Method for extracting coal bed gas under wells through alternate cooling and heating function

A technology of alternating cold and heat, coalbed methane, which is applied in the fields of fluid extraction, earthwork drilling, wellbore/well components, etc. The effect of absorptive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for extracting coalbed methane by using the alternate action of cold and heat in underground mines is carried out in the following steps:

[0046] Step 1, create a well pattern in the coal seam

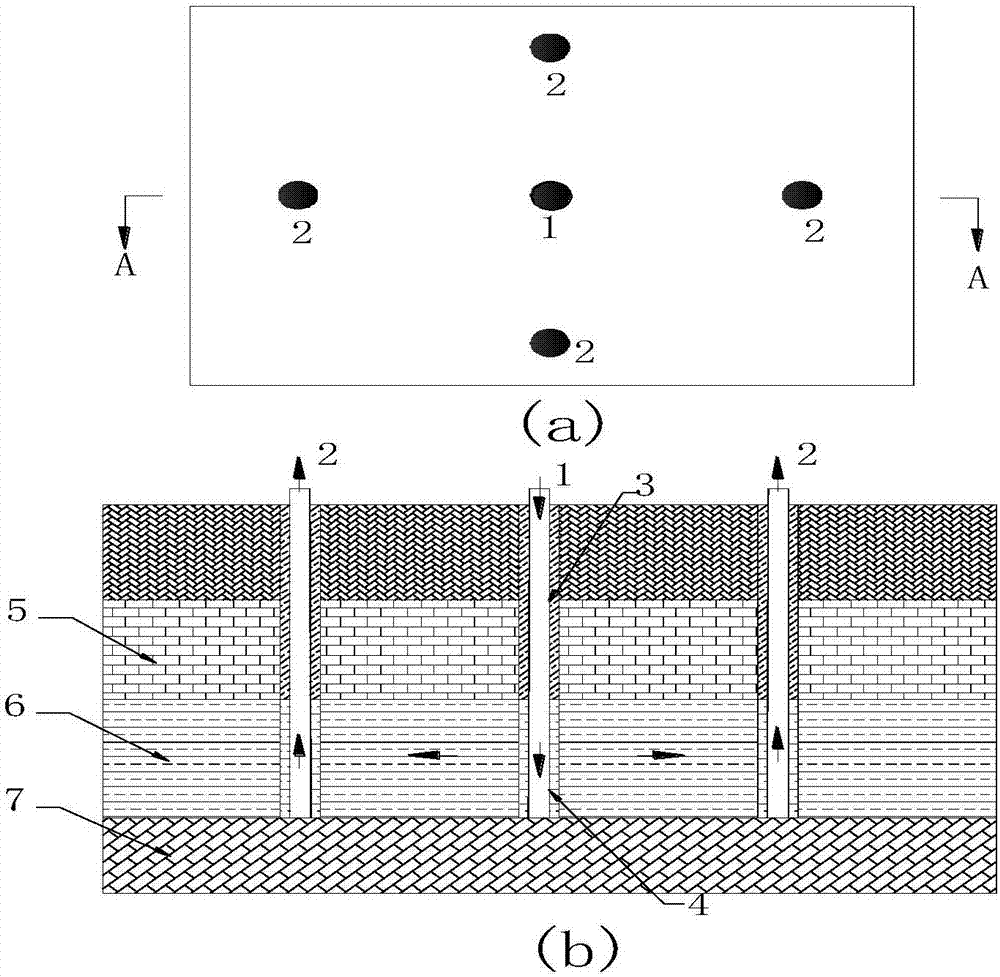

[0047] Drill vertically from the ground and arrange the well pattern, see the well pattern layout diagram figure 1 , figure 1 Among them, (a) is the top view of the well pattern layout, (b) is the cross-sectional view along the A-A line in the figure (a), the drilling interval is 300m, the drilling depth is as far as the coal seam 6, and the number of wellheads is 5, among which, the vertical drilling After entering the coal seam 6, lower the screen casing 4 in the 6th section of the coal seam, and lower the thermal insulation casing 3 in the 5th section of the overlying rock layer on the roof of the coal seam above the coal seam 6, and perform corresponding cementing according to the specifications;

[0048] After cementing, in the well pattern of 5 wells arranged, ...

Embodiment 2

[0060] A method for extracting coalbed methane by using the alternate action of cold and heat in underground mines is carried out in the following steps:

[0061] Step 1, create a well pattern in the coal seam

[0062] Drill vertically from the ground and arrange the well pattern, see the well pattern layout diagram Figure 4 , Figure 4 Among them, (c) is the top view of the well pattern layout, (d) is the cross-sectional view along the B-B line in the figure (c), the drilling interval is 500m, the drilling depth is as far as the coal seam 6, and the number of wellheads is 14. Among them, the vertical drilling After entering the coal seam 6, lower the screen casing 4 in the 6th section of the coal seam, and lower the thermal insulation casing 3 in the 5th section of the overlying rock layer on the roof of the coal seam above the coal seam 6, and perform corresponding cementing according to the specifications;

[0063] After cementing, in the well pattern of 14 wells arrange...

Embodiment 3

[0074] A method for extracting coalbed methane by using the alternate action of cold and heat in underground mines is carried out in the following steps:

[0075] Step 1, create a well pattern in the coal seam

[0076] Vertical drilling is carried out from the ground, the well pattern is arranged, the drilling interval is 100m, the well depth of the drilling reaches to coal seam 6, and the number of wellheads is 3. Among them, after the vertical drilling enters coal seam 6, the screen pipe casing 4 is lowered in the coal seam 6, and the coal seam 6 The thermal insulation casing 3 is lowered in the 5th section of the overlying strata on the roof of the coal seam above, and the corresponding cementing is carried out according to the specification requirements;

[0077] After cementing, in the well pattern of the 3 wells arranged, one of the wells is selected as the working well 1, whose function is to implement alternating cooling and heating; the other wells are used as gas pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com