Design method of six-rod shedding mechanism with long pause angle at lowest position of shed

A technology of the lowest position and opening mechanism, which is applied in the direction of cam opening mechanism, mechanical equipment, transmission device, etc., which can solve the problems of difficulty in stopping and no way to accurately reproduce the given trajectory, and achieve smooth force, small auxiliary force, and rotation sub-low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

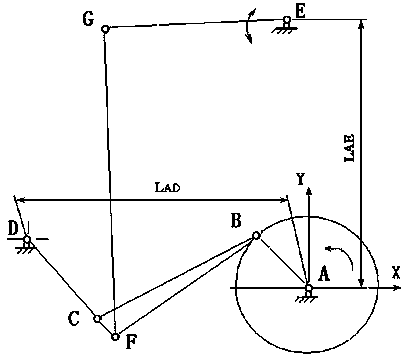

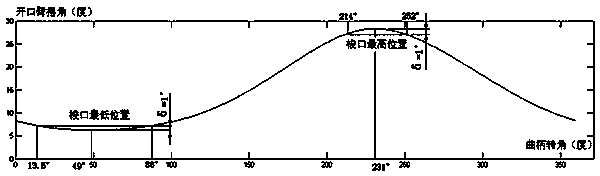

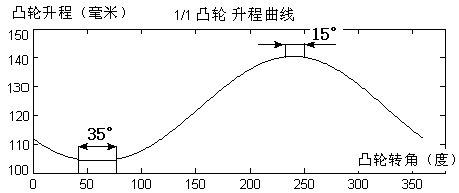

[0047] see figure 1 , Figure 12As shown, a design method of a six-bar shedding mechanism with a long dwell angle at the lowest position of the shed, using the crank AB of a crank-rocker mechanism ABCD to drive a link point F on the extension surface of the first link BC to form a figure-eight curve Movement, the right end of the 8-shaped curve has a slow speed change, a double-rod assembly FGE is connected in series at the connecting rod point F, and the plane movement of the connecting rod point F is driven by the input connecting rod FG of the double-rod assembly FGE The opening arm GE swings; when the connecting rod point F moves along the arc segment at the right end of the figure-eight curve, the swing point G of the double-rod assembly FGE opening arm GE is approximately stationary, thereby realizing the The approximate stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com