Shedding device in weaving machine

a technology of shedding device and weaving machine, which is applied in the direction of shedding mechanism, cam shedding mechanism, other shedding mechanism, etc., can solve the problems of deteriorating the durability of those members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

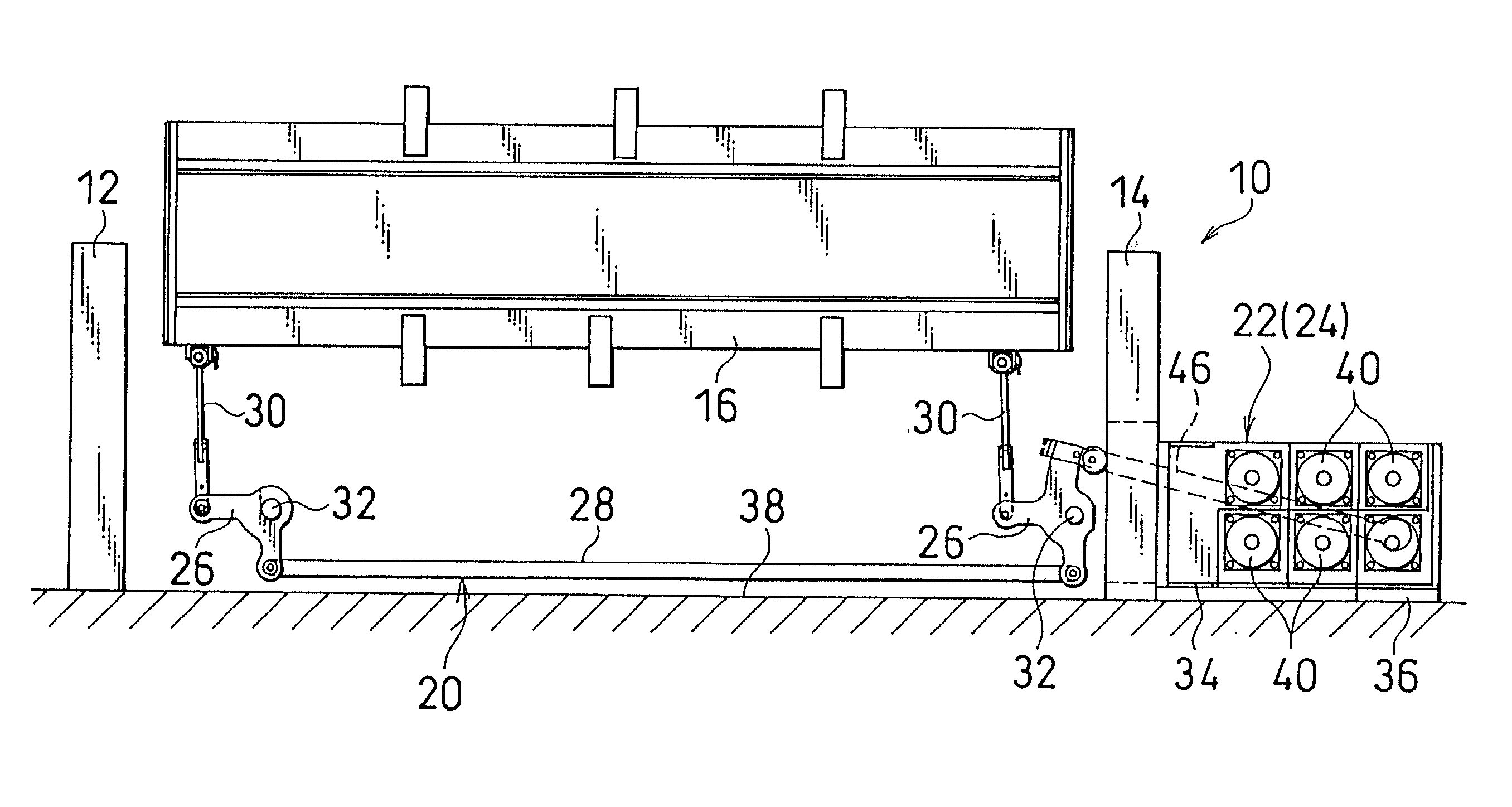

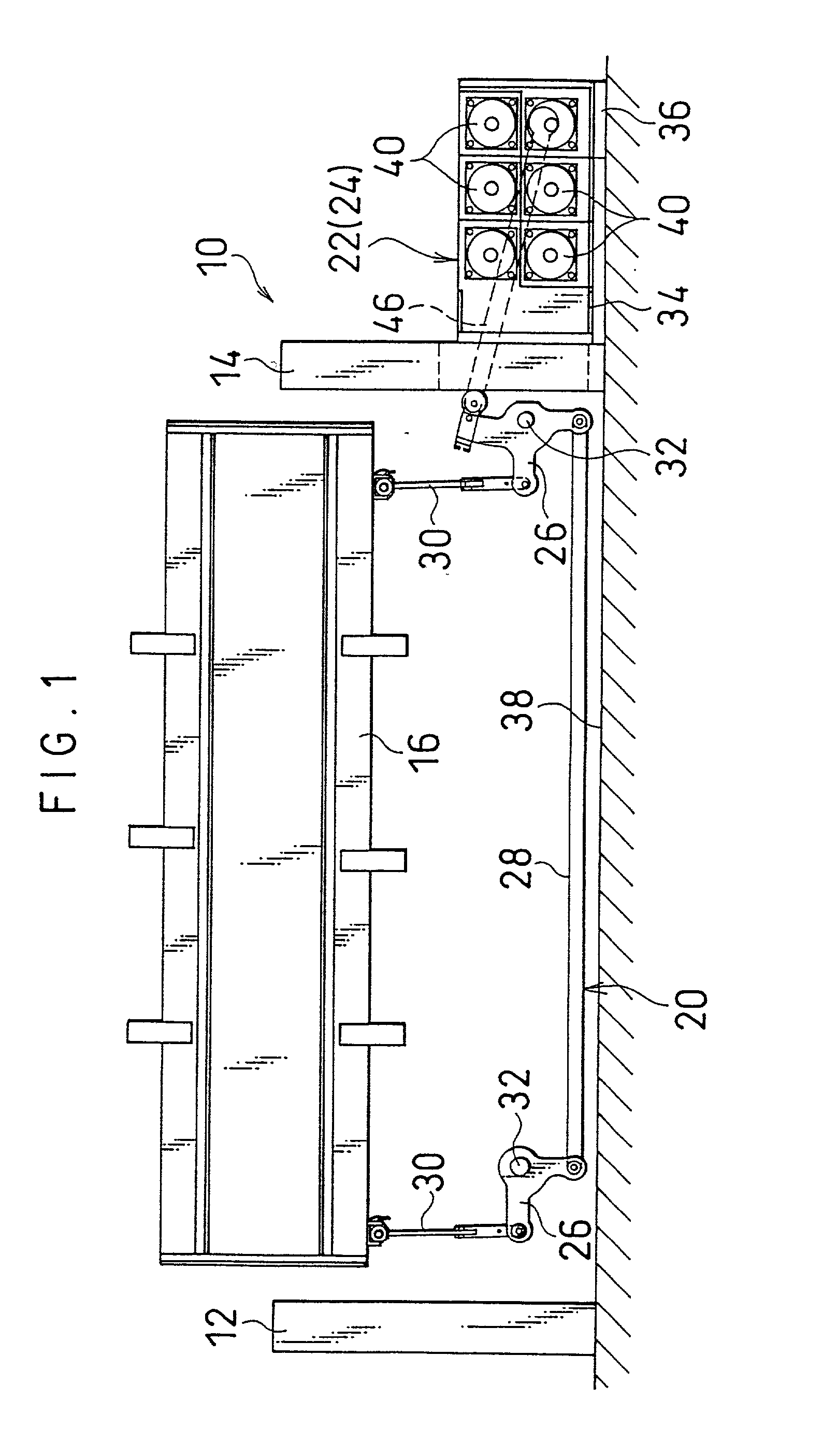

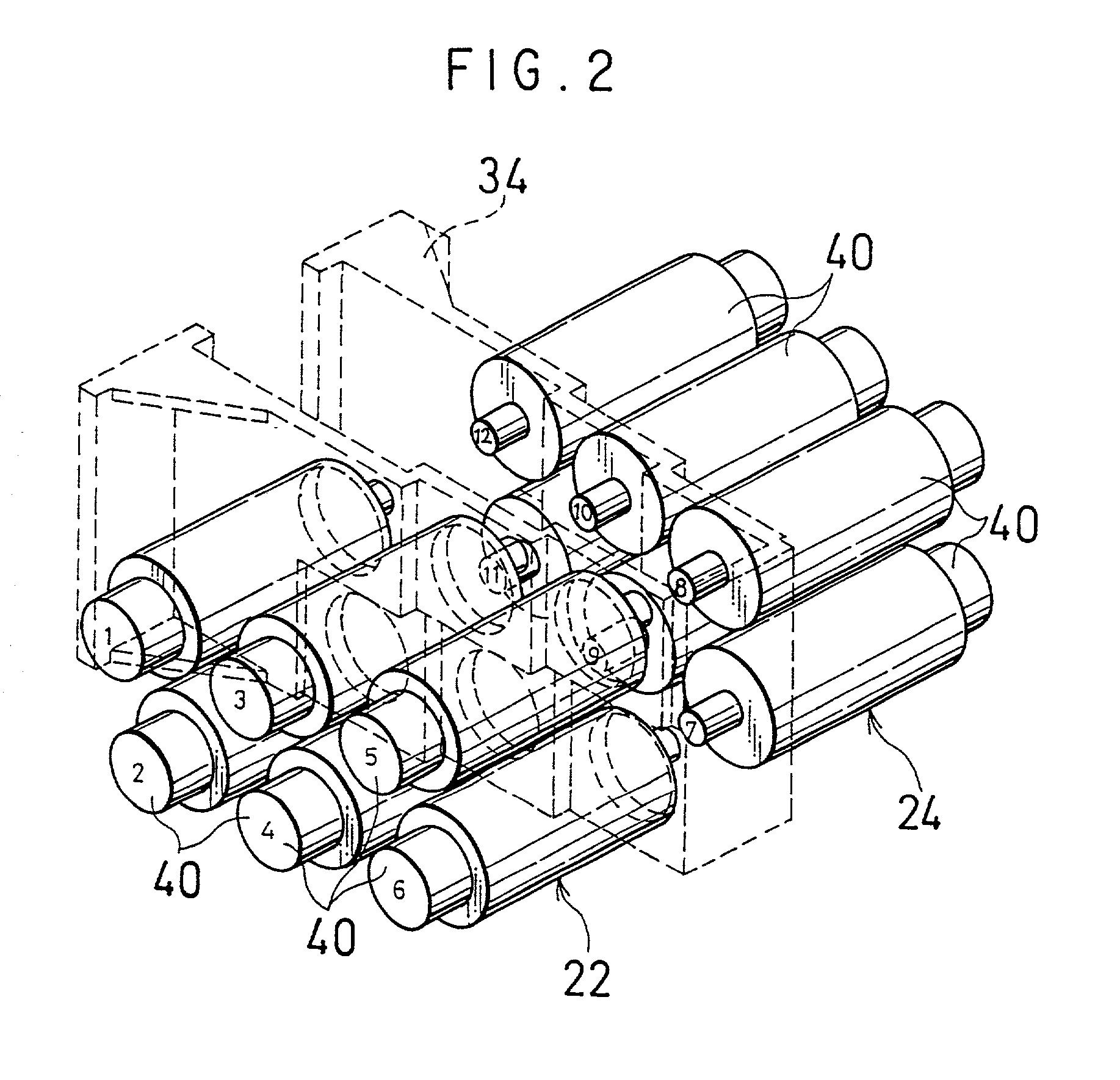

[0040] Referring to FIGS. 1 through 6, a shedding device 10 is used as an electric shedding device which forms a warp shedding by reciprocating upward and downward a plurality of heald frames 16 arranged at intervals in the forward and backward direction between right and left frames 12, 14 of the weaving machine together with the healds disposed on the heald frames 16. In FIG. 1, a warp is moved in a direction perpendicular to a sheet by a let-off from a warp beam not shown, while a weft is run from the left side to the right side or vice versa).

[0041] The heald frames 16 are divided, according to their arrangement positions in the forward and backward direction of the weaving machine, into a first heald frame group including a plurality of heald frames located on the forward side (cloth fell side) and a second heald frame group including a plurality of heald frames located on the backward side (opposite side to the cloth fell). In the illustration, the weaving machine includes twe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com