Gas-liquid-solid three-phase coupling blasting weakening rock burst and permeability increasing method

A technology of rock burst, gas-liquid-solid, applied in the direction of earthwork drilling, gas discharge, mining fluid, etc., can solve the problems of poor continuity of pressure relief and anti-reflection effect, increased outburst risk, and slow recovery speed, etc. The effect of pressure enhancement, reduction of outburst potential energy, and improvement of mining speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

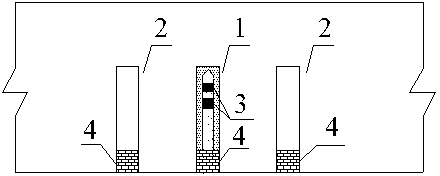

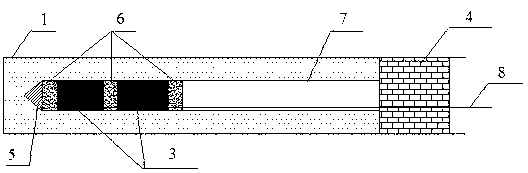

[0015] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0016] In the gas-liquid-solid three-phase coupled blasting method for weakening rockburst and increasing permeability of the present invention, firstly, according to the coal seam geological parameters: coal seam thickness, inclination, direction, gas parameters and roadway layout, the layout parameters of the boreholes are determined, including the borehole The inclination angle and the length through the coal seam determine that the distance between blast hole 1 and extraction hole 2 is 3m, and the final hole position of blast hole 1 passes through the coal seam by 0.5m. Drill holes according to conventional construction. After the drilling construction is completed, use polyurethane sealing material 4 to seal the blast hole and extraction hole to ensure that the blast hole can withstand a pressure above 15MPa. After the hole sealing is completed and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com