SCR catalyst containing copper and iron composite bases and preparation method of SCR catalyst

A technology of SCR catalyst and composite base, applied in the field of chemistry, can solve the problem of low activity, and achieve the effect of excellent catalyst performance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] In the synthetic zeolite with porous structure used for the preparation of the SCR catalyst, copper (II) ions and iron (III) ions can be monodispersed in the framework. Considering the hydrothermal durability as a catalyst, the maximum number of oxygen rings Taking 8 is suitable, from copper (II) ions and iron (III) ions as catalysts, it has the ability to change from NO to NO. 2 From the viewpoint of an oxidation reaction site for selective contact reduction, it is preferable to have a three-dimensional structure. From the viewpoint of high ammonia adsorption performance as a reducing agent, the above-mentioned synthetic zeolite after hydrogenation is used without particular limitation.

[0061] The synthetic zeolite in the preparation of the SCR catalyst of the present invention can be distinguished by the structure code of the International Zeolite Association, such as CHA type (for example, SSZ-13 with a maximum number of oxygen rings of 8) aluminum silicate series ...

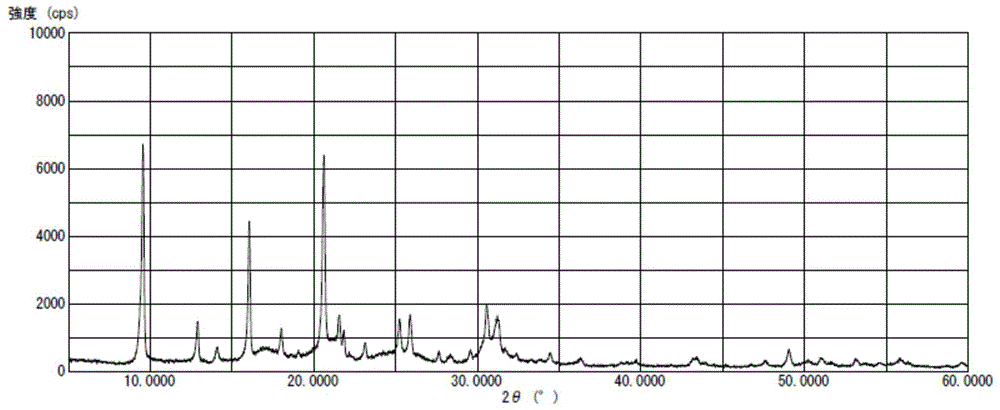

Embodiment 1

[0097] Hydrogenated CHA-type Synthetic Zeolite Supporting Copper(Ⅱ) Ions and Iron(Ⅲ) Ions

[0098] Example 1 A hydrogenated CHA-type synthetic zeolite was obtained by using a silicoaluminophosphate-based CHA-type synthetic zeolite to support copper (II) ions and iron (III) ions.

[0099] Adjustment of zeolite raw materials

[0100] First, ion-exchanged water and 85 wt % orthophosphoric acid were stirred and mixed uniformly in a glass container. Further, pseudo-boehmite (Pural SB) was added, and the mixture was stirred at room temperature for 20 minutes.

[0101] Next, morpholine was gradually added with stirring, and the mixture was kept at room temperature for 1 hour.

[0102] Thereafter, colloidal silica (Ludox AS40) was added, and stirring was continued for 5 minutes to obtain a suspension having a pH of 8.1, which was 1.0 (Al 2 O 3 ): 1.06(P 2 O 5 ): 1.08 (SiO 2 ): 2.09(R): 66(H 2 O) composition.

[0103] hydrothermal synthesis

[0104] The obtained suspension wa...

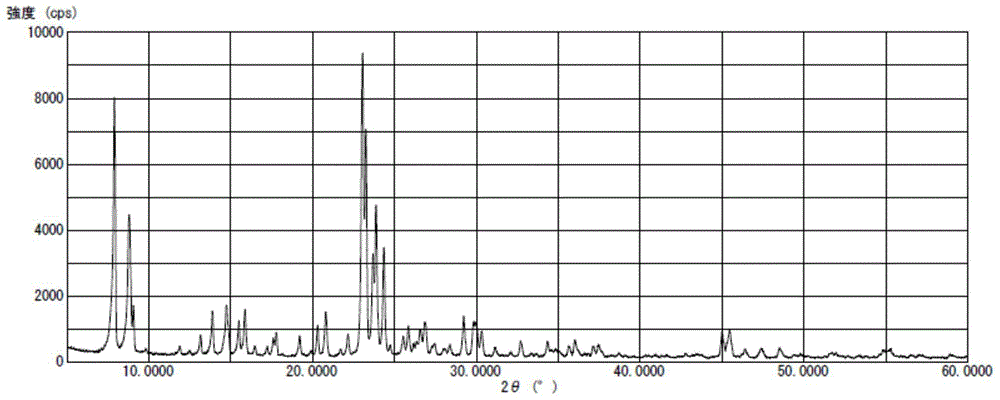

Embodiment 2

[0112] Example 2 is the same as Example 1 except that the degassing treatment is not carried out, and the hydrogenated CHA type synthetic zeolite supporting copper (II) ions and iron (III) ions is used as the SCR catalyst. The ratio (mass / volume percent concentration) of the mass of the hydrogenated synthetic zeolite crystal to the volume of the nitric acid aqueous solution containing copper (II) ions and iron (III) ions is 175%. The average particle diameter (D50) of the obtained SCR catalyst was 7 μm. According to the ICP analysis results, the contents of copper (II) ions and iron (III) ions were 2.5 wt % and 2.5 wt %, respectively. That is, the mass ratio of Cu and Fe contained in the SCR catalyst is 1:1, and the total content of Cu and Fe is 5 wt %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com