Cam opening device suitable for various door widths

A technology of opening device and various door widths, which is applied in cam opening mechanism, textile, textile and paper making, etc., can solve the problems of high production cost, achieve the effects of easy maintenance, convenient operation and improved transmission stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

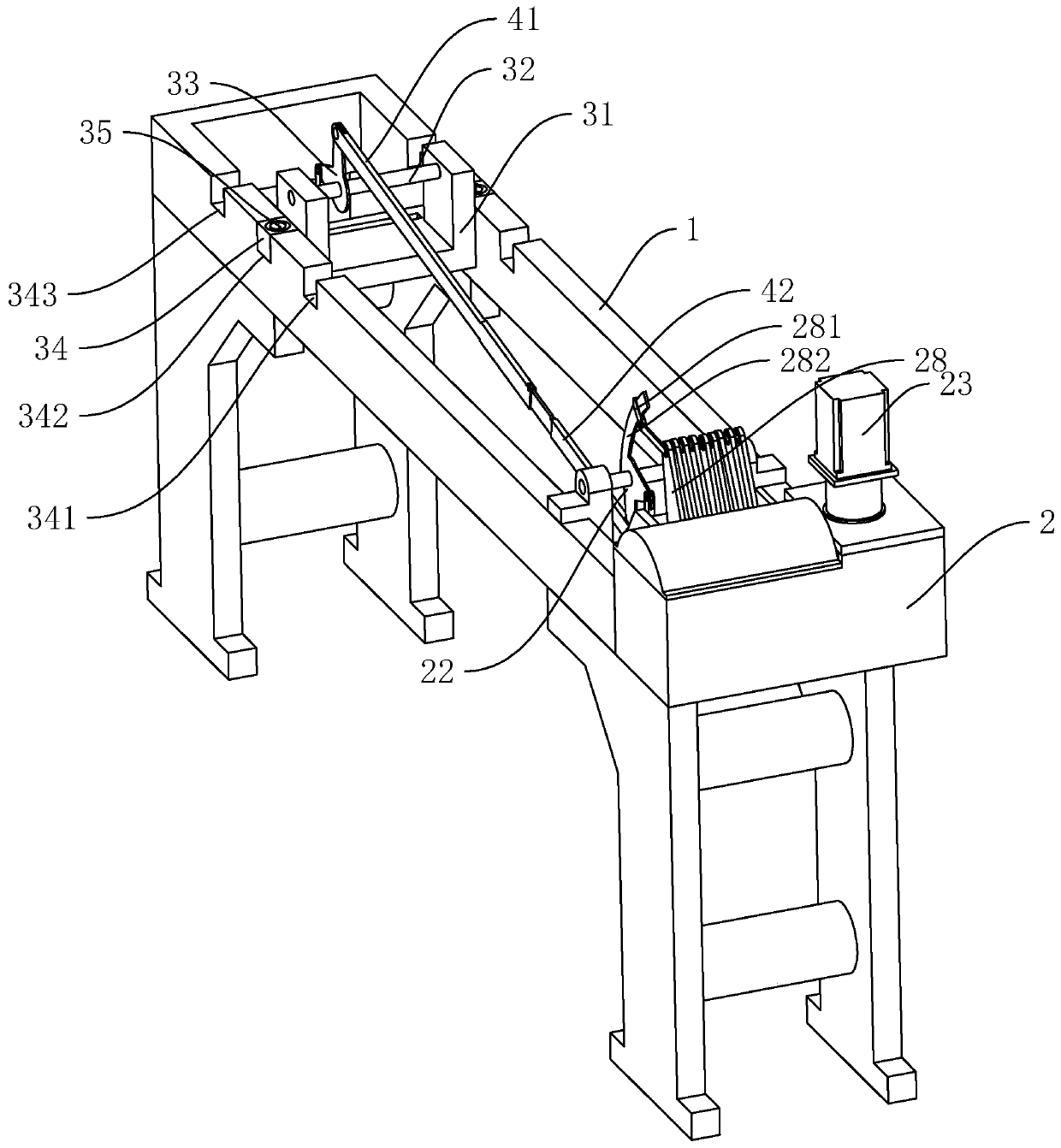

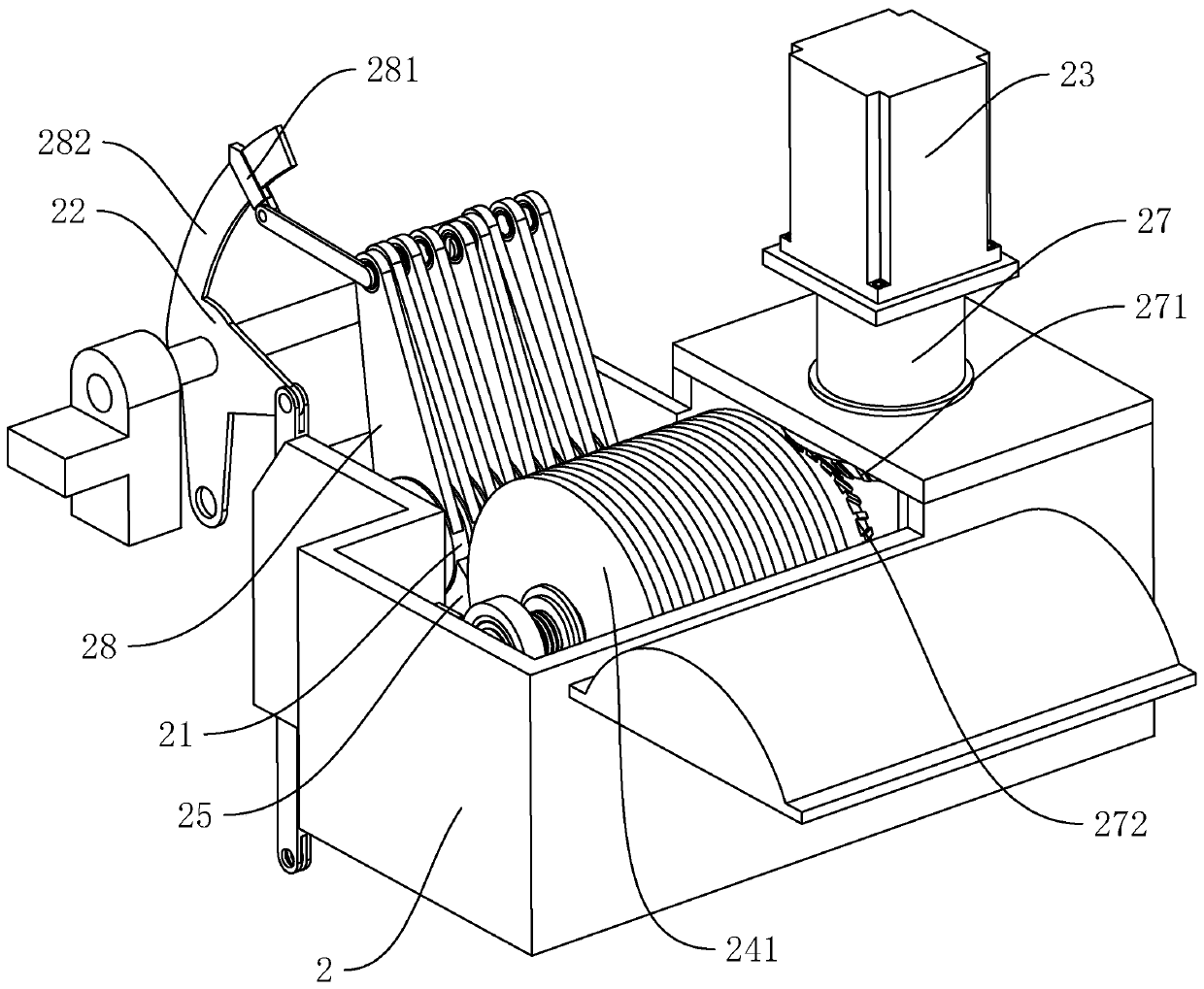

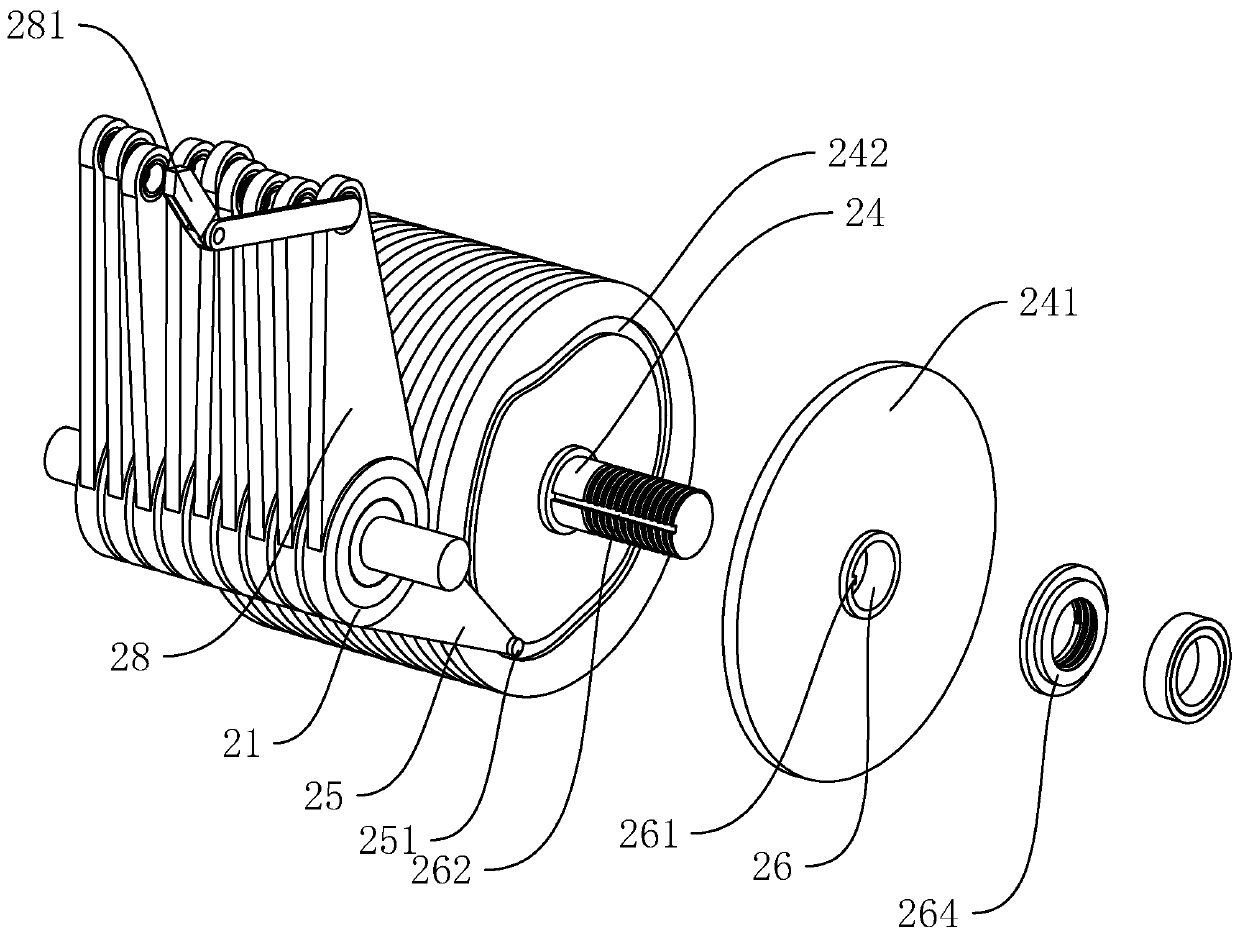

[0031] Embodiment 1: A cam opening device suitable for various door widths, such as figure 1 , figure 2 , image 3As shown, it includes a horizontal beam 1, an active system fixed on the horizontal beam 1, a driven system adjustable on the horizontal beam 1, and a connecting rod for driving the active system and the driven system. The active system includes 1 A box body 2 at one end, a cam set installed in the box body 2, a pendulum plate 21 driven by the cam set, an active blade 22 driven by the pendulum plate 21, and an AC motor 23 for driving the cam set; the driven system It includes a movable base 31, a driven main shaft 32 fixed on the movable base 31, and a driven blade 33 rotatably connected to the driven main shaft 32. The movable base 31 is integrally formed with a bump 34, and the horizontal beam 1 is sequentially along the length direction There are a first notch 341, a second notch 342 and a third notch 343 which snap fit with the bump 34, and the three notches...

Embodiment 2

[0039] Embodiment 2: The difference between Embodiment 2 and Embodiment 1 lies in the difference of the length adjustment parts, such as Figure 6 , Figure 7 As shown, the length adjusting member includes a middle section 48 and two socket sleeves 49 integrally formed at both ends of the middle section 48 respectively. The socket 49 is plugged into the mated plug-in section 51, and the plug-in section 51 is provided with a fixing screw hole 52 threadedly fitted with the fixing bolt 50. It should be noted that the length of the middle section 48 of different length adjustment parts is different. When adjusting the length of the connecting rod, it is enough to replace the corresponding length adjusting part, so that there is no need to replace the entire connecting rod. Compared with the length adjusting part disclosed in Embodiment 1, this method has the advantage that the overall structural strength of the connecting rod is higher , the disadvantage is that the adjustment is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com