Petroleum drilling well depth measuring system and method

A technology of oil drilling and measurement system, which is applied in the direction of measurement, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of cumbersome measurement work, inconvenient operation, inaccurate measurement, etc., and achieve the effect of real-time display of well depth data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

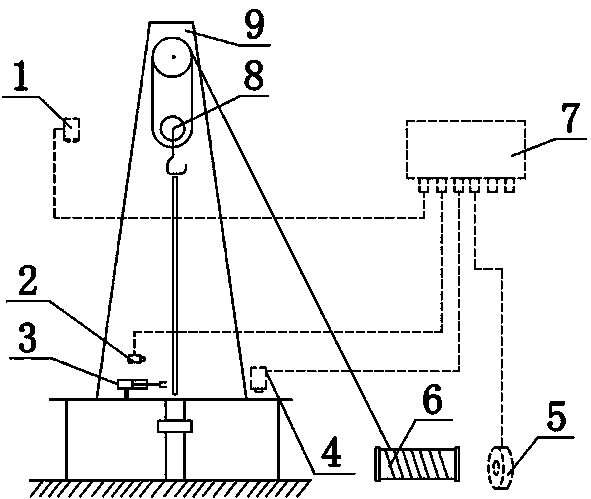

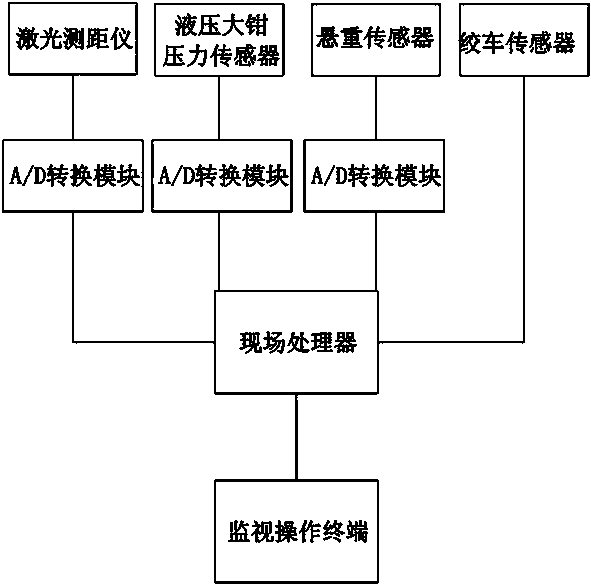

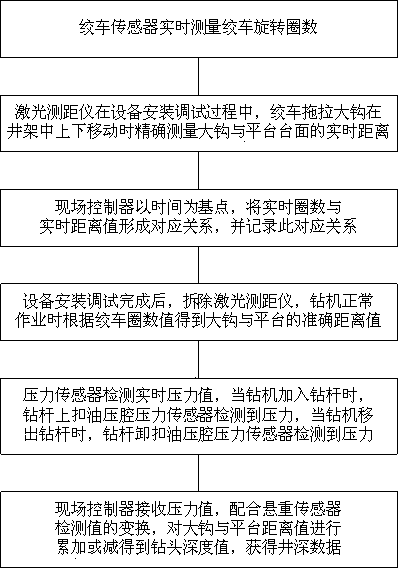

[0022] Such as figure 1 with figure 2 As shown, the oil drilling well depth measurement system comprises a winch sensor 5, a pressure sensor 2, a suspension weight sensor 4, a laser rangefinder 1, a field controller 7 and a monitoring operation terminal, and the winch sensor 5 is fixed on the On the drum shaft of the winch 6, there are two pressure sensors 2, which are respectively arranged at the oil inlet end of the make-up rotation and the oil inlet end of the shackle rotation of the motor oil circuit of the hydraulic tong 3; It is arranged on the dead rope fixer under the derrick 9, the laser rangefinder 1 is fixed on the hook 8, the winch sensor 5, the pressure sensor 2 and the suspension weight sensor 4 are connected to the field co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com