Method for designing safety drilling fluid density window during shale formation drilling

A technology of drilling fluid density and design method, which is applied in the direction of wellbore/well components, earthwork drilling and production, etc., to achieve the effect of authentic and reliable design of safe drilling fluid density window, increase construction cost, and avoid unreasonable design of drilling fluid density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described further below:

[0041] The design method of the safe drilling fluid density window for drilling in shale formations is as follows:

[0042] Step 1: Carry out shale rock mechanics experiments in the target interval of the target well in the drilling block to test the in-situ stress, formation pore pressure, elastic modulus of shale in different directions and Poisson's ratio.

[0043] Step 2: Select a certain well depth value for the target well target layer, and convert the borehole Cartesian coordinate system, in-situ stress coordinate system and geodetic coordinate system according to the designed wellbore structure data to prepare for borehole force analysis .

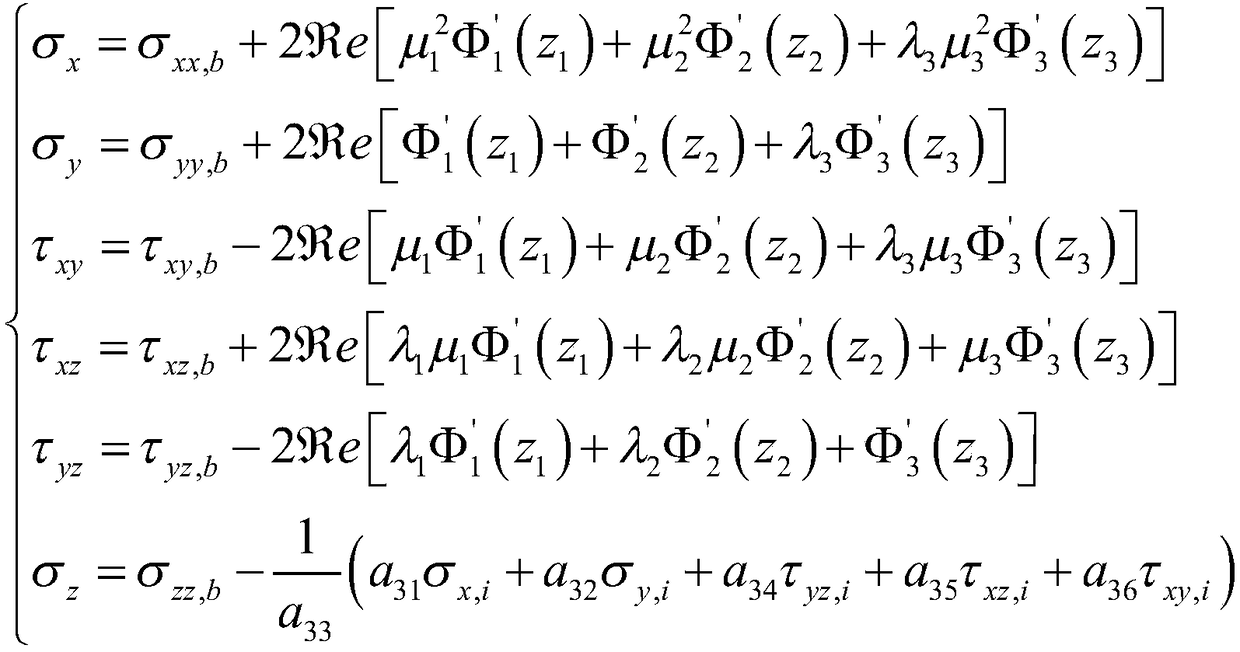

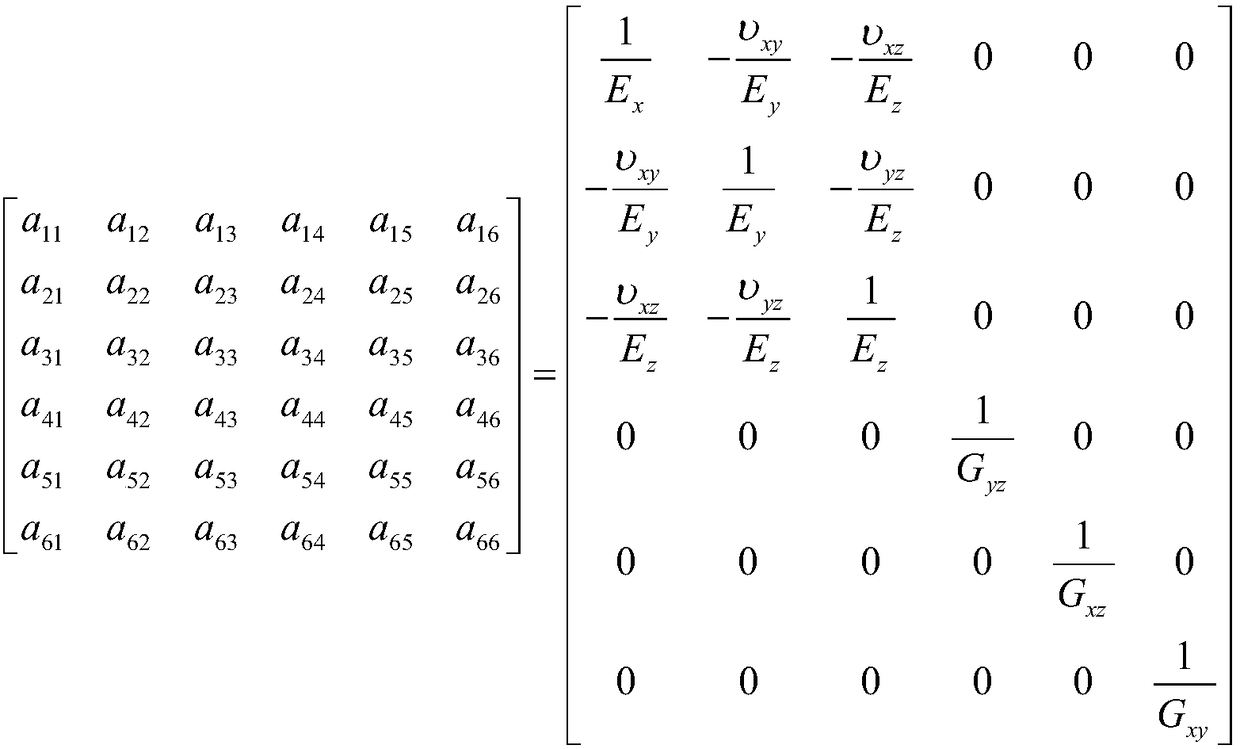

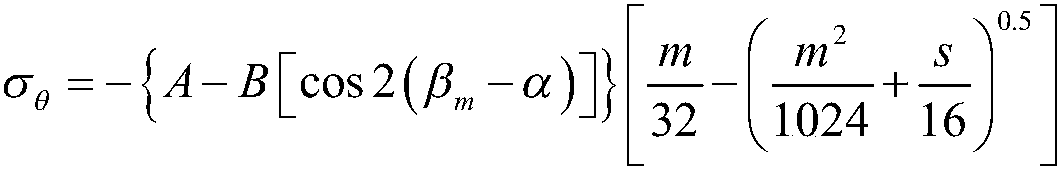

[0044] Step 3, considering the shale formation as a transversely isotropic porous medium, calculating the stress components of the borehole wall caused by the ground stress and the drilling fluid pressure in the borehole;

[0045] Among them, the stress components of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com