A ball-threading and knot-tying machine

A knotting machine and ball groove technology, which is applied in the field of ball-piercing knotting machines, can solve the problems of large and small knots, irregular knots, loose and tight knots, etc., so as to reduce production costs, realize large-scale production, Yield improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

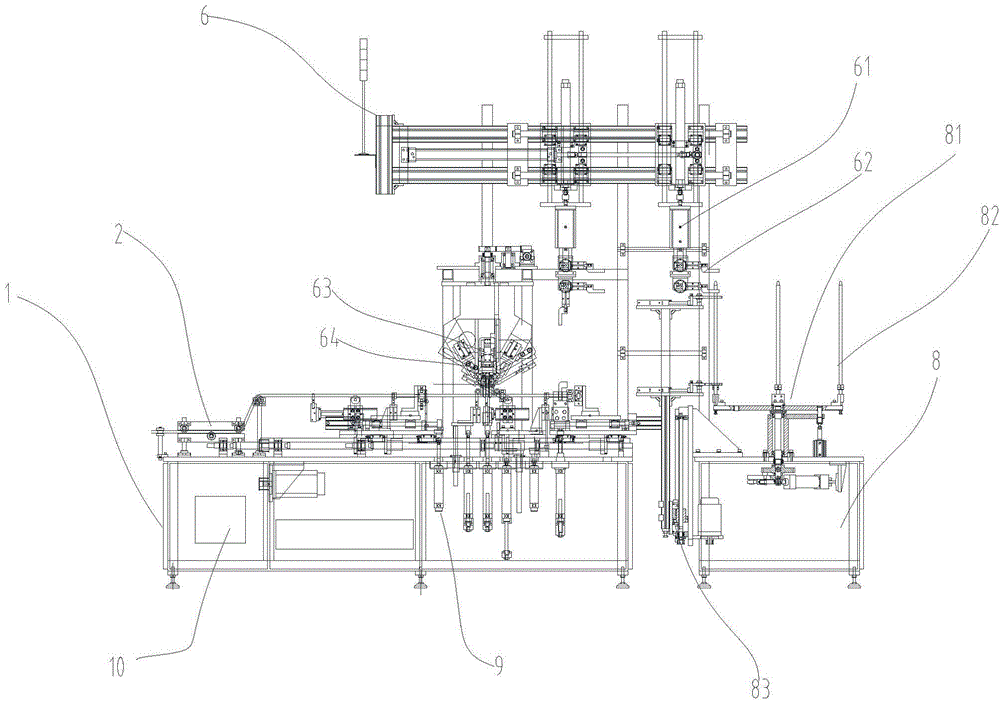

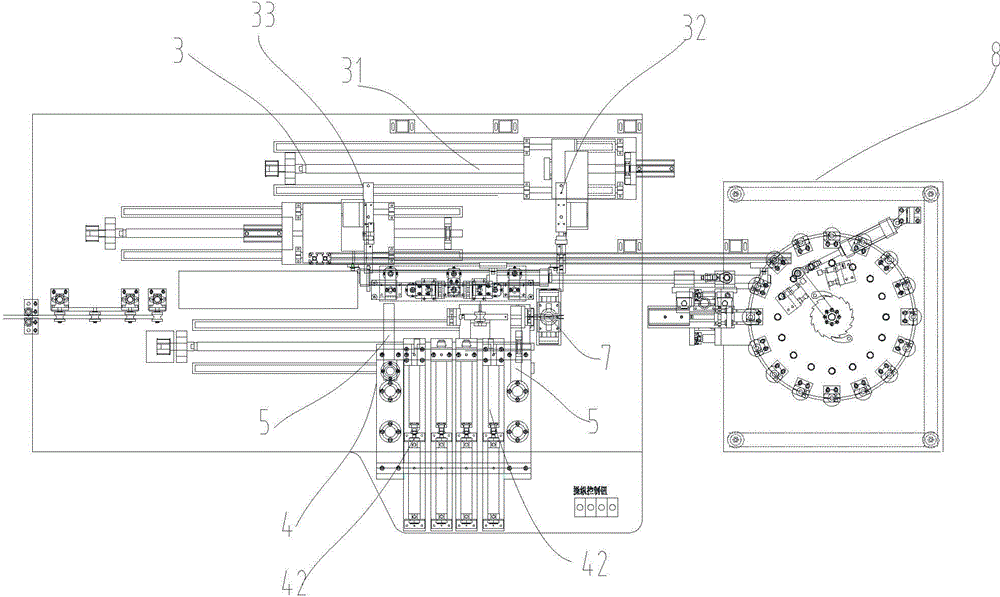

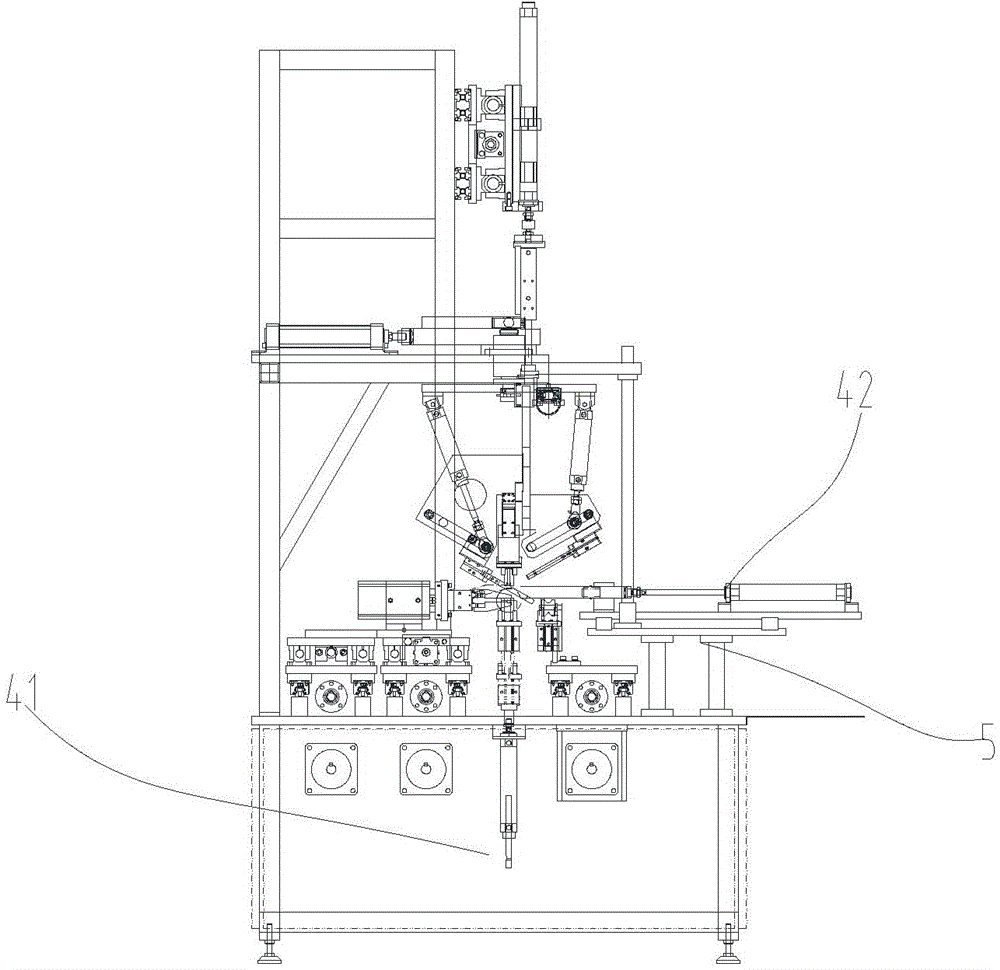

[0020] Such as figure 1 , figure 2 and image 3 As shown, the left end of the main frame 1 of a ball-piercing and knotting machine according to the present invention is provided with a fixed-length cutting machine 2 for cutting the rope, and the fixed-length cutting machine 2 has the function of entering the rope concurrently. The inner side is provided with clamping rope stepping mechanism 3, and clamping rope stepping mechanism 3 comprises clamping rope slideway 31 and is arranged on the preceding clamping rope manipulator 32 and rear clamping rope manipulator 33 on the clamping rope slideway 31, preceding clamping rope manipulator 32 and The back clamping manipulator 33 is a retractable structure, and the outside of the fixed-length cutting machine 2 is provided with a rope-lifting mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com