A design method for local efficiency enhancement of modular wind turbine blades

A technology for wind turbine blades and a design method, which is applied to wind turbines, mechanical equipment, engines, etc., can solve the problems that wind turbine blades cannot be optimized as a whole, improve wind energy utilization efficiency, etc. coefficient, quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

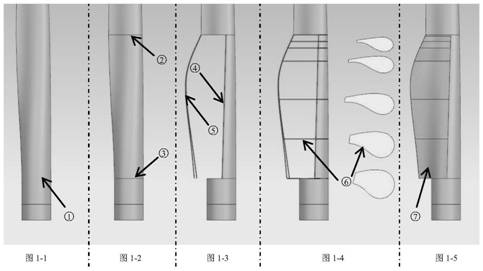

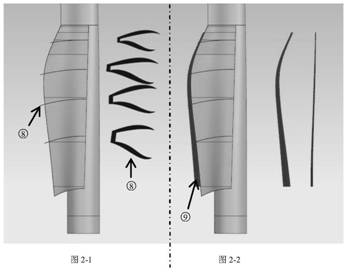

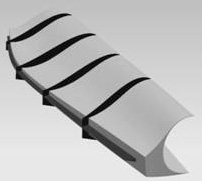

[0021] like Figure 1 ~ Figure 3 As shown in the present invention, a root box design method in a local synergistic design method for a modular wind turbine blade, the steps mainly include:

[0022] (1) UG software is used as the platform, and the existing wind turbine blade ① is used as the reference shape to implement modeling. First, find the position with the largest chord length on the blade and set it as the end position ② of the root box in the span direction and 1.5~ from the bottom. The position of 3 times the bottom diameter is set as the starting position of the root box ③, and the leaves between the two positions are taken as the research object to carry out the root box design;

[0023] (2) The root box generally adopts the form of half wrapping, and the leading edge of the airfoil of each control surface along the blade span still adopts the original leading edge of the blade. Firstly, the length of the root box along the blade chord direction is affected by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com