Device for measuring high-speed electrical sliding wear

A technology for measuring devices and electrical wear, which is applied in the direction of measuring devices, adopting mechanical devices, testing wear resistance, etc., and can solve problems such as the detection of electrical wear of materials that cannot slide electrical contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

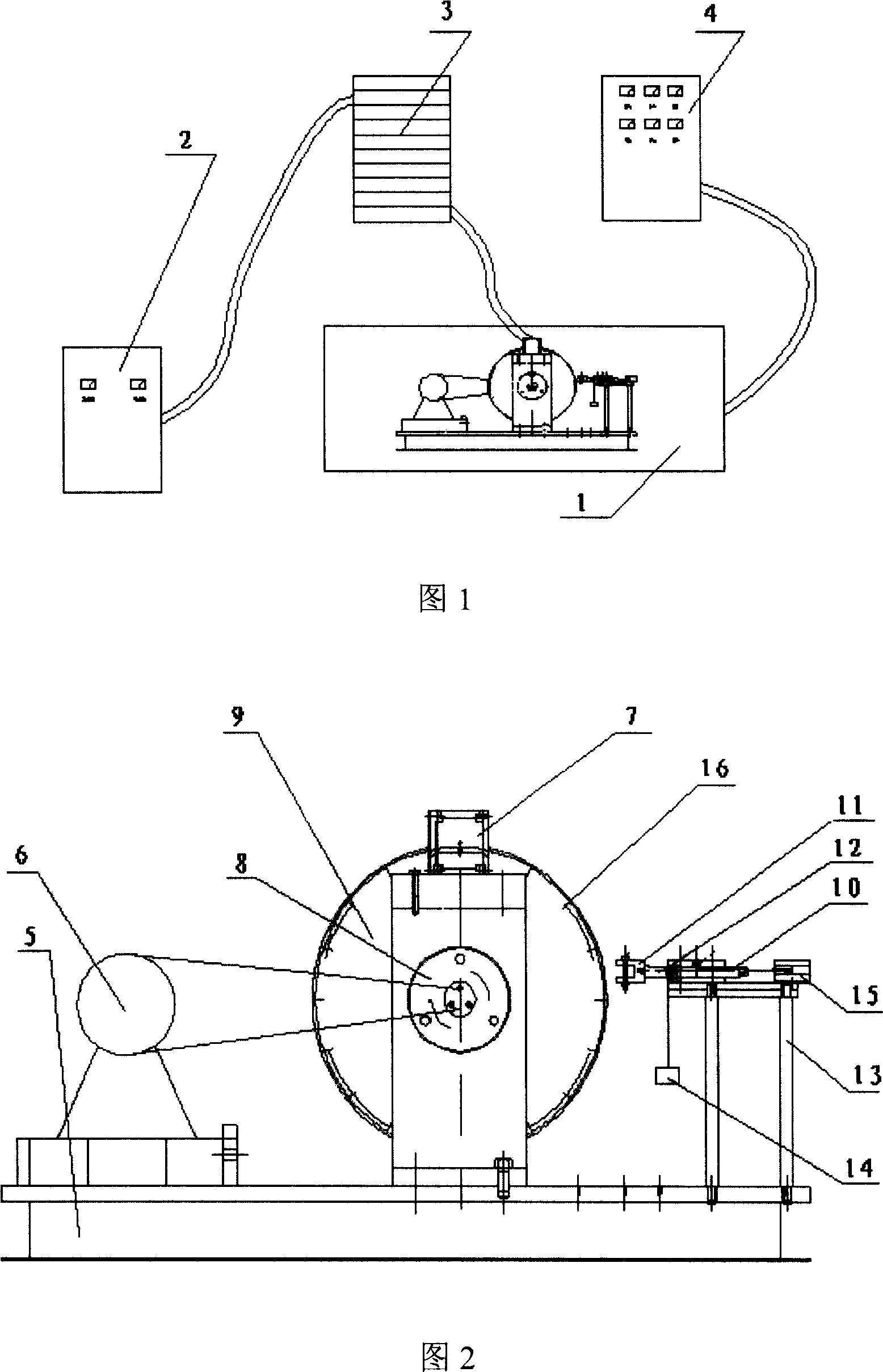

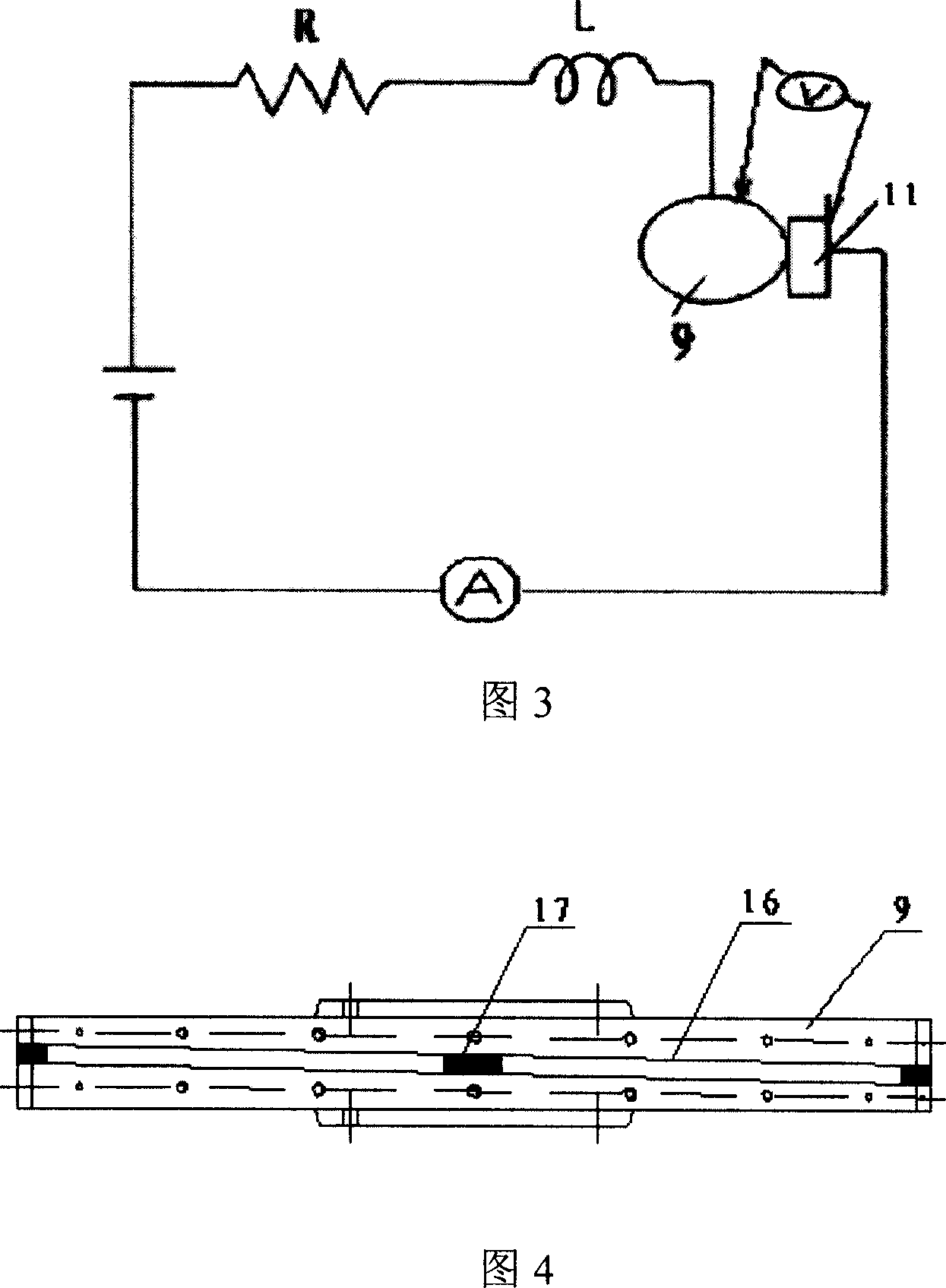

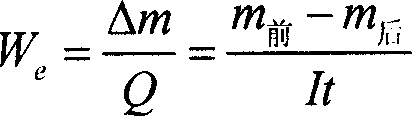

[0025] The high-speed motor 6 and the copper plate 9 rotating at high speed (not less than 200km / h) are fixed on the cast iron base 5 with excellent shock absorption performance. Fasten the tested material to the sample holder 11 with bolts, add a certain load to the tested material through the weight 14, and the load makes the displacement sensor 15 (measuring the amount of mechanical wear in the normal direction) press the sample holder 11 And keep the measured material in line contact with the copper wire 16 on the copper plate 9, adjust the fastening screw on the load transmission rod 10 to ensure that the sample holder 11 does not rotate during the test. After the power is turned on, a large current is introduced into the copper plate 9 through the graphite brush block 7, and the material to be tested (the other end connected to the power supply) mechanically wears out the copper wire 16 fixed on the copper plate 9 under the action of the weight 14, and The generation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com