A device for preventing coal-rock dynamic disasters by high-pressure pulsating water injection

A technology for power disasters and high-pressure water supply, applied in safety devices, gas discharge, mining equipment, etc., can solve the problems of complex process, unsatisfactory anti-outburst and anti-impact effects, etc., achieve simple process, improve safety production coefficient, prevent good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

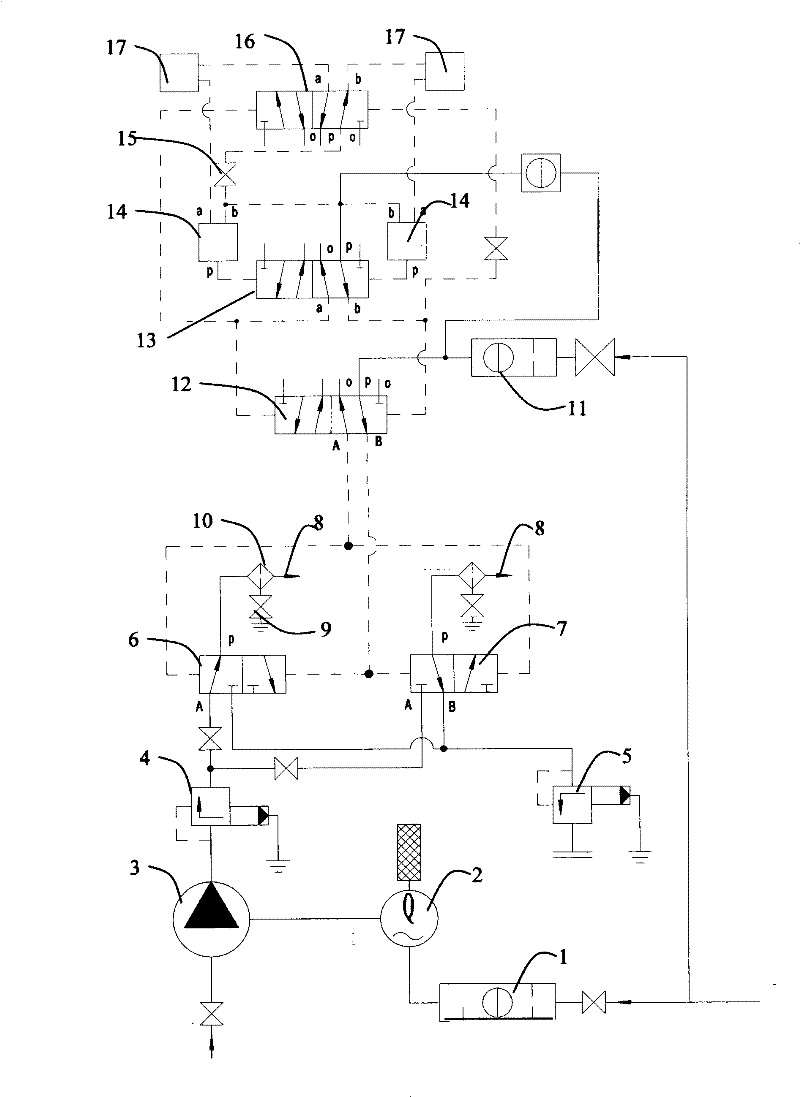

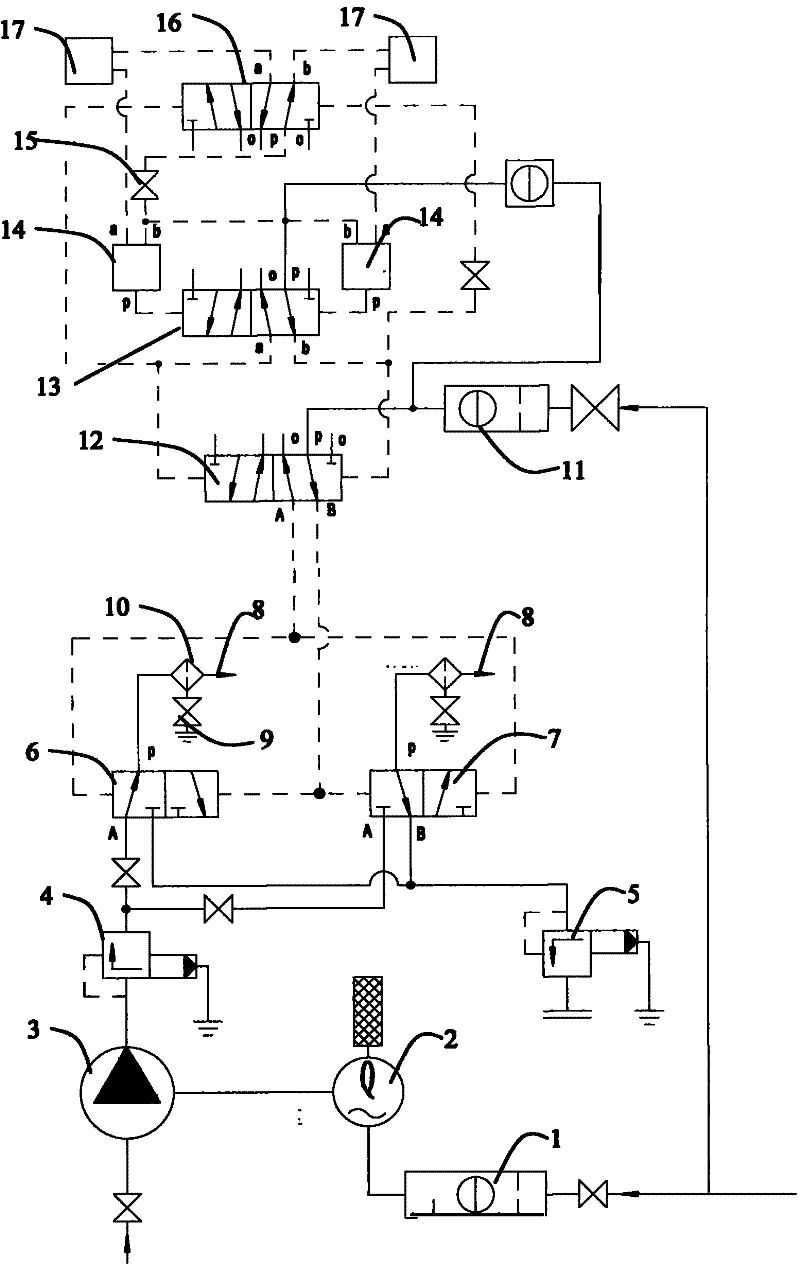

[0015] The method for preventing and controlling coal-rock dynamic disasters by high-pressure pulsating water injection based on the present invention, firstly, drill holes into the mine coal seam from the mine roadway, usually two holes; After the high-pressure water enters the coal seam, it can not only penetrate into different cracks and pores, increase the wettability of the coal body, but also make the cracks continue to penetrate and expand, expand the wetting radius, and change the physical and mechanical properties of the coal seam. At the same time, the periodic The pulsating high-pressure water can also produce repeated effects of "expansion-contraction-expansion" on coal cracks and pores, reducing or eliminating the risk of coal seam outburst. During water injection, the maximum pressure of the pulsating high-pressure water is 25MPa, and the pulsating low pressure and high pressure can be adjusted to ensure the prevention effect and safe use of coal seam water inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com