Installation structure and installation method of earthquake electromagnetic disturbance sensor

An electromagnetic disturbance and installation method technology, applied in the direction of electric/magnetic exploration, instruments, measuring devices, etc., can solve the problems of metal-like pipeline interference, weak anti-interference ability, and inability to directly detect changes in the earth's magnetic field, and achieve easy Achievement and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

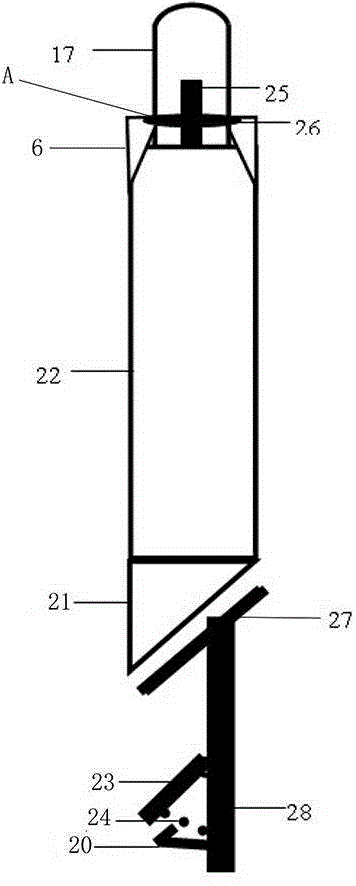

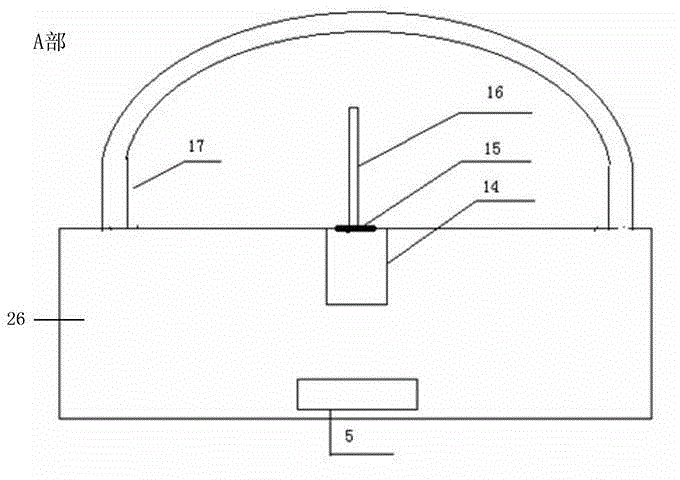

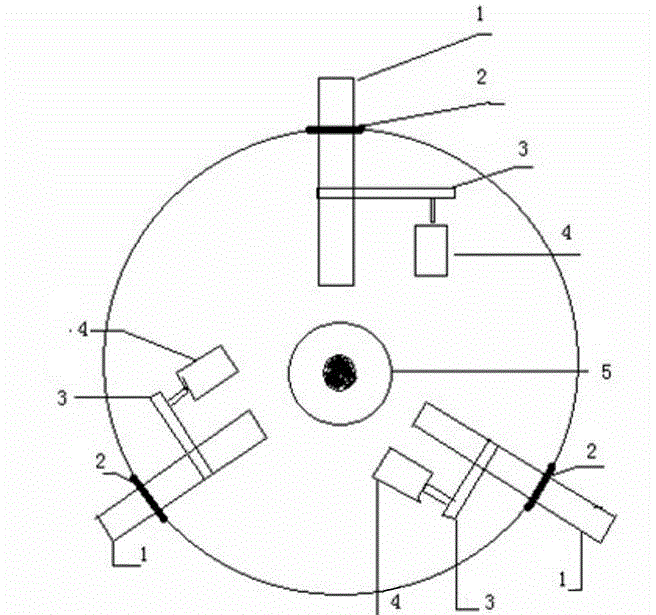

[0015] The installation method of the electromagnetic disturbance sensor is to drill an observation well at the observation station, the diameter of which is greater than 50mm, and the inclination of the drilling hole is less than 5 degrees. The observation well is equipped with a non-magnetic casing, and the electromagnetic disturbance sensor 22 is vertically installed at a suitable position within a depth of 1000m. , the electromagnetic disturbance sensor 22 sends the induced signal to the magnetic signal processor through the signal for amplification, filtering and other related processing, and the signal line passes through the PVC pipe for fixing and protection. A metal lifting ring 17 is fixed on the top of the sensor, which is used to lower the sensor into the well, and the signal monitored by the sensor is sent to the ground equipment through the signal cable, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com