Lithium battery unit defect detection method

A defect detection and lithium battery technology, applied in image data processing, instruments, character and pattern recognition, etc., can solve the problems of inaccurate detection results, low efficiency, low accuracy, etc., and achieve the goal of improving product quality and overcoming low efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

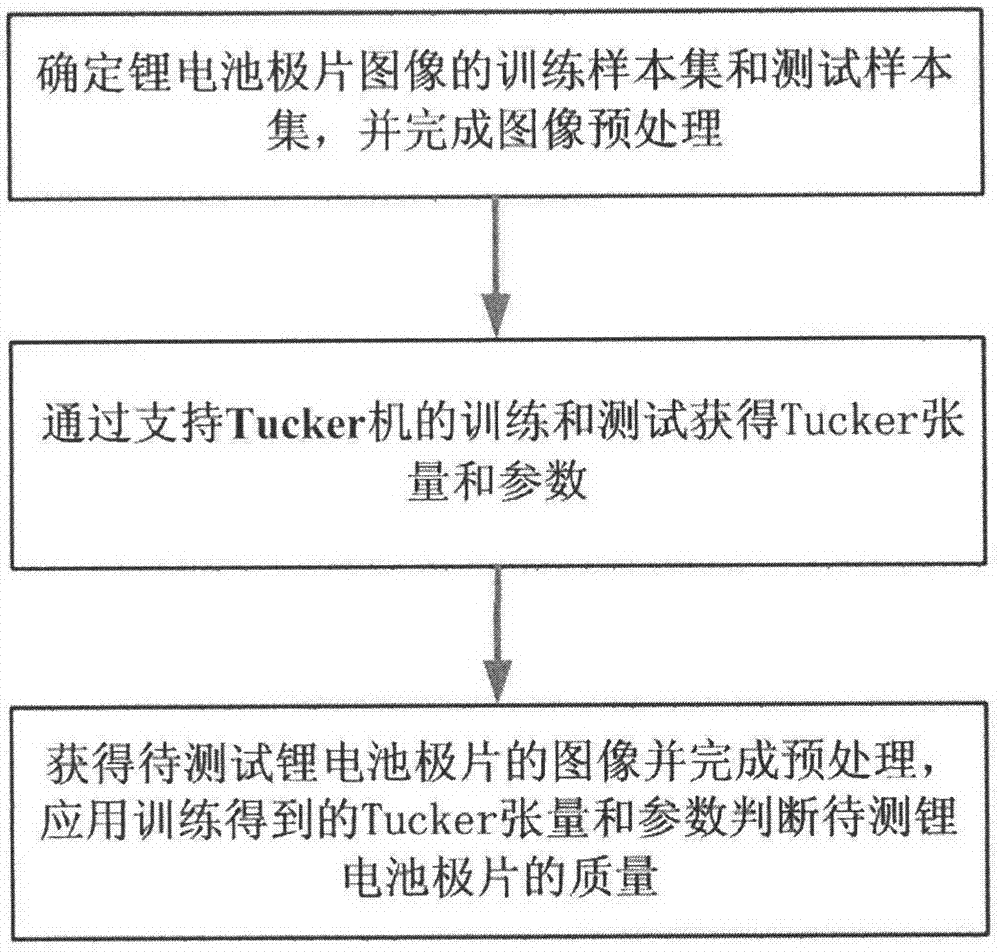

[0092] Below in conjunction with the accompanying drawings, the specific implementation of the lithium battery unit defect detection based on the Tucker machine is described as follows:

[0093] image preprocessing

[0094] The lithium battery unit database used in the present invention is derived from the images collected by the production line, from which 100 photos with defects and 100 photos of lithium battery units without defects are randomly selected, totaling 200 images. All images are preprocessed. The color image is converted into a grayscale image, and the average filter and the Gaussian filter are used for filtering in the frequency domain, and then the two filtered images are differenced. Finally, the image is unified to 64×64 size. The results of the preprocessing of the lithium battery cell grid image are as follows: figure 2 shown.

[0095] Defect Detection of Lithium Battery Unit Pole Grid Based on Supporting Tucker Machine

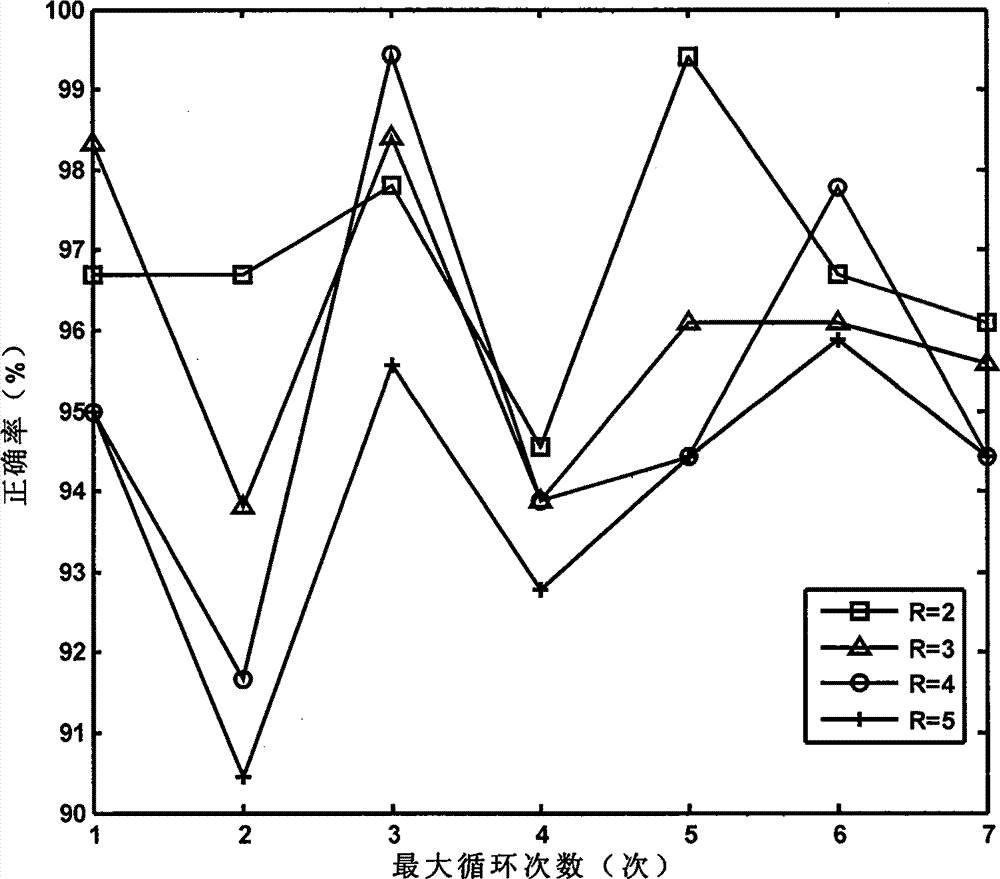

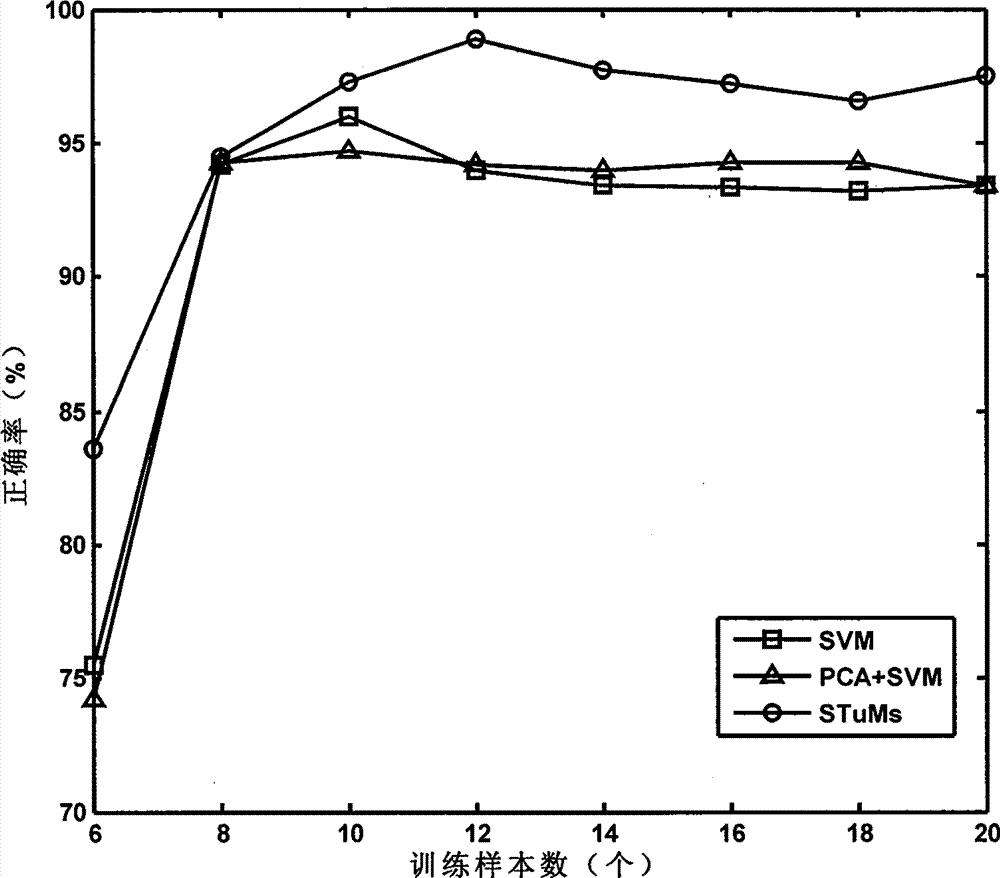

[0096] The training sample s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com