Weaving method for 2.5D satin weave structural fabric

A fabric and satin weave technology, which is applied in the field of weaving opening devices for 2.5D satin weave structure fabrics, can solve problems such as difficult to form effective and clear openings, achieve time and manpower saving, good bending and torsional deformation, and simplify weaving methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

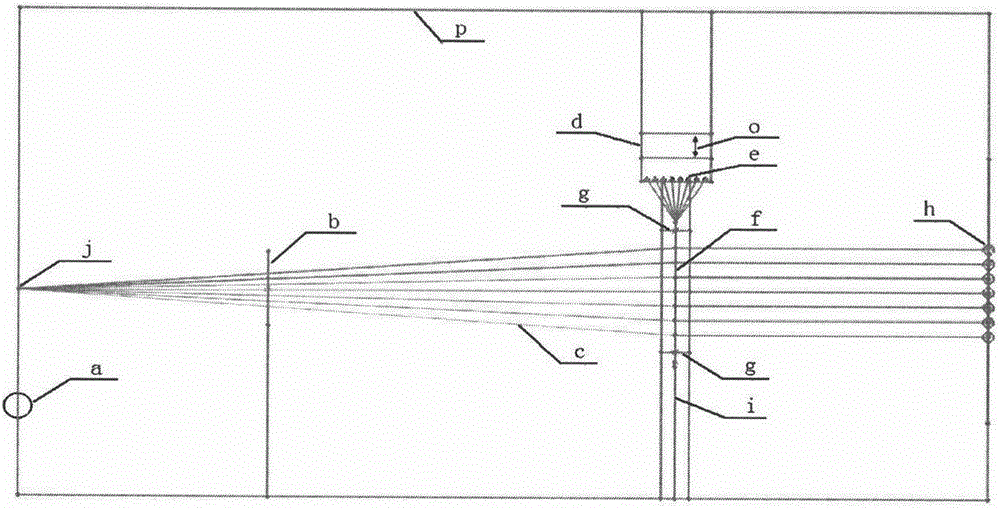

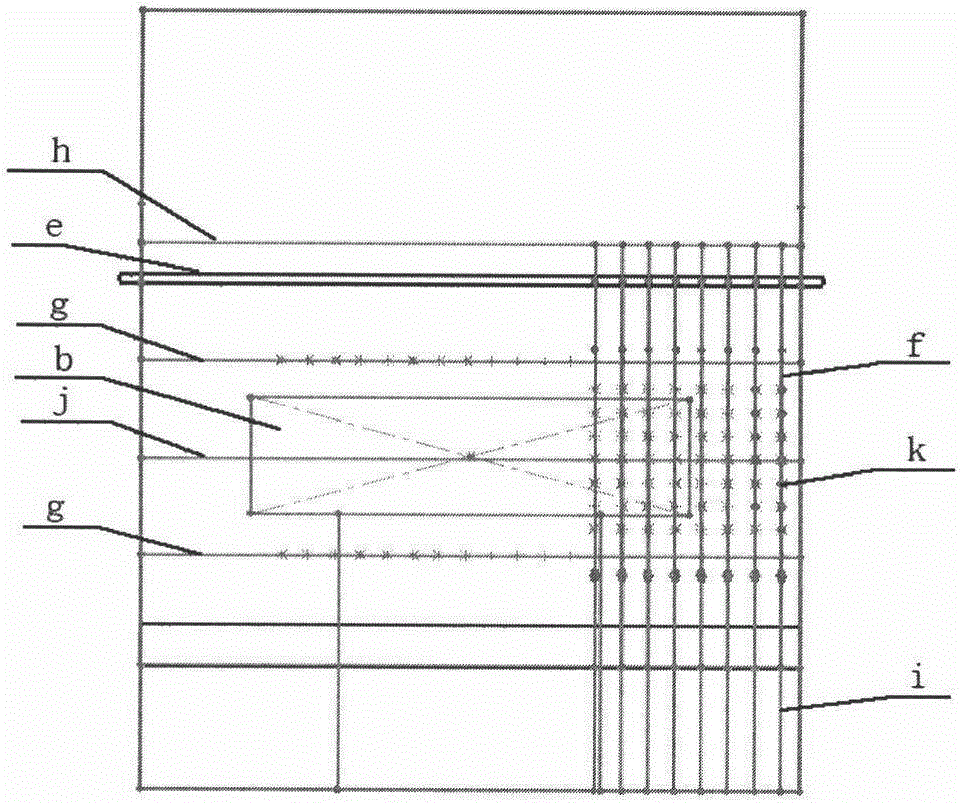

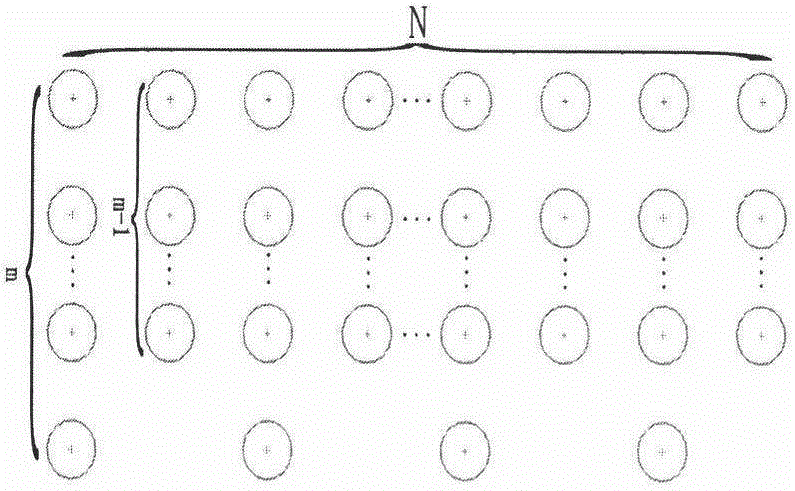

[0051] The structure of a three-dimensional fabric is determined by the interweaving relationship of the warp and weft yarns in the fabric, that is to say, during the fabric weaving process, the openings formed by lifting and lowering different warp yarn columns can weave fabrics of different structures. The shedding process described in this patent is to raise and lower different warp yarn rows under a specially arranged warp yarn group, and lift it twice to realize the shedding required for weaving 2.5D satin weave. Describe the weaving process of a kind of 4-layer 2.5D class satin weave fabric that the minimum number of cycles N is 8 in the embodiment, the fabric parameters are shown in Table 1, and this method is also applicable to the weaving of the 2.5D satin weave fabric that the minimum number of cycles N is N Weaving.

[0052] Preparatory stage before weaving:

[0053] 1. Using carbon fiber as the raw material, one heddle is threaded with 4 yarns, and one heald is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com