A coalbed methane mining method for liquid nitrogen freeze-thaw cracking coal seam permeability enhancement

A mining method and coalbed methane technology, which is applied in the fields of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of complex technical process, difficulty in feeding medicine, high technical cost, etc., and achieve changes in physical mechanics performance, expanding the range of freeze-thaw cracking, and increasing the effect of wetting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

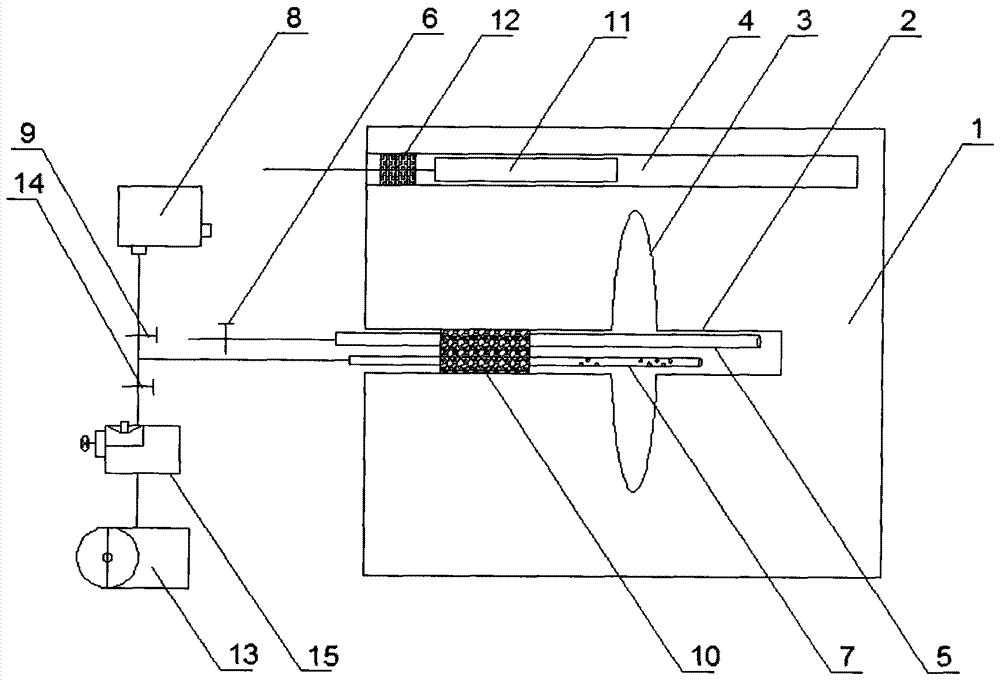

[0037] The coalbed methane exploitation method of liquid nitrogen freeze-thaw cracking coal seam anti-permeability is characterized in that: comprising the following steps:

[0038] a) drilling a drainage borehole 2 into the coalbed methane mining coal seam 1 in the underground roadway, and cutting out a number of slots 3 in the drainage borehole 2;

[0039] b) in the coalbed methane mining coal seam 1, drill a monitoring borehole 4 at a position 4m away from the extraction borehole 2;

[0040] c) arrange the drainage pipeline 5, extend one end of the drainage pipeline 5 into the drainage borehole 2, and communicate with the drainage equipment at the other end, install a drainage pipeline on the drainage pipeline 5 Stop valve 6;

[0041] d) Arrange the injection pipeline 7, extend one end of the injection pipeline 7 into the extraction borehole 2, and communicate with the liquid nitrogen injection pump 8 at the other end, install liquid nitrogen injection on the injection pip...

Embodiment 2

[0055] Compared with Embodiment 1, this embodiment also includes step d1) after step d) and before step i): connecting the water injection pump 13 with the injection pipeline 7, and installing a water injection shut-off valve on the connecting pipeline 14. Determine that the water injection shut-off valve 14 is in a closed state; after step d1) and before step i), step i1): open the water injection shut-off valve 14, start the water injection pump 13, and perform the water injection operation, The water injection speed is 80I / min. After water injection for 3 hours, close the water injection pump 13 and the water injection stop valve 14 to complete the water injection operation.

[0056] In this embodiment, a pulse water injection controller 15 is connected between the water injection pump 13 and the water injection shut-off valve 14 to form a pulsed water flow and adjust the water injection pressure to keep the water injection pressure at 4MPa.

[0057] This embodiment is the ...

Embodiment 3

[0059] Compared with Embodiment 2, this embodiment is all the same except for the following differences:

[0060] In this embodiment, the drainage borehole 2 has a length of 50 m and a diameter of 95 mm.

[0061] In this embodiment, the depth of the cut groove 3 is 45 cm, the distance between two adjacent cut grooves 3 is 1.8 m, and the angle between the cut groove surface of the cut groove 3 and the direction of the maximum principal stress of the coal seam is 90°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com