Drilling and completion integration device and method using coiled tubing carrying sieve tubes for sidetracking

A technology of tubing and sidetracking, applied in drilling equipment, directional drilling, drill pipe, etc., can solve the problems of complicated procedures and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

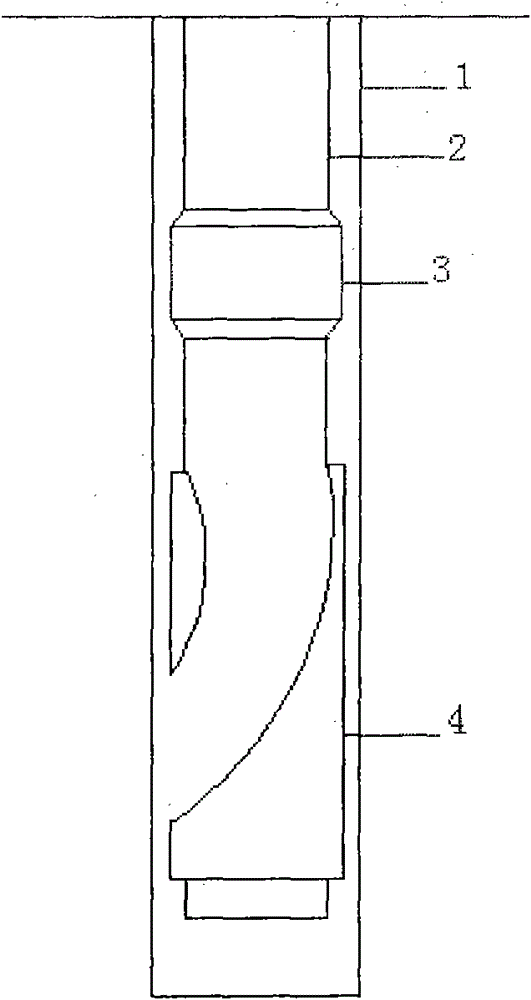

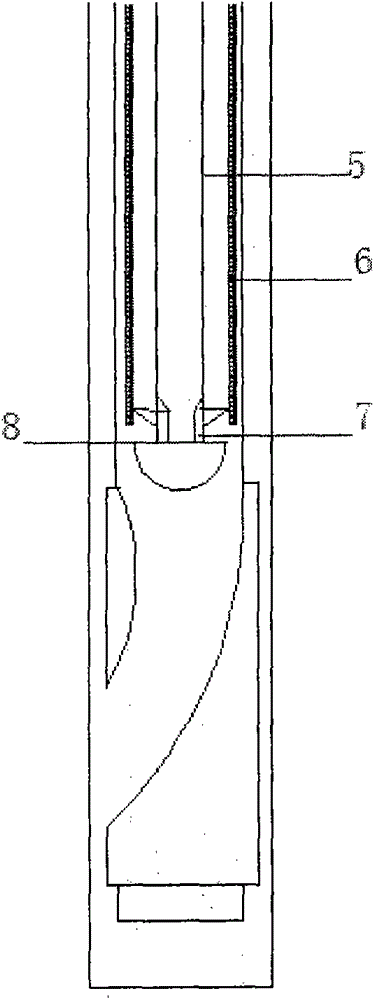

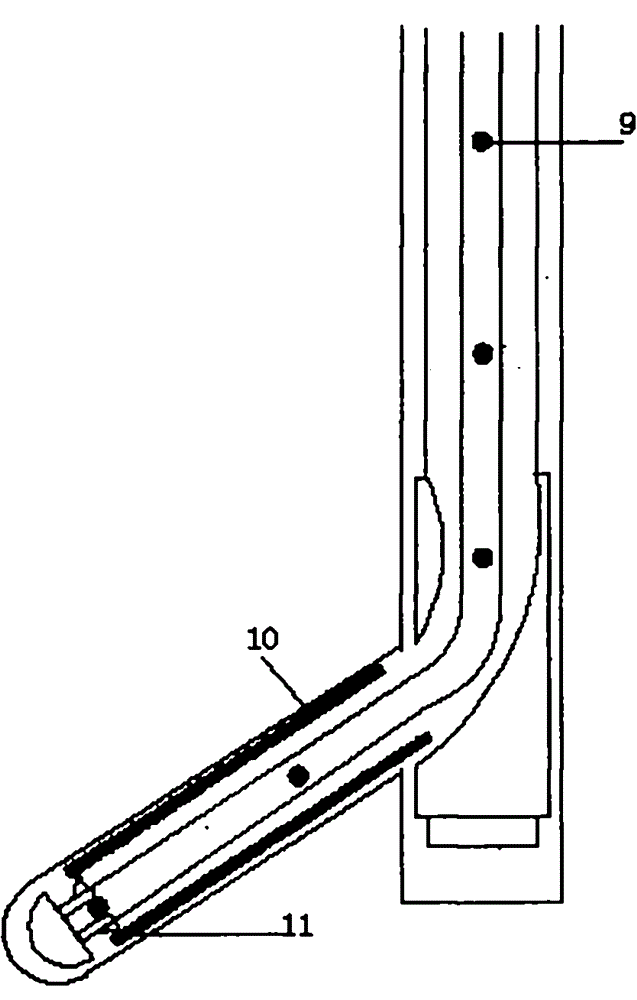

[0015] Combine the following figure 1 and figure 2 The method and device for integrated drilling and completion of lateral pinnate lateral wells with coiled tubing are further described and illustrated. see figure 1 , the process of integrated drilling and completion of coiled tubing sidetracking pinnate lateral well includes figure 1 There are five processes in (1), (2), (3), (4), and (5). (1) That is, the casing 1 is run in the main horizontal well section and cemented, and then the tubing string 2 is run in. The tubing anchor 3 and the diverter 4 are connected to the lower part of the tubing string 2. The orientation of the steering gear 4 is set in front of the well and the tubing string 2 is anchored. (2) That is, the coiled tubing 5 with the screen 6 is lowered into the tubing string 2, and the coiled tubing 5 and the screen 6 are connected through the lower separation device 7, and the front end of the separation device 7 is connected with a jet drill bit 8. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com