A method for predicting blasting grade distribution in block stone mining

A forecasting method and grading technology, applied in forecasting, neural learning methods, instruments, etc., can solve problems such as slow algorithm convergence and easy to fall into local minimum points, and achieve small calculation errors, improved performance and prediction accuracy, and high efficiency The effect of grading predictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

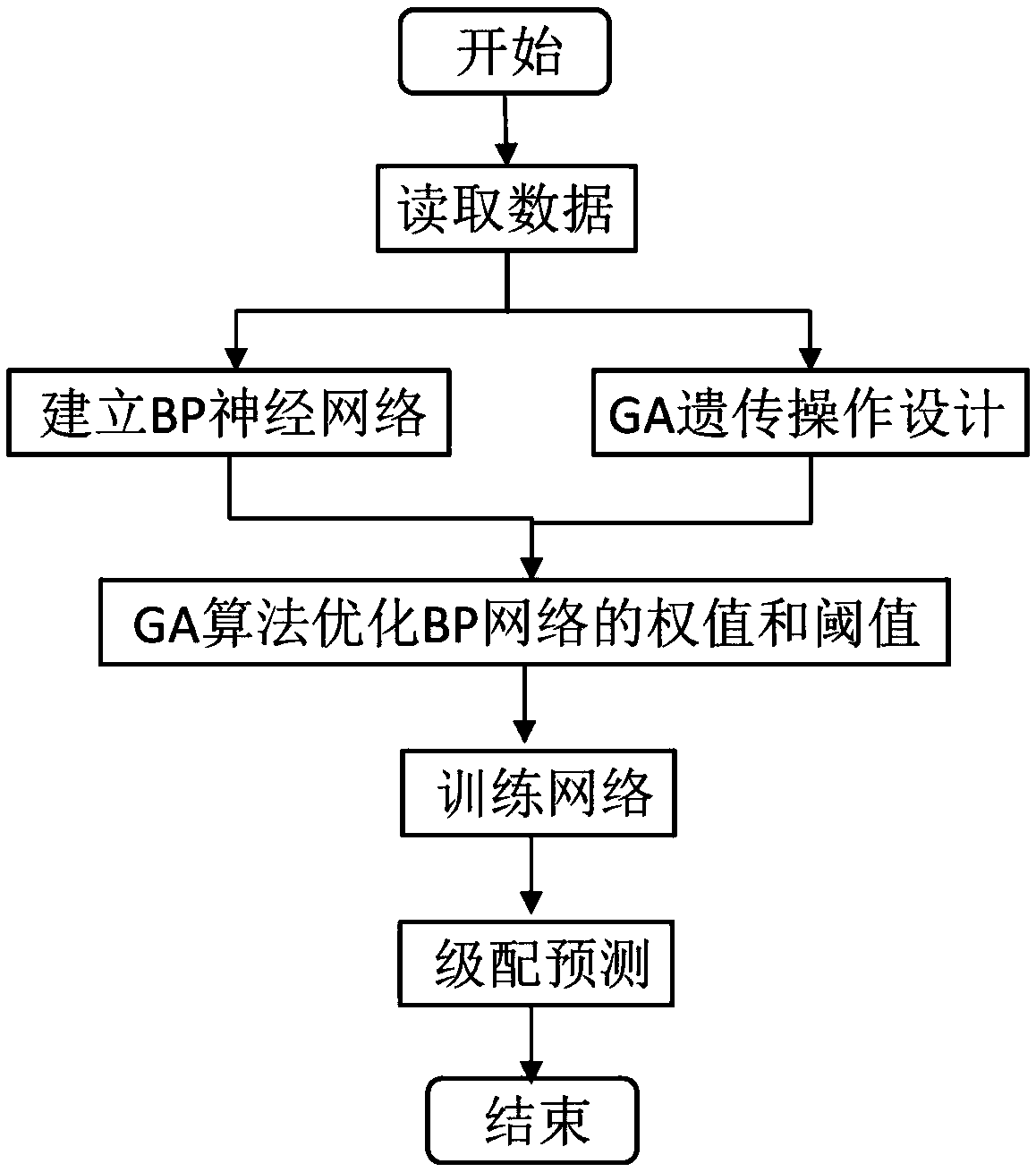

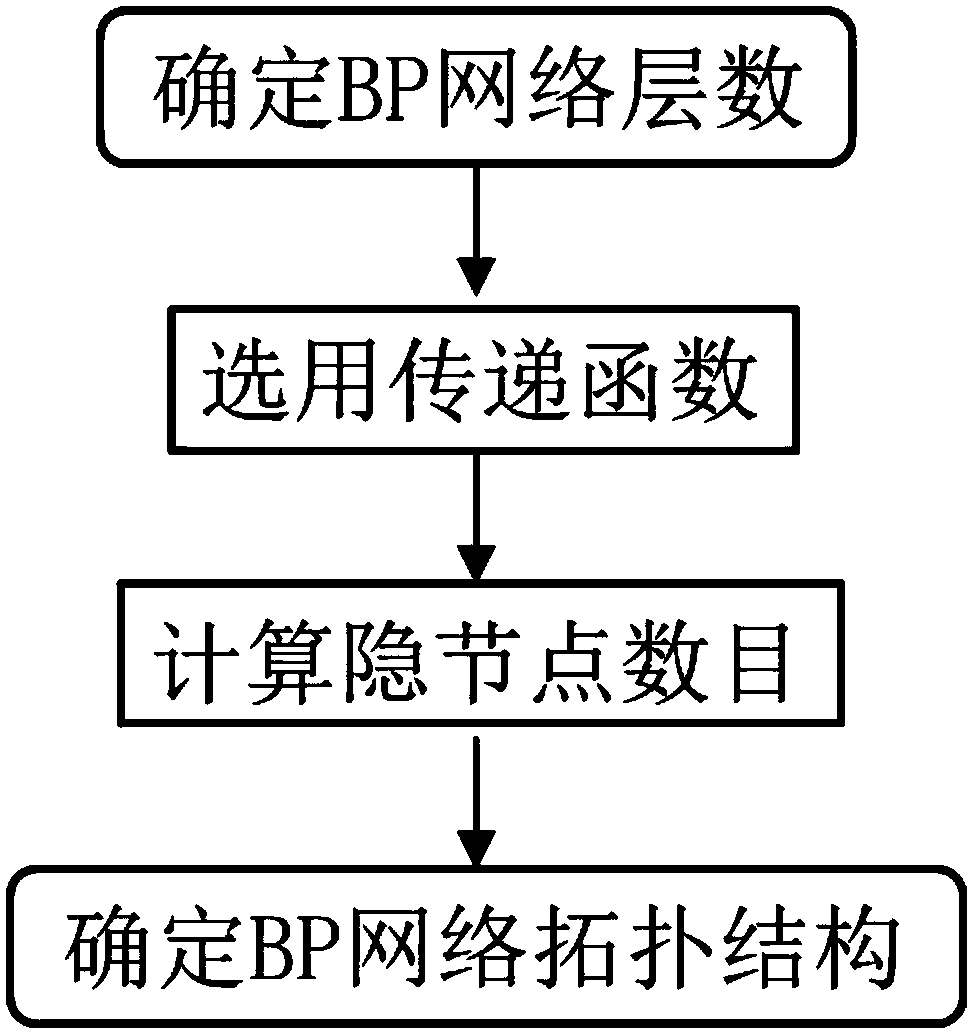

[0037] like Figure 1-4 As shown, a method for predicting blasting gradation in block stone mining includes the following steps:

[0038] Step 1: Obtain the influencing factors of blasting effect as input parameters, and the blasting gradation distribution index as output parameters, and establish a sample database.

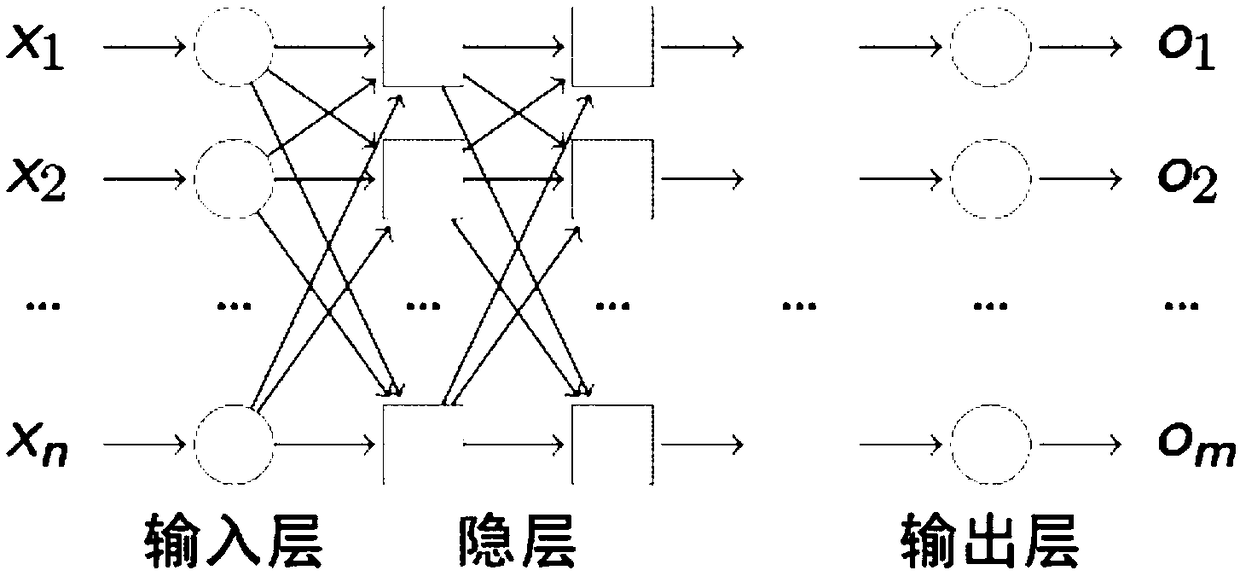

[0039] Input parameters include drilling diameter, hole spacing, row spacing, blasting hole density factor, plugging length L d , charge length L e , L d / L e Influencing factors of blasting effect, such as explosive unit consumption, are used as input parameters of the model; the cumulative percentage content under the sieve of each particle size and the blasting gradation distribution indicators such as the unevenness coefficient Cu, curvature coefficient Cc, and fractal dimension D are selected as the input parameters of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com