Method for determining minimum heating common requirement of heat exchange network containing non-isothermal phase-change fluid

A phase change fluid and heat exchange network technology, applied in general control systems, comprehensive plant control, instruments, etc., can solve problems such as the inability to correctly estimate the limitations of heat exchange networks containing non-isothermal phase change fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

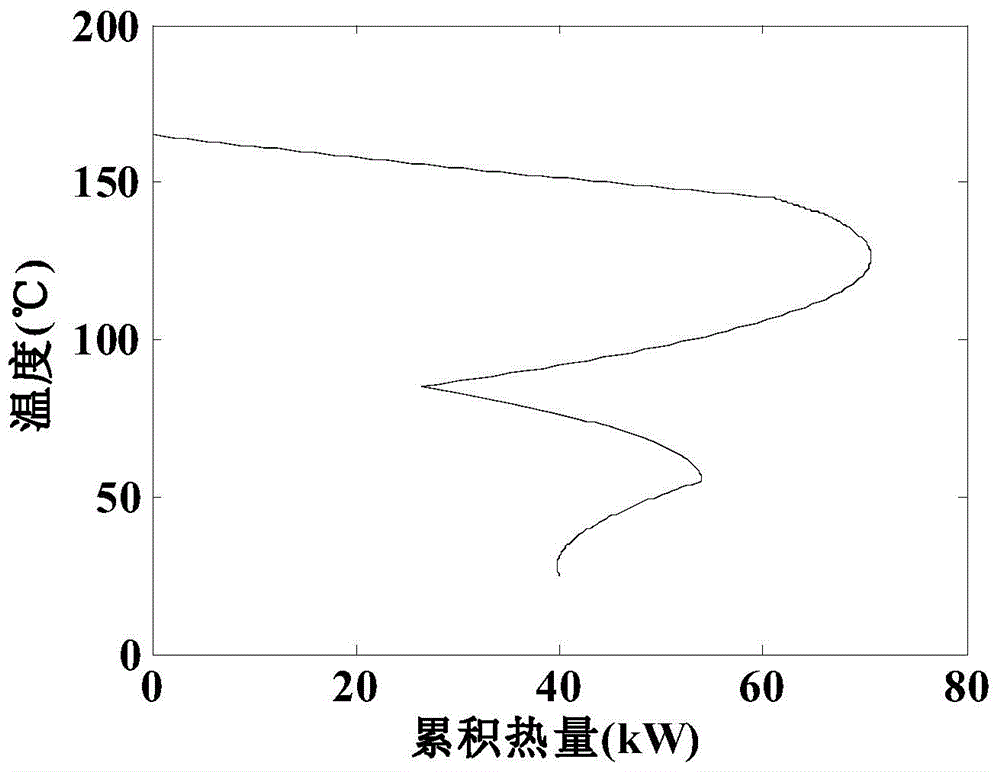

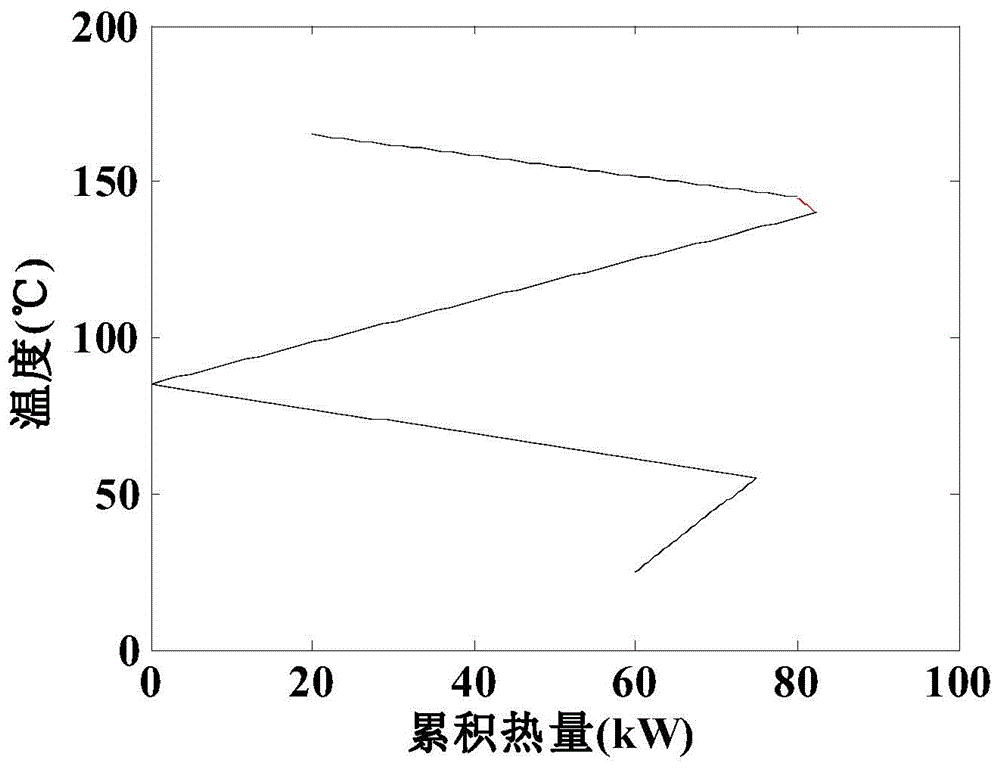

[0047] The present invention will be further described below in conjunction with the accompanying drawings.

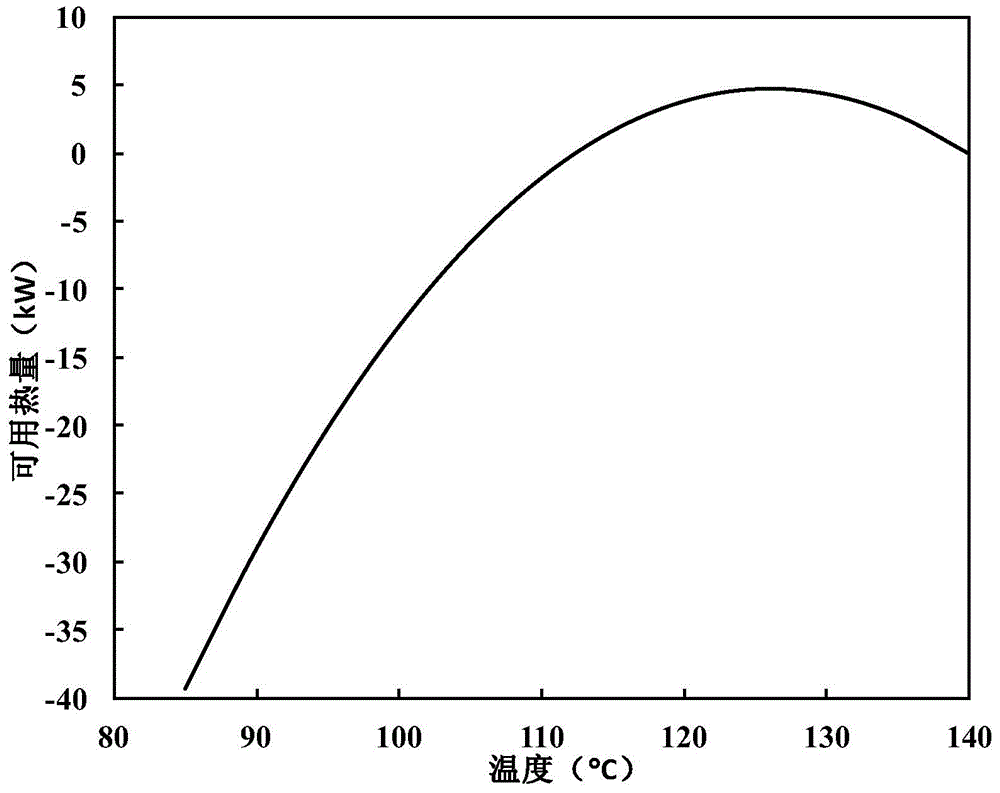

[0048] refer to Figure 1 ~ Figure 3 , a method for determining the minimum heat utility demand of a heat exchange network containing a non-isothermal phase change fluid, comprising the following steps:

[0049] 1) Extract the process parameters and physical property data of the fluid

[0050] The process parameters and physical data of logistics include: composition, flow rate, inlet temperature T in (initial temperature), outlet temperature T out (specified target temperature), enthalpy and specific heat capacity. The method is based on the actual physical properties of the fluid, and adopts the actual temperature-enthalpy physical property relationship of the fluid instead of assuming that the specific heat capacity of the substance is constant.

[0051] 2) Set the minimum heat transfer temperature difference ΔT of the heat exchange network min

[0052] Set th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com