Hard top coal weakening method based on combination of plasma blasting and liquid injection

A combination of plasma and technology, applied in drilling equipment and methods, chemical instruments and methods, earthwork drilling and mining, etc., can solve problems such as weakening, and achieve the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

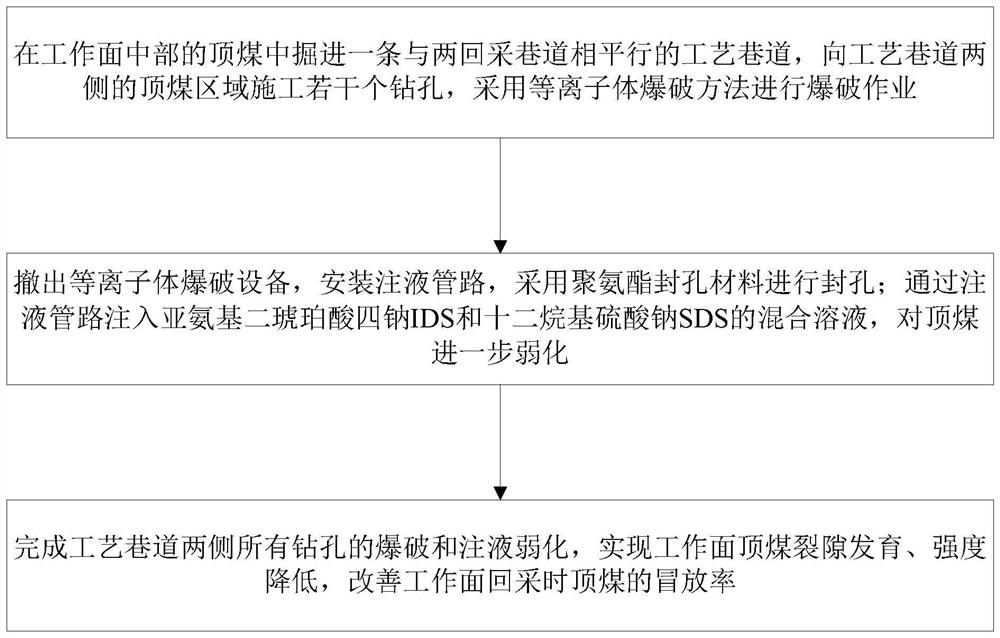

Method used

Image

Examples

Embodiment Construction

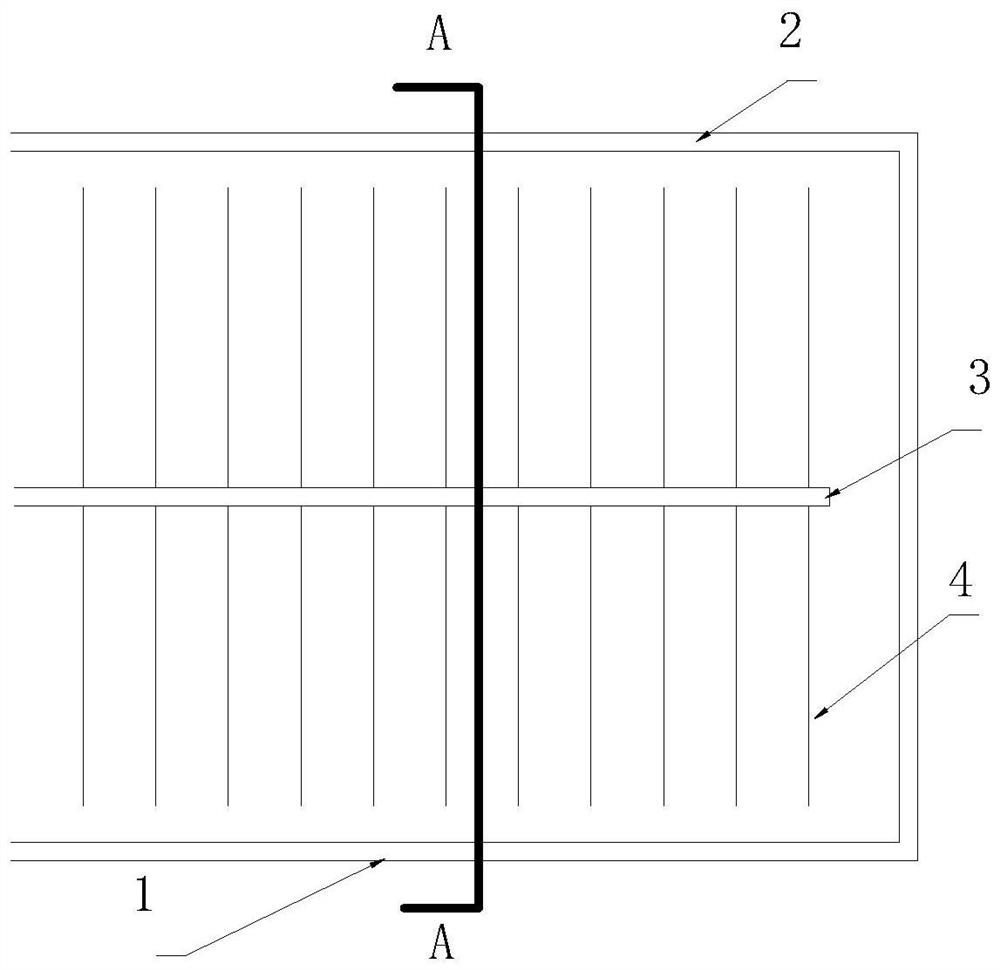

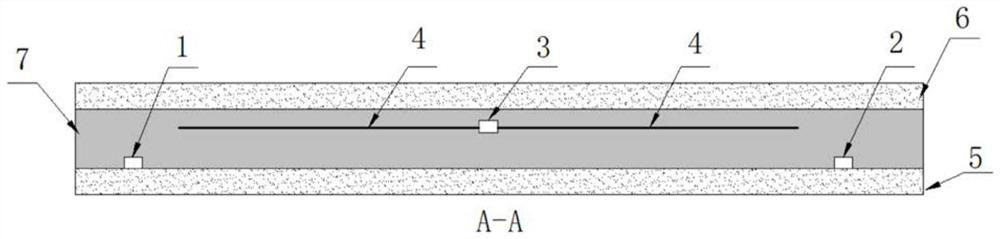

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0032] A fully mechanized caving face has a length of 200m and a strike length of 950m. The thickness of the coal seam is 8m, the coal seam is a hard coal seam, and the uniaxial compressive strength is 21MPa. The working face adopts comprehensive mechanized top-coal caving mining method, the mining height is 3.8m, and the coal caving height is 4.2m. The top-coal cavitation of other adjacent working faces under similar conditions is poor, which seriously affects the recovery rate of the top-coal in the working face.

[0033] Such as figure 1 As shown, the hard top-coal weakening method based on the combination of plasma blasting and liquid injection in this embodiment is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com