Pipeline opener

A spreader and pipeline technology, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of difficulty in removing pipeline components and inconvenient reassembly of pipeline components, so as to improve work efficiency and work quality. , The structure is simple and scientific, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

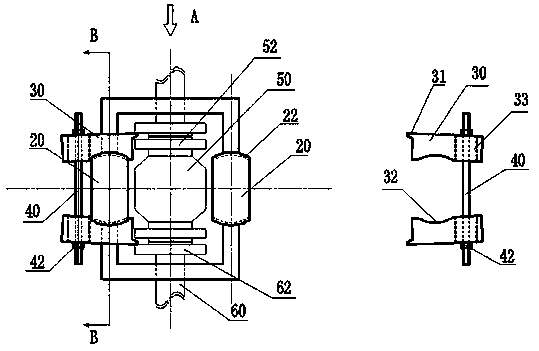

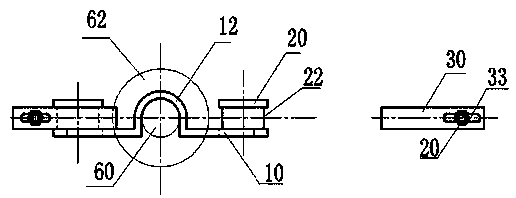

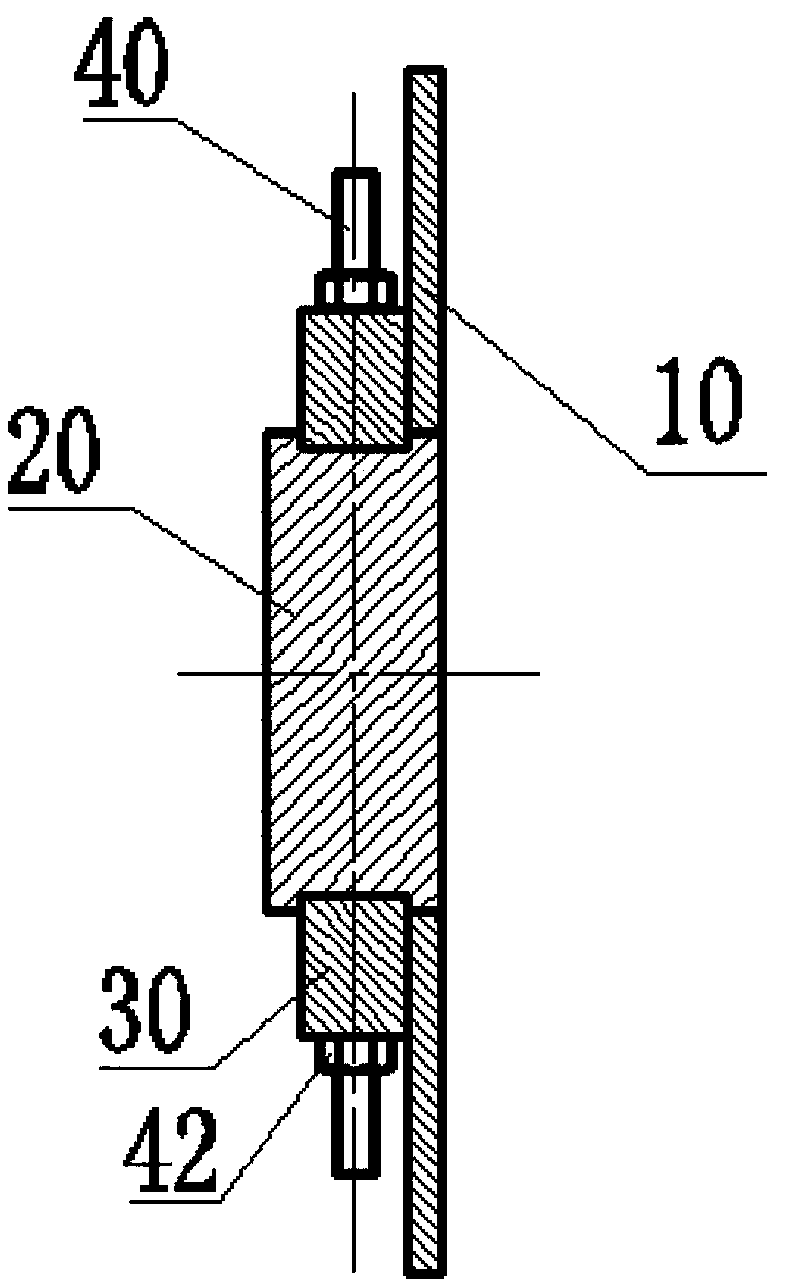

[0014] like figure 1 , figure 2 , image 3 Shown, specific embodiment of the present invention is described as follows:

[0015] A pipeline spreader, which is composed of a bracket 10, four claws 30 and two pull rods 40, and is characterized in that the bracket 10 corresponds to the pipeline 60 on both sides of the pipeline element 50 and is vertically provided with two arc-shaped shoulders 12. Two pivots 20 are set vertically on the other two sides of the bracket 10 corresponding to the pipeline element 50; braces 31 are set on the outside of the top of the brace 30, and a sliding surface 32 is set on the inside of the brace 30 corresponding to the pivot 20, and the tail end of the brace 30 The pull rod through hole 33 is set; the pull rod 40 is provided with threads at least at one end, and the pull rod 40 is screwed with a lock nut 42; the two support claws 30 on the same side are slidingly matched with the corresponding pivot shafts 20, and the brace angles 31 at the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com