Construction method of blasthole stemming structure for drilling blasting and concrete block structure for method

A construction method and blast hole blocking technology, which are applied in the field of concrete block structures, can solve the problems of unsatisfactory blocking effect and difficulty in obtaining, and achieve the effects of facilitating on-site operation, prolonging action time, and being easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

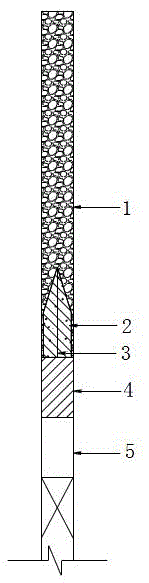

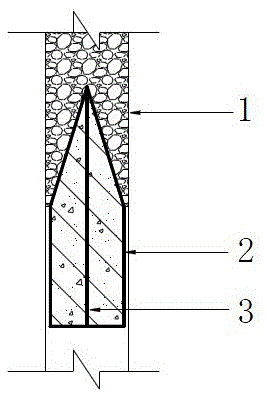

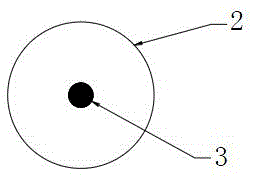

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. In the figure, 1 is a rock slag filling body, 2 is a column-cone reinforced concrete block, 3 is a steel bar in a column-cone body, 4 is a buffer section, and 5 is an air layer.

[0024] Such as figure 1 As shown, the construction method adopts the following steps:

[0025] Step 1, according to the hole diameter of the hole to be plugged and the length of the plugging section, select a cone-shaped concrete block 2 with a cone shape at the other end and a column-cone concrete block 2 with built-in steel bars 3 of appropriate size, and collect rocks from the construction site. The slag is sieved, and the particles with a particle size of 0.1 cm to 2.0 cm are taken.

[0026] Step 2, after the charge of the blast hole is finished, put the buffer material 4 into the blast hole, and then place the column-conical reinforced concrete block 2 in step 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Drilling diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com