Heald-frame height adjusting apparatus

A height adjustment device and heald frame technology, which is applied in the field of height devices, can solve the problems of increased manufacturing costs of shedding devices, and achieve the effects of suppressed manufacturing costs, less prone to failure, and easier height adjustment work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

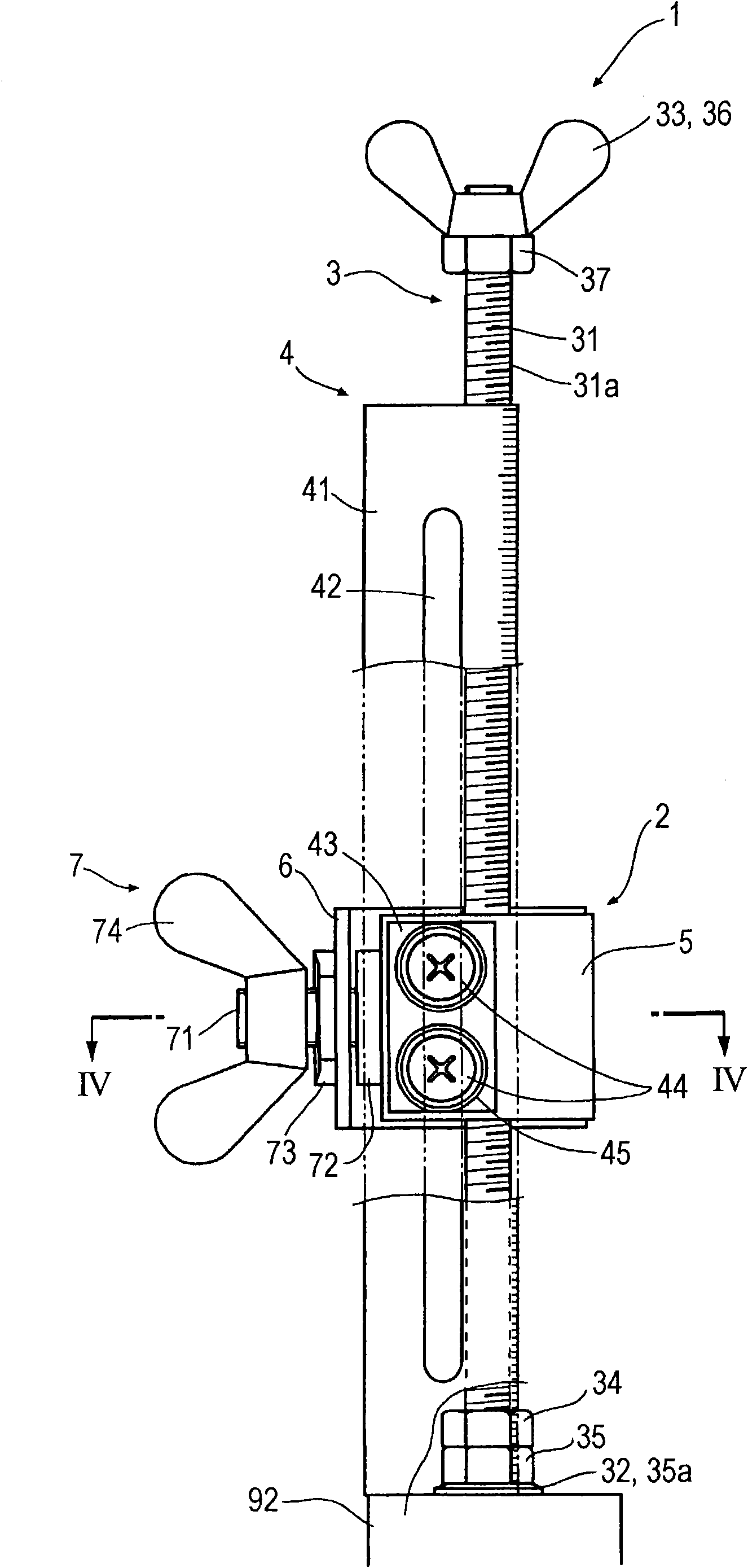

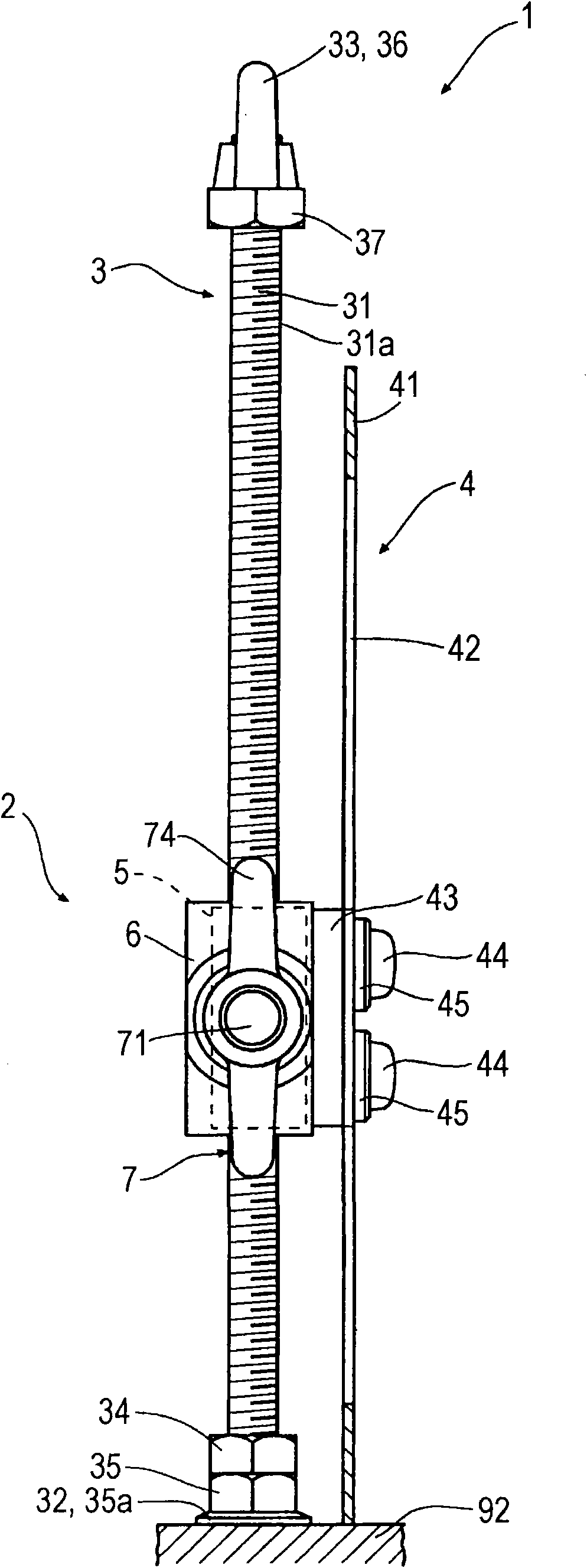

[0032] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

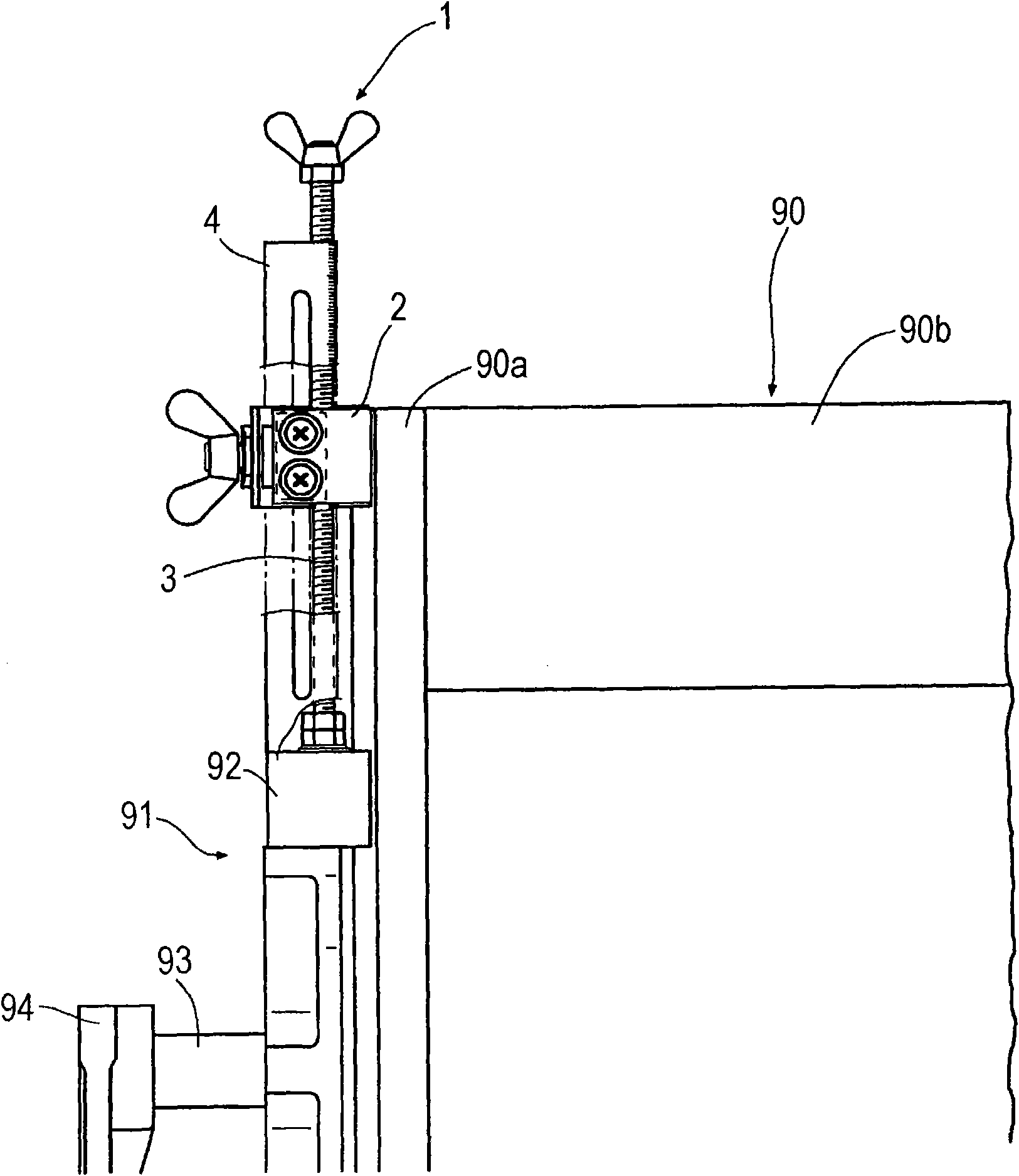

[0033] according to Figure 9 ~ Figure 11 An example of a loom to which the heald frame height adjusting device 1 is applied will be described. Figure 9 The structure which raises and lowers the heald frame 90 is shown. Figure 10 The structure of the left side of the leading heald frame 90 is shown. Figure 11 A structure in which the shedding device 80 supports the heald frame 90 from below is shown.

[0034] An example of a loom suitable for the heald frame height adjusting device 1 is as follows: Guide rails 91 are provided on the left and right sides of the heald frame 90, and the guide rails 91 guide the vertically moving heald frame 90 in the front, rear, left and right directions, and pass through the opening below the heald frame 90. The device 80 moves the heald frame 90 up and down. Hereinafter, it will be further describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com