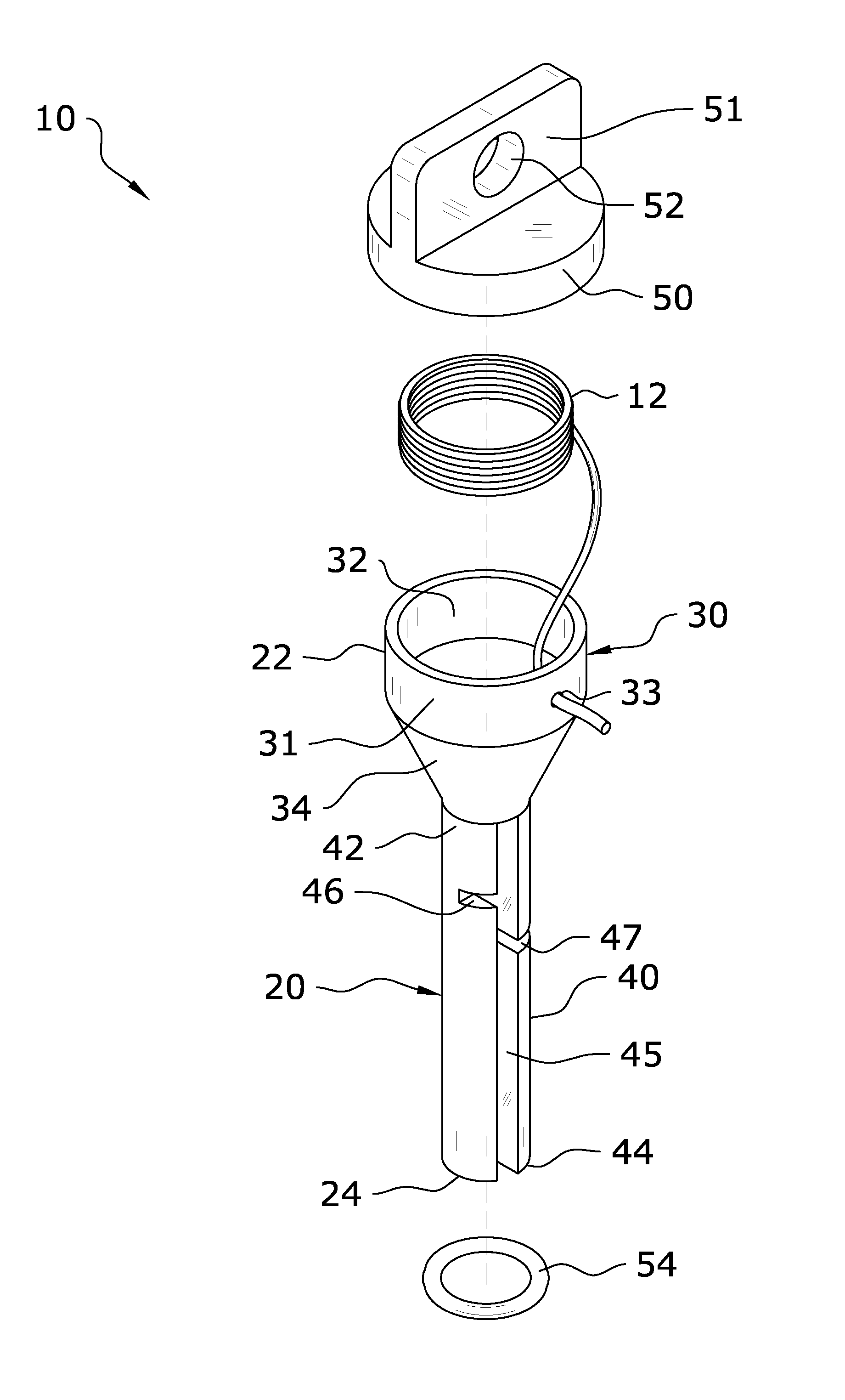

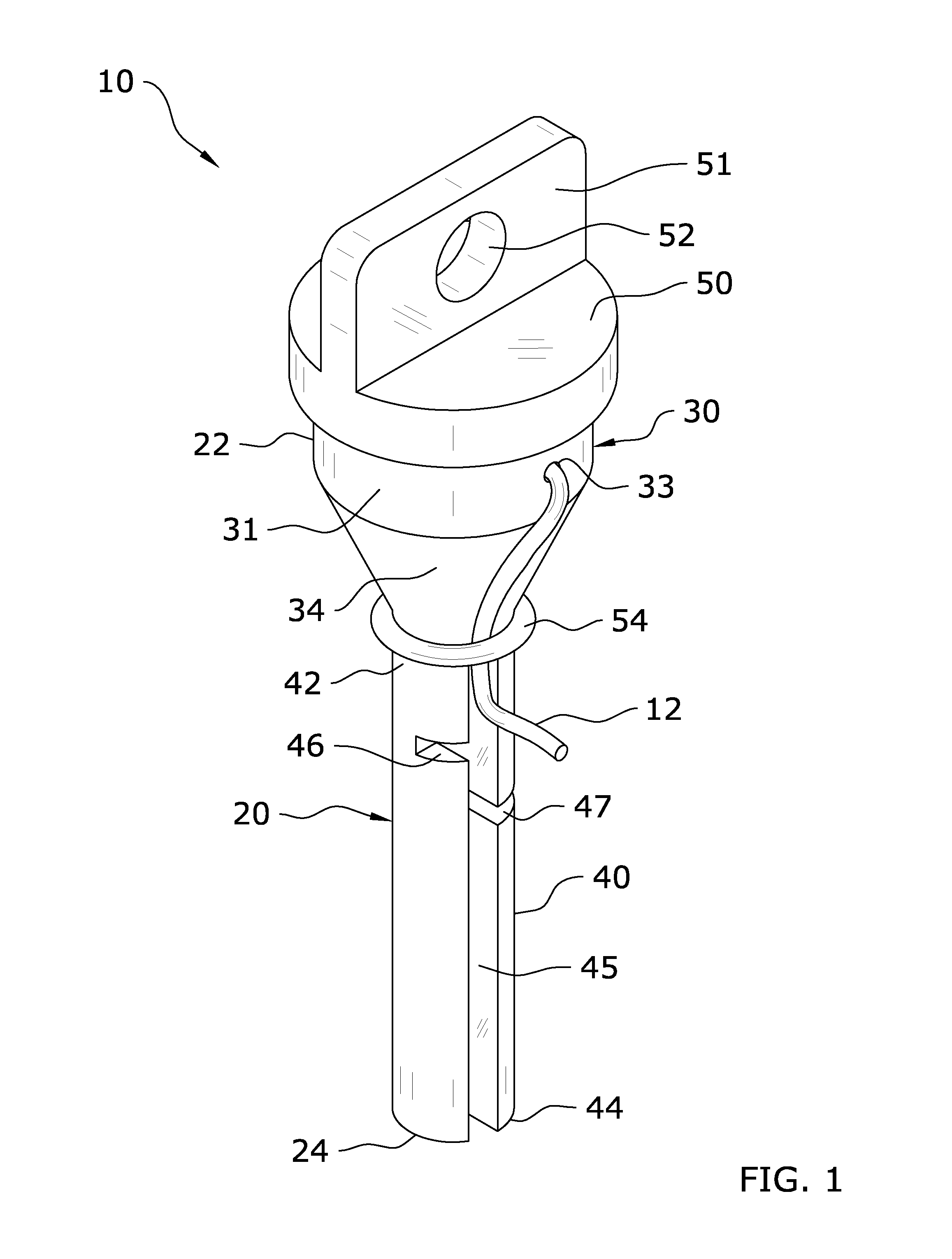

A stop knot tying device which aids with tying a stop knot directly on a fishing line for use with a slip bobber. The stop knot tying device generally includes a main body having a retainer portion and an elongated portion extending therefrom. The retainer portion includes a ring member and funnel member which act to retain a coil of string. A distal, free end of the coil of string exits the retainer portion through an aperture on its ring member. The elongated portion includes a slot running along its length and at least one notch. By positioning a fishing line within the slot through one of the notches and winding a cut-away portion of string around the line, one can utilize the present invention to efficiently and safely tie a stop knot on a fishing line.

Owner:BERDAHL BRIAN R

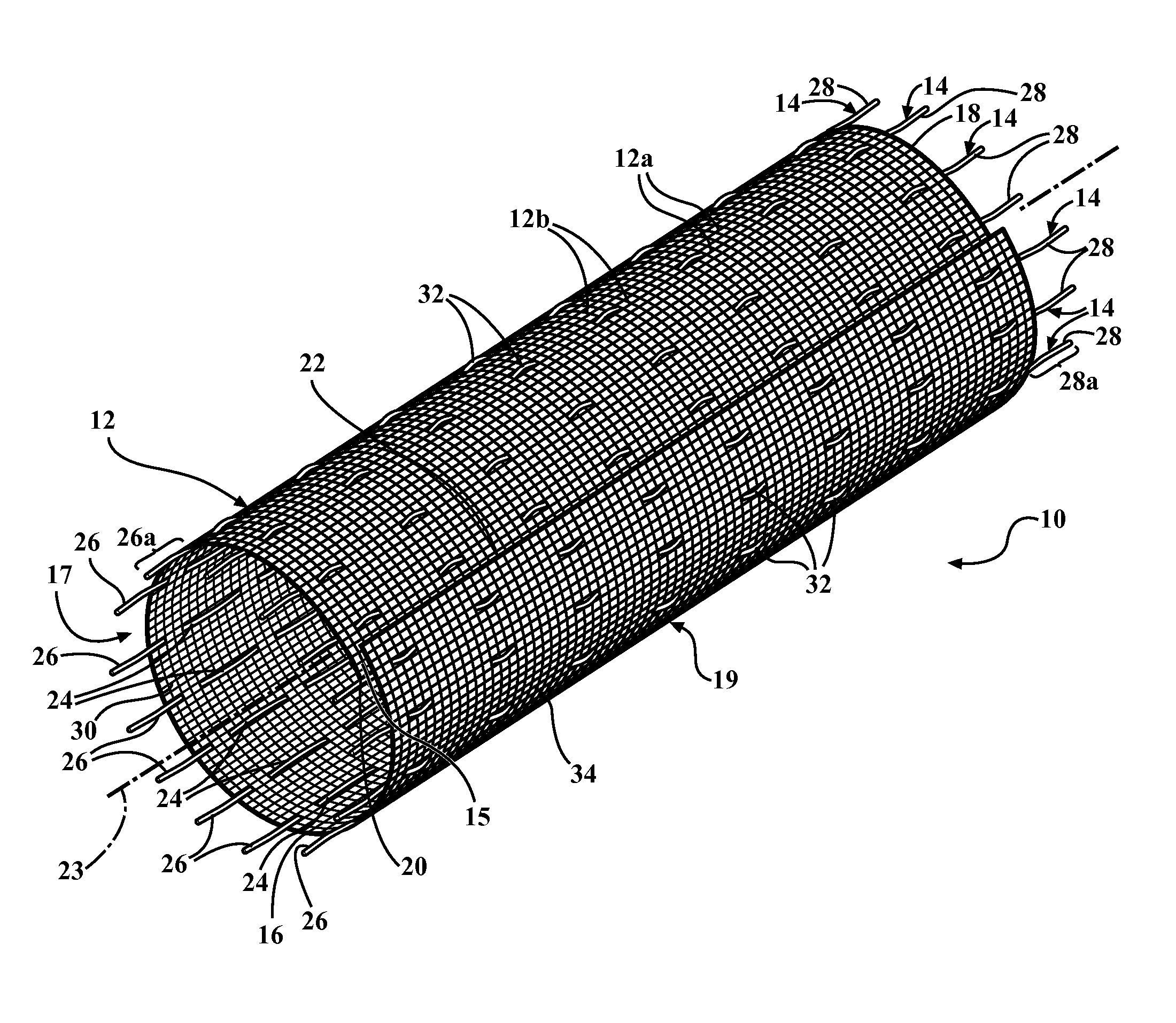

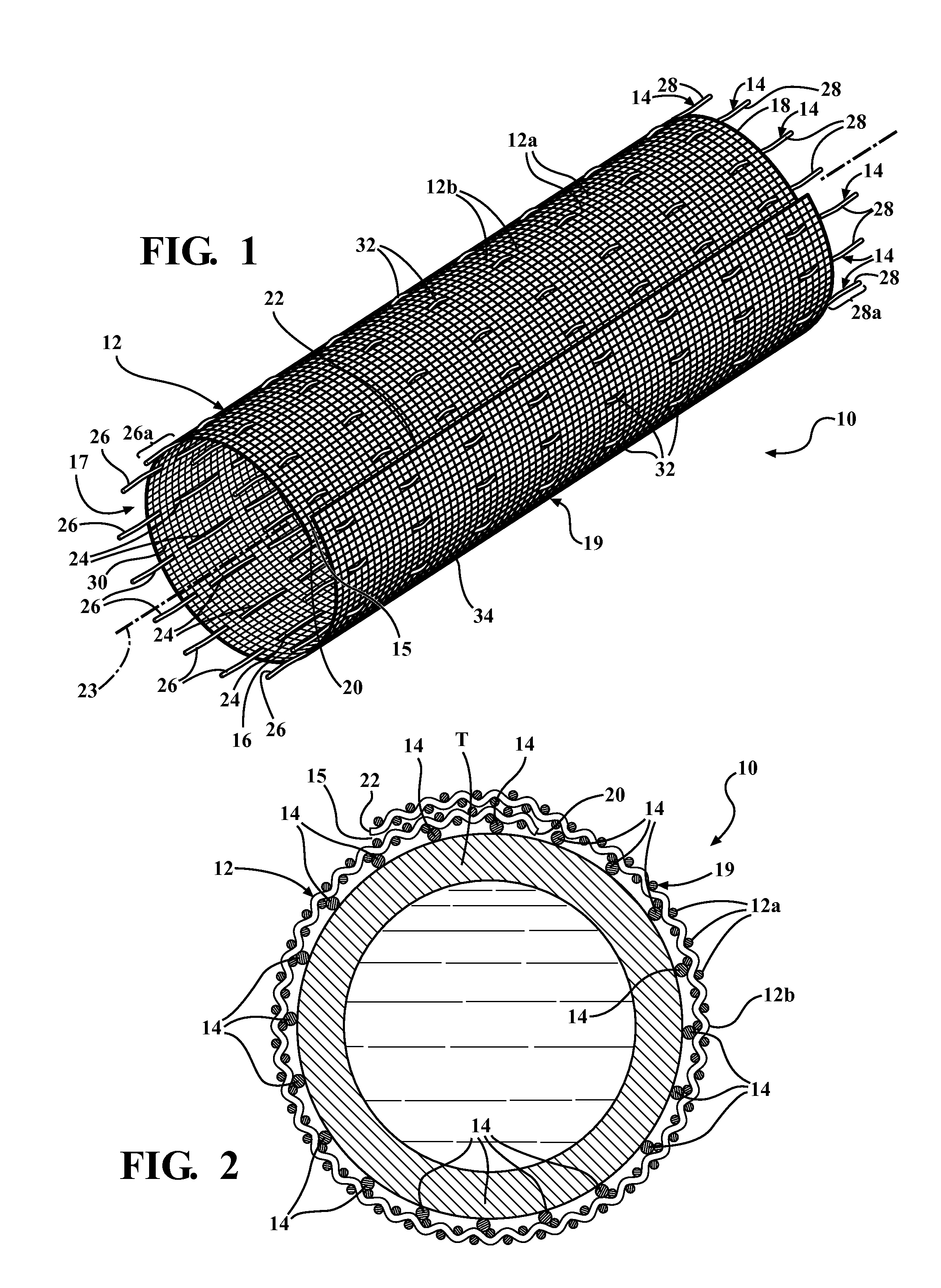

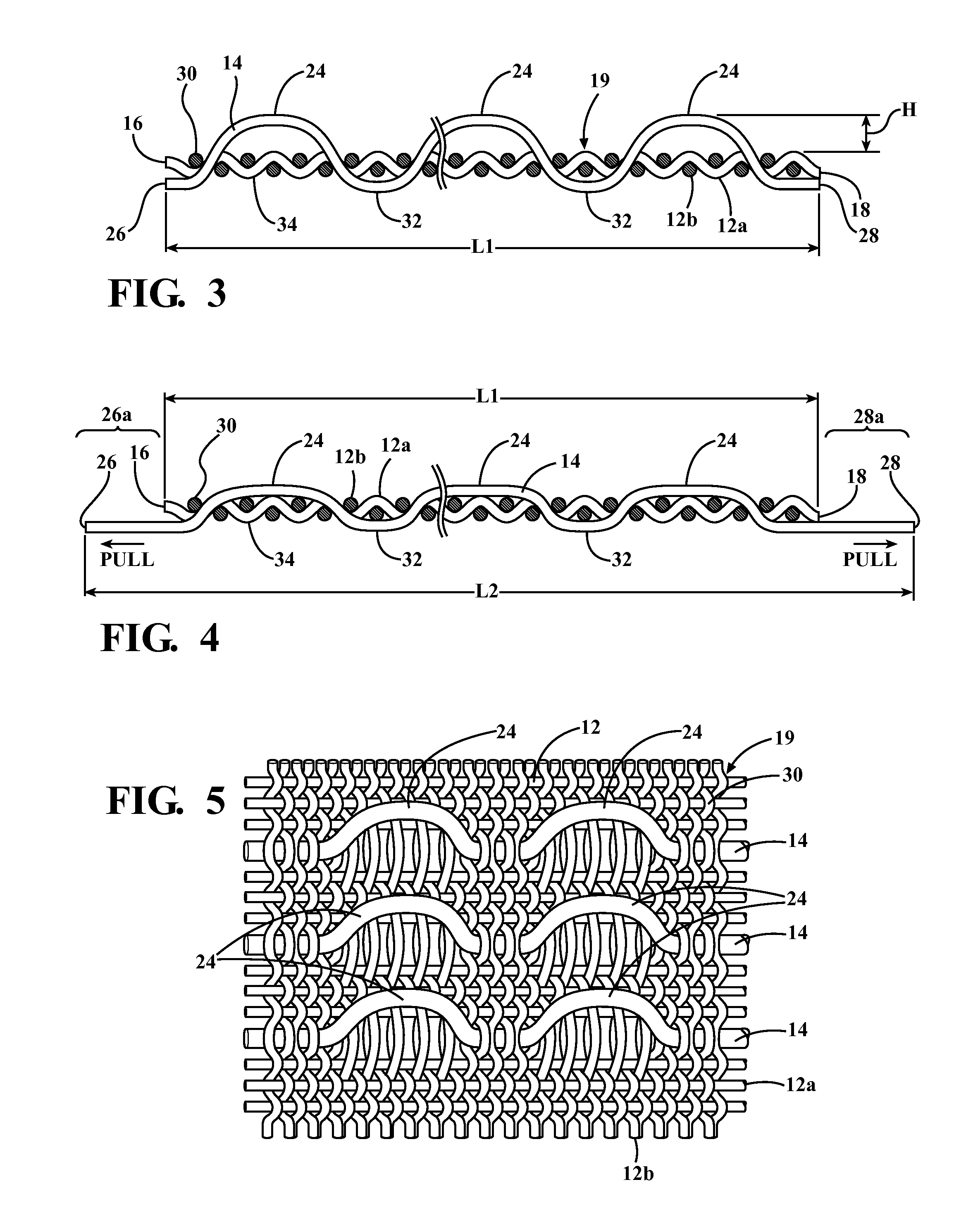

Wrappable textile sleeve with extendable electro-functional yarn leads and method of construction thereof

ActiveUS20140305536A1Maximize effectivenessMaximize contact areaOhmic-resistance electrodesAuxillary apparatusYarnEngineering

A wrappable textile sleeve and method of construction thereof is provided. The sleeve has a wall of interlaced yarn with opposite edges extending lengthwise between opposite ends. The opposite edges of the wall are wrappable to overlap one another to form a tubular cavity. At least one electro-functional member extends lengthwise between the opposite ends of the wall. The at least one electro-functional member is interlaced in the wall at a plurality of nodes and forms at least one unrestrained loop intermediate the opposite ends of the sleeve. The at least one electro-functional member has a straightened length that is greater than the straightened length of the sleeve, thereby allowing opposite ends of the at least one electro-functional member to be pulled axially outwardly away from the ends of the sleeve to form leads for attachment to a power source, which in turn constricts the at least one loop.

Owner:FEDERAL MOGUL POWERTAIN LLC

Balloon filling and tying device

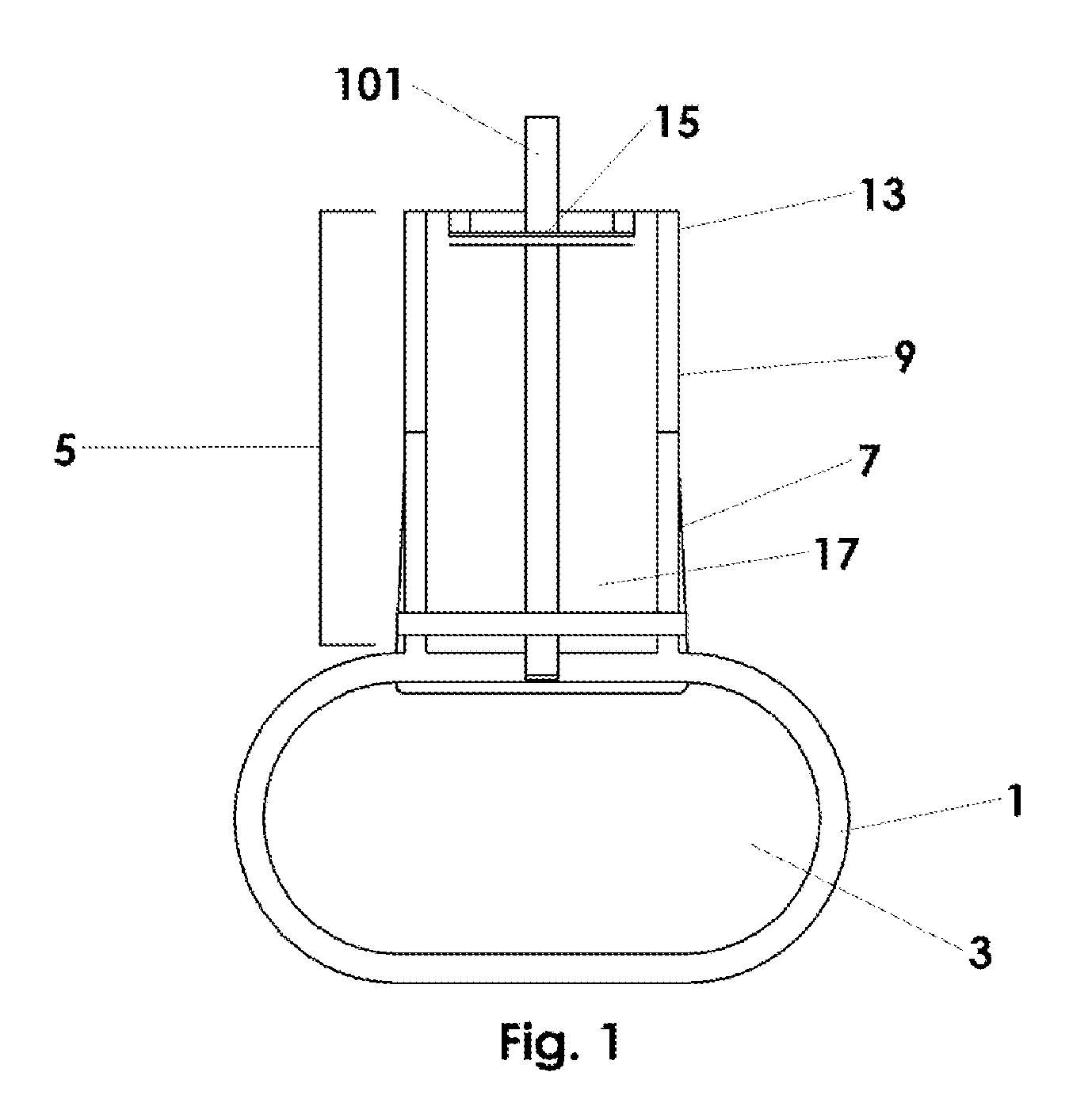

An apparatus for filling a balloon with a fluid and tying a knot in the neck of the balloon, having a filling device body engaging a source of fluid under pressure. A balloon barb extends outwards from the body, and a fluid passageway in the body communicates with a control to allow the passage of fluid from the source to the balloon barb. A tying device extends from the body substantially parallel to the balloon barb, the tying device being detachable from and reattachable to a receptacle in the body of the filling device. A keyway is located either the tying device or an inner surface of the receptacle, and a key is located in the other of the tying device or the receptacle. The key corresponds in dimensions to fit in the keyway, where the key removably fits into the keyway when the tying device is inserted in the receptacle of the body of the filling device. A snap fit removably holds the tying device in the receptacle, and an elongated nozzle flange on the balloon barb prevents leakage of fluid when the balloon is being filled.

Owner:SIKORCIN WAYNE

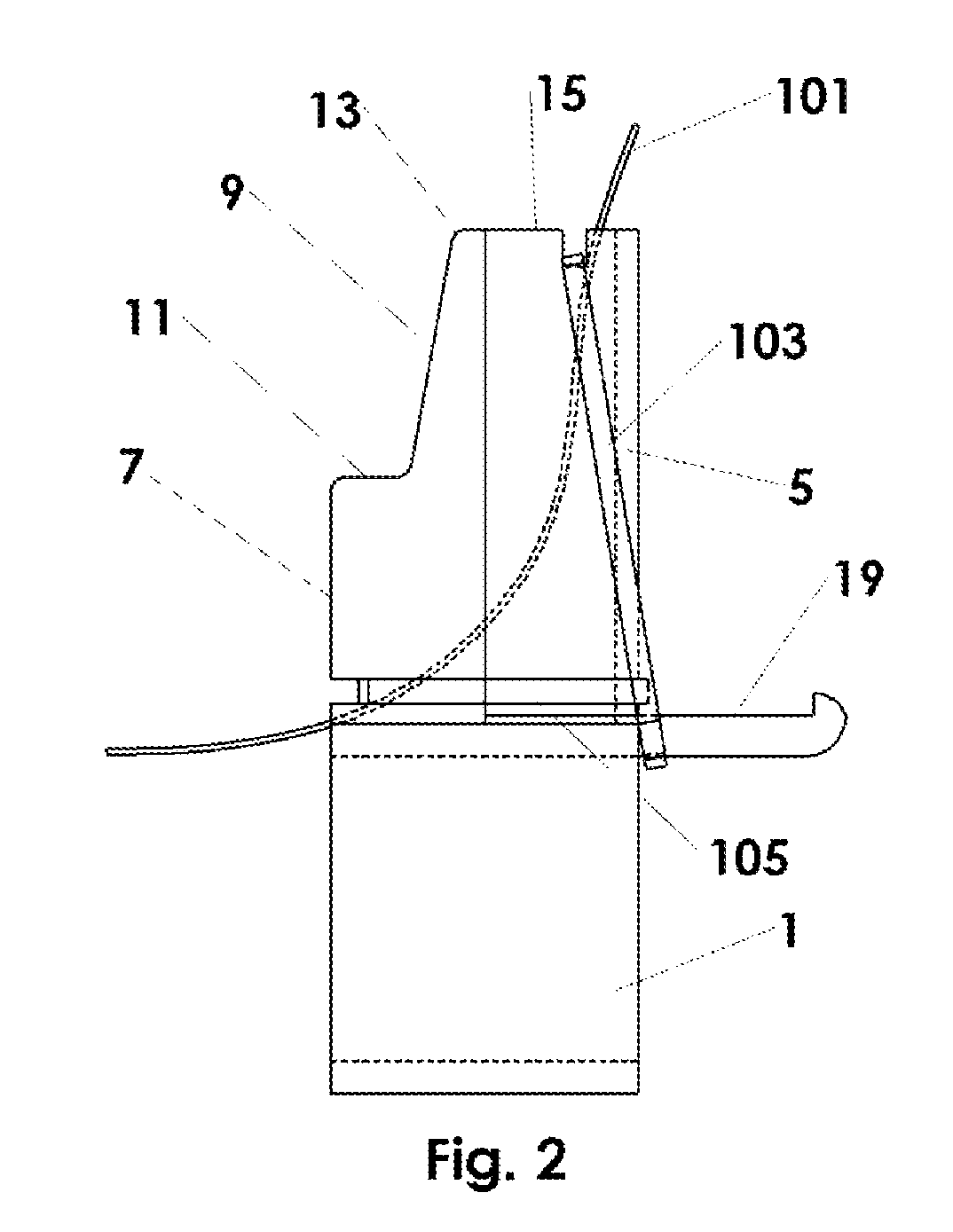

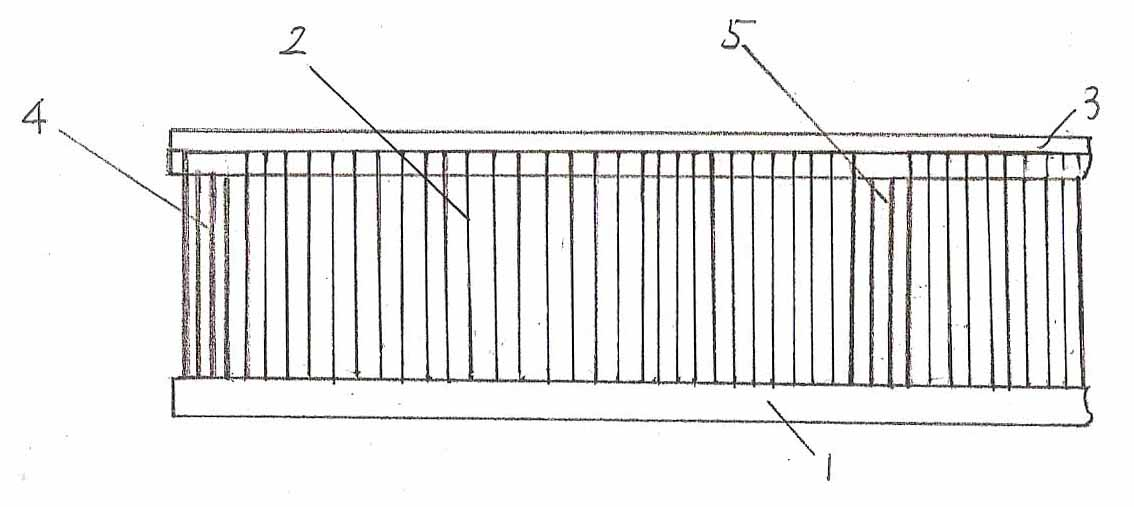

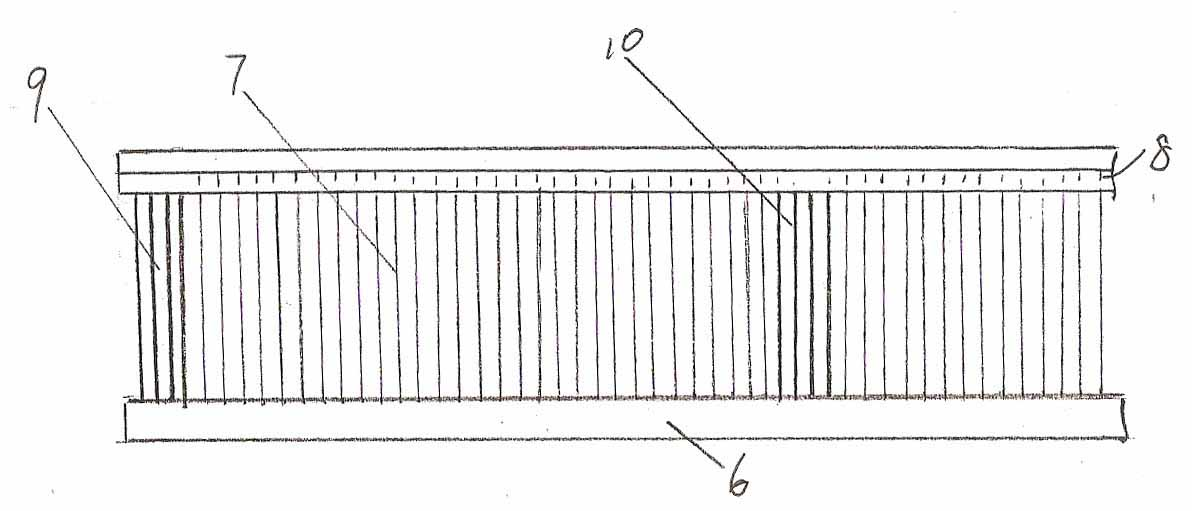

Weft yarn curve woven fabric, weaving method thereof and special elastic free reed thereof

The invention discloses a weft yarn curve woven fabric, a weaving method thereof and a special elastic free reed thereof. Weft yarns of the woven fabric are in a curved shape. The weaving method comprises pacing of warp, opening, wefting insertion, beating-up and take-up, and is characterized in that during the beating-up, the elastic free reed of which the dent is bent according to beating-up force is adopted; the filling rate of the woven fabric which is in the weft direction on a weaving machine in the same line is different from the change of fabric weaves or the thickness change of weft yarns, so that the beating-up force varies; when the elastic free reed is subjected to the beating-up, the dent is bent according to the beating-up force, namely the filling rate is large, so that thebending of the dent is large; and the filling rate is small, so that the bending of the dent is small to realize weft yarn curves. In the weaving method, the conventional horizontal and vertical weaving form is changed, the weft yarns of the woven fabric are in the curved shape, and if colored threads are used, beautiful curved patterns can be generated, so the grade of woven fabric varieties canbe improved.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com