Hand loom

a hand-loom and loom technology, applied in the field of looms, can solve the problems of difficult operation, limited fabric size of other looms, and complicated construction of past looms,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

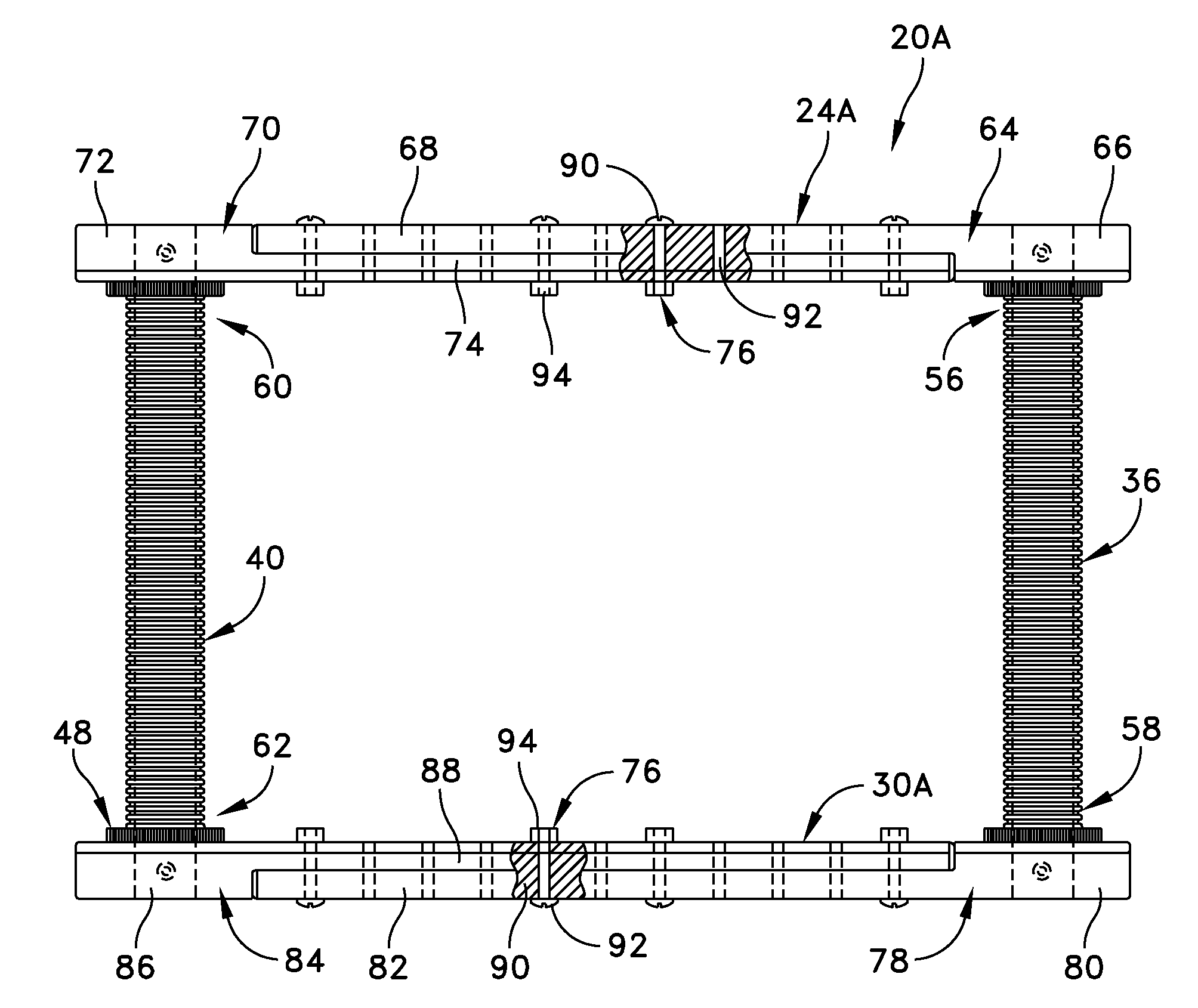

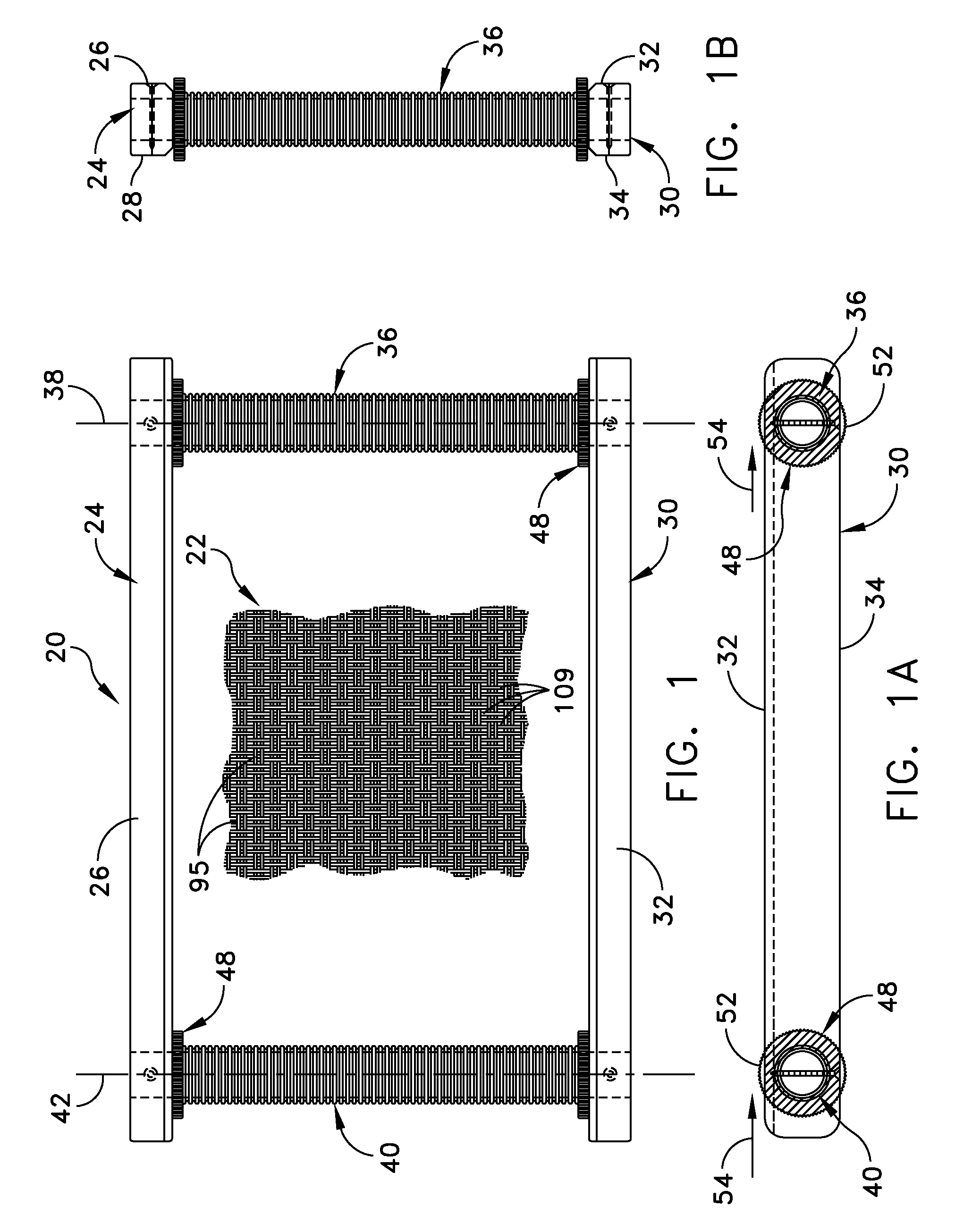

[0050]Refer initially to FIGS. 1, 1A, and 1B which illustrate a loom 20, embodying the invention, for producing a woven fabric 22 diagrammatically illustrated in FIG. 1. Although the present invention will be described with reference to the embodiments shown in the drawings, it should be understood that the present invention can be embodied in many alternate forms or embodiments. In addition, any suitable size, shape or type of elements or materials could be used.

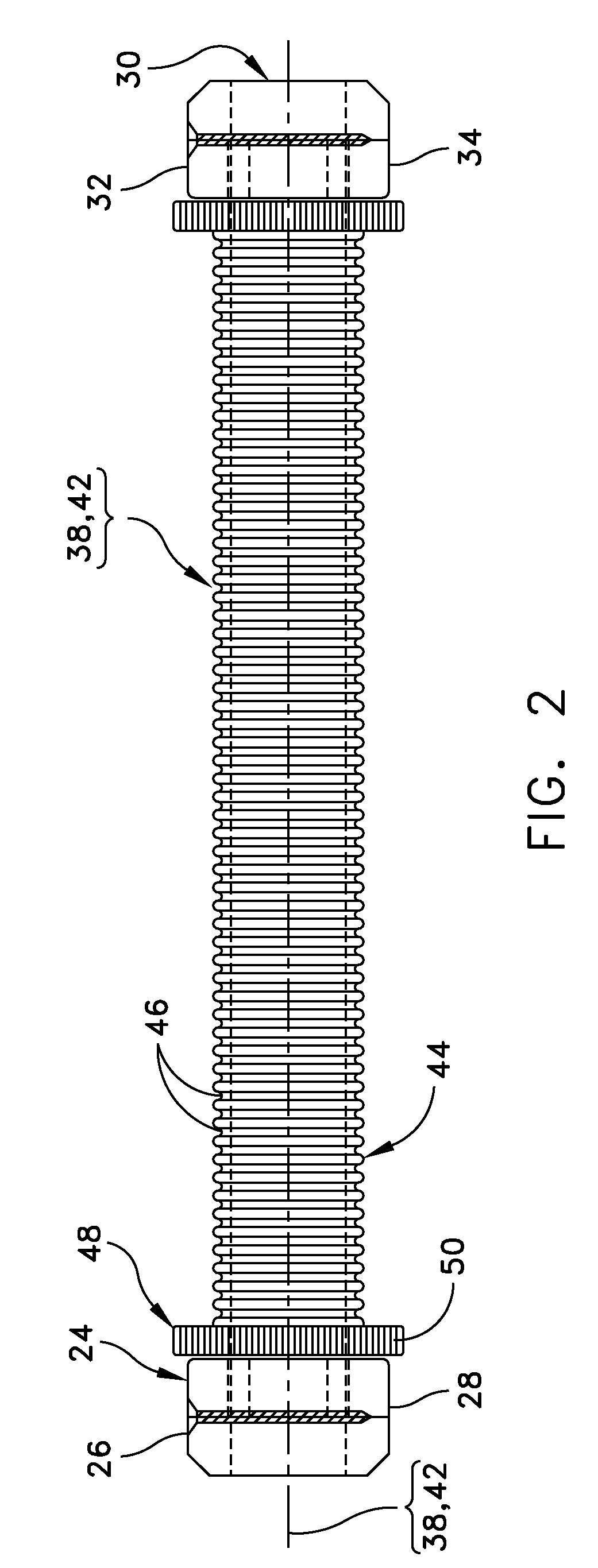

[0051]The loom 20 is size-non-adjustable and includes a first elongated beam 24 having upper and lower surfaces 26, 28 and a second elongated beam 30 having upper and lower surfaces 32, 34 parallel to and spaced from the first beam 24. A first transverse roller 36 has a first longitudinal axis 38 and is rotatably mounted on and extends between the first and second beams 24, 30. In similar fashion, a second transverse roller 40 has a second longitudinal axis 42 and is parallel to and spaced from the first transverse roller 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com