Variable speed supercharge oil well cement consistometer and thickening time measuring method thereof

A technology of oil well cement slurry and measurement method, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the consistency and thickening time of oil well cement slurry do not conform to the actual situation in the well, and achieve the effect of improving the cementing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

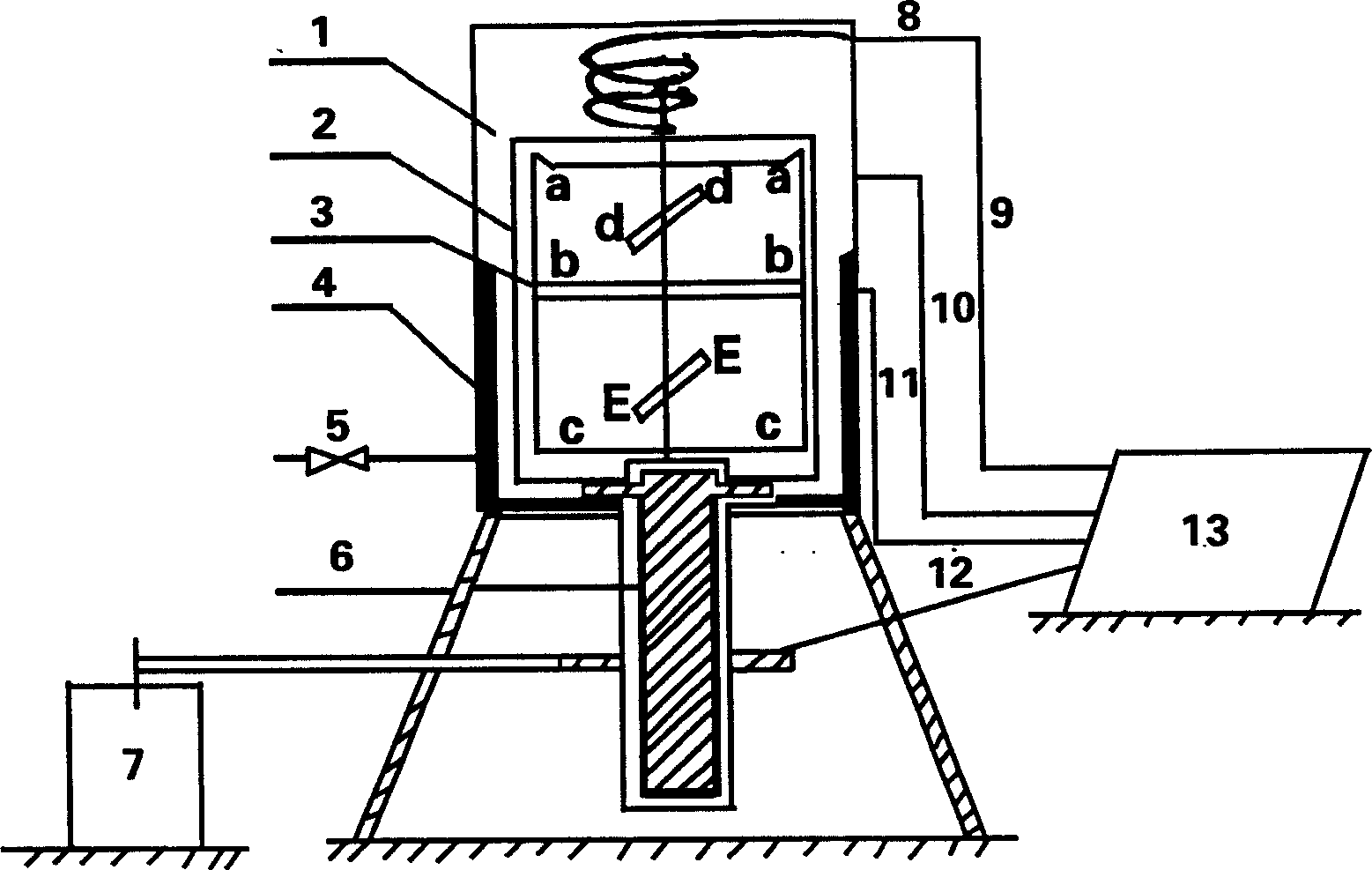

Method used

Image

Examples

specific example

[0032] 1. Prepare four kinds of oil well cement slurries with different properties according to the API standard, and their densities are about 1.40 and 1.90 (see Table 2);

[0033] 2. According to the well depth of 2000-4000m, set the experimental temperature and pressure of oil well cement slurry (Table 2);

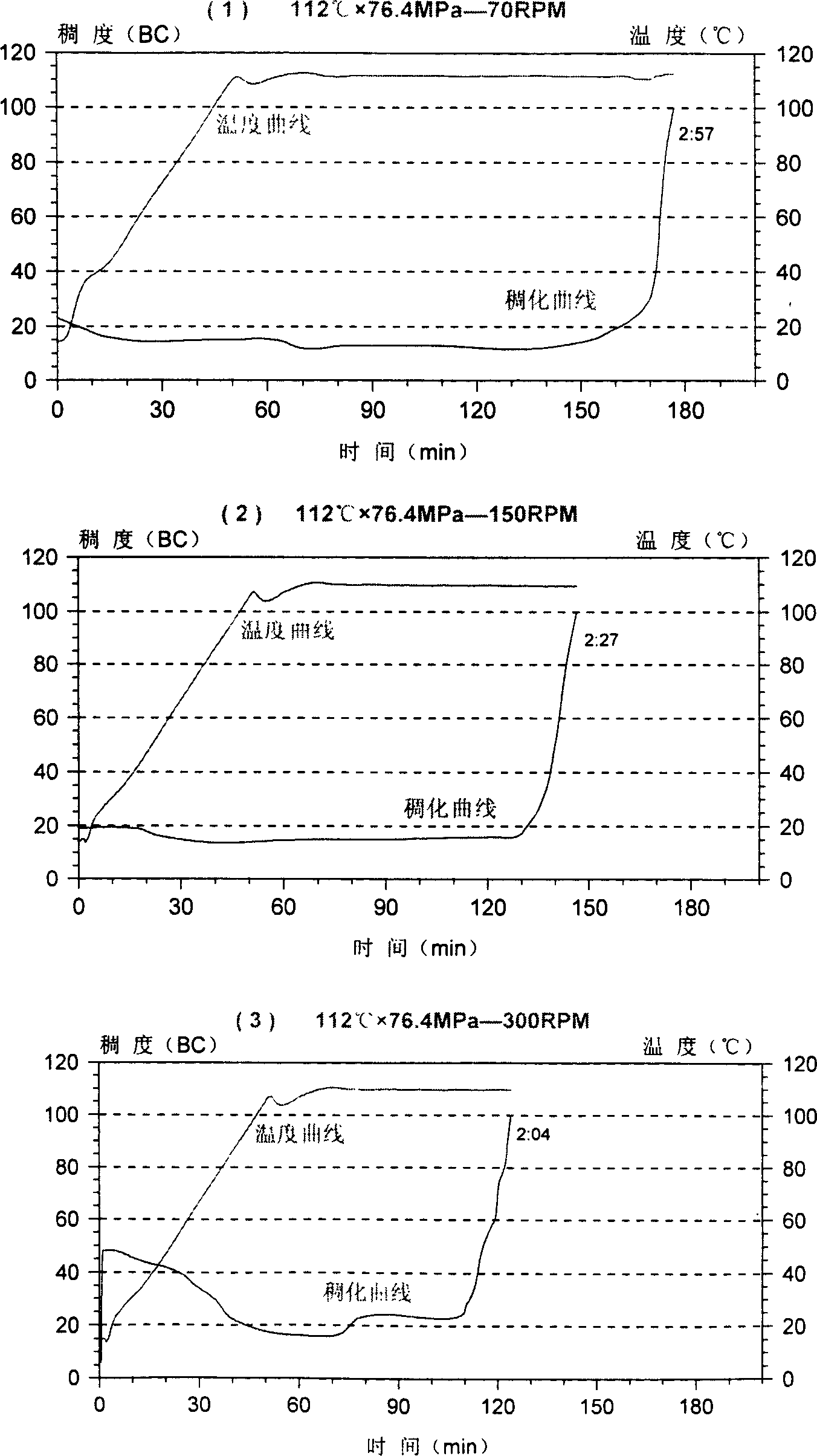

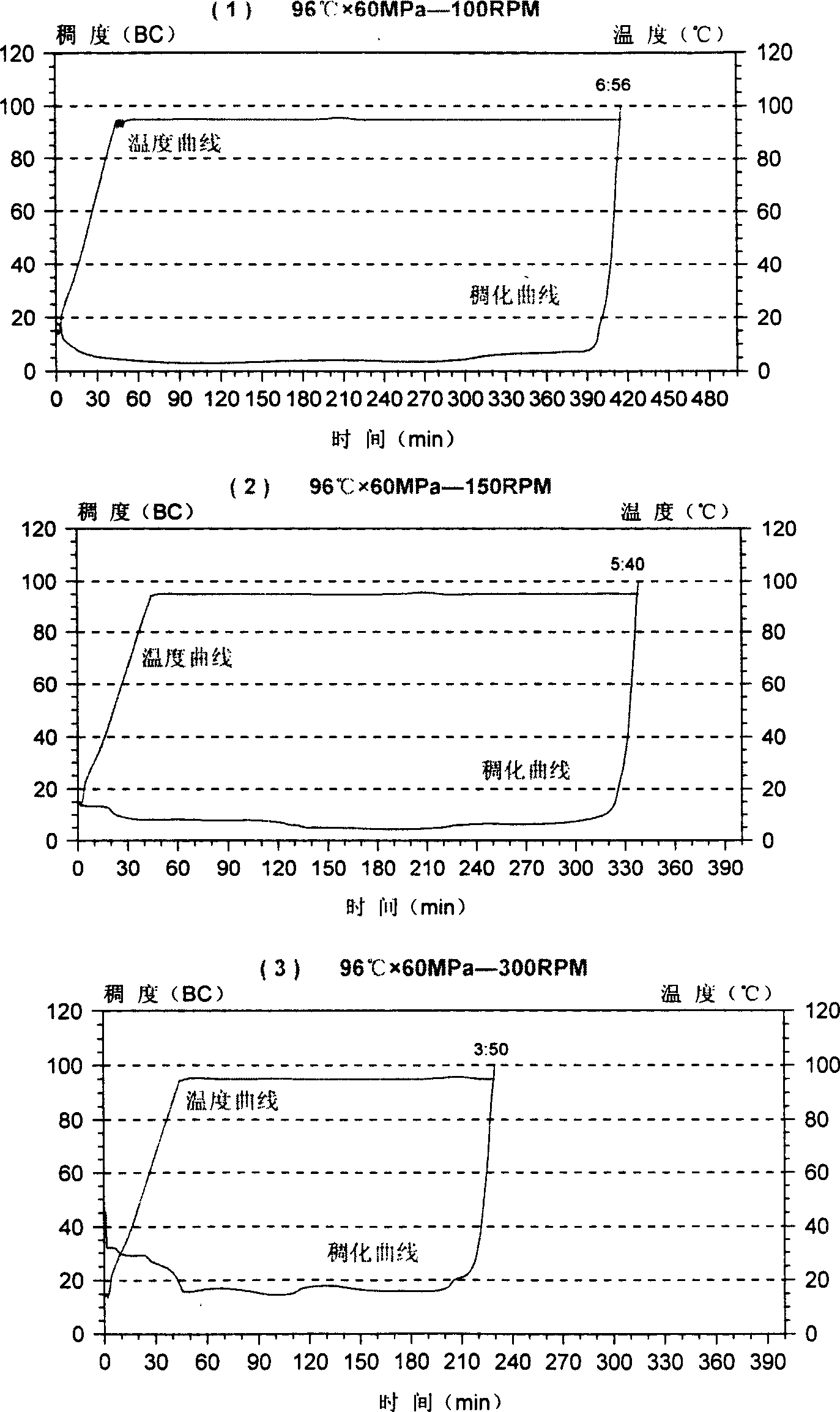

[0034] 3. according to 150RPM of API standard and selected 70,100,300RPM in addition, use variable-speed pressurized type consistency meter of the present invention, record the thickening curve and the thickening time of oil well cement slurry (see attached Figure 2-5 ,Table 2).

[0035] serial number

density

temperature °C

pressure MPa

Cup speed RPM

70

(100)

150

300

1

1.90

112

76.4

2:57

2:27

2:04

2

1.89

96

60

(6:56)

5:40

3:50

3

1.905

96

60

3:50

3:08...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com