Suspender opening mechanism and plastic woven fabric water-jet loom

A technology of opening mechanism and sling, applied in cam opening mechanism, loom, textile, etc., can solve the problems of low efficiency and long production cycle, and achieve the effect of saving procedures, improving production efficiency, and neat and orderly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

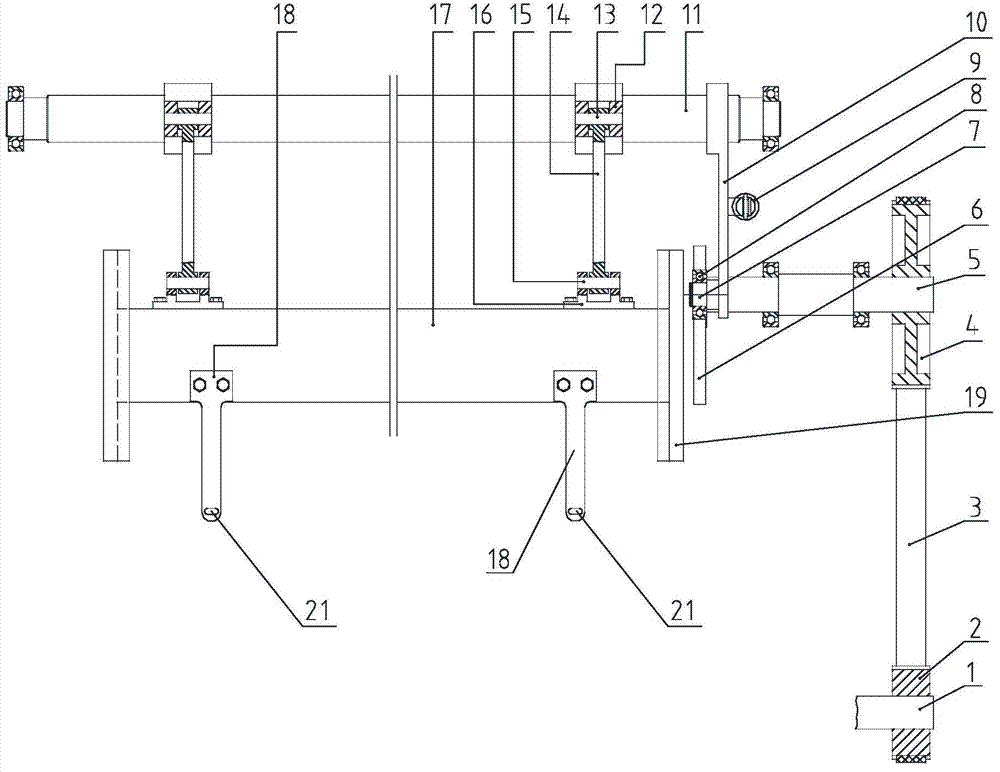

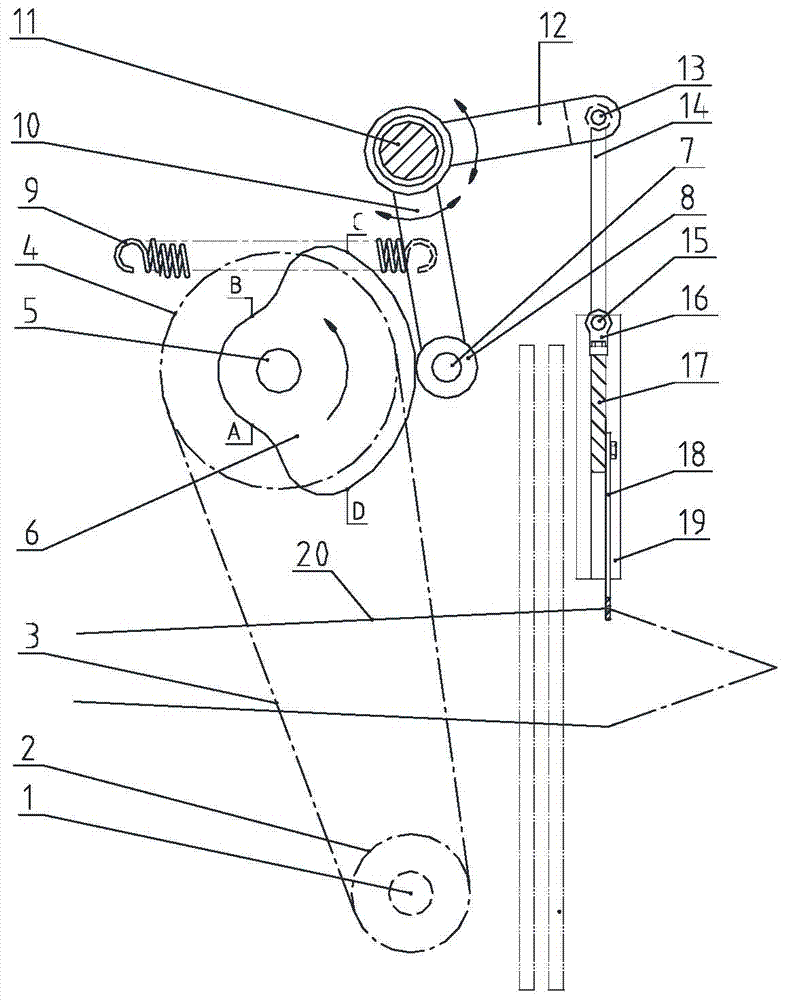

[0052] combine figure 1 As shown, the sling opening mechanism includes a transmission shaft 5, a cam 6, a rotor 7, a rotor shaft 8, a rotor arm bar 10, a swing shaft 11, a connecting rod mechanism, a heald beam 17 and a guide plate 19. in,

[0053] One end of the transmission shaft 5 is provided with a power device or a power transmission assembly, and the other end is connected with the cam 6 .

[0054] The rotor 7 is mounted on the rotor shaft 8 and pressed against the outer edge of the cam 6 .

[0055] The rotor shaft 8 is connected to one end of the rotor arm 10 , and the other end of the rotor arm 10 is fixed on the swing shaft 11 .

[0056] A tension spring is arranged on the rotor arm 10 for tensioning the rotor arm and making the rotor 7 tightly pressed against the outer edge of the cam 6 . During use, one end of the tension spring 9 can be fixed on the rotor arm 10, and the other end can be fixed on the frame of the loom.

[0057] There can be one or more sets of ...

Embodiment 2

[0075] This embodiment 2 proposes a plastic woven cloth water-jet loom, which includes a main opening mechanism, a water jet weft insertion mechanism, a warp let-off mechanism, a coiling mechanism and a main transmission mechanism, as well as those described in embodiment 1. The sling opening mechanism.

[0076] The sling opening mechanism will not affect the working status of the original mechanisms of the plastic woven cloth water jet loom, and through the cooperation with the main shedding mechanism, water jet weft insertion mechanism, warp let-off mechanism, coiling mechanism and main transmission mechanism, it is convenient The suspenders are woven into the inside of the woven cloth while weaving it.

[0077] Specifically, one end of the transmission shaft 5 is connected to the main transmission mechanism through a power transmission assembly. The power transmission assembly includes a first toothed synchronous pulley 2 , a second toothed synchronous pulley 4 and a tooth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com