Ribbon loom transmission apparatus

A transmission device and a technology for a belt loom, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of inability to increase production capacity, easy wear, and high jerkiness, and achieve the effects of increasing production capacity, prolonging service life, and improving jitter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings and preferred embodiments of the present invention.

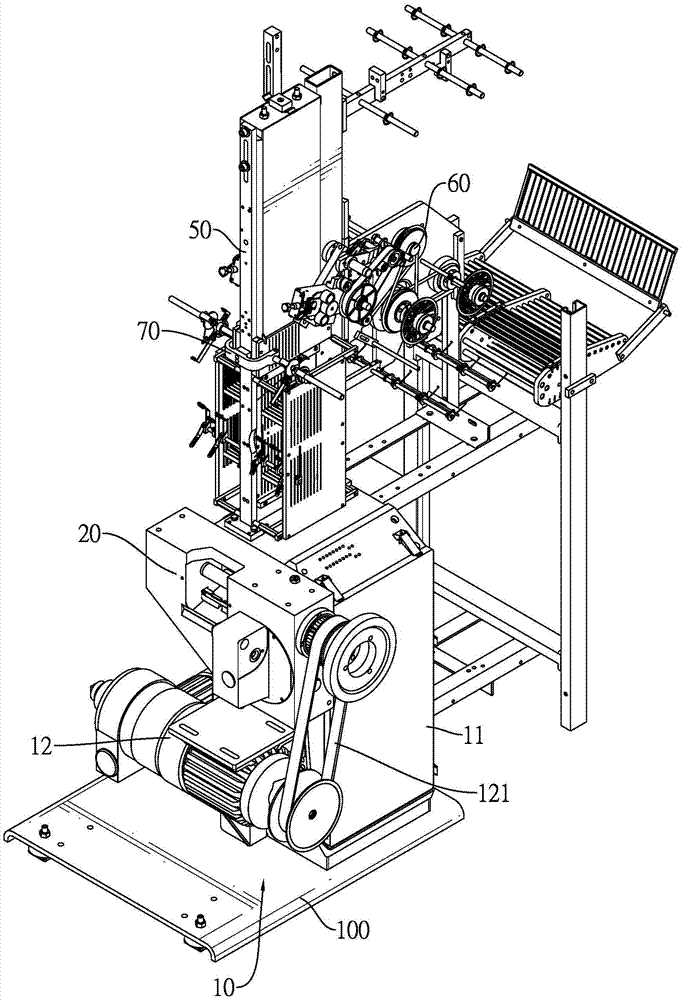

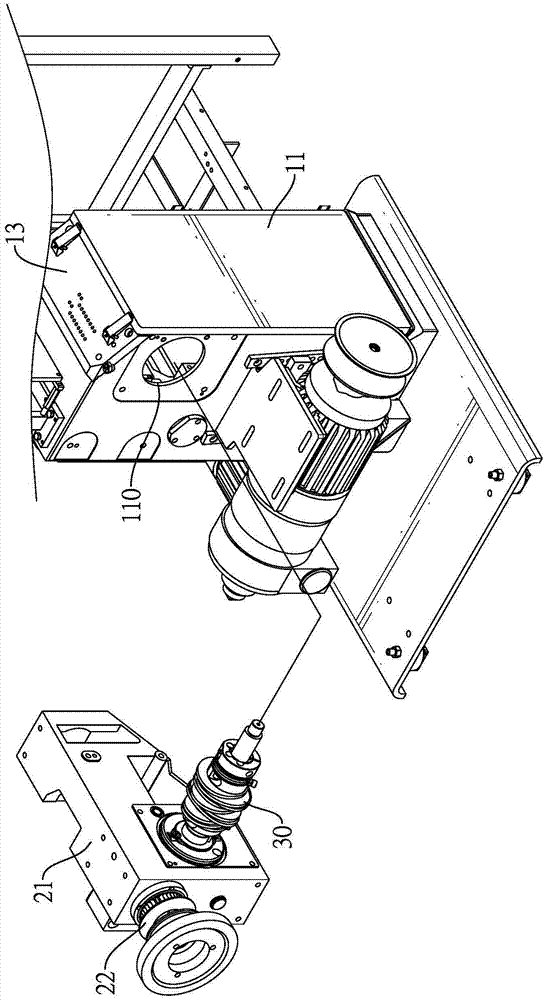

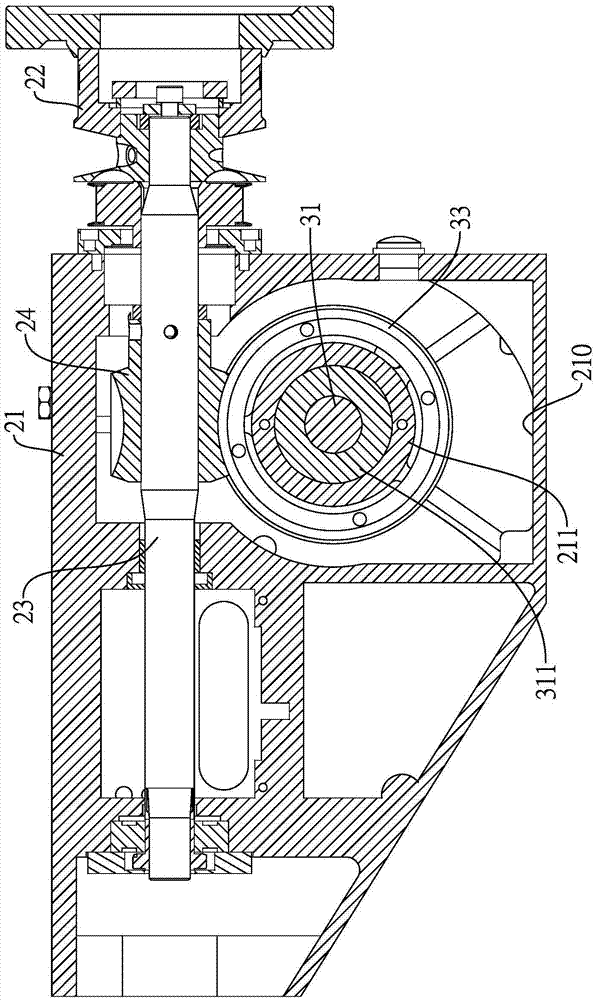

[0094] Please refer to figure 1 , figure 2 and Figure 5 As shown, the belt loom transmission device of the present invention has a base set 10, a worm gear box drive set 20, a cam set 30, a knife-off rocker set 40 and a heald frame set 50; At the same time, cooperate with a weft yarn sending device group 60 and a weft yarn breakage control seat group 70 to actuate, the weft yarn sending device group 60 and the weft yarn breakage control seat group 70 are used to transport the weft yarn, and further cooperate to pass through the heald frame group 50 warp brown silk pieces to complete the interweaving action of the ribbon loom.

[0095] Please refer to figure 1 , figure 2 and Figure 5 As shown, the base set 10 has a mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com