Thread control device for a textile machine in particular for a shedding device

A technology of yarn control and opening device, applied in the cam opening mechanism, other opening mechanisms, knitting and other directions, can solve the problems of reduced loom efficiency, high cost, reduced motor speed, etc., and achieve the effect of simple structure and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

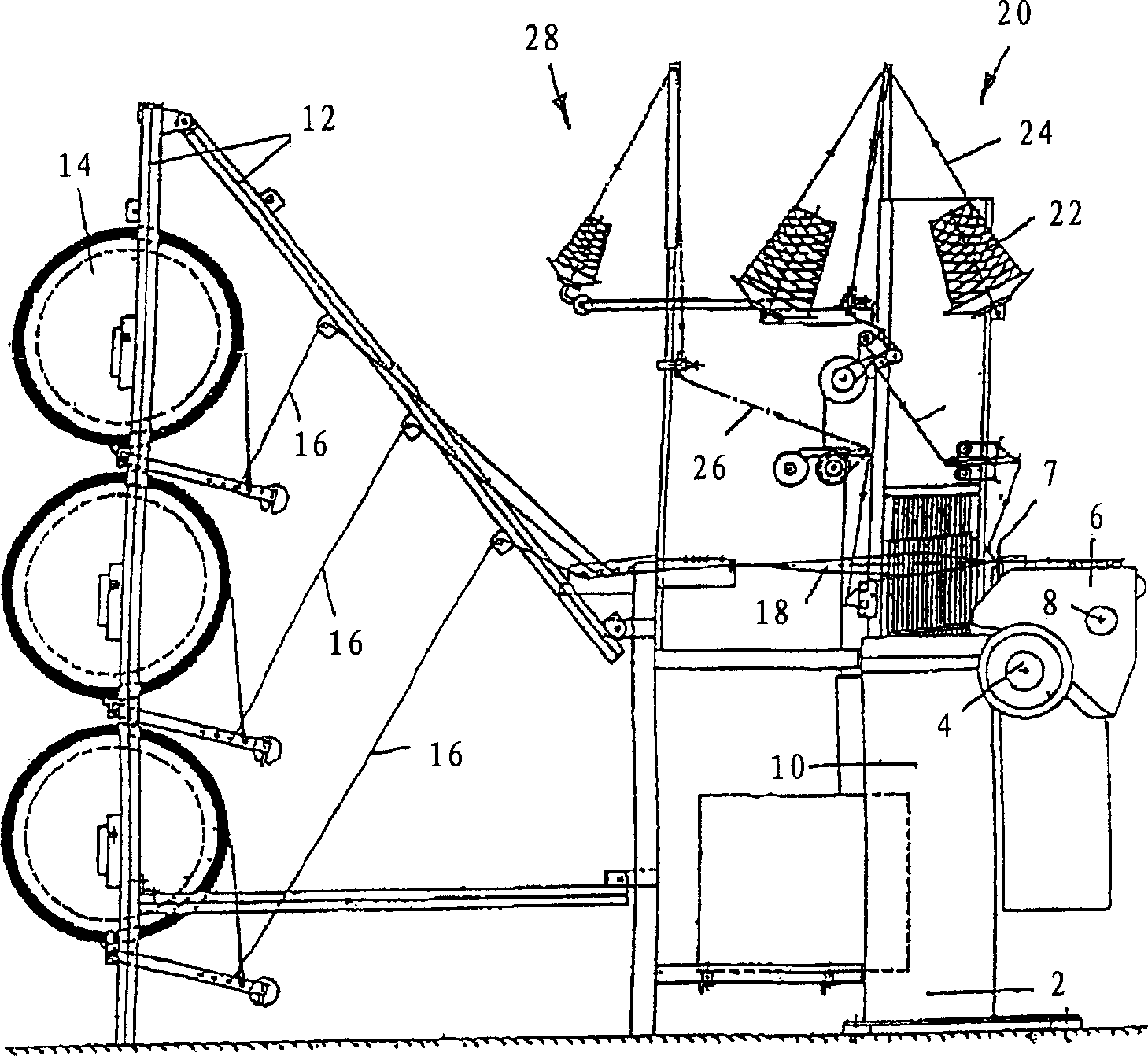

[0029] figure 1 Shown is a needle-type weaving machine with a frame 2 in which is mounted a main drive shaft 4 driving at least one weft needle 6 (not shown in more detail); a reed 7; fabric A take-up device 8 and a yarn control device formed as a heald frame device 10 . The needle loom has a beam support 12 carrying a warp beam 14 from which warp threads 16 are supplied to a heald frame arrangement 10 which opens the warp threads to form a shed 18 . Via the yarn supply device 20 , weft yarn 24 is supplied from the bobbin 22 to the weft yarn needle 6 , which guides the weft yarn loops into the shed 18 . The continuous loop of weft yarn can be knotted by itself, or by means of a tuck yarn 26 (not shown in more detail here) supplied to the knitting needles via another yarn supply device 28, to knot and secure the inserted Weft loops.

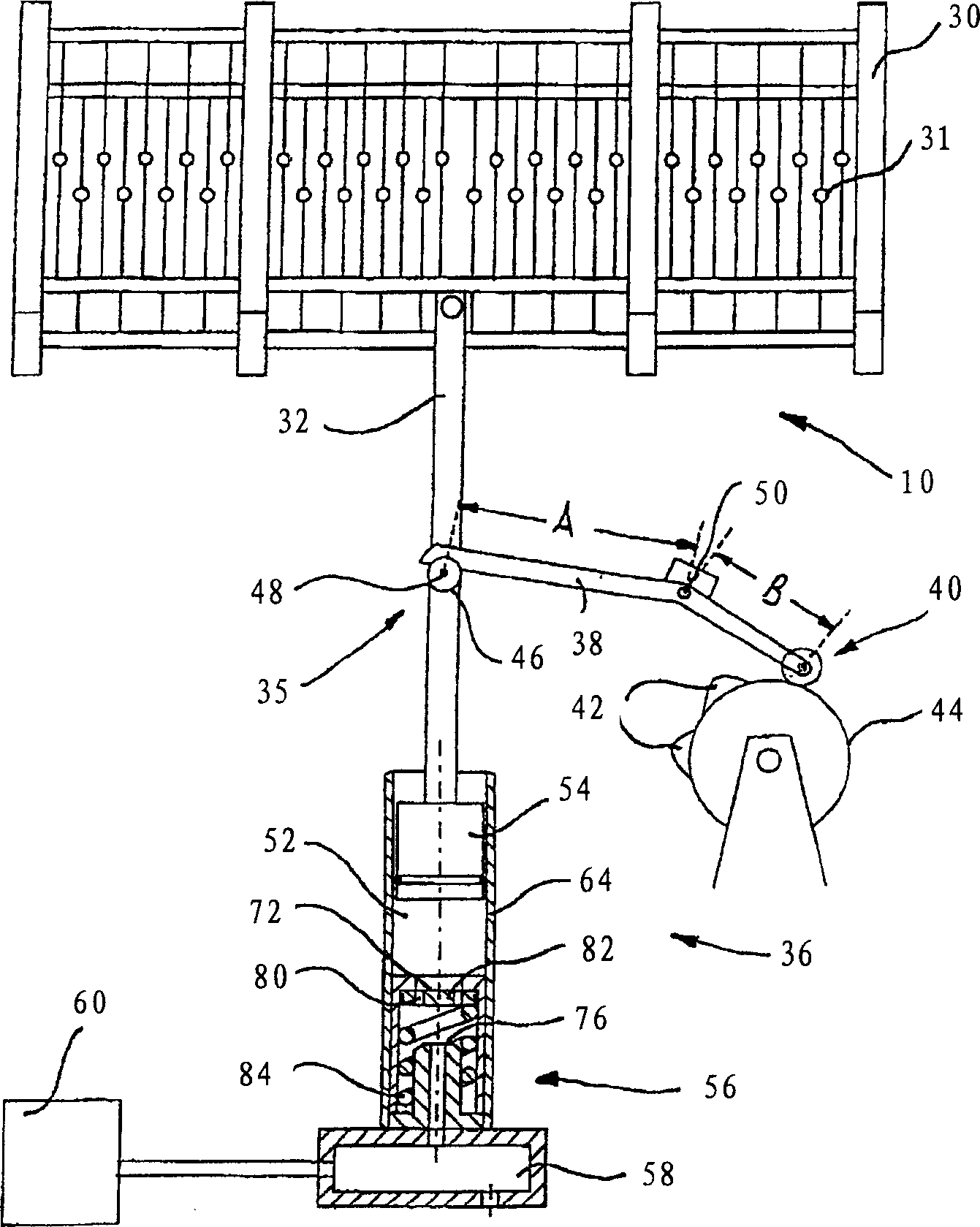

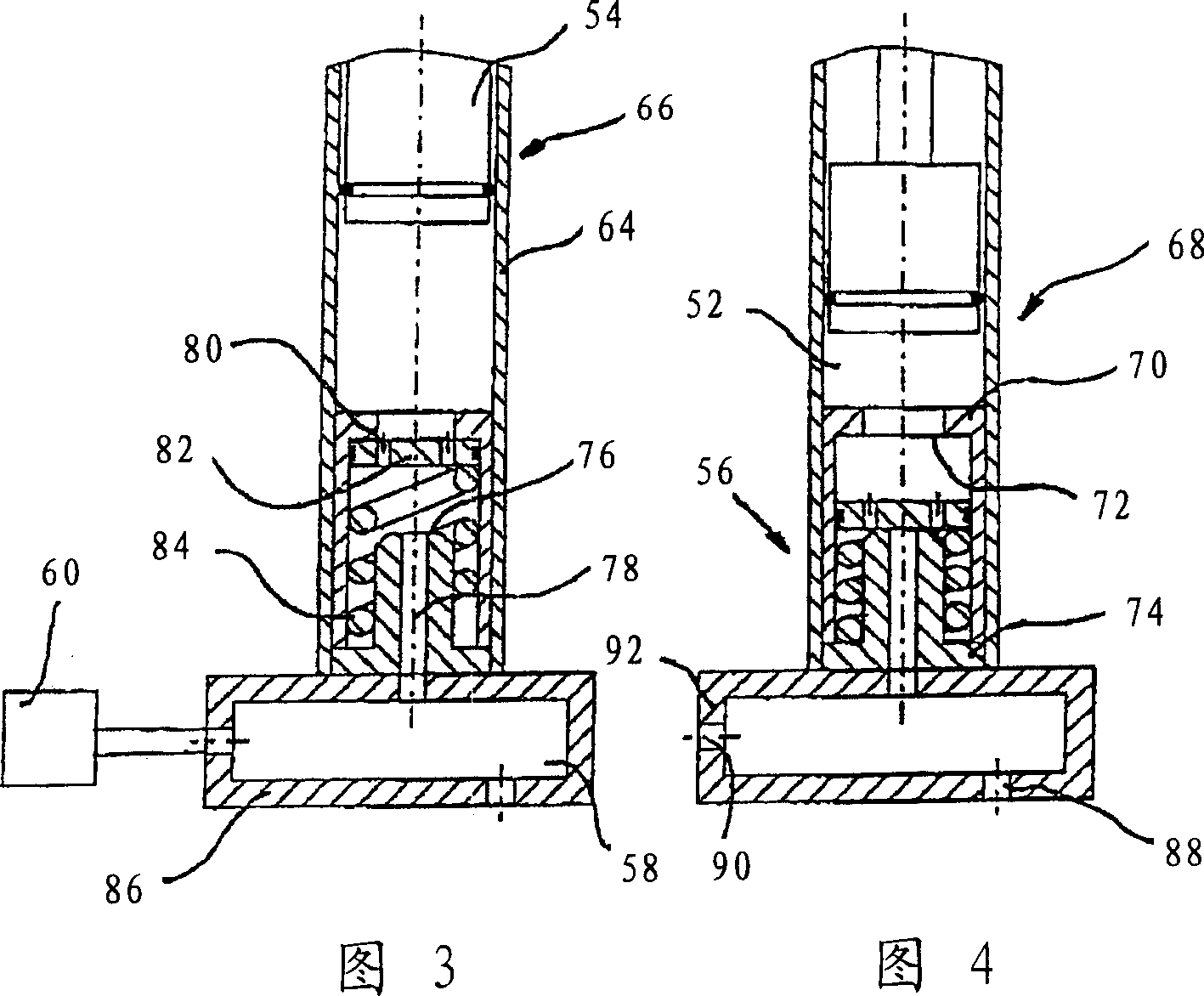

[0030] figure 2Shows a heald frame arrangement 10 in which, in each case, a plurality of heald frames 30 with thread guide elements 31 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com