Automatic steel rail inclined joint electrical arc welding method and device

An arc welding method and welding device technology, which are applied to arc welding equipment, electrode support devices, rails, etc., can solve problems such as endangering driving safety, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

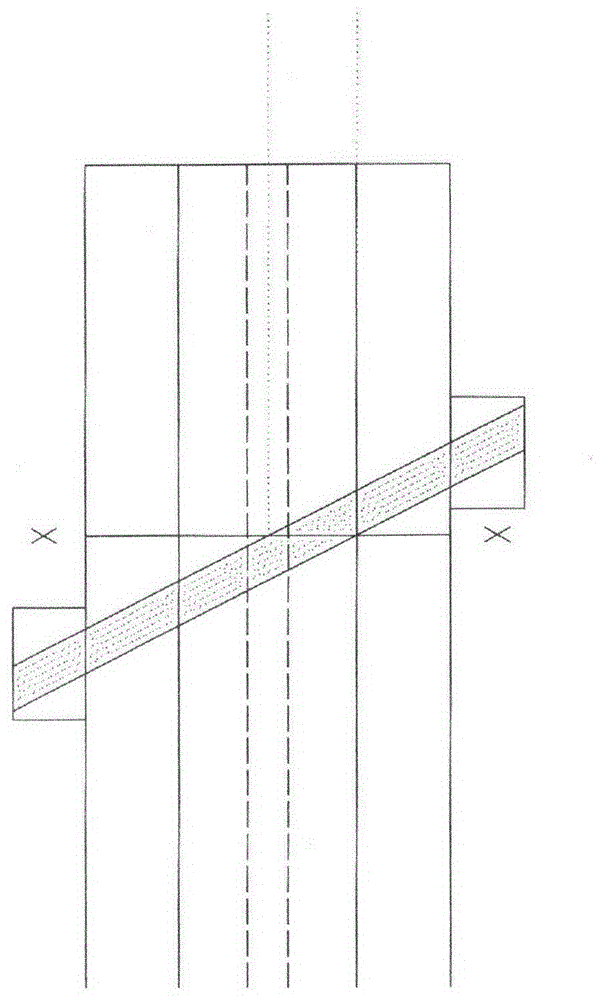

[0016] like figure 1 As shown, the welding seam welded by the present invention is obliquely placed at a certain angle with the rail axis, therefore, the weld seam ratio on the working section of the rail (perpendicular to the rail axis) x-x is only a part (the part shown by the shadow on the figure). Seam stress state has been greatly improved. The two sides of the rail in the figure are arc strike plates.

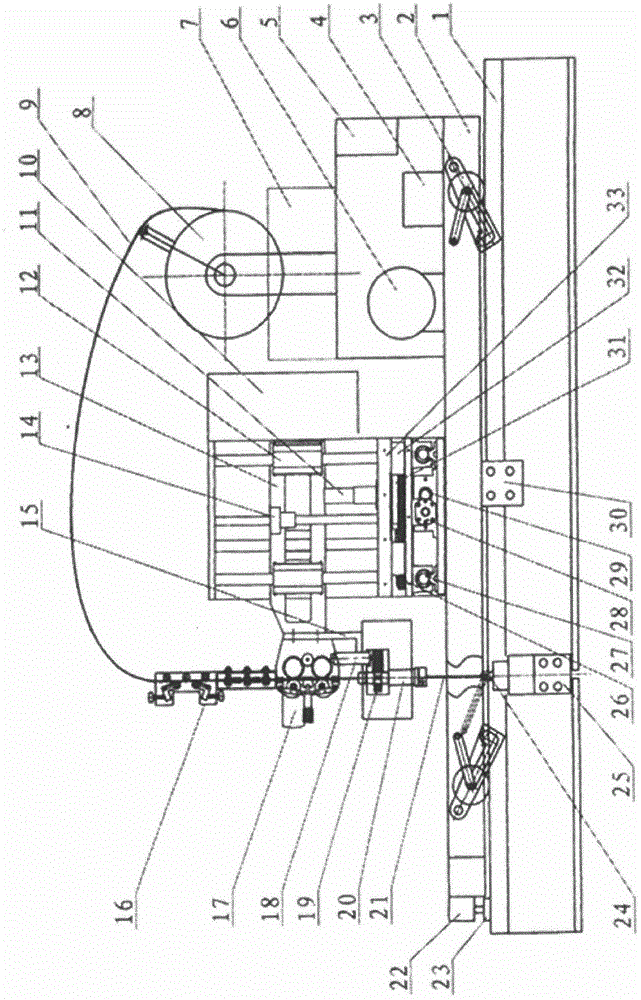

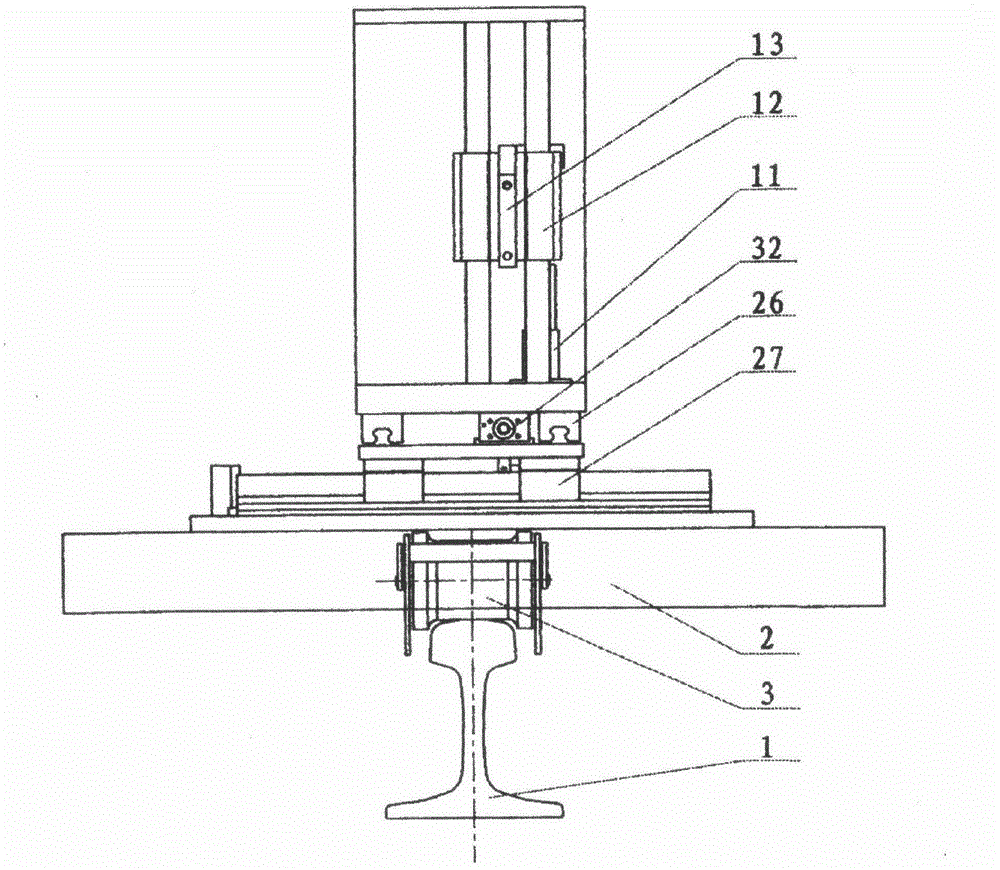

[0017] figure 2 Shown is the automatic arc welding device for rail oblique seams of the present invention: 1 is a rail, and the device includes a frame 2, a traveling wheel set 3, an air pressure system control cutting 4, a power board 5, an air storage tank 6, an industrial computer 7, and a welding wire reel 8 , Self-shielding flux-cored wire 9, electrical control box 10, Z-axis servo motor 11, Z-axis guide post and guide sleeve 12, Z-axis moving plate 13, ball s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com