Logging method of ultrasonic logger system

A logging tool and logging technology, applied in wellbore/well components, measurement, instruments, etc., can solve problems such as inability to accurately fit horizontal section curves at the same depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

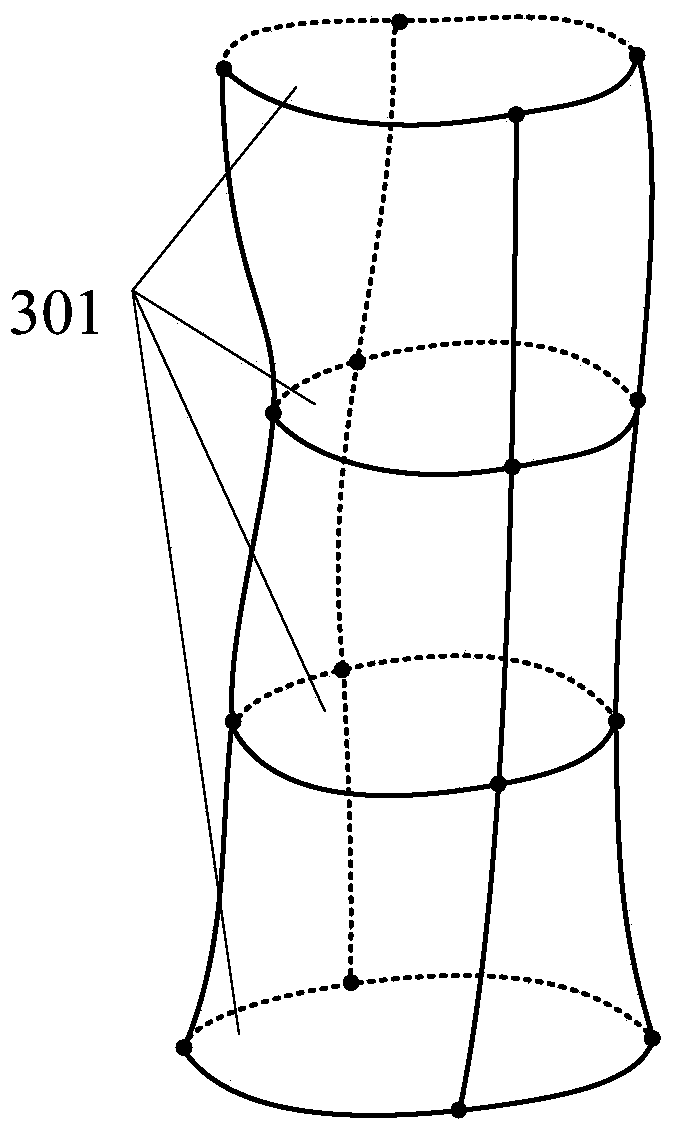

[0061] According to attached Figures 1 to 12 , the specific embodiment of the present invention is described further:

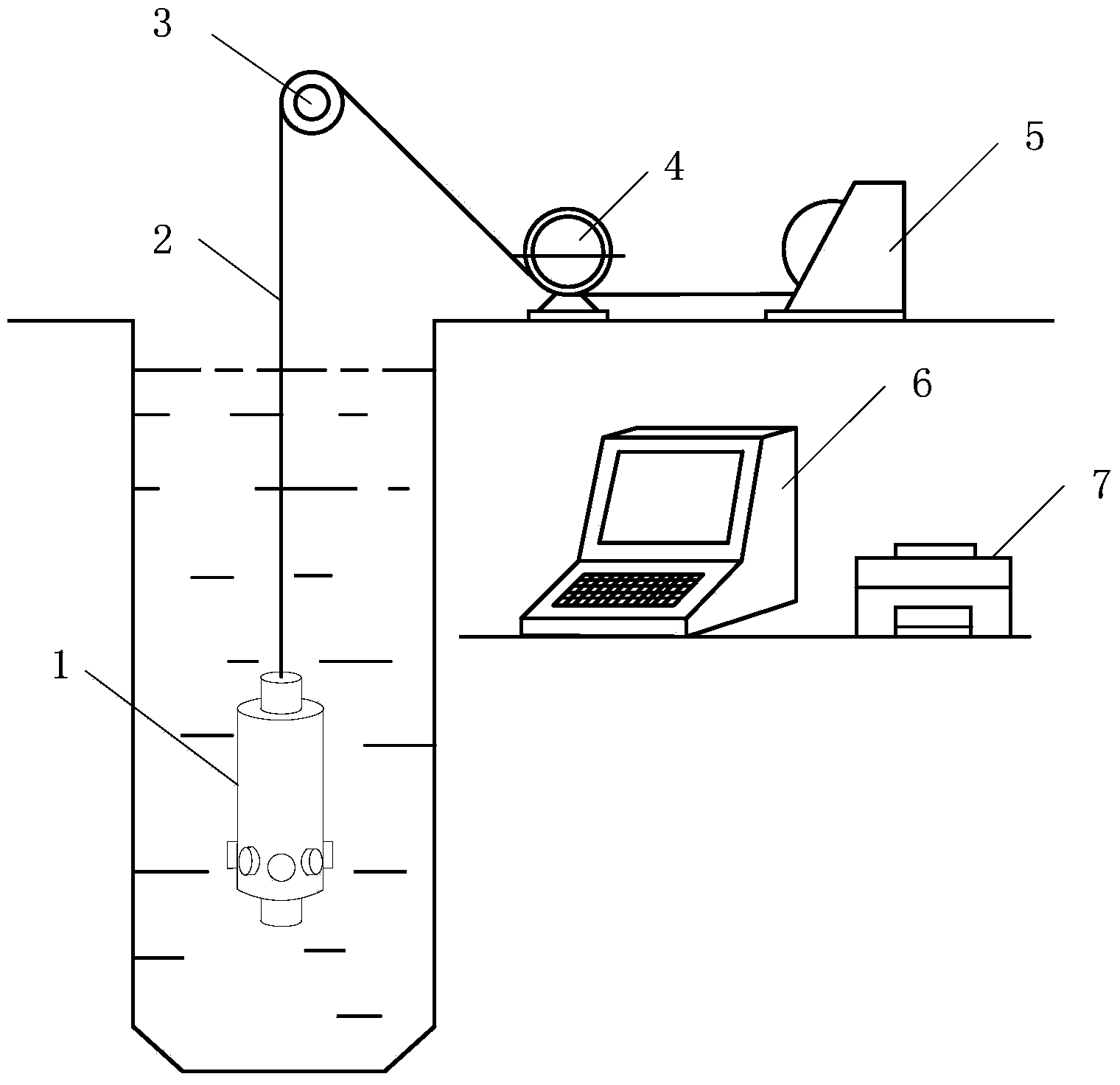

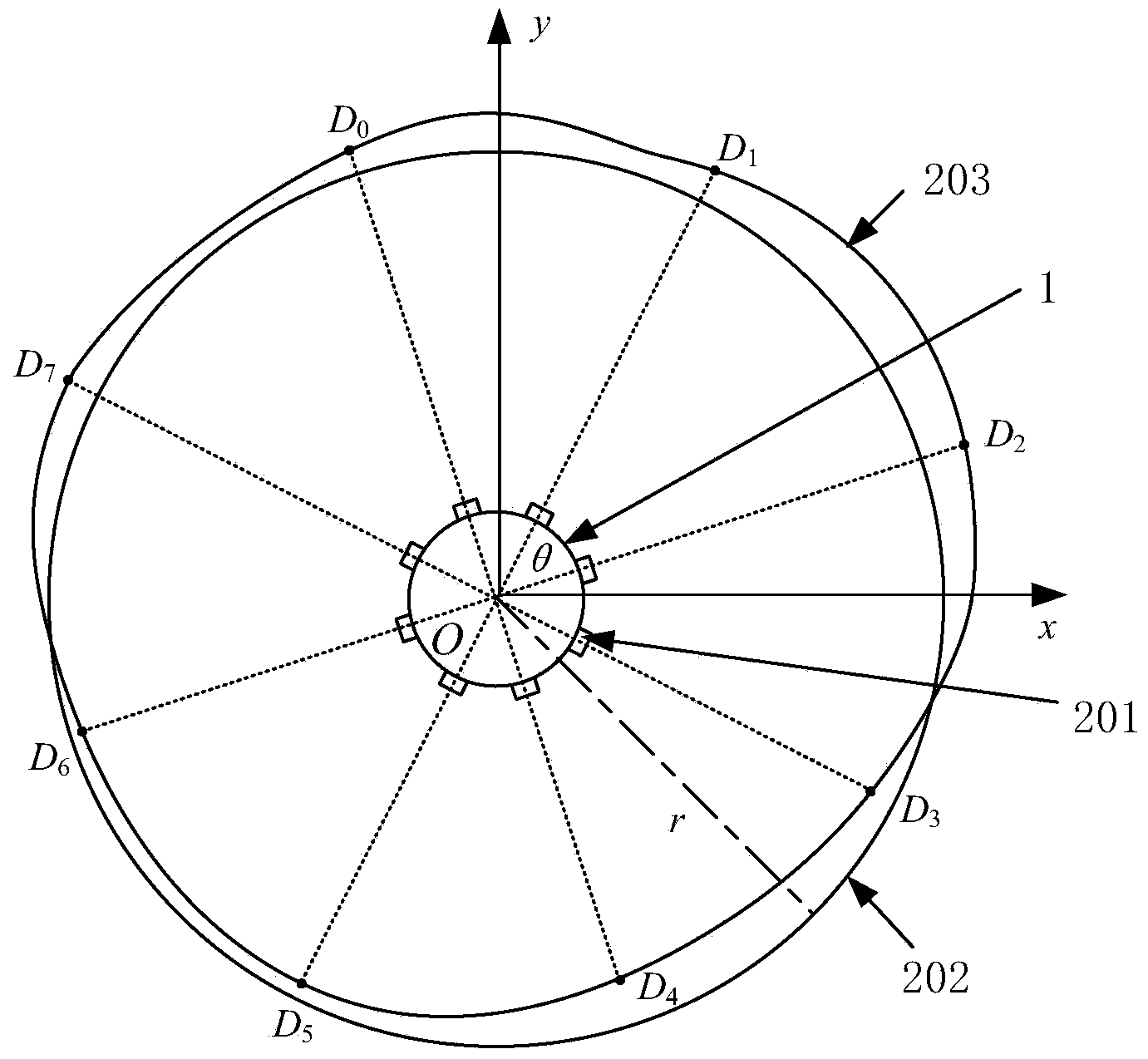

[0062] An ultrasonic logging system, such as figure 1 , including a downhole instrument 1, a depth instrument 5, a logging drawworks 5, a cable 2 and an uphole workstation 6. The downhole tool 1 is cylindrical. The bottom of the downhole tool 1 is evenly distributed with m ultrasonic transducers with an angle of θ. The downhole tool 1 is vertically suspended in the well through the cable 2. The cable 2 passes through the depth gauge 4 and the logging drawworks. 5 phases are connected, and the well logging drawworks 5 is connected to the well work station 6, and the well work station 6 is connected to a printer 7. The downhole tool 1 is lowered vertically through the depth gauge 4, the borehole diameter data is measured by the downhole gauge 1, the length of the lowering cable 2 is measured by the depth gauge 4, the well depth data is obtained, and the bore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com