Gas power nail gun

A gas-powered, nail-shooting technology, applied in nailing tools, manufacturing tools, etc., can solve problems such as difficulty in ensuring the balance of force on the left and right striker arms, skewed combustion cylinder, deformation under force, etc., and achieves a simple structure , smooth movement, balanced force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

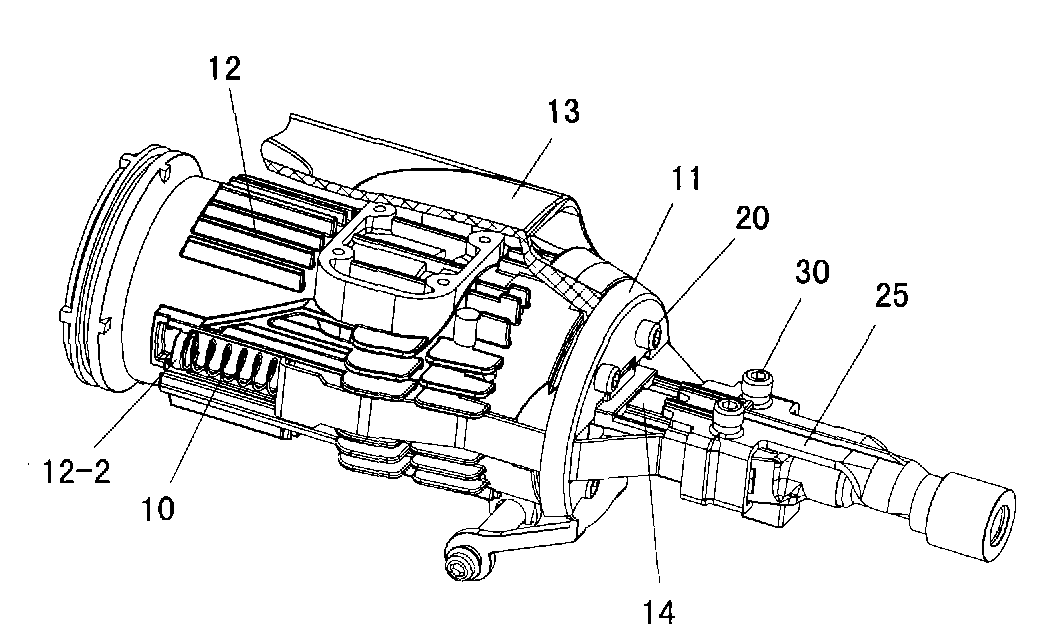

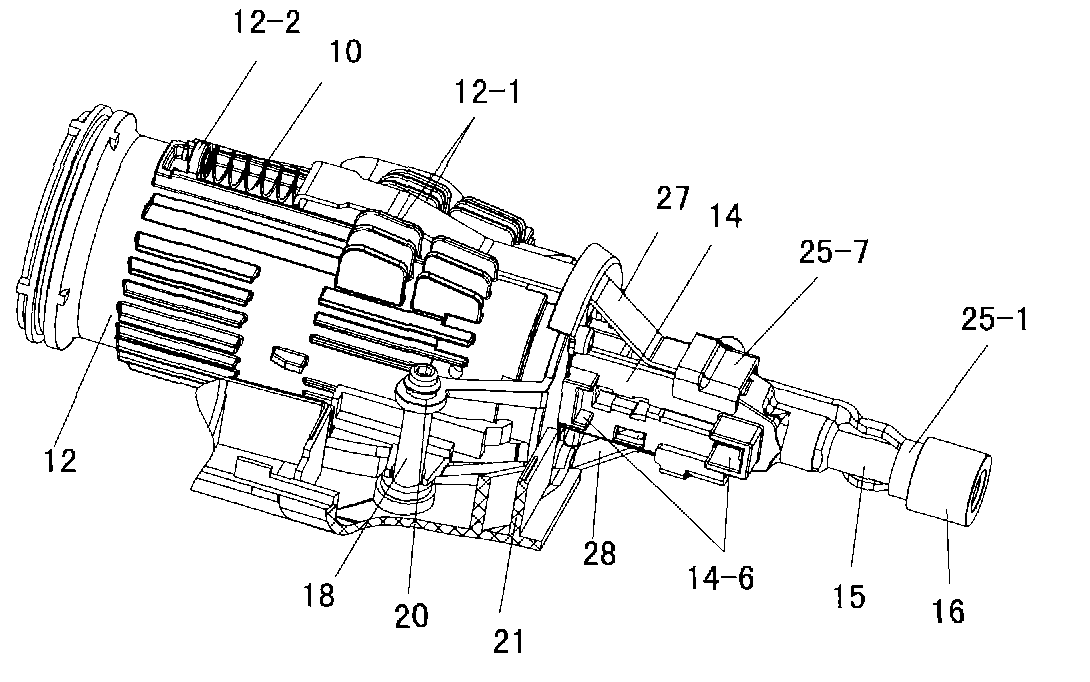

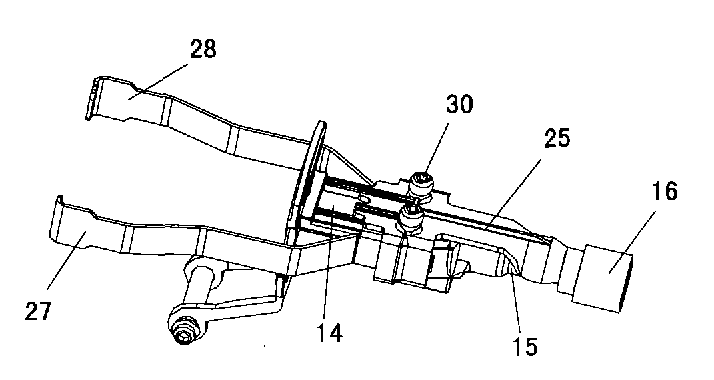

[0066] The gas power nail gun of the present embodiment is as Figure 1 to Figure 4Shown, its casing 13 inside is equipped with cylinder block 12, and this cylinder block 12 bottoms are nailing seat 14. The nailing seat 14 is fastened to the cylinder block 12 by screws 20 . The nailing seat 14 bottom is provided with the striking head 25 that is fixedly connected with the left and right striking arms 27 and 28 by screws 30 . The two sides of the cylinder block 12 are respectively formed with a guide groove 12-1 formed by heat dissipation ribs and an overhanging flange 12-2. The left and right striker arms 27 and 28 are respectively embedded in the guide grooves 12-1 on both sides, and the upper top surfaces 27-7 and 28-7 of the left and right striker arms are respectively connected with the outwardly extending The flanges 12-2 engage. Both sides of the nailing seat 14 are shaped on vertical slide rails 14-1, and the lower end is equipped with a gun nozzle 15, and a conduit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com