Main machine system of air jet loom

A technology of air-jet loom and host system, which is applied in looms, auxiliary equipment for weaving, textiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

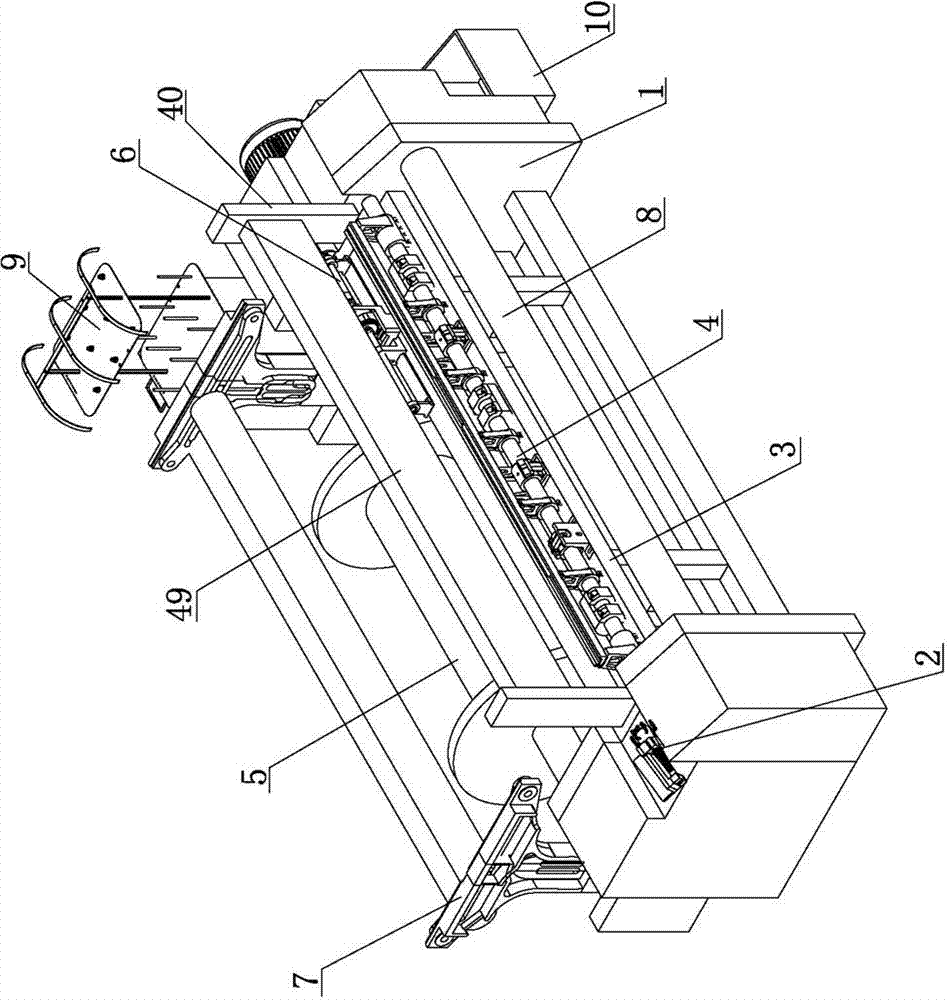

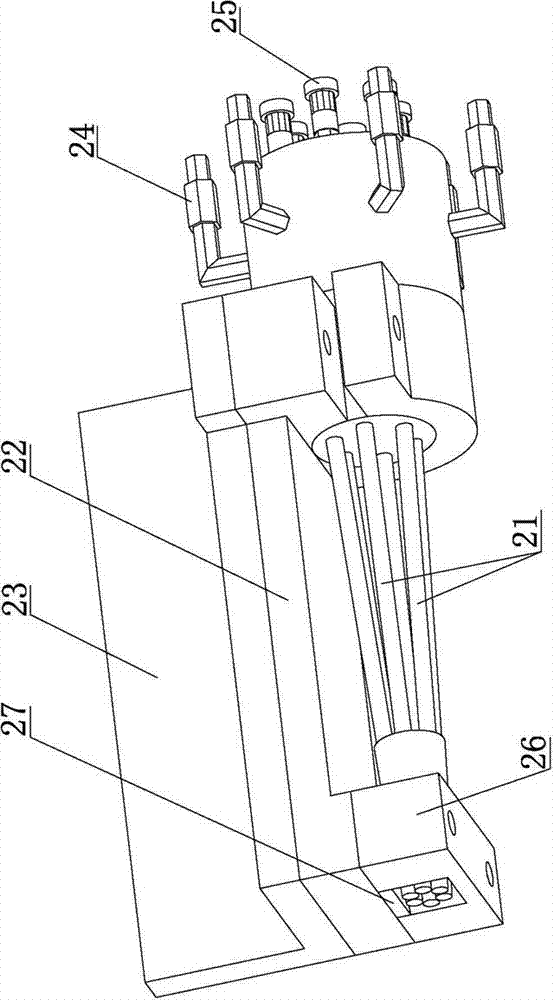

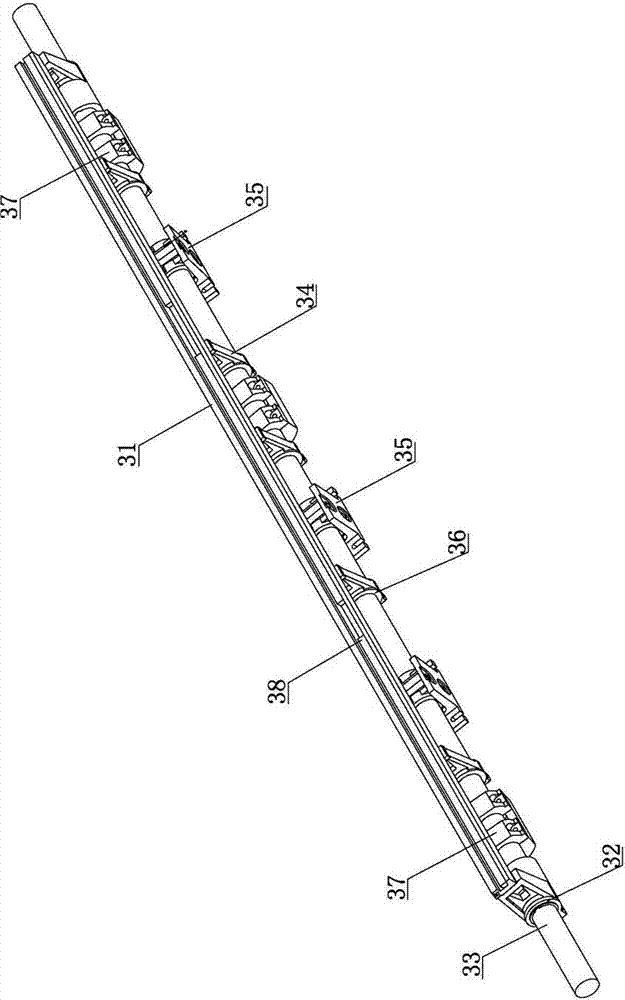

[0027] Please refer to the attached figure 1 To attach Figure 9 As shown, the present invention is a host system of an air-jet loom, which consists of a frame 1, a weft insertion mechanism 2, a weft beating mechanism 3, an opening mechanism 4, a warp let-off mechanism 5, a temple mechanism 6, a back beam frame 7, It consists of several parts such as winding mechanism 8, yarn end processing mechanism 9 and dustbin 10.

[0028] Wherein, the weft insertion mechanism 2 is arranged on one side of the front end of the frame 1, and it is docked with the weft beating mechanism 2. The weft insertion mechanism 2 is used to introduce the weft thread into the host system. The weft beating mechanism 2 is installed on the frame 1, and it beats the weft yarn to the fell to form a fabric.

[0029] The opening mechanism 4 is arranged above and below the weft beating mechanism 3, which drives the warp yarn in time according to the change rule of the warp and weft interweaving of the fabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com